Frame welding positioning structure

A welding positioning and frame technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to achieve positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

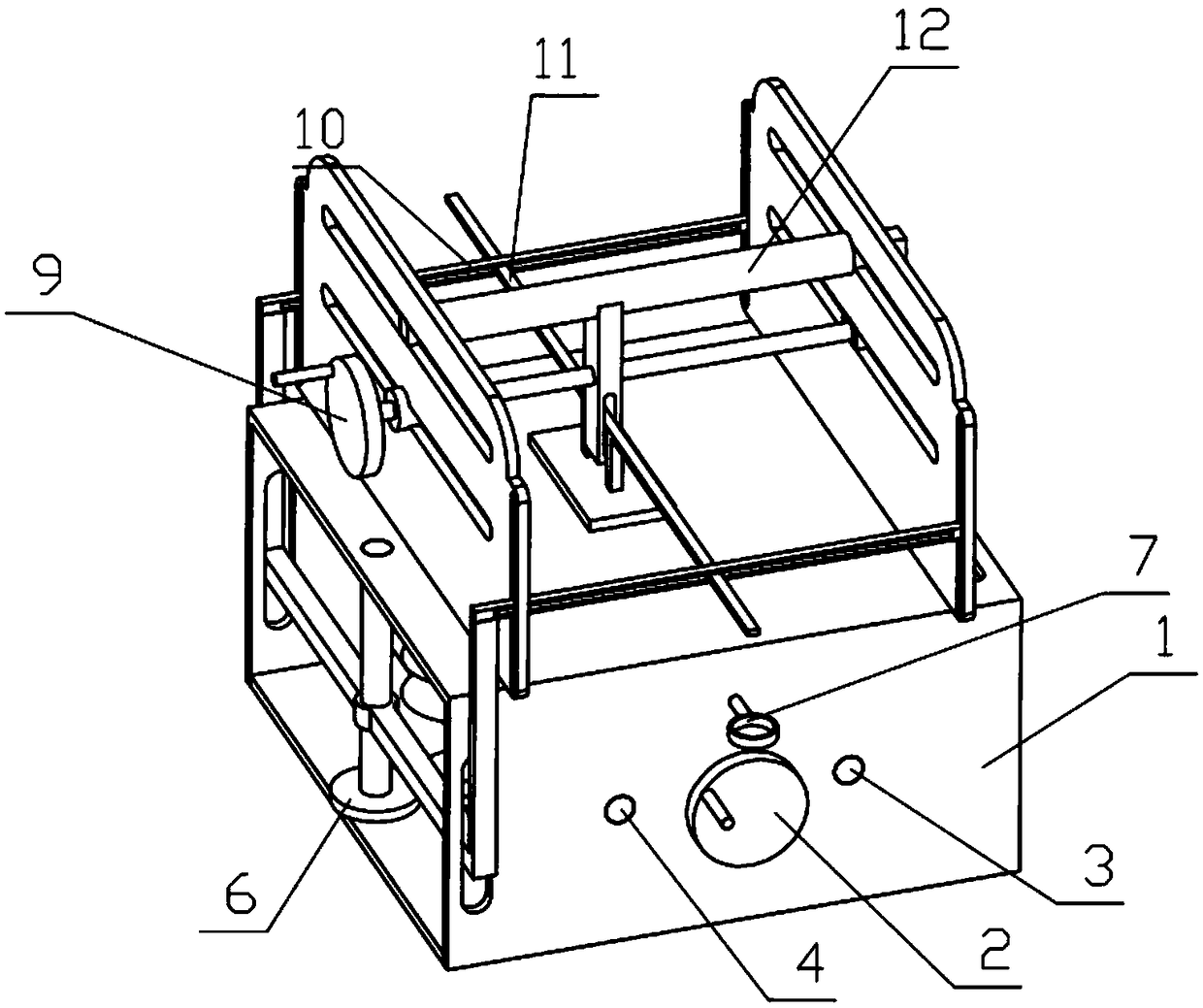

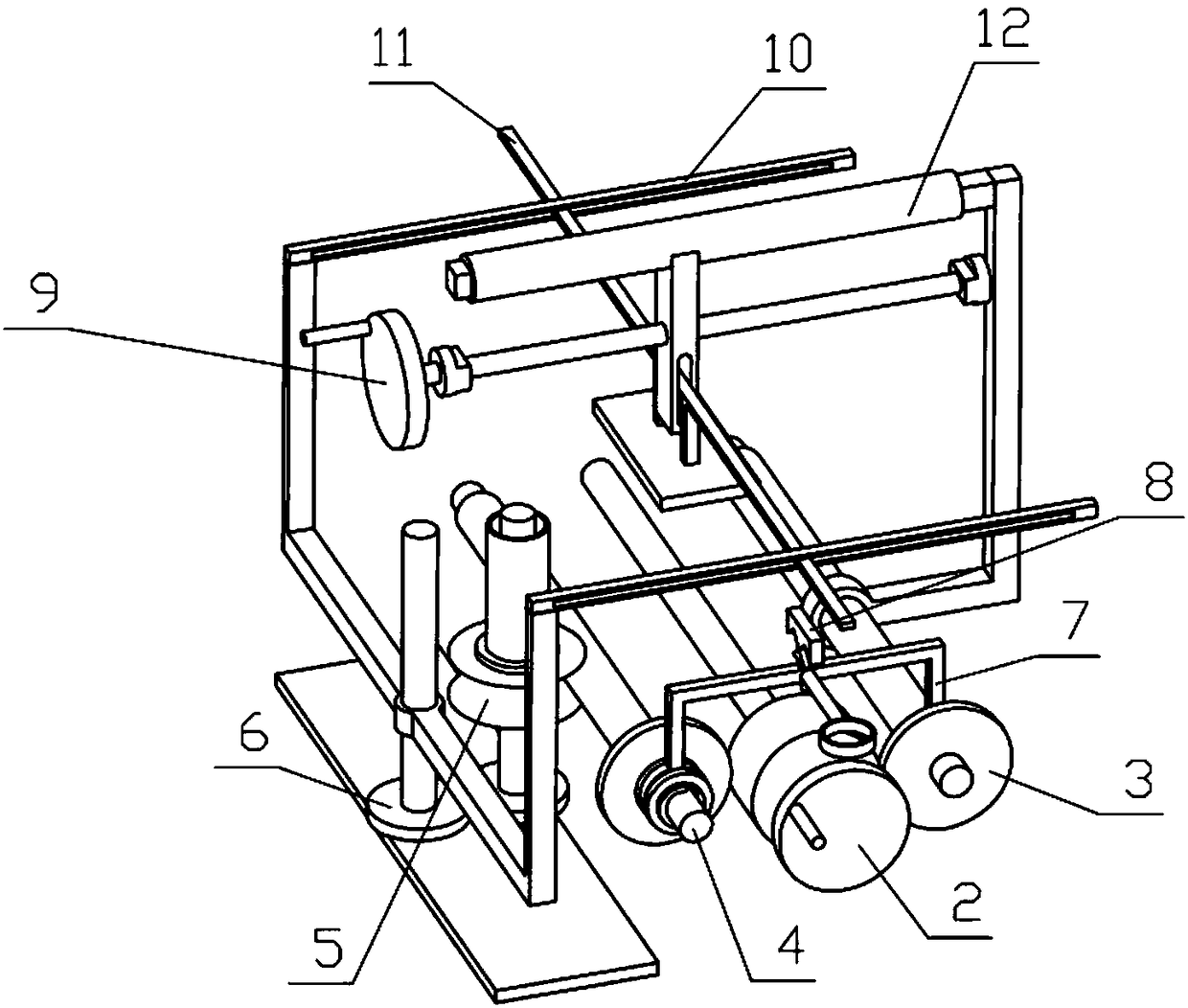

[0037] Combine below Figure 1-18 Describe this embodiment, a frame welding positioning structure, including the whole machine bracket 1, the power mechanism 2, the lateral movement mechanism 3, the vertical movement mechanism 4, the transmission mechanism I5, the transmission mechanism II6, the switching mechanism 7, the switching fixed block 8, Horizontal movement mechanism 9, sliding support rod 10, positioning 11 and sliding column 12, the switching mechanism 7 includes a shift fork 7-1 and a switching sliding block 7-2, and the shift fork 7-1 includes a shift fork body 7-1-1 , pushing body 7-1-2 and switching sliding hole 7-1-3, described pushing body 7-1-2 is provided with two, and two pushing bodies 7-1-2 are respectively welded on shift fork body 7-1 On the left and right sides of the lower end of -1, the switching sliding hole 7-1-3 is arranged at the middle end of the shift fork body 7-1-1, and the switching sliding block 7-2 includes a spring mounting column 7-2-1 a...

