An automated sheet metal bending production line

A production line and sheet metal technology, applied in the field of sheet metal sheet processing, can solve problems such as slow speed, inflexibility, and large structural size, and achieve the effects of preventing deviation, large moving range, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

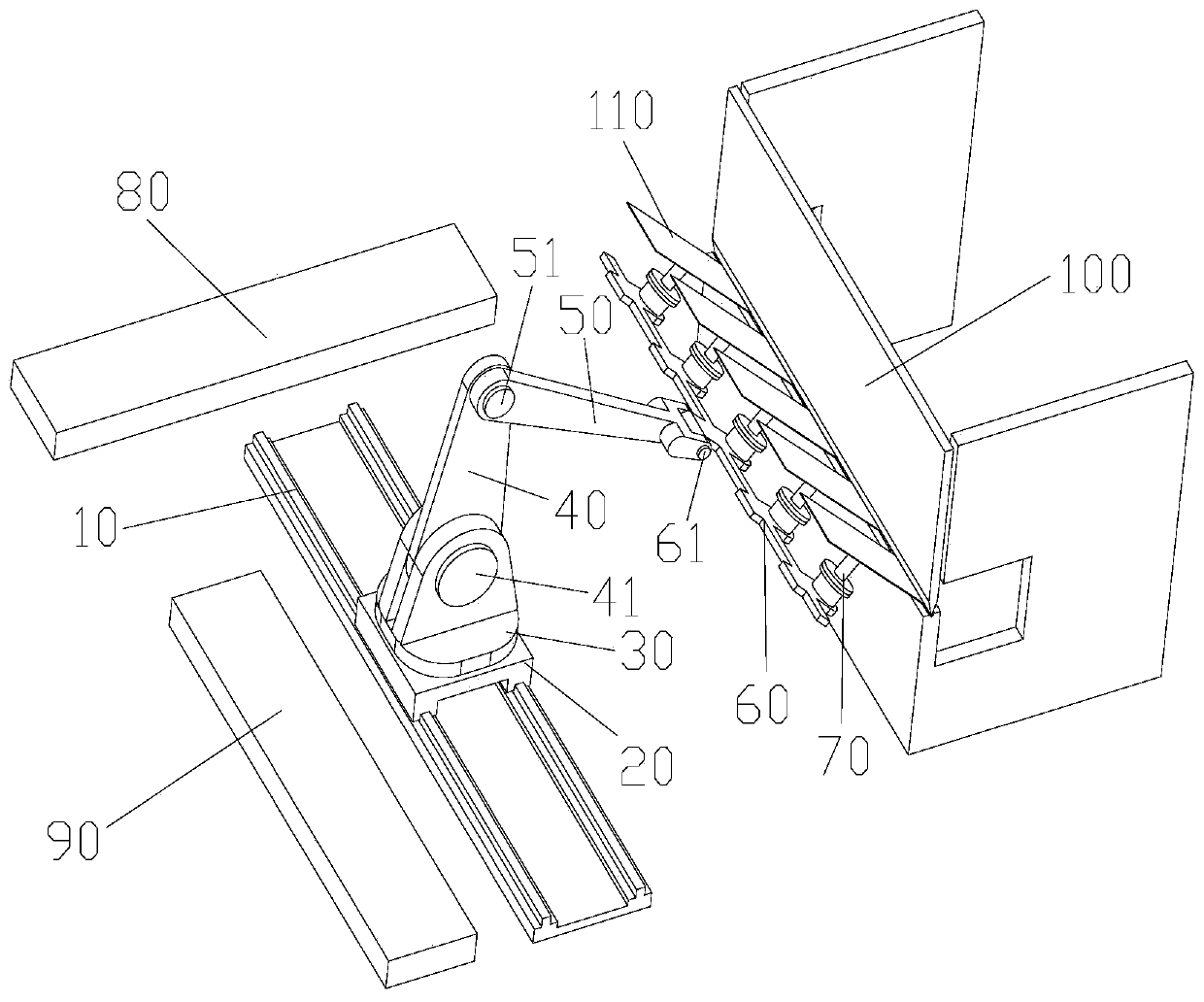

[0057] Embodiment 1: The rear end of the arm joint is directly hinged to the top of the slider through two axes, that is, no rotating support is required. At this time, the bending robot of the present application is a five-axis robot, which has a larger moving range compared with a six-axis general-purpose robot, and one axis is a linear moving axis, which expands the moving range of the robot. In addition, compared with the 6-axis general-purpose robot, one less axis is beneficial to save costs; there is no redundant degree of freedom, and the control is simple.

