Implementation method of multi-channel circumferential quasi-sinusoidal distribution samples for installation angle error blades

A technology of sinusoidal distribution and installation angle, which is applied in the field of realization of multi-channel circumferential sinusoidal distribution samples, can solve the problems of compressor blade installation angle error, compressor aerodynamic performance degradation, geometric design parameter error, etc., to reduce the installation angle In the case of a large gradient change in the error, the effect of reducing the degree of deterioration and consistent design status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

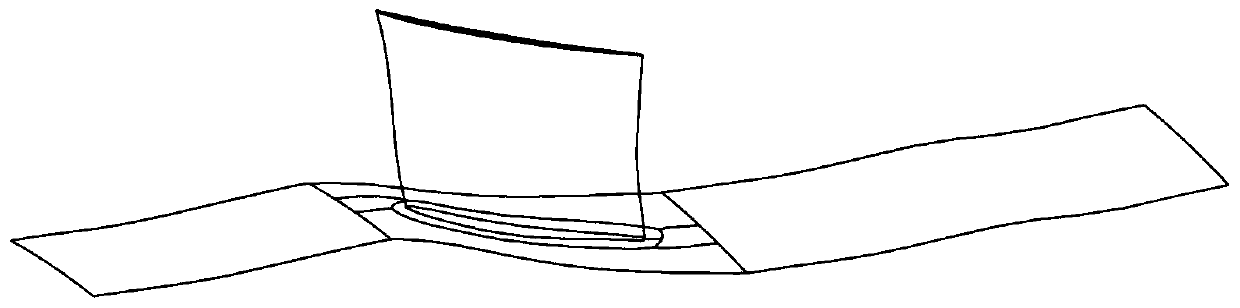

[0019] Such as figure 1 As shown, this embodiment specifically includes the following steps:

