Energy-saving and environment-friendly heating stove

An energy-saving and environmental-friendly heating furnace technology, applied in the heating field, can solve the problems of slow heating, single heat collecting device, and no filtering measures for waste smoke, so as to achieve the effect of improving heating efficiency and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

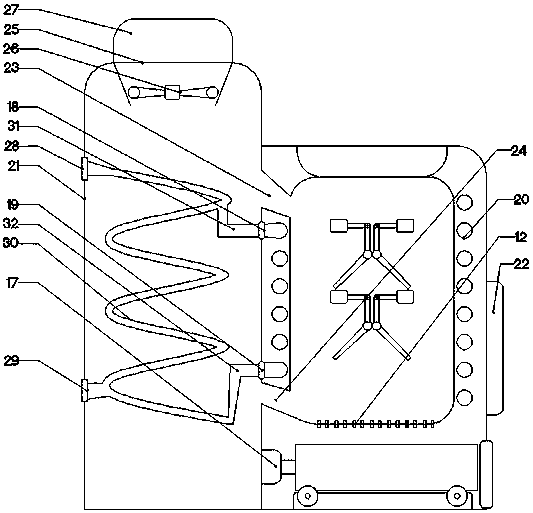

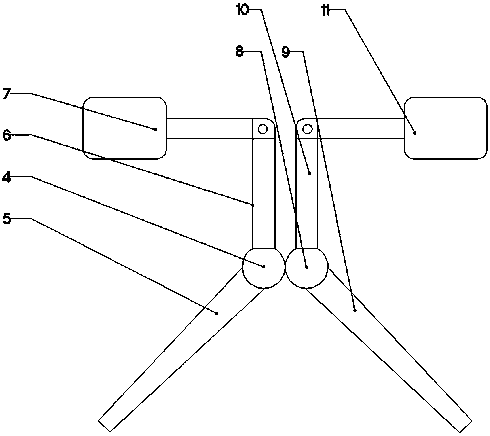

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, it includes a rectangular box-1, and a combustion device is arranged inside the rectangular box-1, and the combustion device is fixedly connected with the rectangular box-1 at the center of the rectangular box-1. 1. The combustion furnace 3 located on the lower surface of the fixed ring 2 and fixedly connected to the fixed ring 2 in the vertical direction, located on the opposite side surface of the combustion furnace 3 and with one end protruding from the rectangular box-1 and the circle connected to the combustion furnace 3 by inserting Shape rotating rod-4, be positioned at the baffle plate-5 that the outer surface of circular rotating rod-4 is fixedly connected with circular rotating rod-4, be positioned at the connecting rod that one end of circular rotating rod-4 is fixedly connected with circular rotating rod-4 6. A linear motor located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com