Novel scribing machine

A scribing machine, a new type of technology, applied in workshop equipment, workpiece clamping devices, manufacturing tools, etc., can solve problems such as product looseness, affecting product processing yield, artificial fixing products, etc., to avoid loosening and improve processing yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

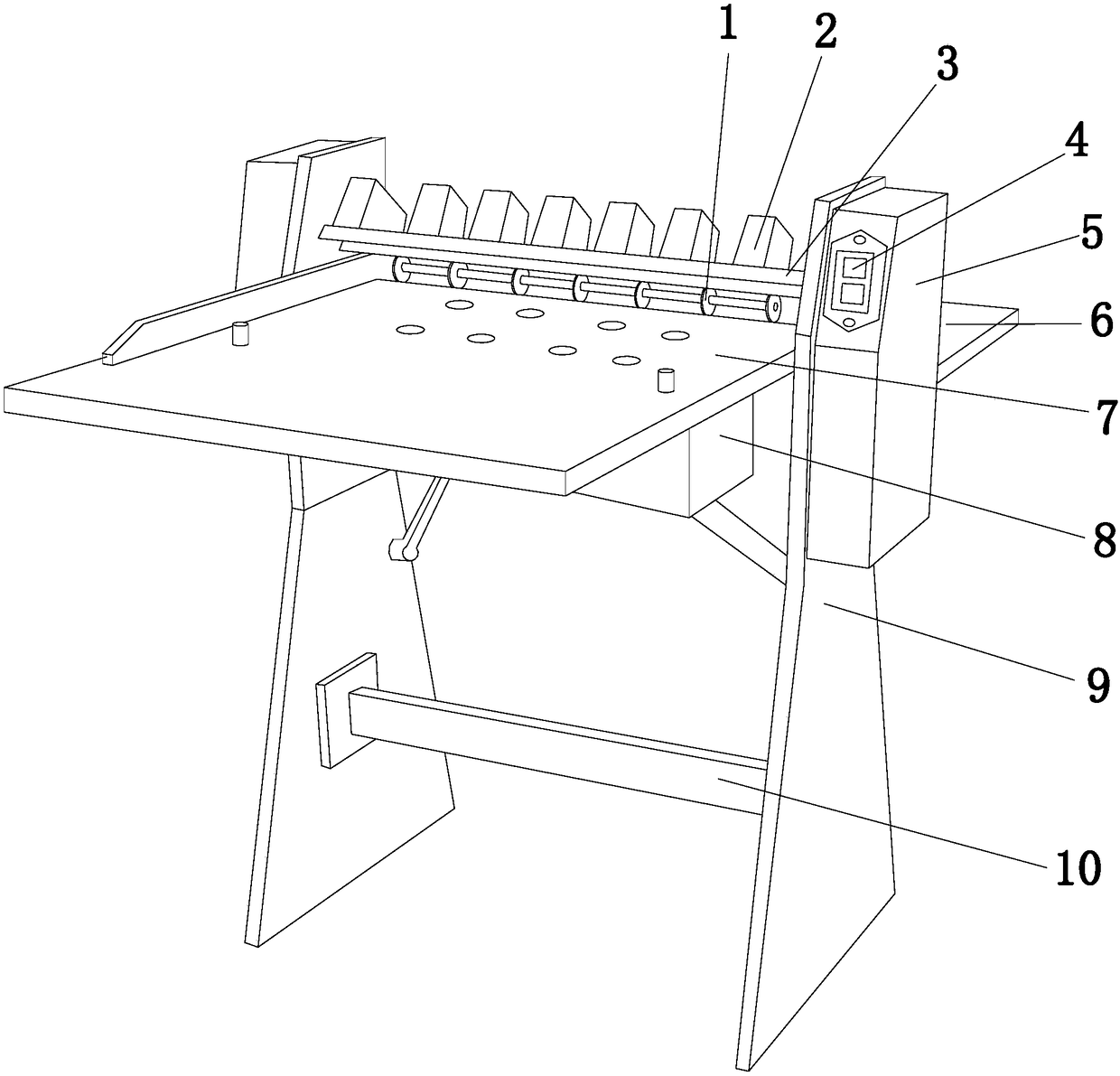

[0026] see Figure 1-Figure 6 , the present invention provides a new type of marking machine: its structure includes a marking wheel 1, a transmission motor 2, a swing frame 3, a control switch 4, a main engine 5, a discharge port 6, a processing table 7, a positioning device 8, and a fixed base 9. Fix the pull rod 10, the fixed base 9 is provided with two and the top is fastened with the two sides of the processing table 7, the rear end of the processing table 7 is provided with a scribing wheel 1, and the scribing wheel 1 is provided with two or more equidistantly installed on the bottom of the swing frame 3, the upper end of the swing frame 3 is provided with more than two transmission motors 2, the transmission motor 2 is connected with the marking wheel 1, and the swing The left and right sides of the frame 3 are fastened with the top of the fixed base 9, and the host 5 is mounted on the upper right side of the fixed base 9 by buckling, and the top of the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com