specific Embodiment approach 2

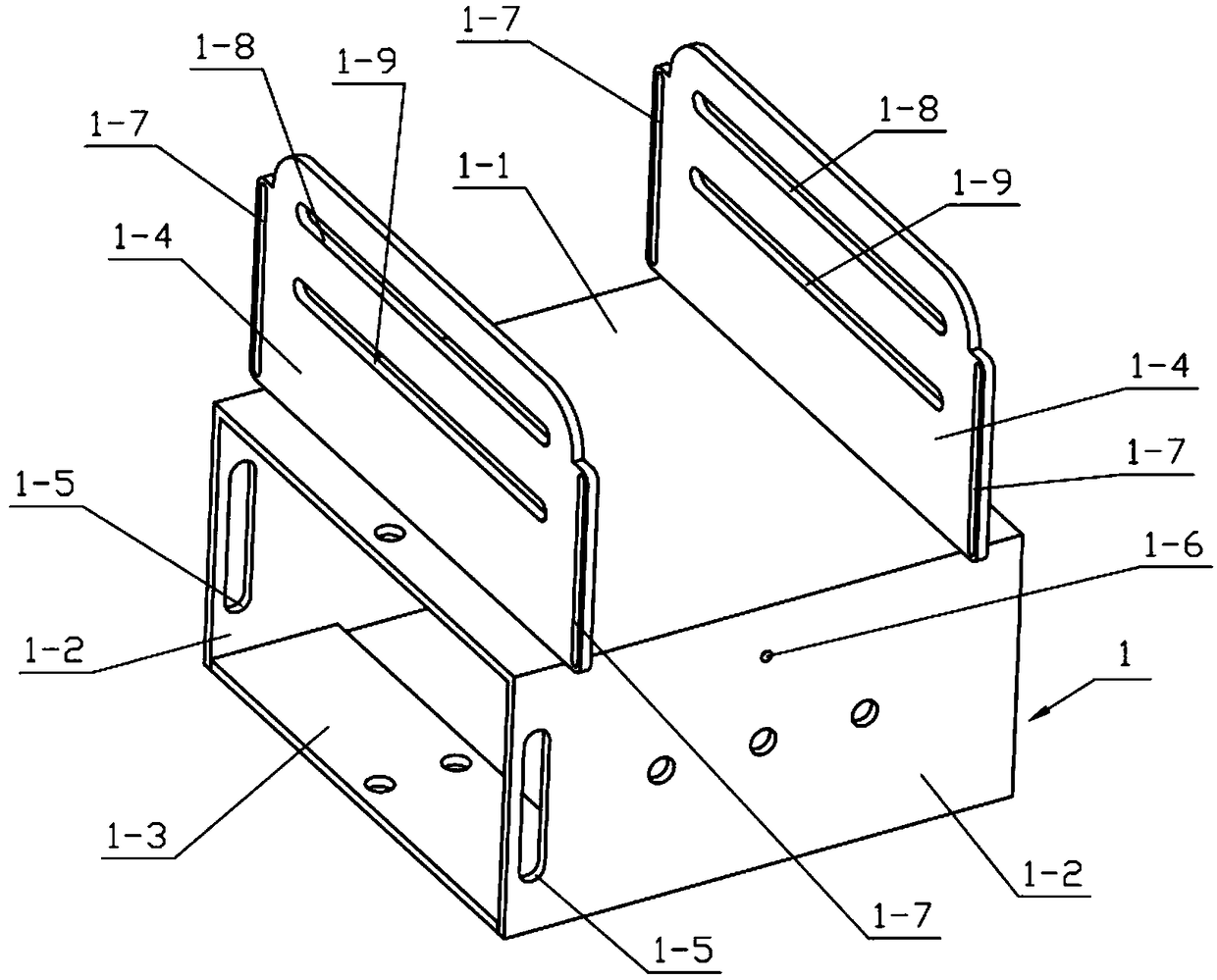

[0038] Combine below Figure 1-18 Describe this embodiment, this embodiment will further explain Embodiment 1, the whole machine support 1 includes a workbench 1-1, a support base plate 1-2, a base plate 1-3, a sliding support plate 1-4, and a vertical sliding groove Ⅰ1-5, switching sliding port 1-6, vertical sliding groove Ⅱ1-7, horizontal sliding groove Ⅰ1-8 and horizontal sliding groove Ⅱ1-9, the supporting bottom plate 1-2 and the sliding supporting plate 1-4 are respectively provided with two , two support base plates 1-2 are respectively fixedly connected to the left and right sides of the lower end of the workbench 1-1, two sliding support plates 1-4 are respectively fixedly connected to the front and rear sides of the upper end of the workbench 1-1, and the base plates 1-3 The two ends of the two support base plates 1-2 are respectively fixedly connected, the switch sliding port 1-6 is arranged on the support base plate 1-2 on the right side, and there are two vertical...

specific Embodiment approach 3

[0039] Combine below Figure 1-18 Describe this embodiment, this embodiment will further explain the second embodiment, the power mechanism 2 includes a power shaft 2-1, a rotating handle 2-2 and a power gear 2-3, and the rotating handle 2-2 is fixedly connected to the power shaft At the right end of 2-1, the power gear 2-3 is fixedly connected to the power shaft 2-1, and the two ends of the power shaft 2-1 are respectively connected to the two support base plates 1-2 in rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com