Pump cover assemble machine

A technology of assembling machine and pump cover, applied in the direction of assembling machine, metal processing, metal processing equipment, etc., can solve the problems of time-consuming and laborious assembly, low installation accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

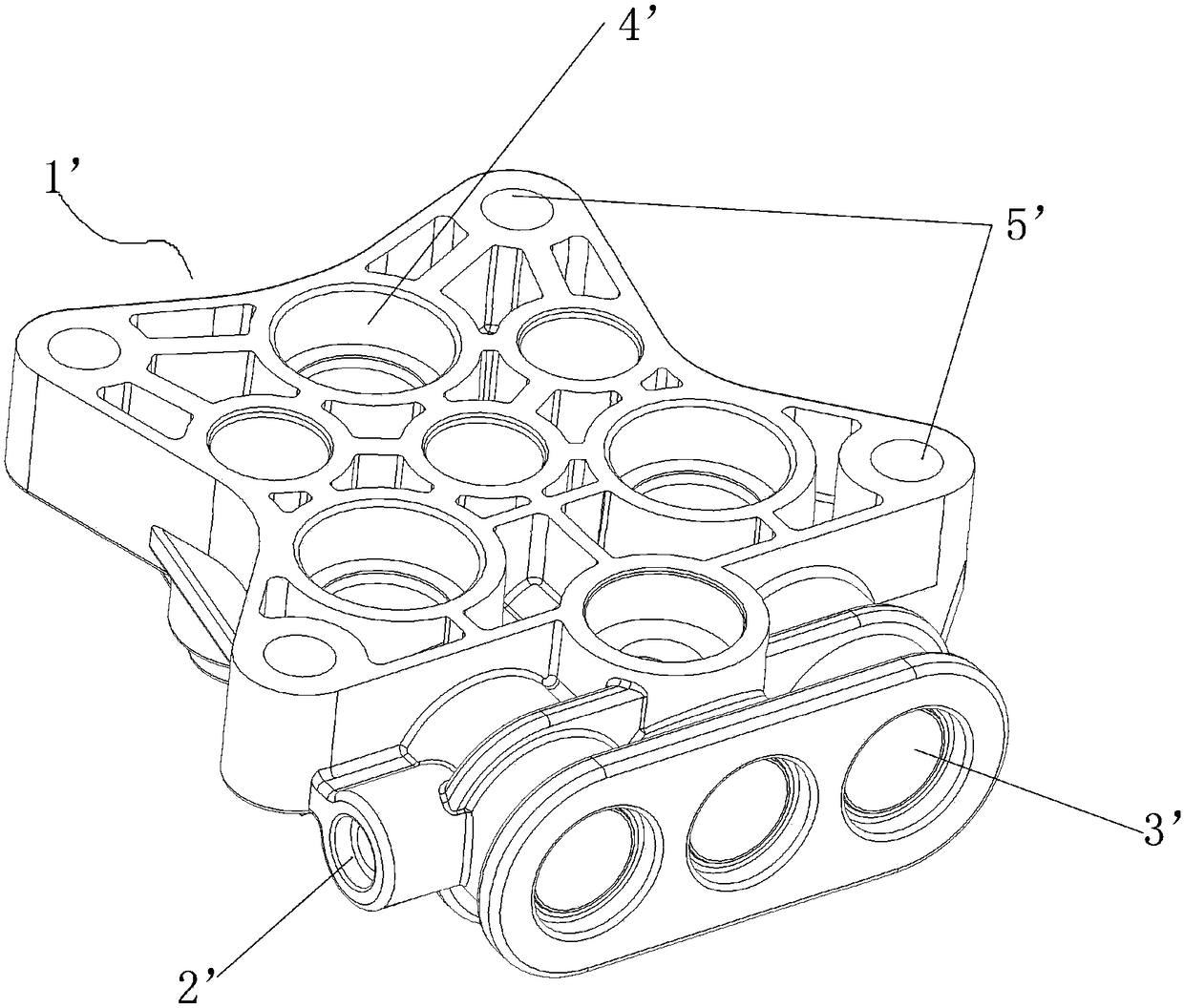

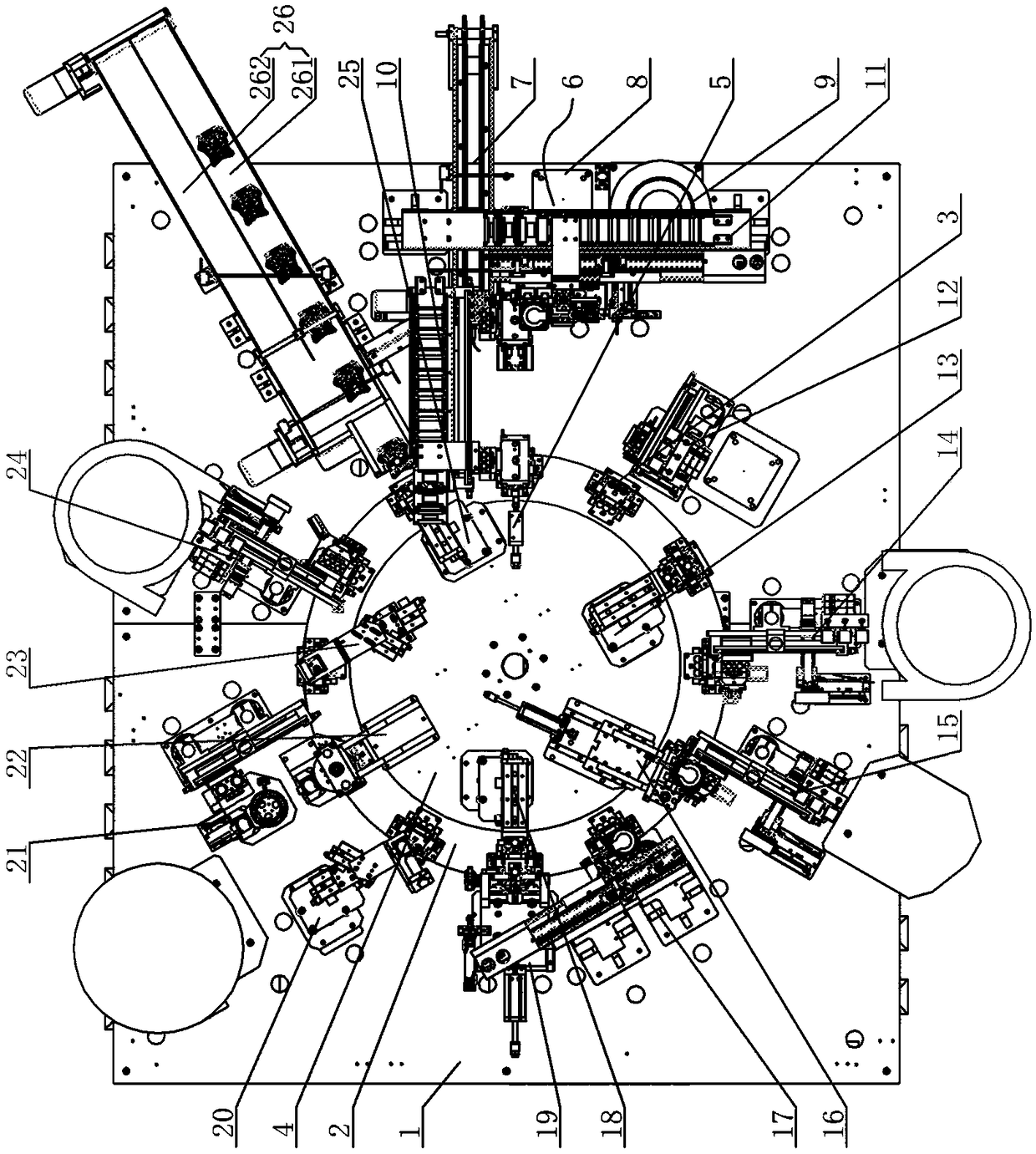

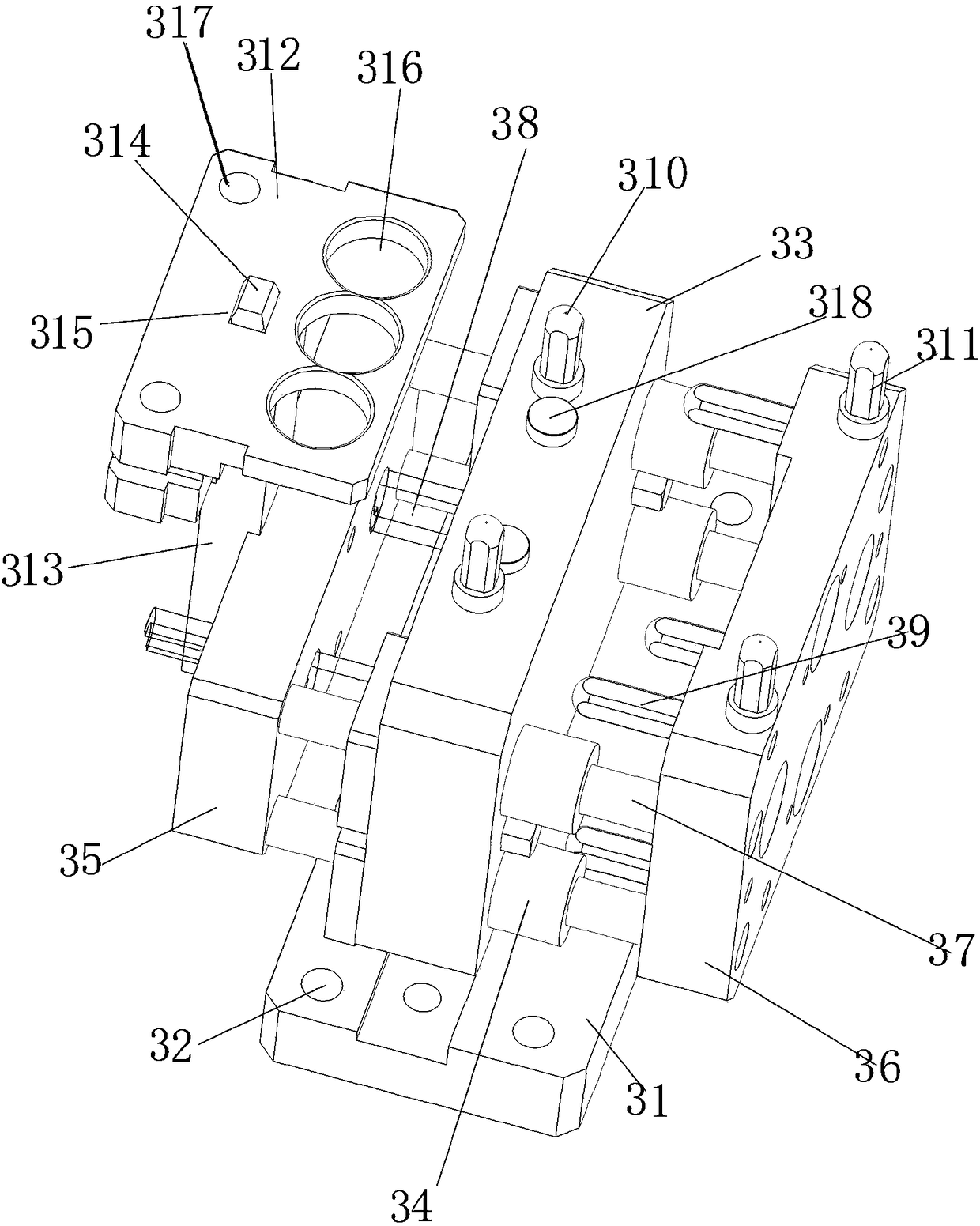

[0046] A pump cover assembly machine, see Figure 1-Figure 14 : It includes a machine platform 1, an annular material channel 2 is arranged at the center of the base, the annular material channel 2 revolves around the center as the center of a circle, twelve carriers 3 are evenly distributed on the annular material channel 2, and the circular material channel 2 An auxiliary circular machine 4 is arranged in the inner ring, and the corresponding machine 1 of the annular channel 2 and the auxiliary circular machine 4 are sequentially provided with a pump cover feeding station, a large sealing ring feeding station, Carrier placement guide block station, one-way valve detection and loading station, plug detection and feeding and the first plugging station, the second plugging station, pump cover flipping station, water seal oiling station , Water seal loading station, water seal detection station, extended one-way valve detection feeding station, finished product unloading station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com