Embodiment 2

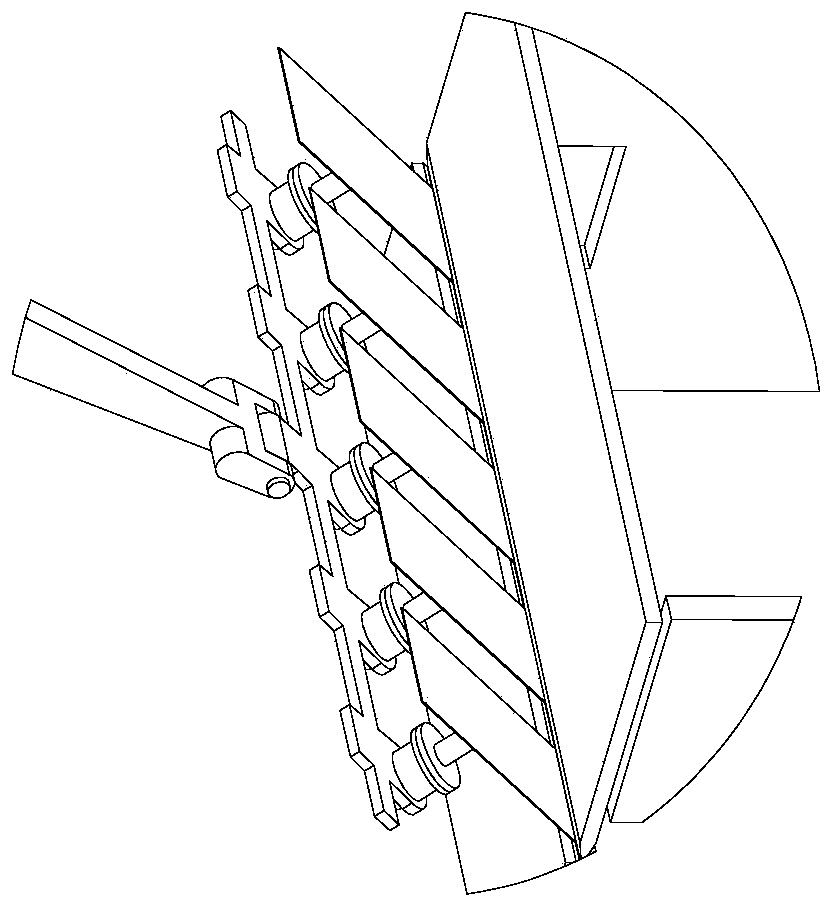

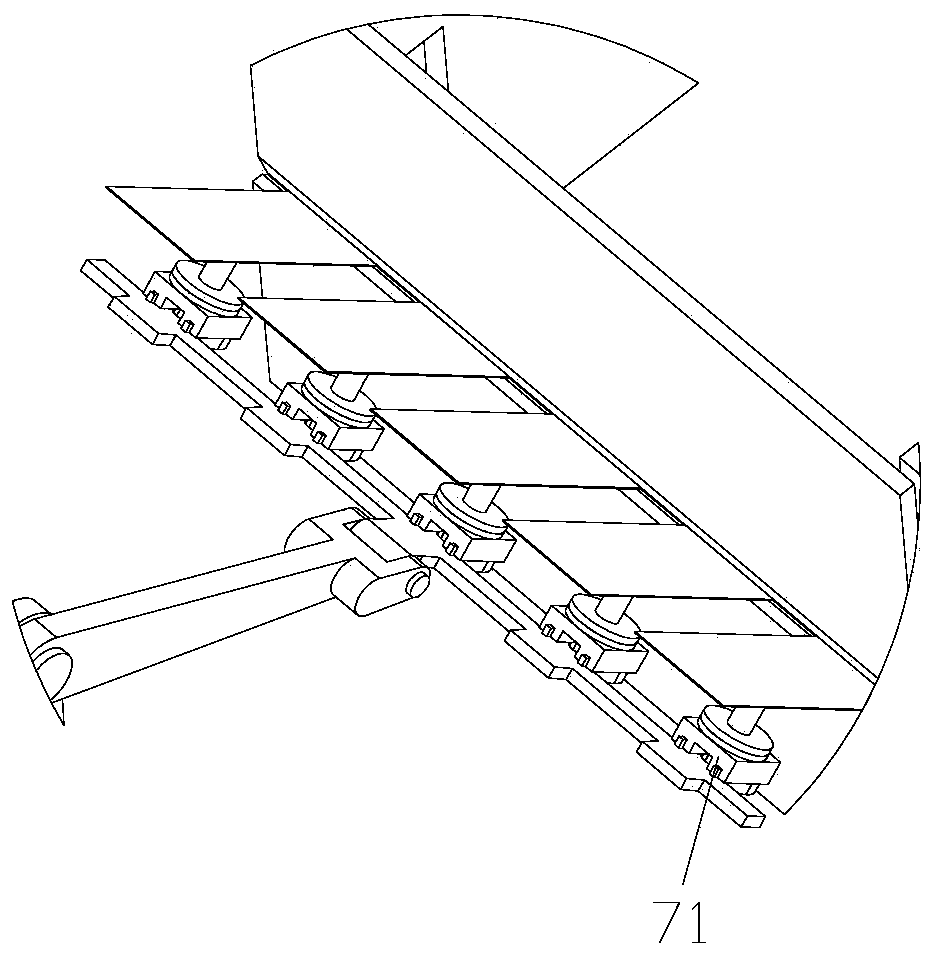

[0058] Embodiment 2: the rear end of the arm joint is indirectly hinged to the top of the slider through two shafts 41, as Figure 5 As shown, the bottom of the rotary support is rotationally connected with the top of the slider through additional six shafts 31, and the top of the rotary support is rotationally connected with the rear end of the big arm joint through two shafts. The use of the rotating support makes the bending robot of the present application a six-axis robot with a large range of movement. The position and quantity of the blank material rack 80 and the finished material rack 90 are variable, and fully automatic bending without manual intervention can be realized. .

[0059] The front end of the big arm joint is hinged with the rear end of the small arm joint through three axes 51 .

[0060] The grip is linear, the middle part of the rear end of the grip is hinged to the front end of the forearm joint through four shafts 61, and the front end of the grip is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap