Calibration device for auto parts

A technology of auto parts and proofreading devices, which is applied in the direction of measuring devices, fluid utilization devices, instruments, etc., can solve the problems of damage to the surface of parts and affect the yield of parts, so as to ensure stability, reduce labor, reduce The effect of human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

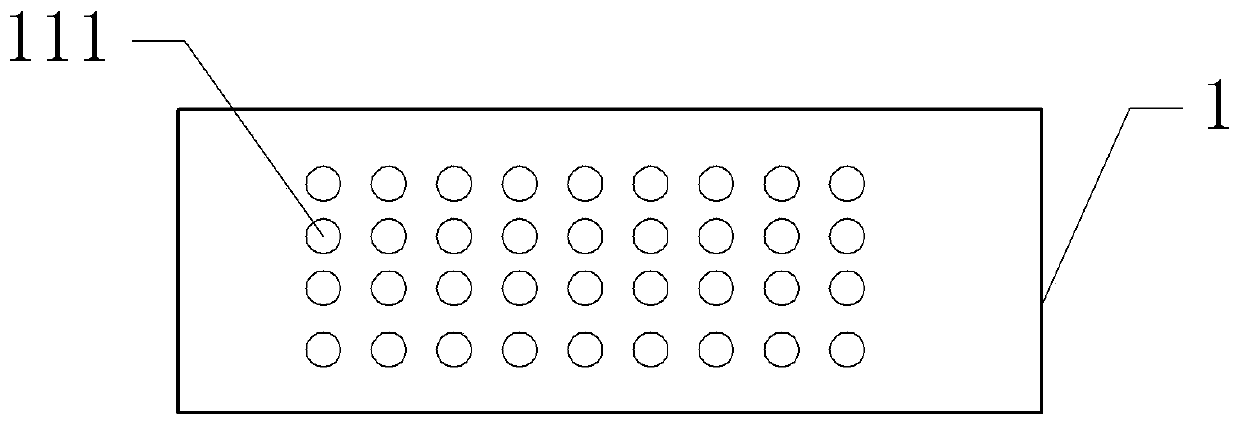

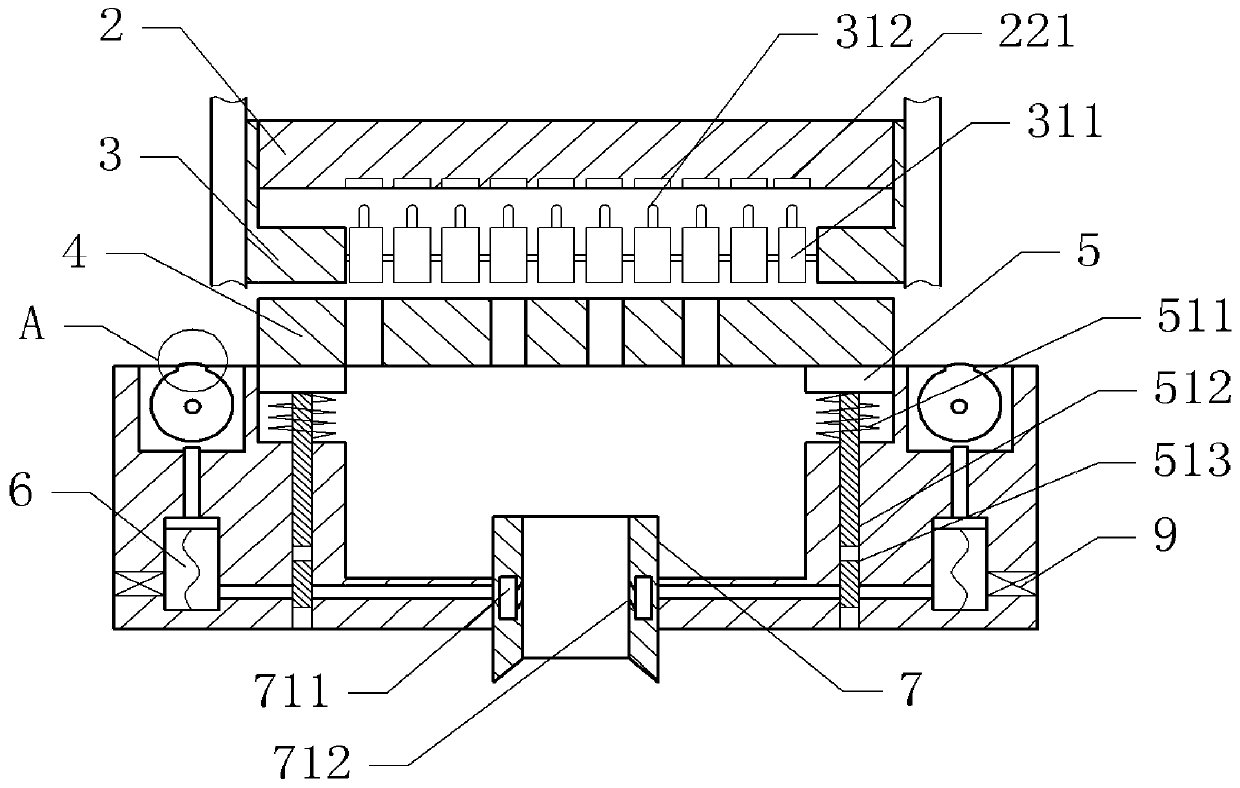

[0028] as attached figure 1 And attached figure 2 As shown, an auto parts calibration device includes a frame, a display board 1, an output board 2, an input rack 3 and a placement table.

