Manufacturing method of aluminum branch pipe of refrigeration pipeline

A manufacturing method and technology of refrigeration pipes, applied to branch pipelines, pipes/pipe joints/fittings, pipes, etc., can solve the problems of high leakage incidence and poor pressure resistance, and achieve low leakage risk and high pressure resistance High force, improve the effect of compressive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

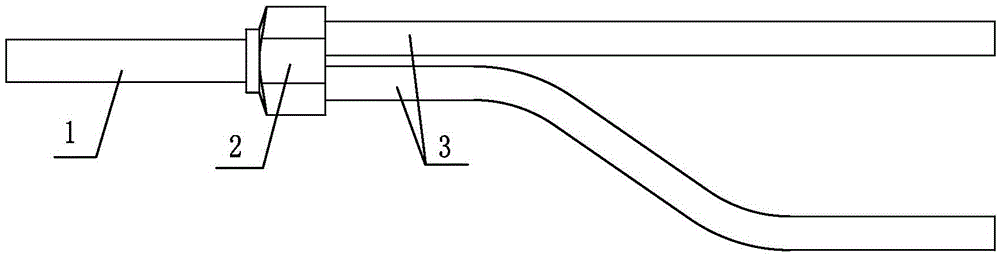

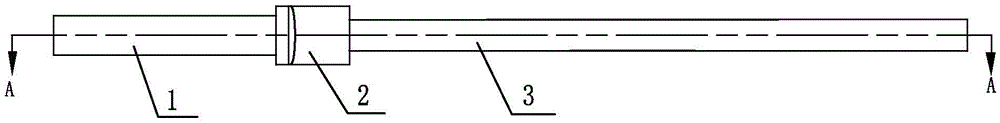

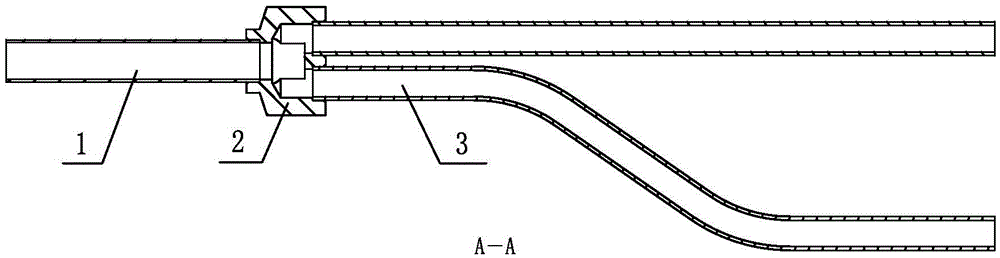

[0018] The utility model includes an input pipe 1, two output pipes 3 and a multi-way joint 2 connecting the input pipe and the output pipe. The base body of the multi-way joint adopts extruded aluminum alloy profiles or die-casting It is made of formed aluminum alloy castings. The shape of the multi-way joint base is a drum-shaped cylinder with two parallel planes. The number of input holes is one, and the number of output holes is two. , are all cut and formed on the base of the multi-way joint. The distance between the centerline of the input hole and the centerline of the two output holes is equal. There is a socket at the end of the input hole and the output hole. The side walls of the socket are the input hole and the output hole. The radially concave cylindrical surface on the hole wall forms an axial end face shoulder facing the orific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com