Small corn harvester

A harvester and corn technology, applied in the direction of harvesters, cutters, crop processors, etc., can solve the problems of high labor intensity, high labor cost, and inability to handle stems, and achieve the effect of flexible operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

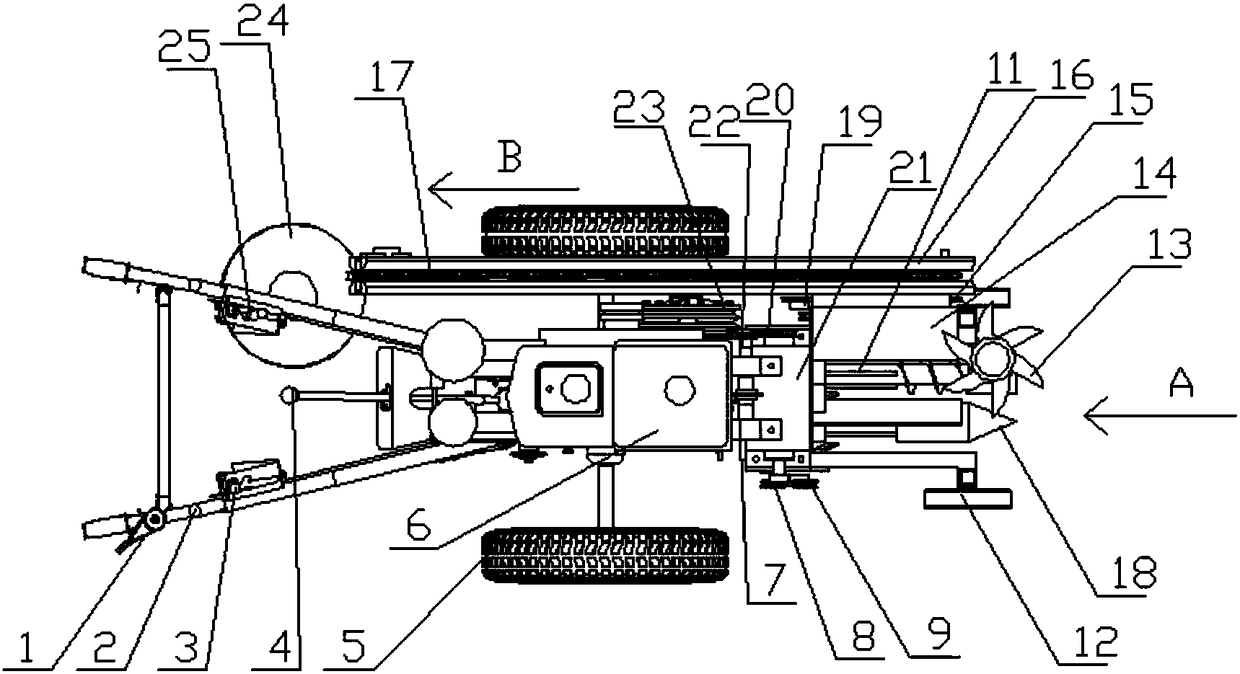

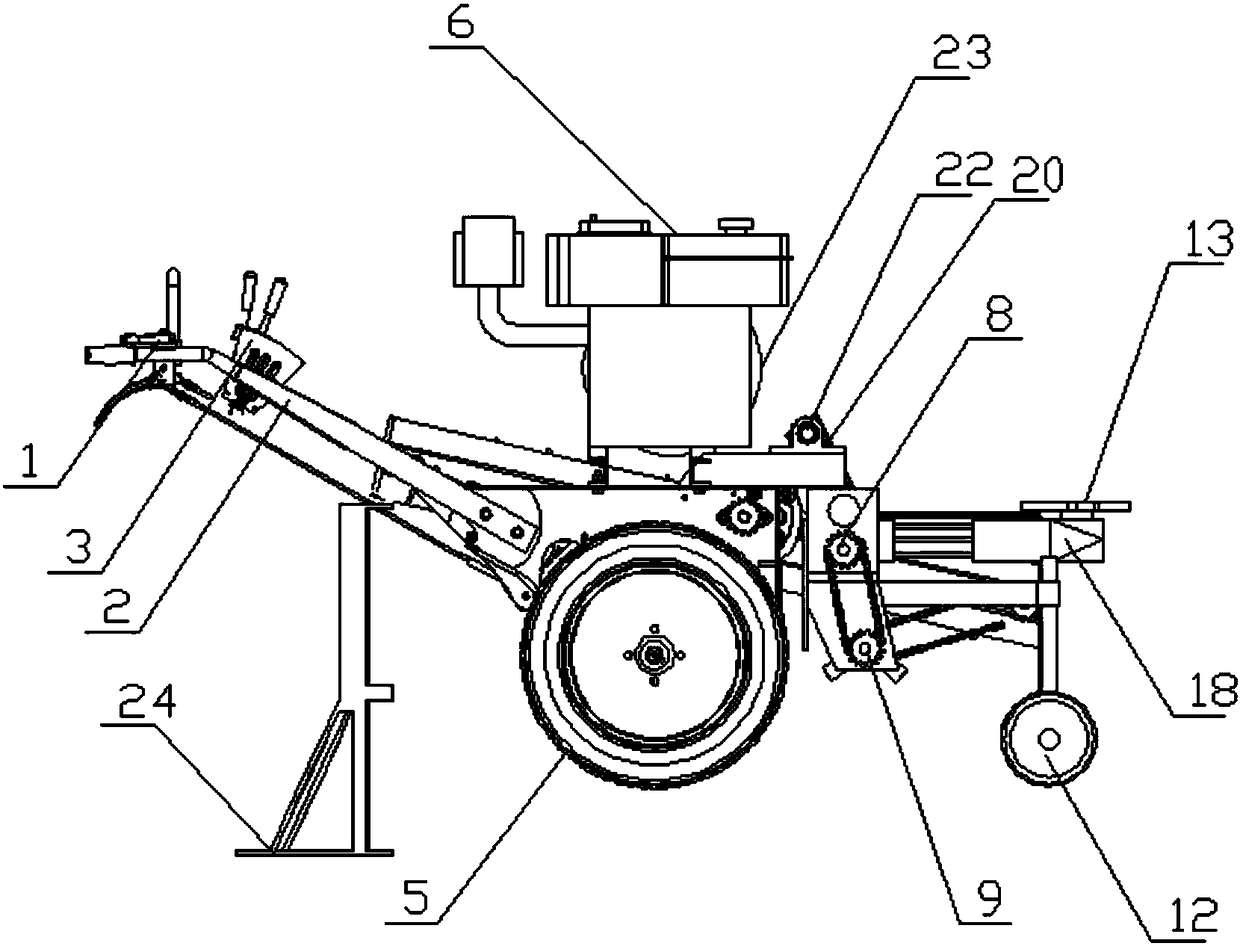

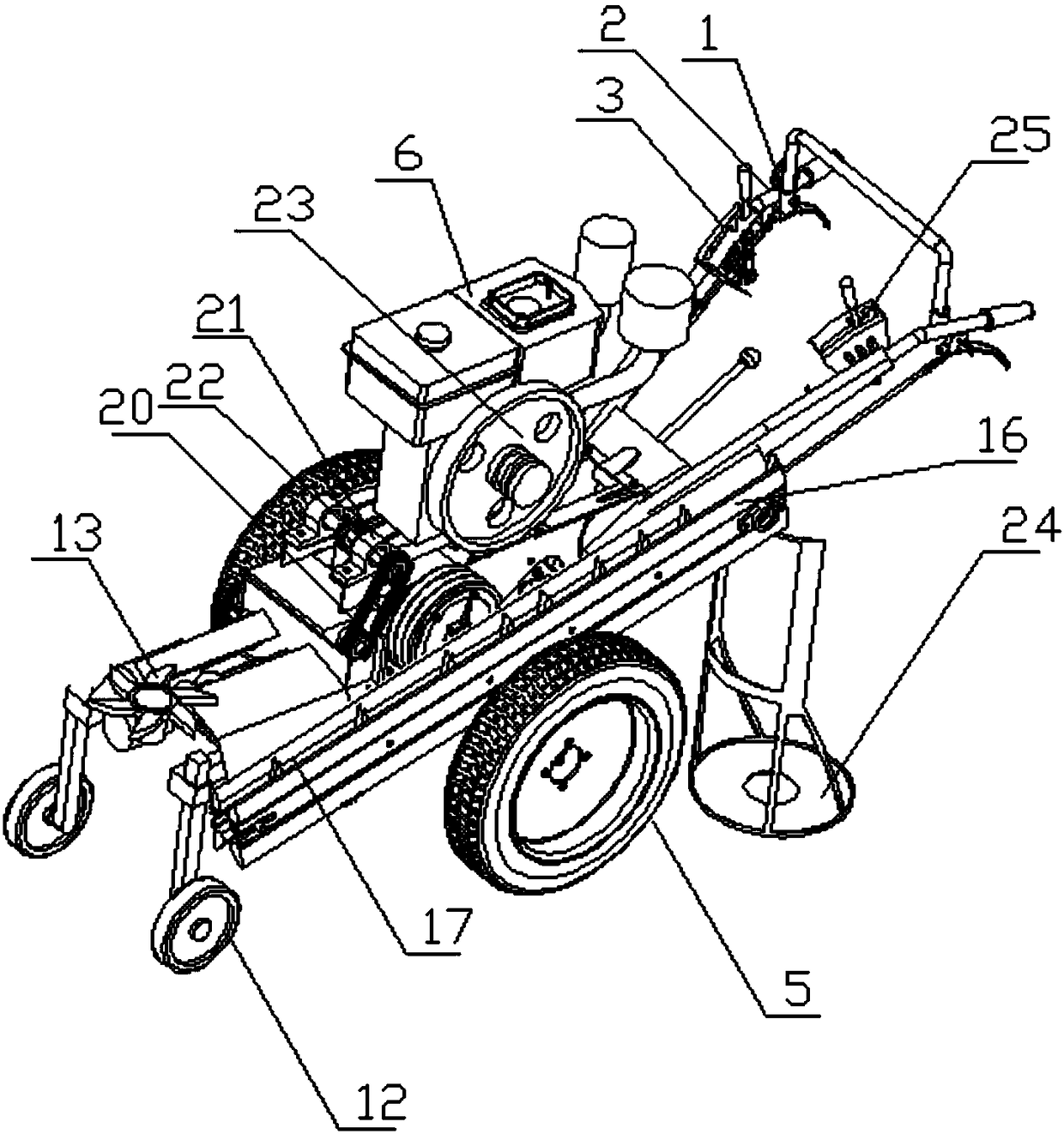

[0016] Such as Figure 1-3 Shown, 1. a kind of small-sized corn harvester is characterized in that: comprise walking system, corn collecting system, stalk pulverizing system, power system, control system.

[0017] In practical applications, the walking system includes a driving wheel 5 and a front supporting wheel 12, the driving wheel 5 is powered by a power system, the driving wheel 5 is larger than the front supporting wheel 12, and the front supporting wheel 12 is steerable.

[0018] In practical application, described corn collection system comprises reel 13, left pinch roll 18, right pinch roll 11, guide plate 14, delivery trough 16, conveyor chain 17, corn collection bag support 24, left pinch roll 18 and right pinch roll The front end of the clip roller 11 is conical, and the middle and rear parts are cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com