Calibration method of aircraft automatic drilling and riveting parallel attitude adjusting bracket

An automatic drilling riveting and bracket technology, applied in the direction of self-adaptive control, control/adjustment system, instrument, etc., can solve the problem of low attitude adjustment and positioning accuracy, and meet the requirements of ensuring error identification accuracy and bracket attitude adjustment accuracy , The effect of improving the movement accuracy of the bracket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

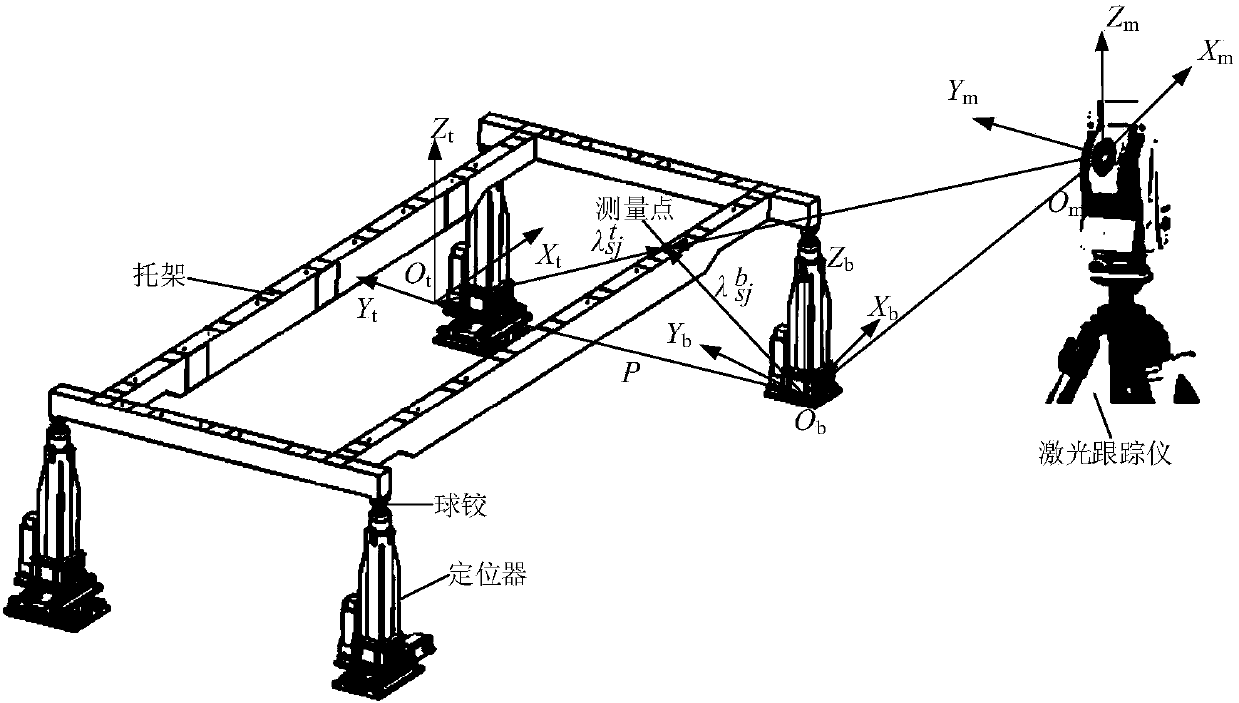

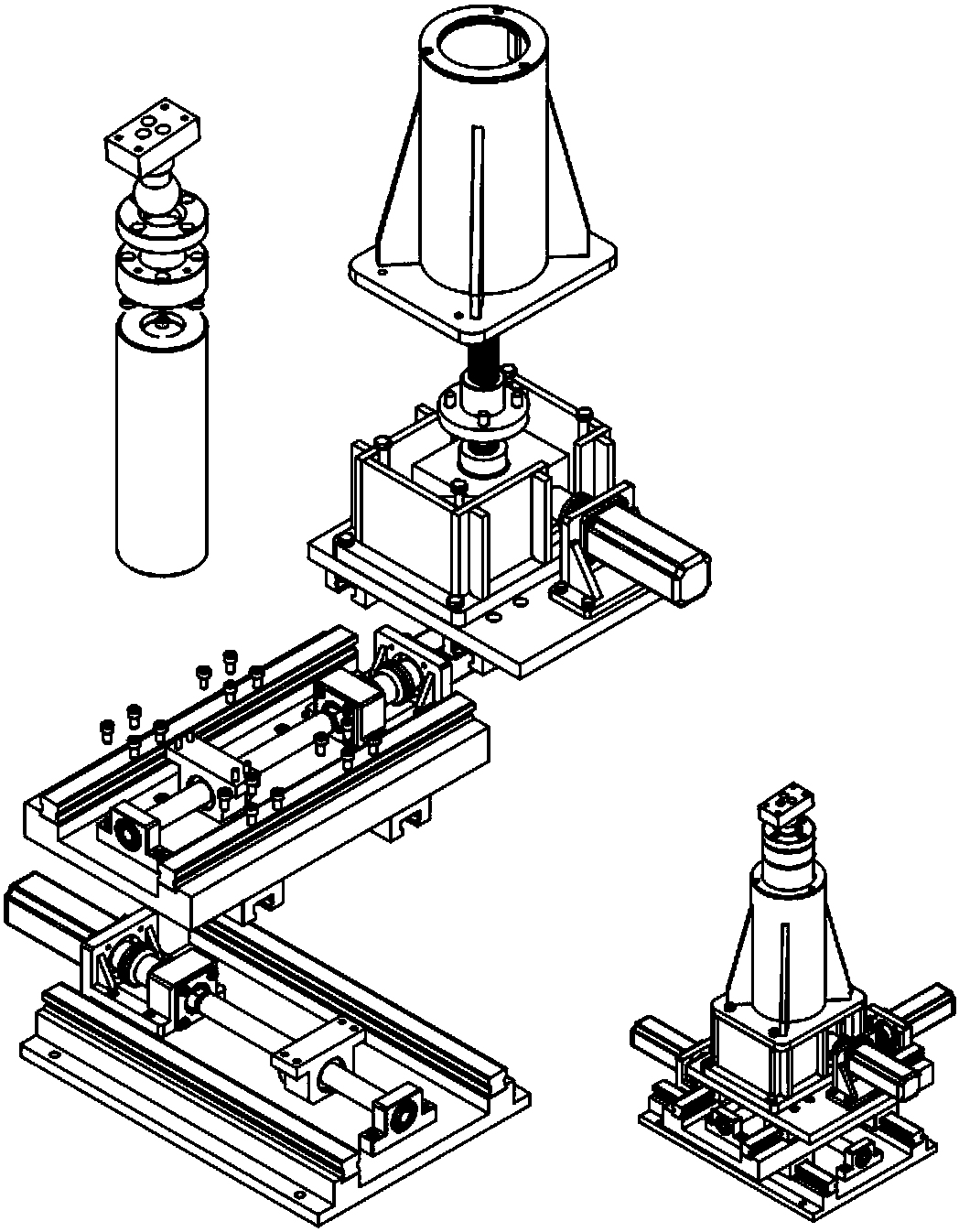

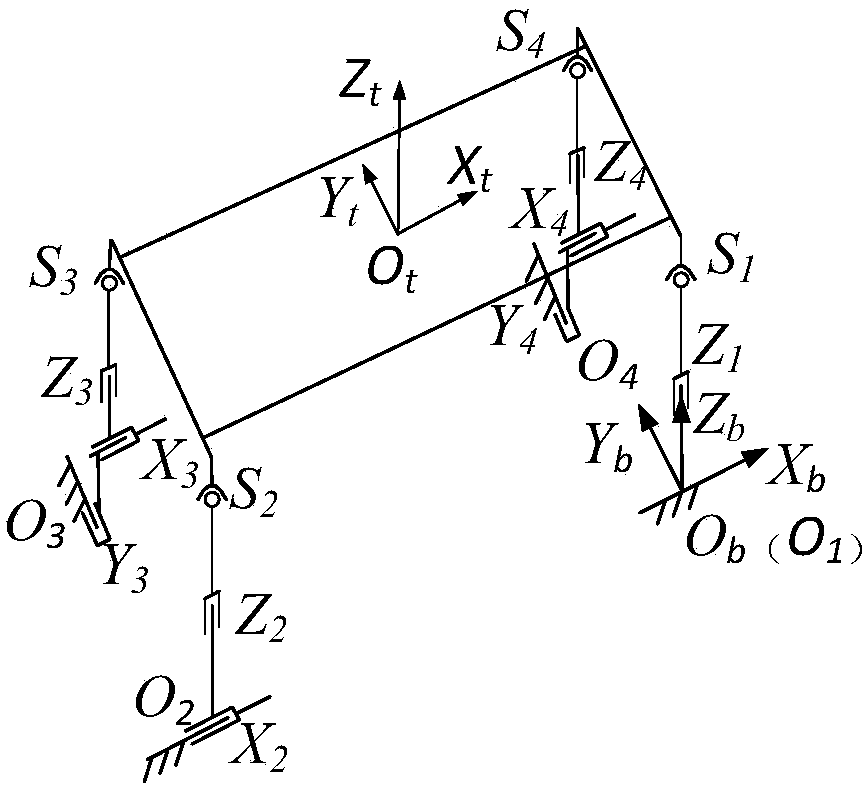

[0025] Such as Figure 1-7 shown.

[0026] A calibration method for an aircraft automatic drilling and riveting parallel attitude adjustment bracket, the specific steps are:

[0027] (1) Before calibration, the laser tracker is used to measure the coordinates of the specified points on the bracket, and the actual pose A of the bracket is fitted. For the target pose B, the kinematics inverse solution is used to obtain the position from pose A under the nominal structural parameters. The ideal displacement of each active movement pair in posture B;

[0028] (2) Drive the motion of the active motion pair according to the calculated ideal motion amount of each active motion pair, use the laser tracker to measure the coordinates of the specified point on the bracket, and fit the actual pose C of the bracket;

[0029] (3) Compare the actual pose C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com