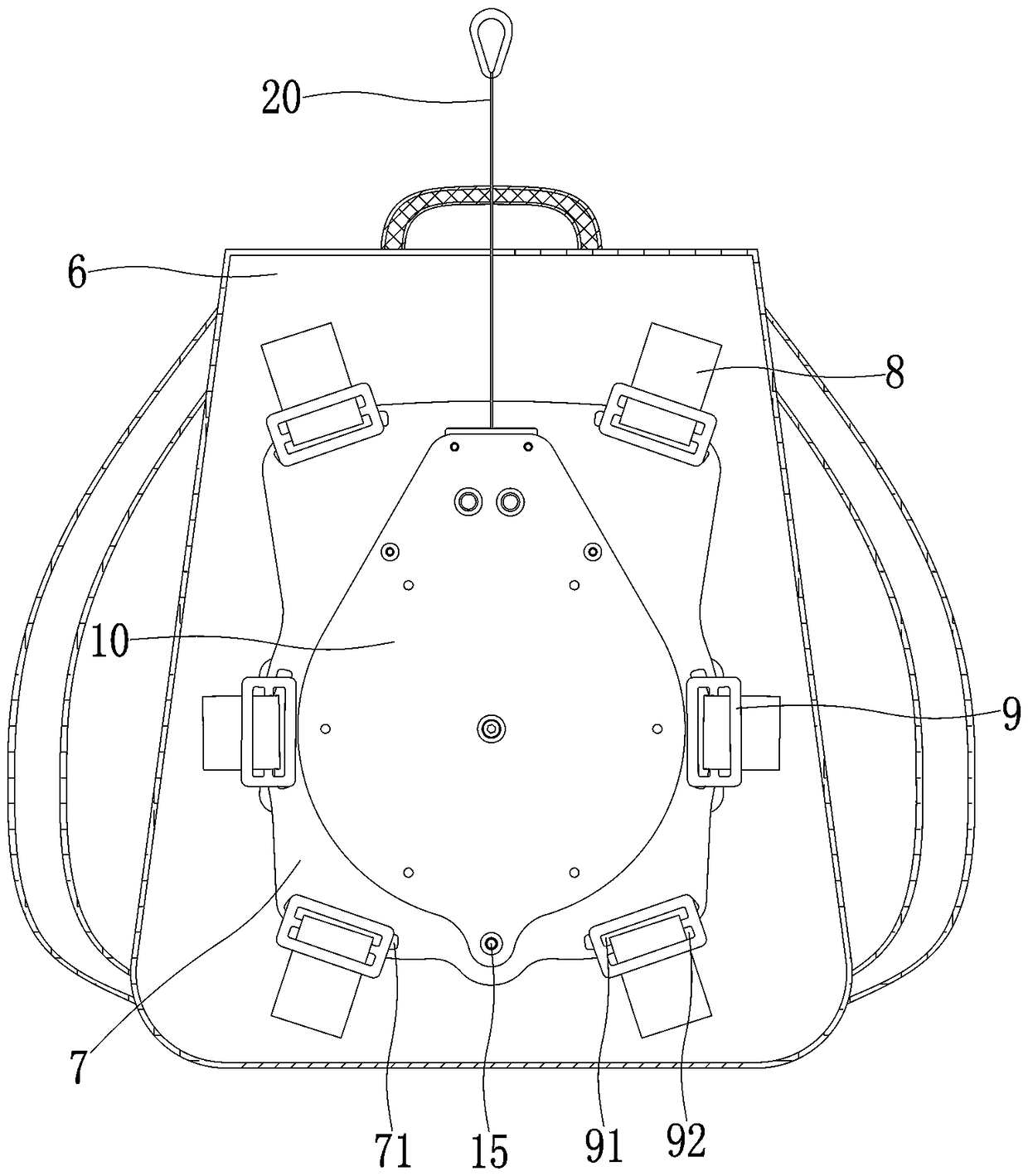

Retarder and escape bag with same

A slow-down device and slow-down technology, applied in the field of slow-down devices and escape bags, can solve the problems of low safety performance of slow-down escape equipment, limited ways to evacuate the accident scene, and poor slow-down effect, so as to save wearing time , High reliability, fixed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

