Unitized lifting and traversing intelligent stereo garage equipment

A three-dimensional garage, lift and traverse technology, applied in the direction of buildings, building types, buildings, etc. where cars are parked, can solve the problems of high installation accuracy, low reuse rate, long waiting time, etc., and achieve high safety and improved Efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

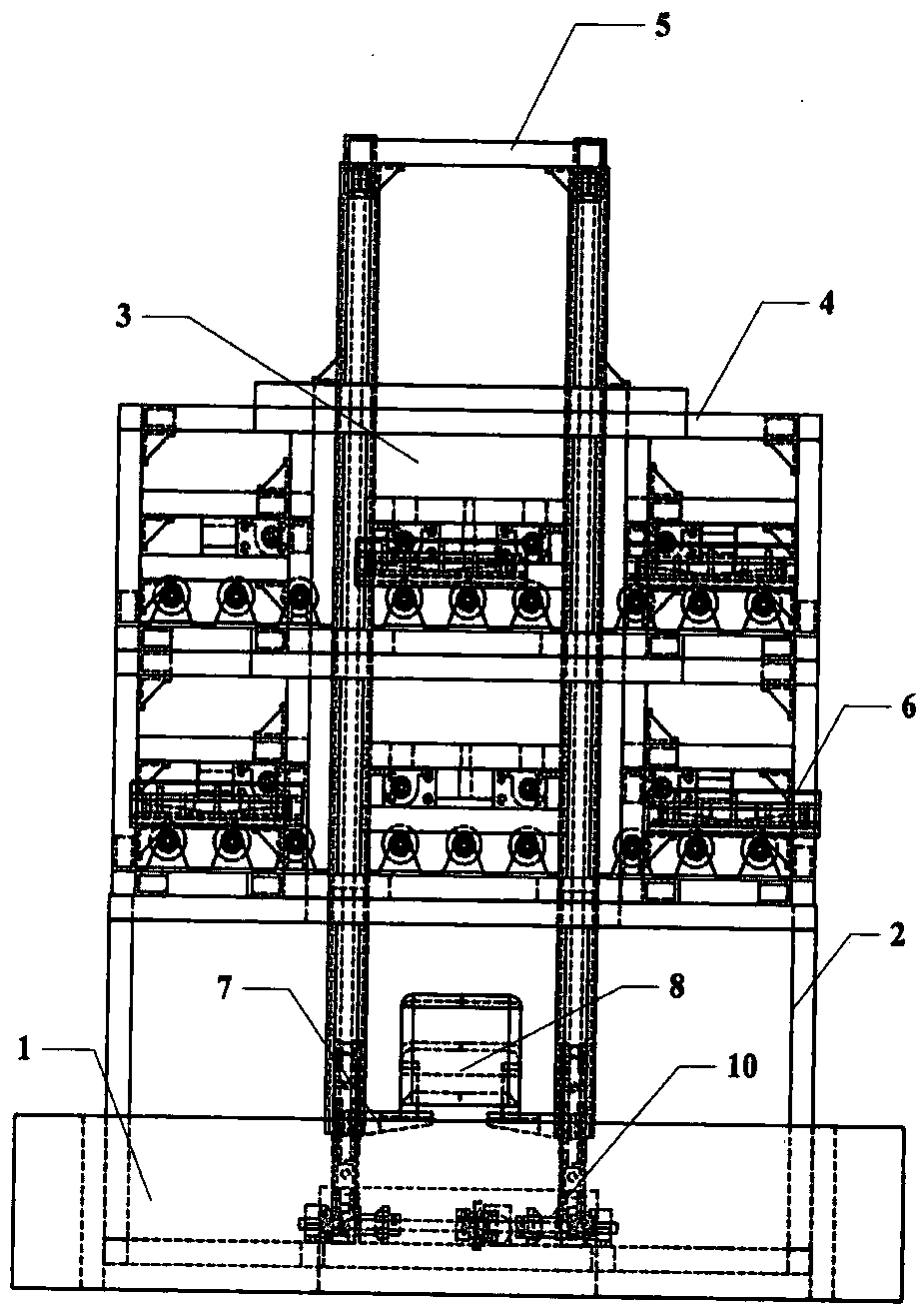

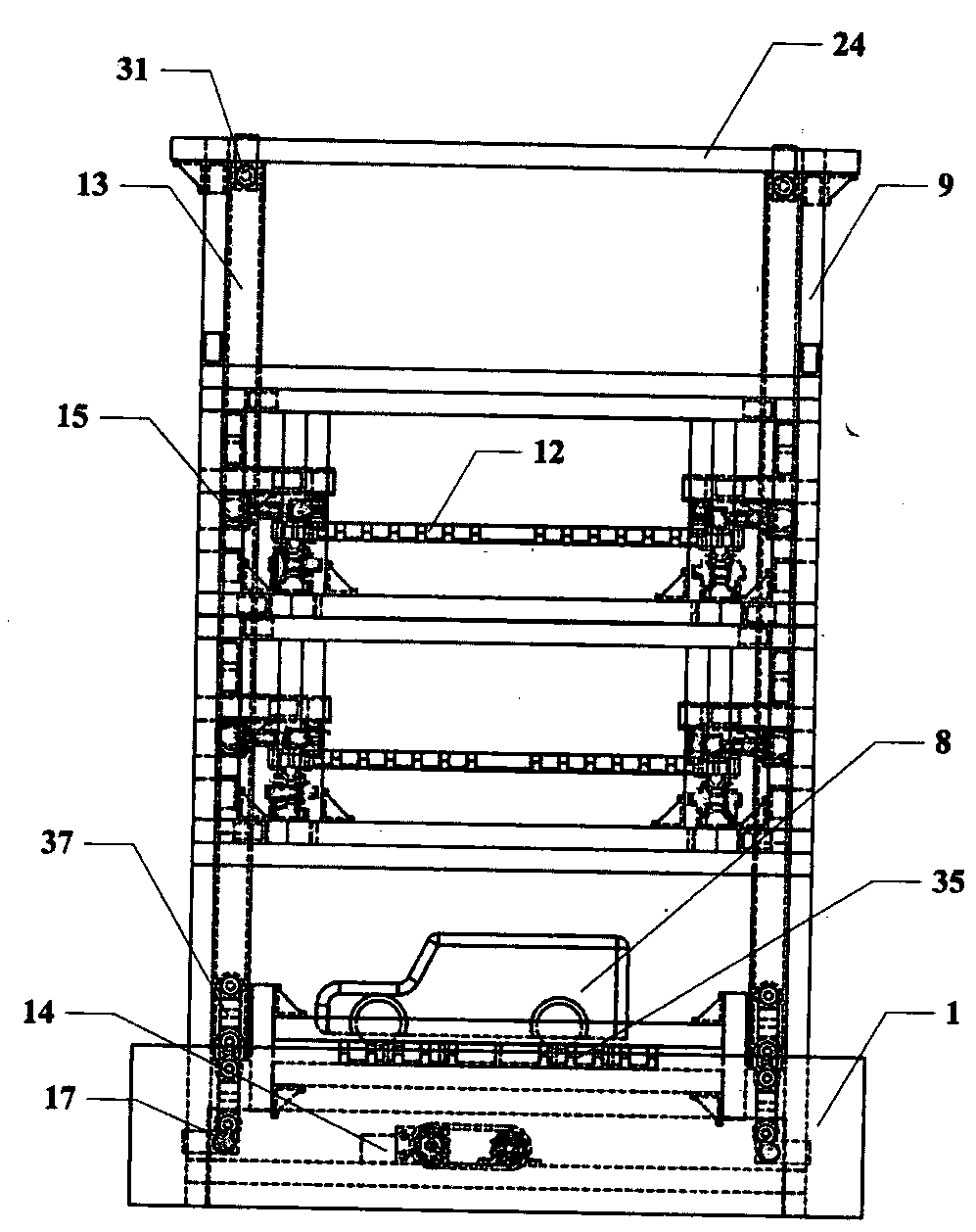

[0029] Such as Figure 1-2 As shown, a unitized comb-tooth lifting and traversing three-dimensional garage equipment provided by the present invention includes five unit modules, namely, the bottom foundation frame module 2, the middle unit module 3, the side unit module 4, and the top floor hoisting frame The module 5, the horizontally moving comb frame 6 and the vertically lifting comb frame 7, the horizontally moving comb frame 6 and the vertically lifting comb frame 7 are collectively referred to as a staggered comb frame module, and various modules are installed in cooperation with each other to form A three-dimensional garage. Such as Figure 1-2 It is a case of three floors and six parking spaces designed and realized by the present invention.