[0020] Step 1. Blade installation angle tolerance range and PDF selection

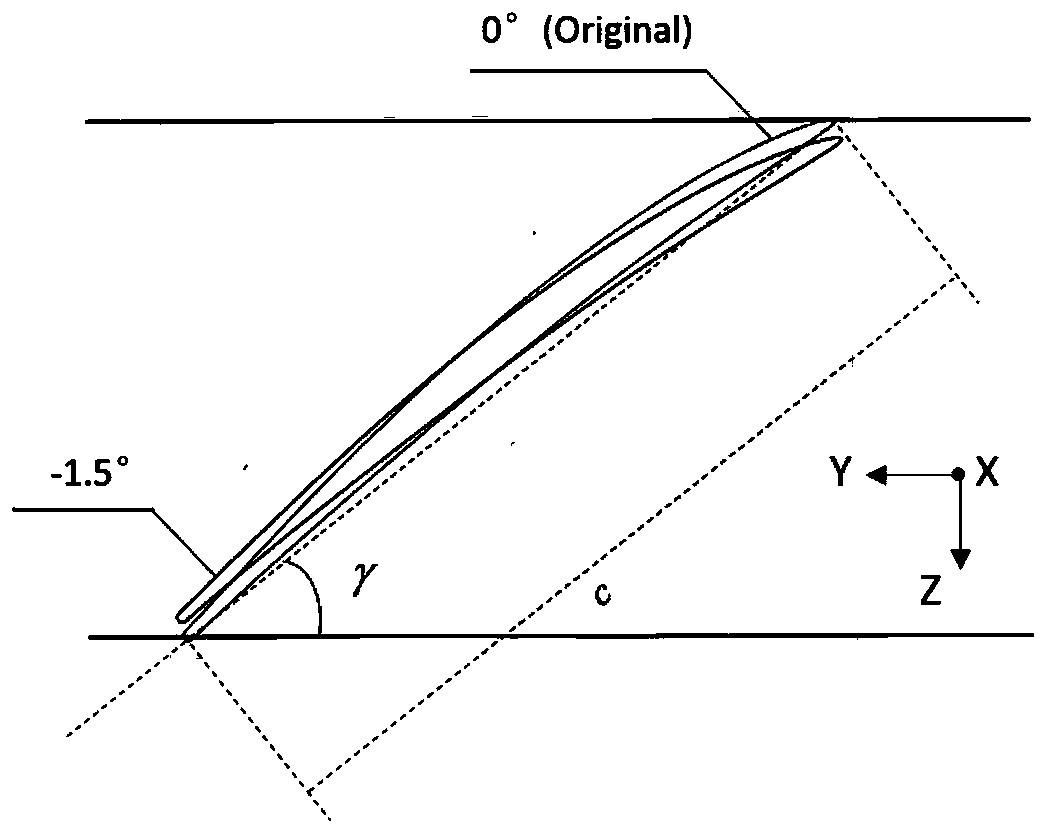

[0021] 1.1 First of all, for this compressor blade, the tolerance range of its installation angle is selected as [-1.5°, +1.5°].

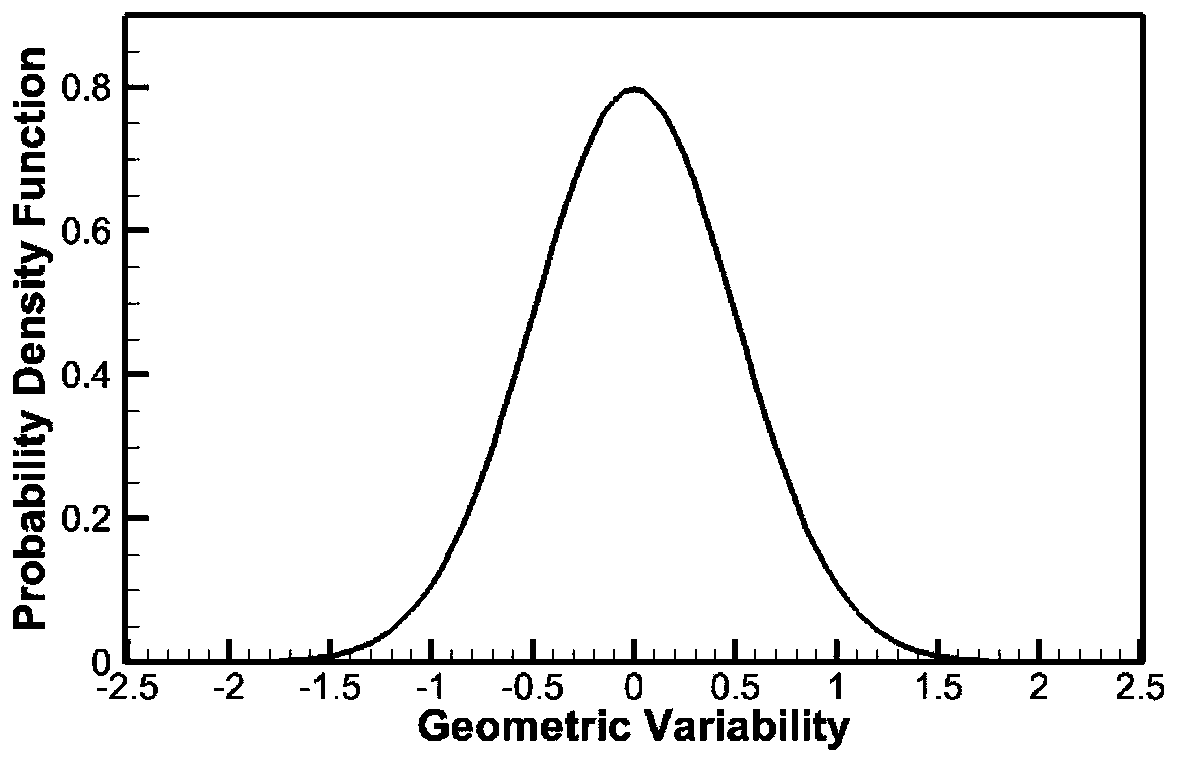

[0022] 1.2 Under the selected tolerance range, establish a reasonable Gaussian distribution probability density function, so that the geometric distribution satisfies: the farther away from the prototype, the lower the probability density, and the probability density is close to 0 when reaching the tolerance boundary, so this example In the probability density function of the Gaussian distribution, the standard deviation σ is taken as 0.5, then the function image is as follows image 3 shown.

[0023] Step 2. Random generation of installation angle error

[0024] 2.1 Reasonably divide the tolerance range [-1.5°, +1.5°] to construct multiple small areas. In this example, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com