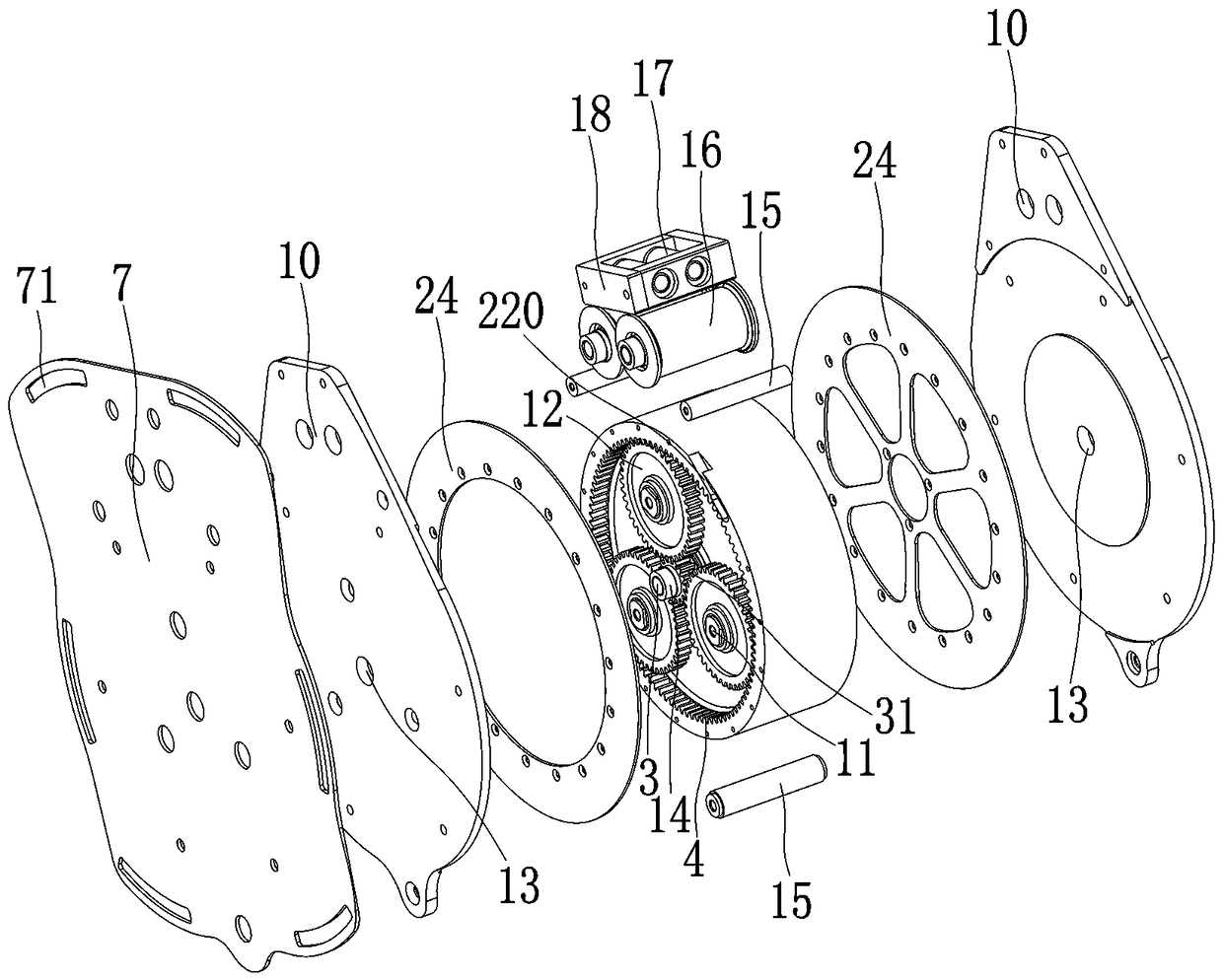

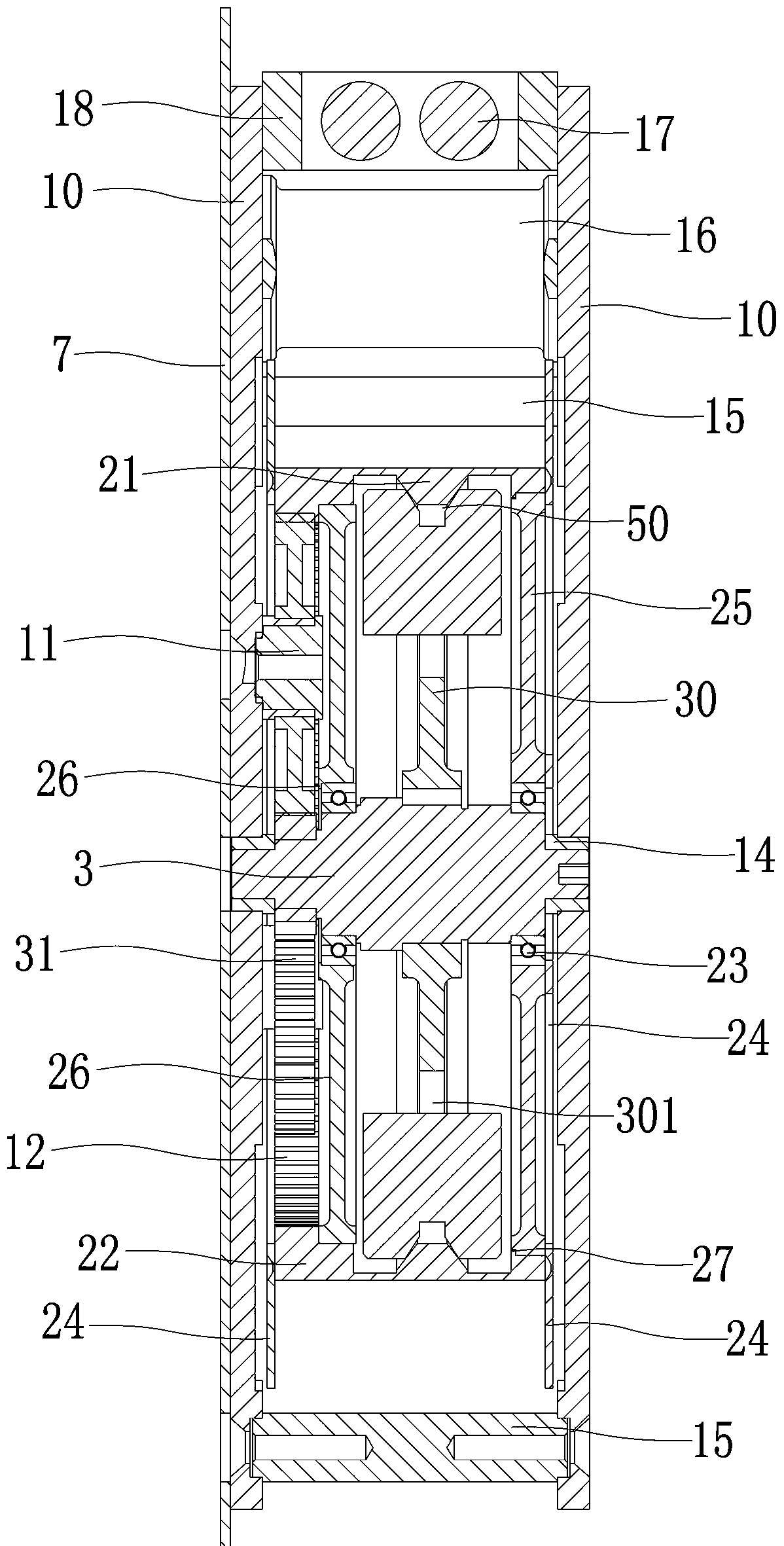

[0024] The present invention will be further described below according to the accompanying drawings and specific embodiments.

[0025] Depend on Figure 1 to Figure 8 As shown, a slow descender of the present invention includes a housing, and the housing includes two mounting plates 10 oppositely arranged. A rope reel and a rotating shaft 3 are rotatably fixed between the two mounting plates 10, and the rope reel is sleeved on the The rotating shaft 3 is circumferentially outward, and the slow-down rope 20 is wound on the rope drum. The inner gear ring 4 is arranged on the rope drum. The inner side extends to form a protrusion 21 to be contacted for contact with the friction block 5 to generate friction, and a plurality of first gear shafts 11 are fixed on the inner wall of a mounting plate 10, and the axis of the first gear shaft 11 is arranged parallel to the axis of the rotating shaft 3, and A planetary gear 12 is fixed on the first gear shaft 11, a friction block holder 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com