Rigidity measuring device for large-size shaft-shaped part under bending and twisting synchronous loading condition

A measuring device and large-scale technology, applied in the field of mechanical equipment, can solve the problems of not being able to jointly apply bending load and torsional load, and unable to measure the stiffness of large-sized shaft parts, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

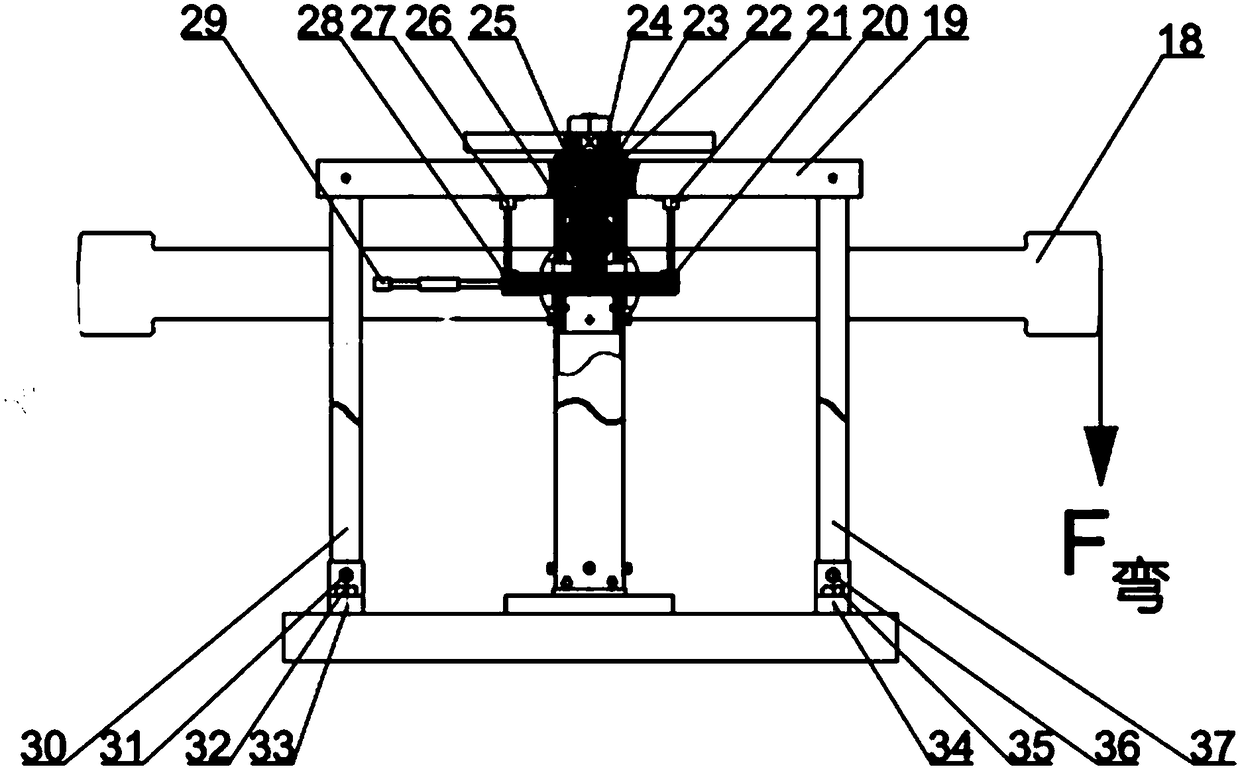

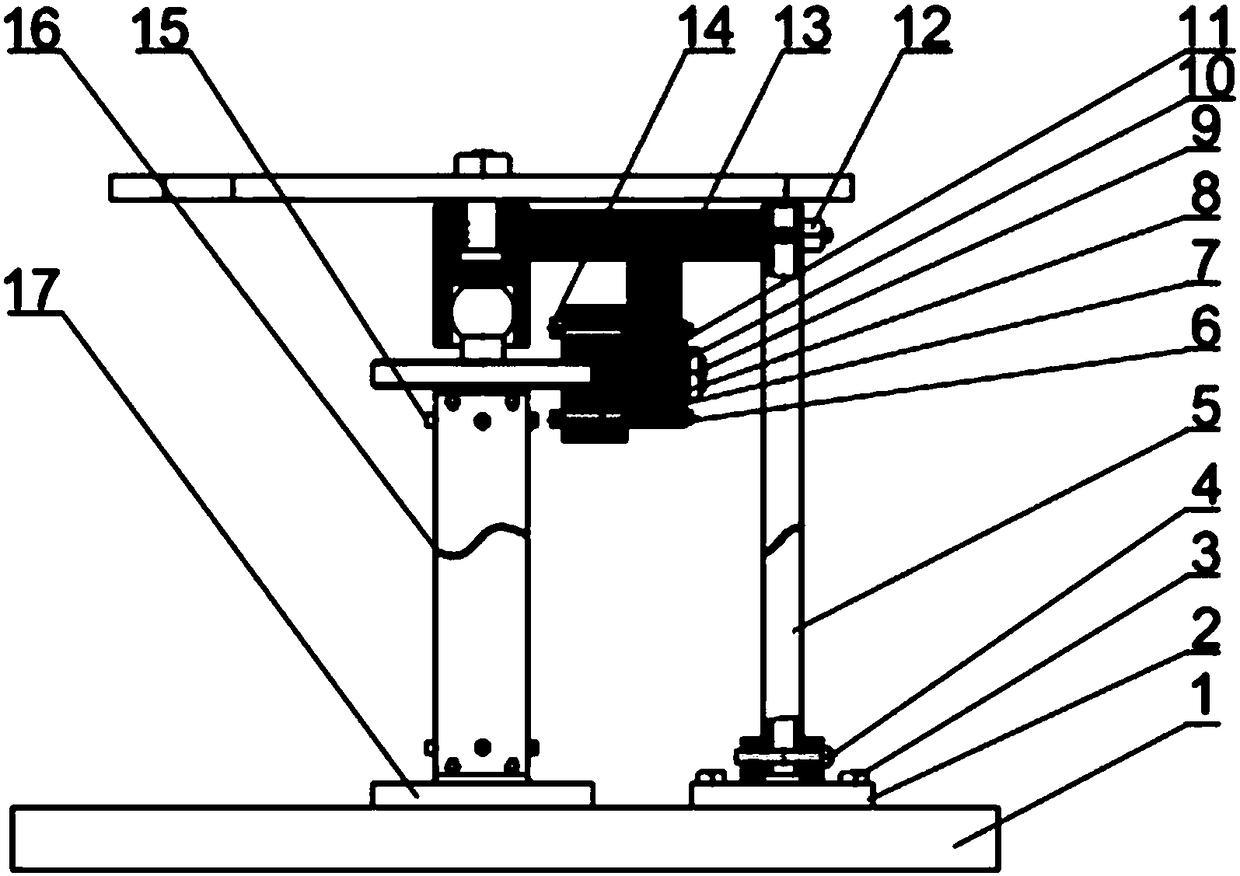

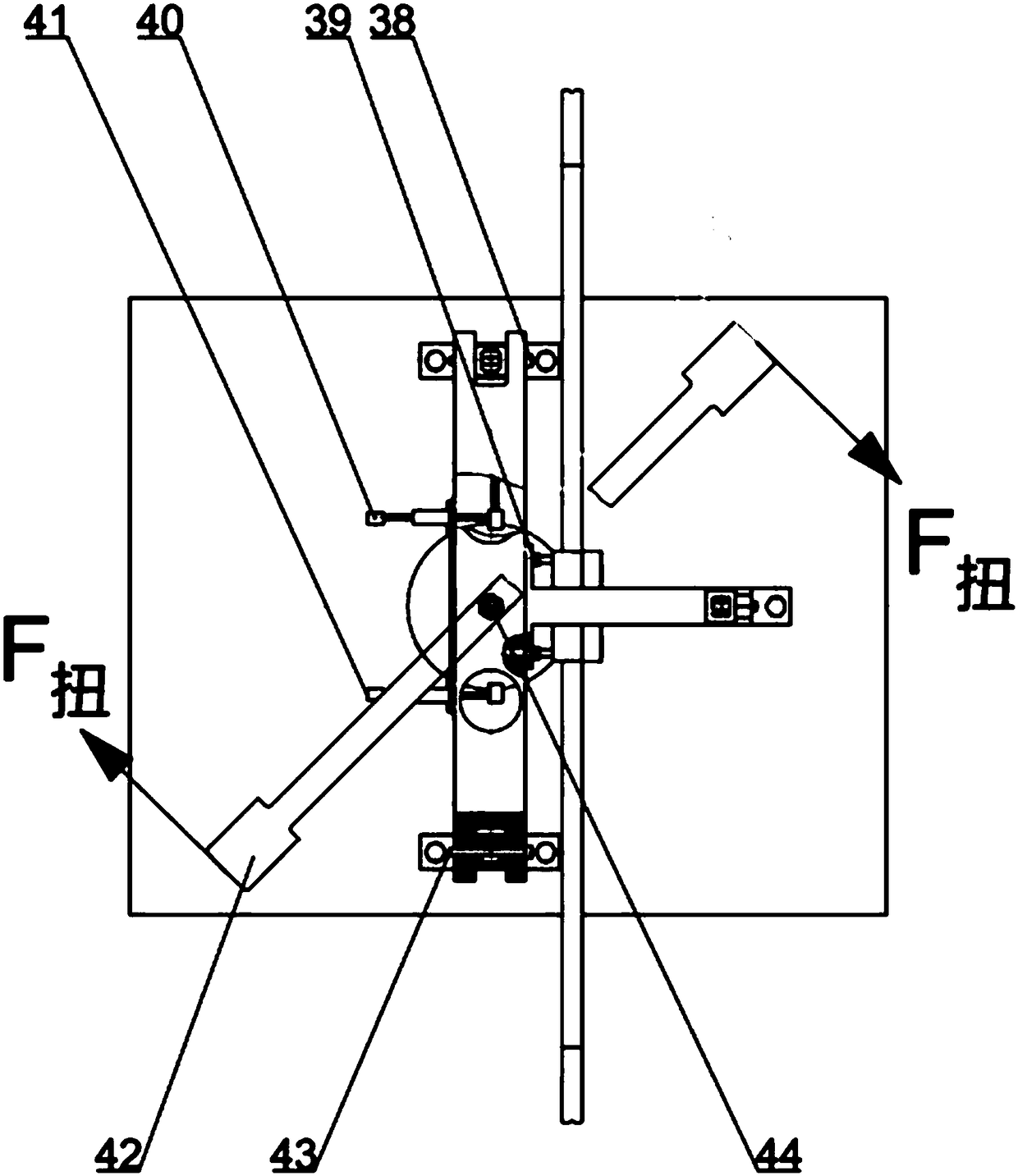

[0030] A device for measuring the stiffness of a large shaft-shaped part under the condition of simultaneous bending and torsion loading, such as Figure 1 to Figure 3As shown, the device includes a base 1; the upper surface of the base 1 is fixedly equipped with square steel pipe fixed supports one 2, two 33, and three 34; Square steel pipe one 5, two 30, three 37 are fixedly installed by bolt one 3, five 32, six 35 and pin one 4, two 31, three 36; One end of 13 transverse arms is fixedly connected; the other end of the transverse arm of the T-beam 13 is fixedly installed on the side wall of the transverse beam 19; a bearing 2 23 is installed in the middle of the transverse beam 19; a torque loading connector 25 is installed in the bearing 2 23 The bottom end of the vertical arm of the T-shaped beam 13 is fixedly equipped with a bending moment loading connector 10; the bending moment loading arm 18 is installed on the bending moment loading connector 10; The twisted axisymme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com