Crane Handling System for Cement Rotary Kiln

A cement rotary kiln and processing system technology, applied in rotary drum furnaces, furnaces, furnace types, etc., can solve problems such as errors, seriousness, and inability to accurately locate the shape of garbage at the driving position, and achieve the effect of reducing positioning errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] like figure 1 As shown, the driving handling system for cement rotary kiln includes the driving weighing system used to solve the driving weighing and the driving auxiliary system used to solve the driving positioning.

[0038] In use, the actual position of the vehicle can be determined through multiple positioning devices, which greatly reduces the positioning error and achieves the effect of auxiliary positioning. At the same time, based on the weighing system, the grab can obtain the weight of the garbage it grabs every time it grabs. .

Embodiment 2

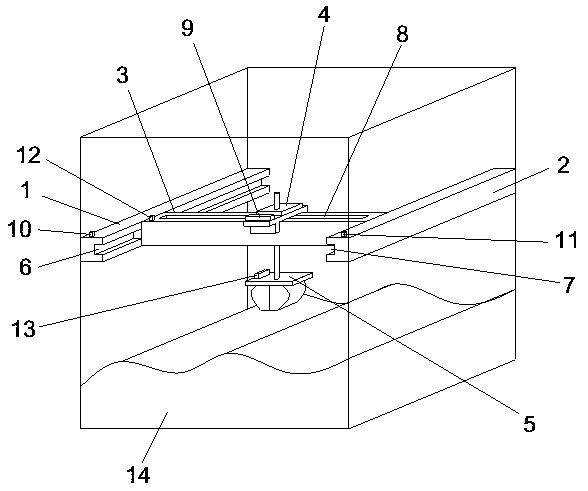

[0040] Based on Example 1, such as figure 2 As shown, the driving assistance system includes a first beam 1, a second beam 2, a movable beam 3, a driving 4 and a grab bucket 5, the first beam 1 is set opposite to the second beam 2, and the first beam 1 is provided with a first guide rail 6. The second beam 2 is provided with a second guide rail 7, the two ends of the movable beam 3 are respectively arranged in the first guide rail 6 and the second guide rail 7, and the movable beam 3 is provided with a third guide rail 8, and the driving 4 and the movable beam 3 It is movably connected and connected with the grab bucket 5 through the lifting rod passing through the third guide rail 8. The first beam 1 is provided with a first fixed positioning device 10, and the second beam 2 is provided with a second fixed positioning device 11. The movable beam 3 is provided with a first mobile positioning device 12, the driving 4 is provided with a second mobile positioning device 9, the g...

Embodiment 3

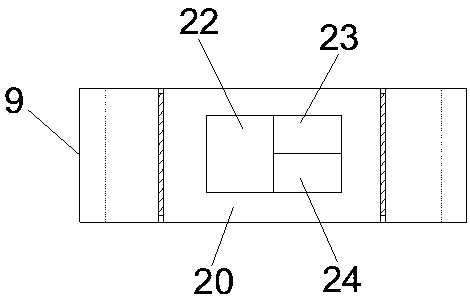

[0043] Based on Example 2, such as image 3 As shown, the second mobile positioning device 9 is provided with a working chamber 20 , and the working chamber 20 is provided with a wireless communication module 22 , a power supply 23 and a control module 24 electrically connected to each other.

[0044] In use, the wireless communication modules in the first fixed positioning device, the second fixed positioning device, the first mobile positioning device, the second mobile positioning device and the third mobile positioning device are close to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com