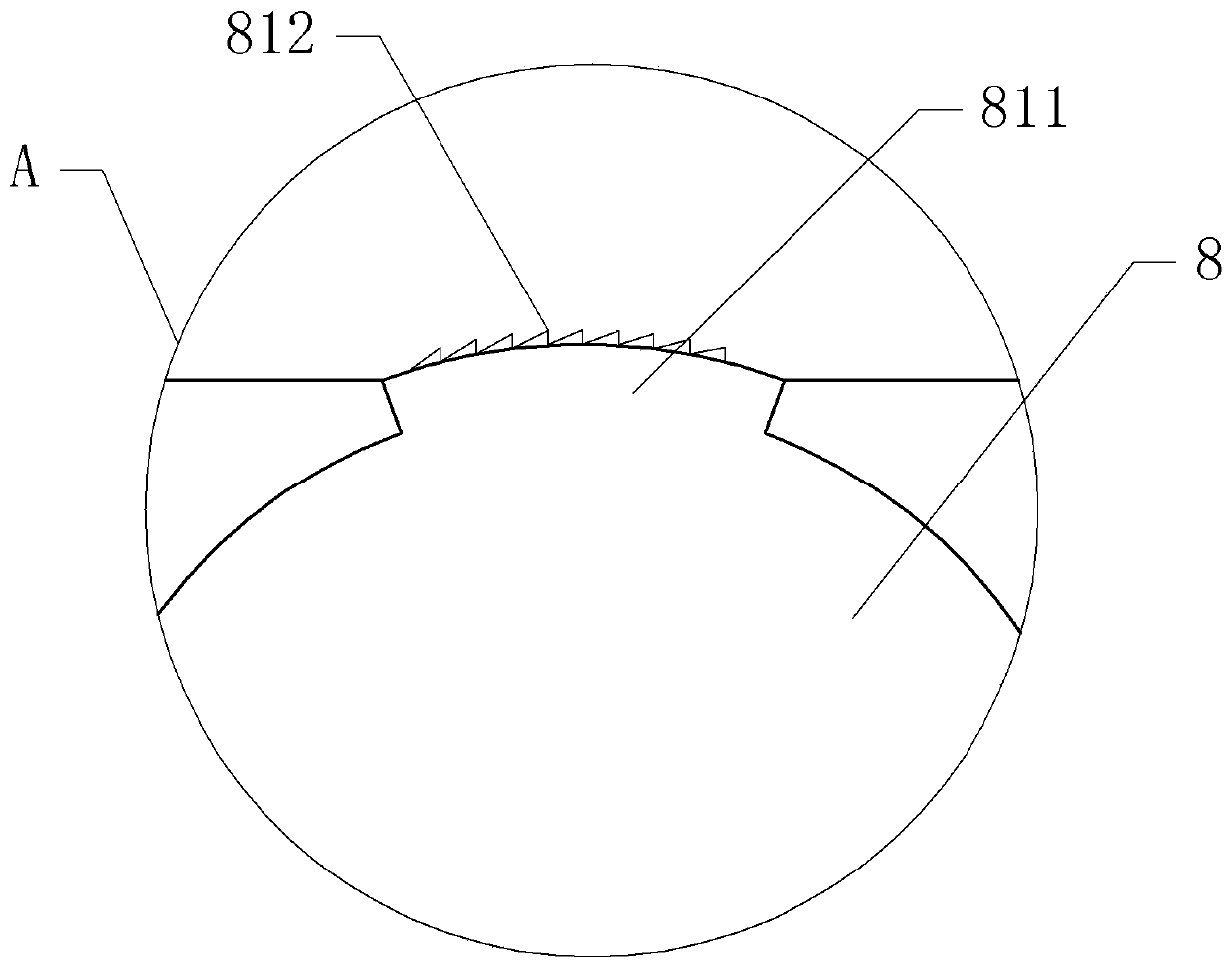

[0029] LED lights 111 are fixed on the display board 1 in a matrix through glue, and the input frame 3 is slidably connected with the frame along the vertical direction. Fixed connection. The output board 2 is fixed on the upper part of the input frame 3 , and the bottom of the output board 2 is fixed in a matrix with push button switches 221 electrically connected to the LED lamps 111 in one-to-one correspondence. as attached Figure 4 As shown, the bottom of the input frame 3 is provided with rubber blocks 311 in a matrix, between two adjacent rubber blocks 311, and between the rubber blocks 311 and the input frame 3 are fixed by elastic parts, the elastic parts are rubber bands, two adjacent The distance between the rubber blocks 311 is 2cm, and the rubber blocks 311 correspond to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com