A high-efficiency composting device

A composting and high-efficiency technology, applied in the direction of fertilization equipment, organic fertilizers, organic fertilizer equipment, etc., can solve the problems of insufficient oxygen supply, difficult collection of beneficial fertilizers, and reduced final effect of composting, so as to avoid uneven reaction and inconvenience and cost increase, to solve the effect of rationalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

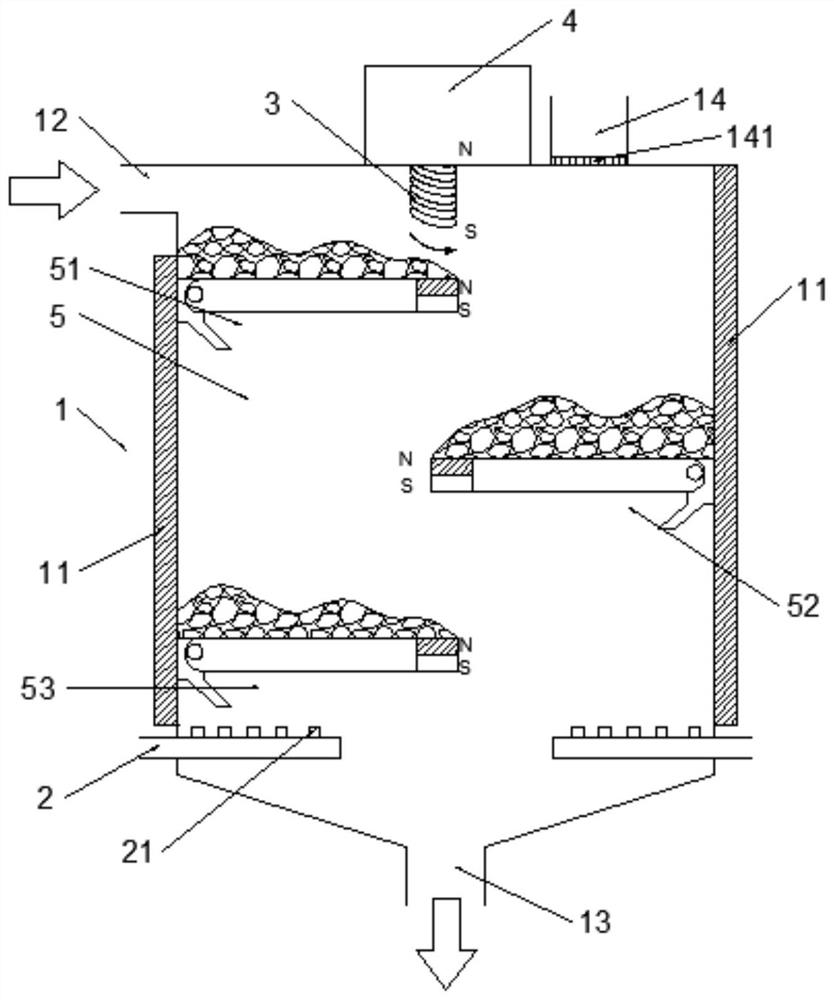

Embodiment 1

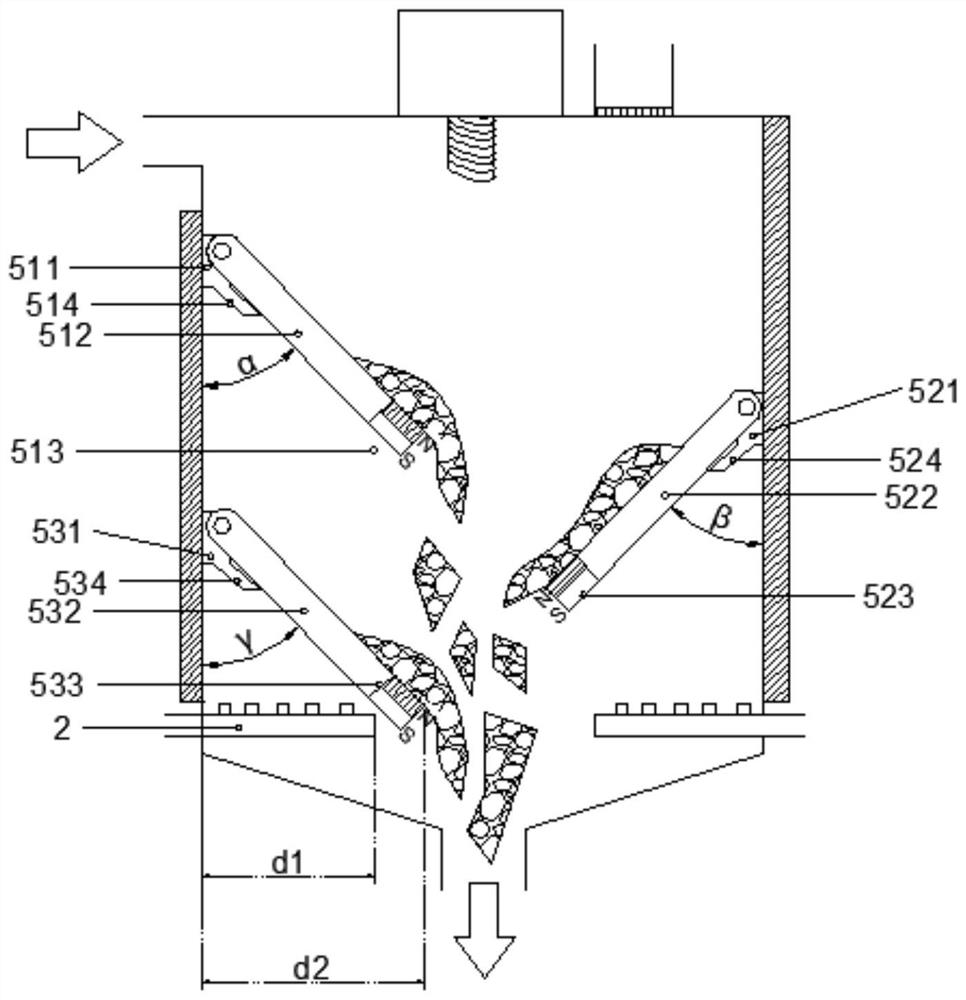

[0033]Example 1, the angle α is 55°, the angle β formed between the second baffle plate 524 and the reaction tank 1, the angle β formed between the third baffle plate 534 and the reaction tank 1 The angle γ is equal to the angle α. At this moment, the compost falling in the first 512 of the setting plate easily collides with the tail end of the second 522 of the setting plate, and the compost falling in the second 522 of the setting plate easily collides with the tail end of the third 532 of the setting plate. Collision between them will easily cause the pollution of the inner wall of the reaction tank 1 and the blockage of the air hole 21 by the impact and splash of the compost.

Embodiment 2

[0034] Example 2, the angle α is 65°, the angle β formed between the second baffle plate 524 and the reaction tank 1, the angle β formed between the third baffle plate 534 and the reaction tank 1 The angle γ is equal to the angle α. At this time, the tail of the lowermost mounting plate 3 532 collides with the air pipe 2, and d2 is smaller than d1, which may easily cause the air hole 21 to be blocked.

Embodiment 3

[0035] Example 3, the angle α is 60°, the angle β formed between the second baffle plate 524 and the reaction tank 1, the angle β formed between the third baffle plate 534 and the reaction tank 1 The angle γ is equal to the angle α. In this state, d2 is greater than d1, and there will be no collision between the falling compost between the upper and lower placement plates. At the same time, the falling compost can just fall along the axis center position of the discharge port 13 .

[0036] Specifically, as attached figure 1 As shown, when the energization mechanism 4 is energized, the coil 3 electrically connected to the energization mechanism 4 will also be energized, and the current trend in the coil is as follows: figure 1 As shown by the arrow in the middle curve, through Ampere's law, it is not difficult to distinguish that the top of the coil 3 is an N pole, and the bottom is an S pole. In the present invention, the magnetic pole at the top of the magnetic block 513 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com