A retractable boarding trestle with position compensation

A telescopic, trestle technology, applied in construction and other directions, can solve the problems of easy damage, passing people and transporting materials, and difficulty in overlapping, achieving the effect of easy overlapping, no energy consumption, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

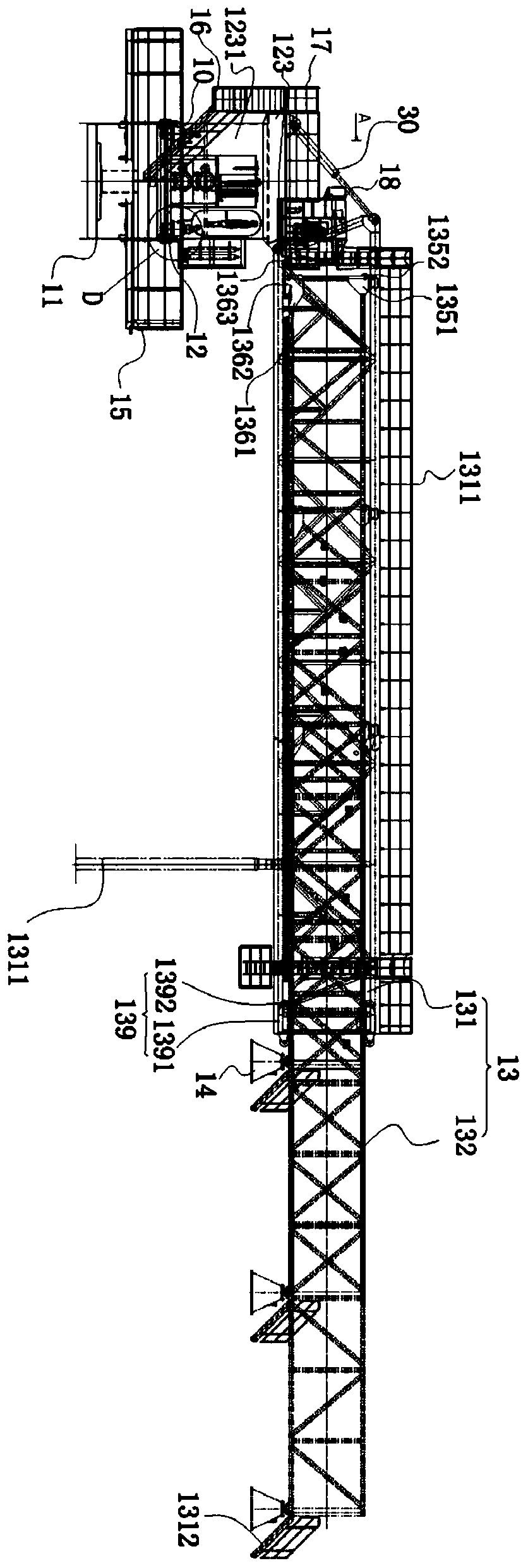

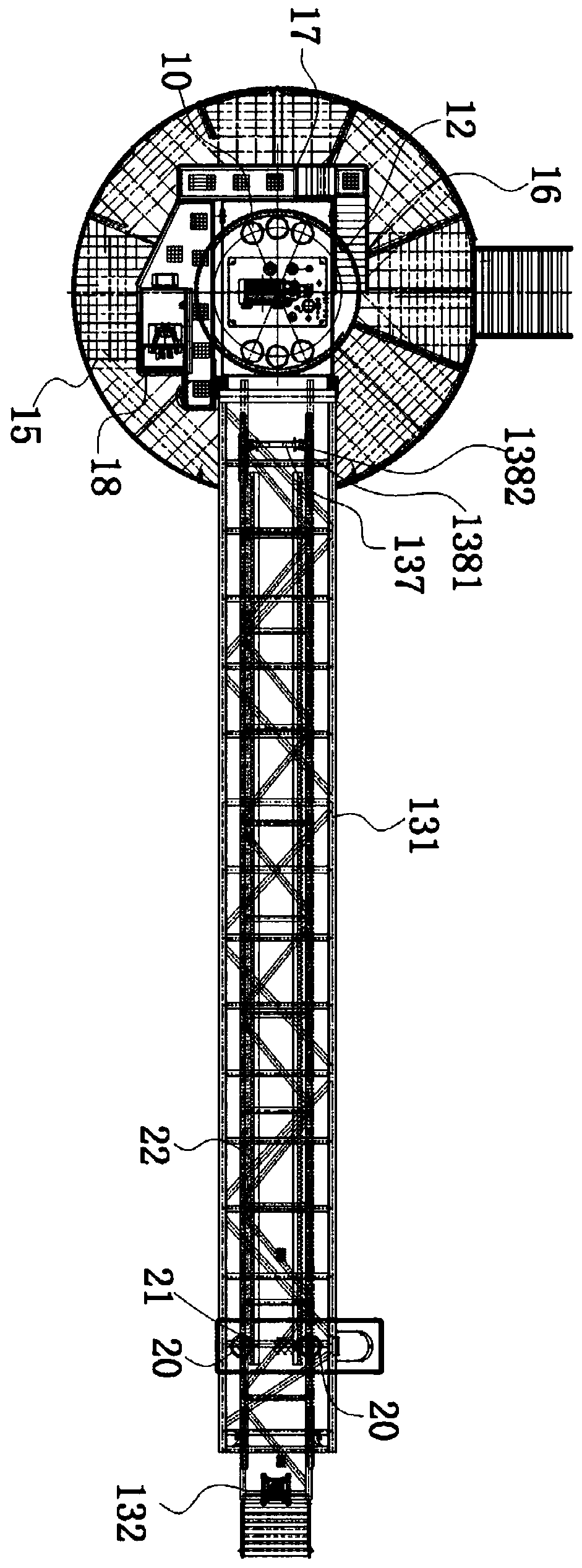

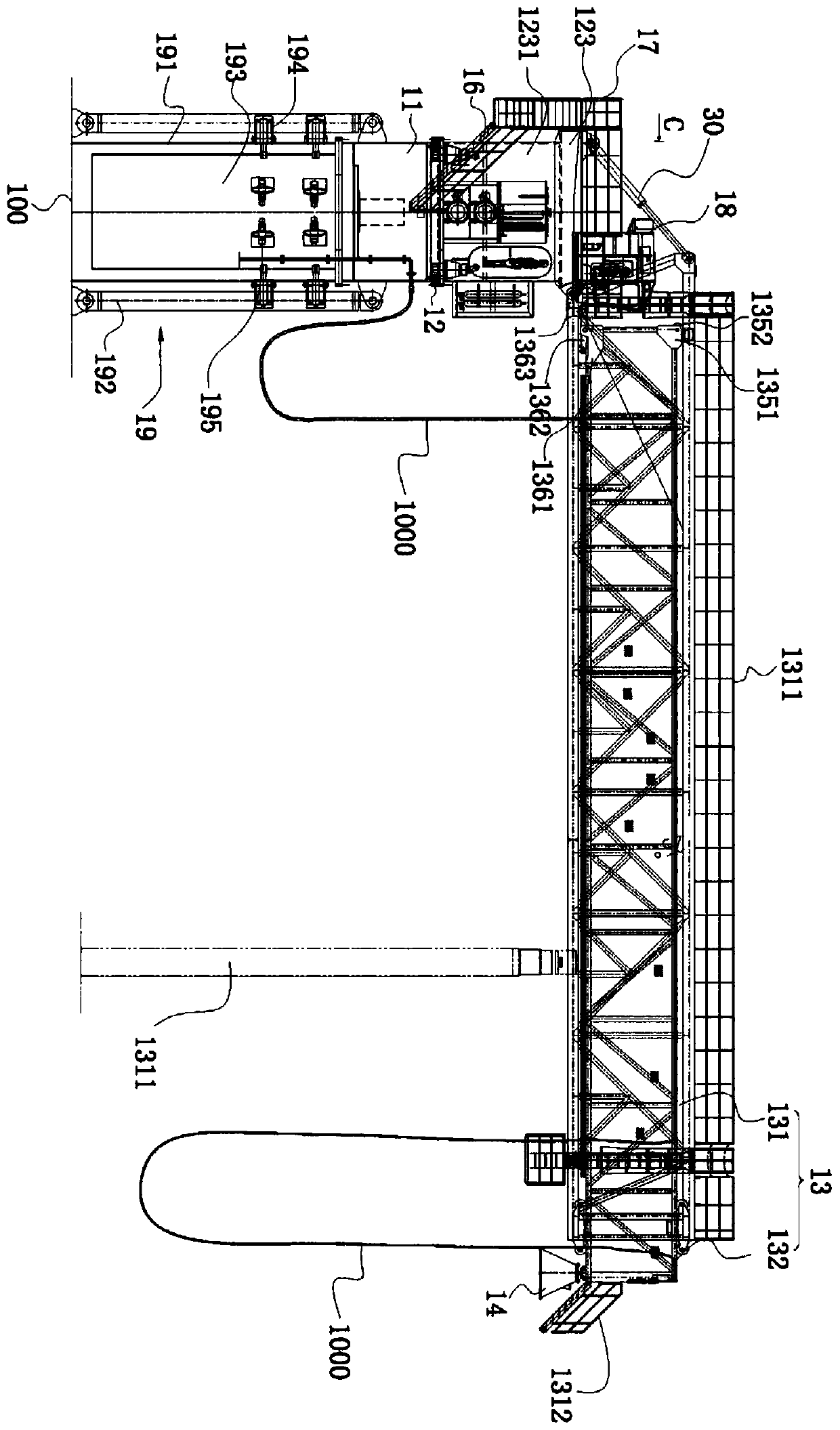

[0077] Such as Figure 1 to Figure 6 As shown, the position-compensated telescopic boarding trestle includes a base 11, a slewing platform 12, a telescopic trestle 13, a landing device 14, a rotary hydraulic motor 10, a luffing cylinder 20, a position compensation control system 4, and a position compensation hydraulic system 5.

[0078] Such as Picture 9 As shown, the rotary platform 12 includes a rotatably mounted ring gear 121 on the base 11, a rotary drive gear 122 mounted on the output shaft of the rotary hydraulic motor 10, and a rotary seat 123 fixed on the ring gear 121. The hydraulic motor 10 is mounted on the base 11. Two or more rotary hydraulic motors 10 are provided. There is an accommodating cavity 1231 in the swivel seat 123, which can be used to place hydraulic systems such as control systems and hydraulic oil tanks, which can effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com