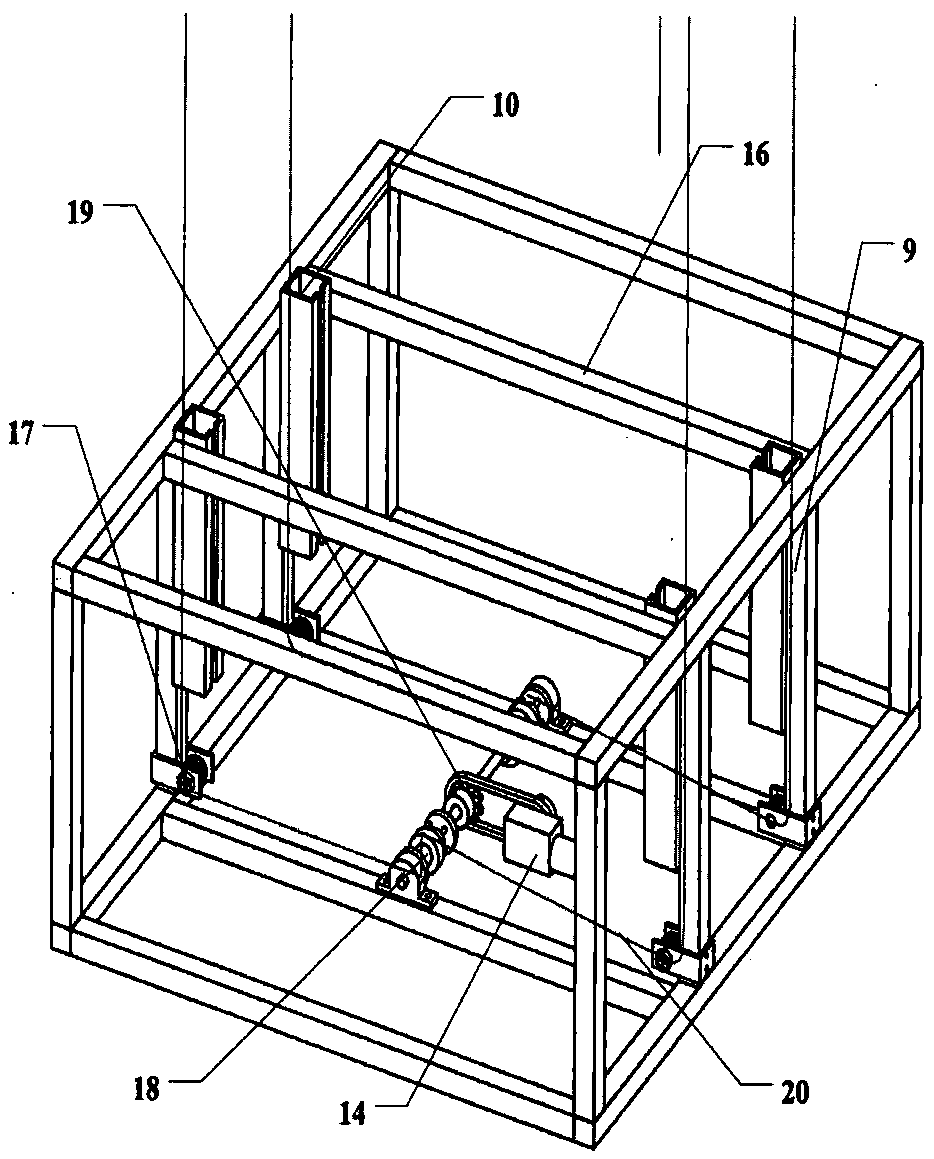

[0030] Such as Figure 1-3, the bottom foundation frame module 2 can be set up on the foundation 1 and cooperate with the foundation 1, and can also be directly buried under the ground surface. Those skilled in the art can bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com