Solid oil paint and preparation method thereof

A kind of oil paint and solid technology, applied in the field of painting materials, can solve the problems of inconvenient creation and inability to see the color of oil painting intuitively, and achieve the effect of not being sticky

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

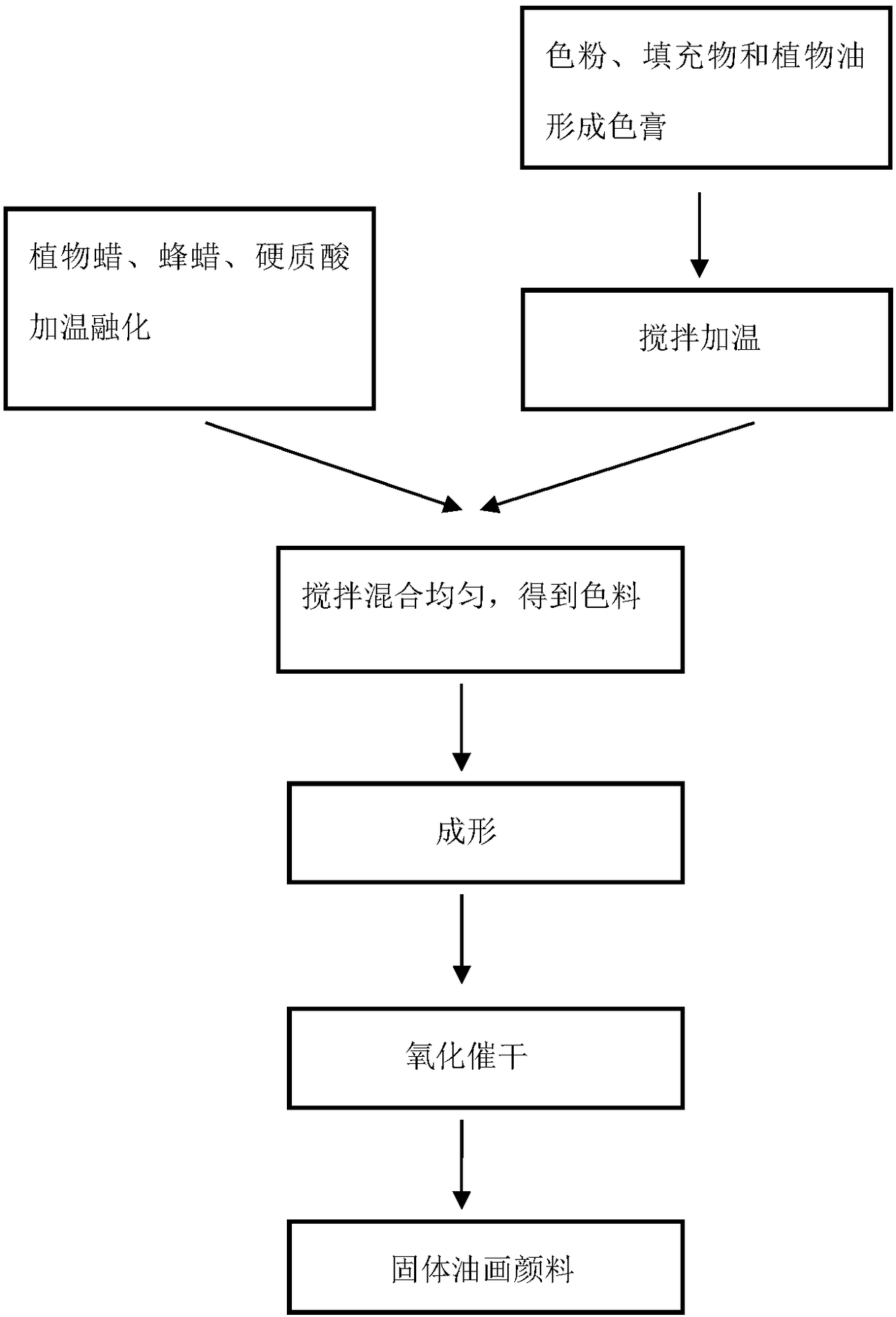

[0054] The embodiment of the present invention also discloses a preparation method of solid oil paint, comprising the following steps, see for details figure 1 :

[0055] (A) uniformly mixing 25-30 parts by weight of toner, 10-20 parts by weight of filler, and 30-35 parts by weight of plants to make a color paste;

[0056] (B) heating and melting 10-15 parts by weight of vegetable wax, 15-25 parts by weight of beeswax and 5-8 parts by weight of stearic acid, and mixing them with the heated color paste to obtain a colorant;

[0057] (C) Cooling and demoulding the coloring material, performing oxidation and drying to obtain solid oil paint.

[0058] In the present invention, the adding order of each component and the regulation of temperature directly affect the state and painting effect in the pigment group.

[0059] First, 25-30 parts by weight of toner, 10-20 parts by weight of filler, and 30-35 parts by weight of plants are uniformly mixed to make a color paste;

[0060] ...

Embodiment 1

[0072]25 parts by weight of milled toner, 10 parts by weight of filler and 30 parts by weight of linseed oil are fully mixed evenly, and the wear-resistant toner is used in a three-roll mill to make a color paste and heated to 75-80°C.

[0073] 10 parts by weight of palm wax, 15 parts by weight of beeswax and 5 parts by weight of stearic acid are melted at 75-80°C. Stir evenly with the heated color paste to obtain the color material.

[0074] Put the melted color material into the mold and cool it down to 2-5°C to remove the mold. The mold can be made into different shapes according to the needs.

[0075] Put the solid oil painting into the oxidation drying room for oxidation drying treatment. After the oxidation drying treatment takes 48 hours, the painting has reached the level of non-staining.

Embodiment 2

[0077] 30 parts by weight of milled toner, 20 parts by weight of filler and 30 parts by weight of linseed oil are fully mixed evenly, and the wear-resistant toner is used in a three-roll mill to make a color paste and heated to 75-80°C.

[0078] 10 parts by weight of palm wax, 15 parts by weight of beeswax and 8 parts by weight of stearic acid are melted at 75-80°C. Stir evenly with the heated color paste to obtain the color material.

[0079] Put the melted color material into the mold and cool it down to 2-5°C to remove the mold. The mold can be made into different shapes according to the needs.

[0080] Put the solid oil painting into the oxidation drying chamber for oxidation and drying treatment. The oxidation and drying treatment lasts for 60 hours, and the painting has reached the level of non-staining.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com