A height-adjustable triangular bus handle

A bus and height technology, applied in the field of transportation, can solve problems such as inability to stand firm and dangerous, and achieve the effect of solving the problem of inability to adjust the height, easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

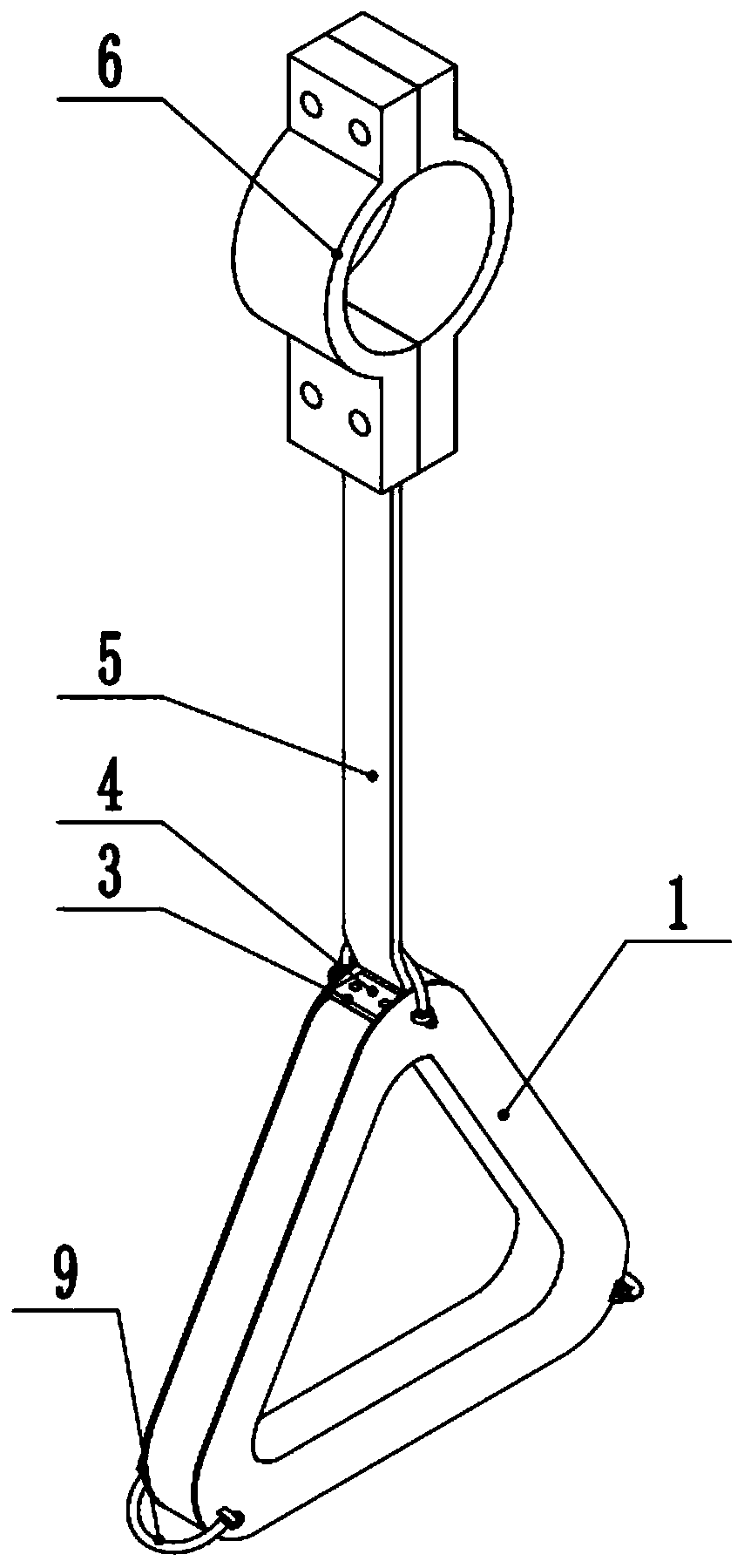

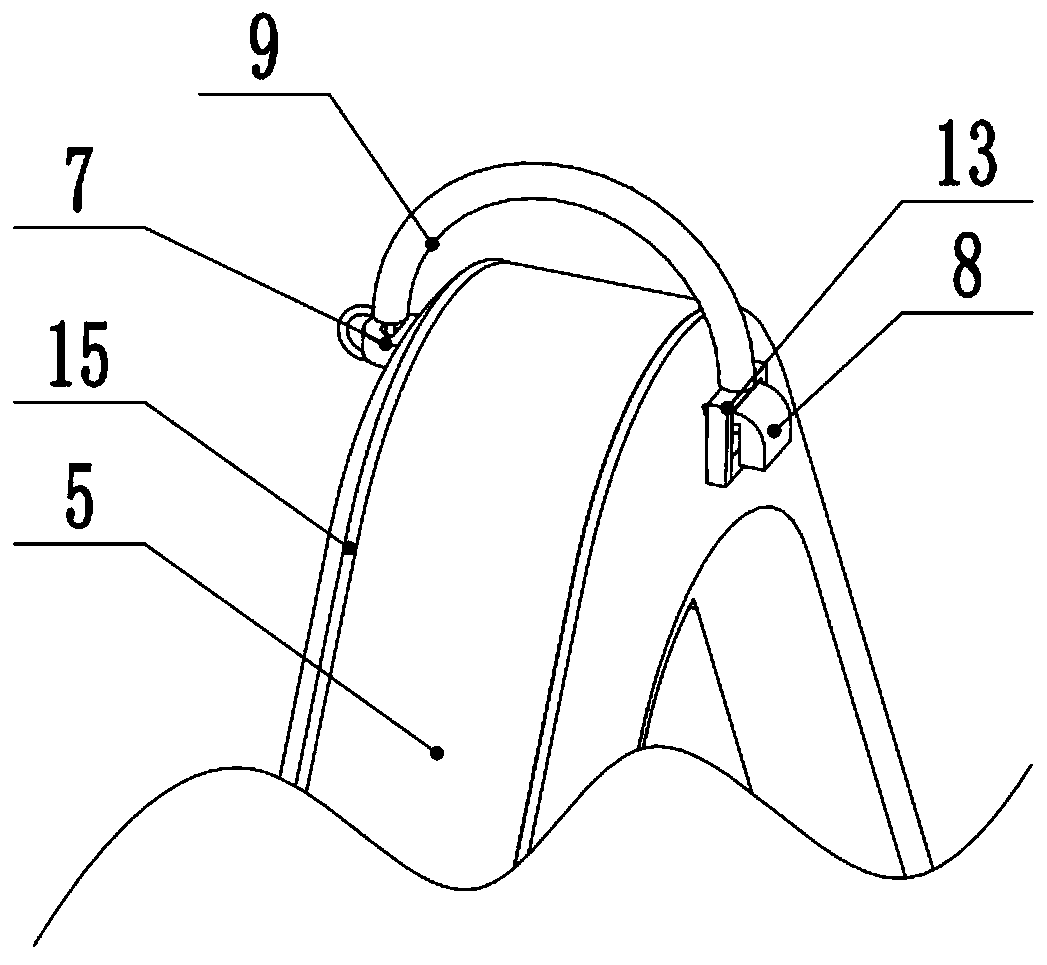

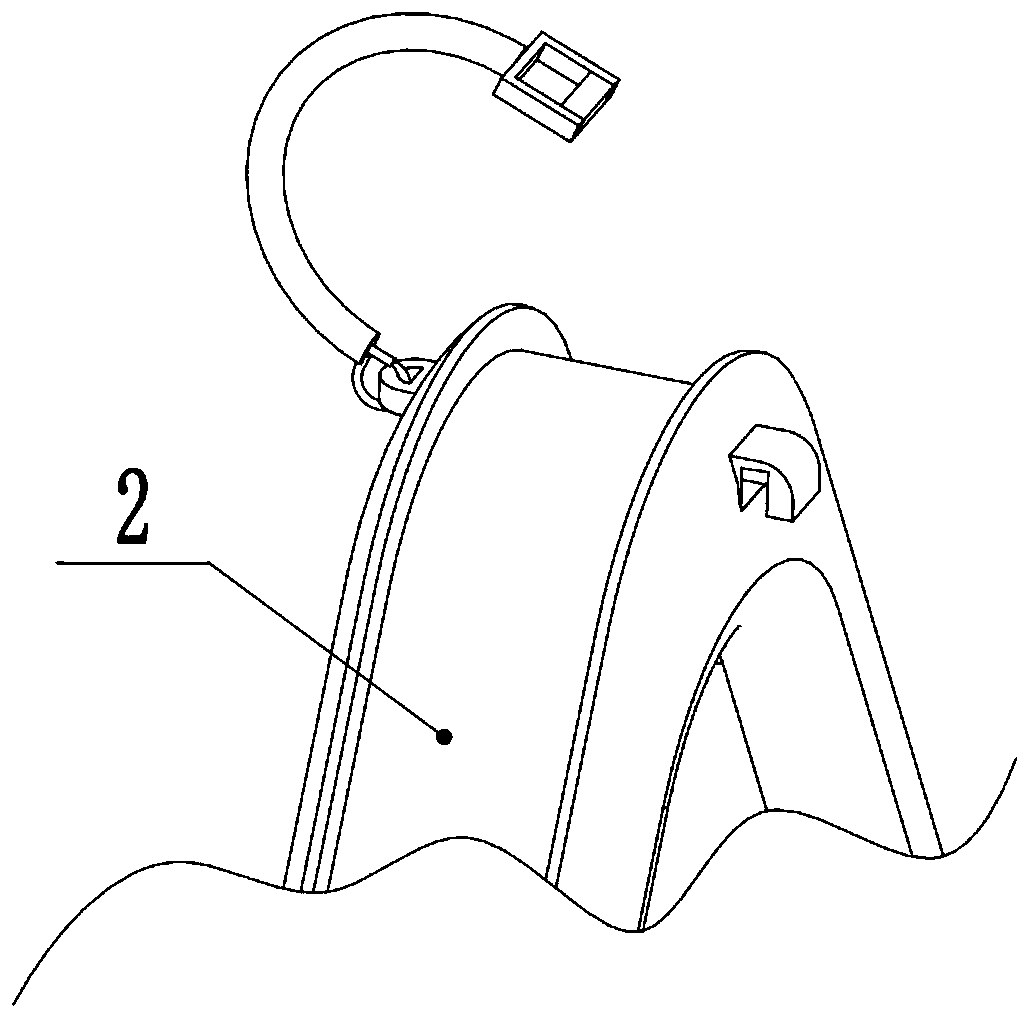

[0019] A height-adjustable triangular bus handle, comprising a regular triangular ring handle 1, a belt groove 2 is provided on the circumference of the handle 1, and a rope is fixed on the belt groove 2 at a vertex of the handle 1 Groove 3, one end of the rope 5 is fixed on the rope fixing groove 3 through the clamping plate 4 on the rope fixing groove 3, the rope 5 is wound along the belt groove 2, and the other end of the rope 5 is fixed to the fastener 6, a rope hole 7 is provided on the three corners of the front side of the handle 1, and a magnetic fixed hook 8 facing the center of gravity of the handle 1 is fixed on the three corners of the rear side of the handle 1. One end of the fixed rope 9 is fastened, and the other end of the fixed rope 9 is installed on the magnetic suction fixed hook 8 .

[0020] Such as Figure 4 As shown, in order to be able to stably lock the rope 5, the fixed rope 9 is stably connected to the magnetic fixed hook 8, and the magnetic fixed ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com