Multi-gear transmission

A multi-speed transmission and two-stage deceleration technology, which is applied to gear transmissions, belts/chains/gears, mechanical equipment, etc., can solve the problems of multi-speed transmissions such as complex structure, difficult manufacturing, and high cost, and achieve light weight, The effect of simple and compact structure and high reusability of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

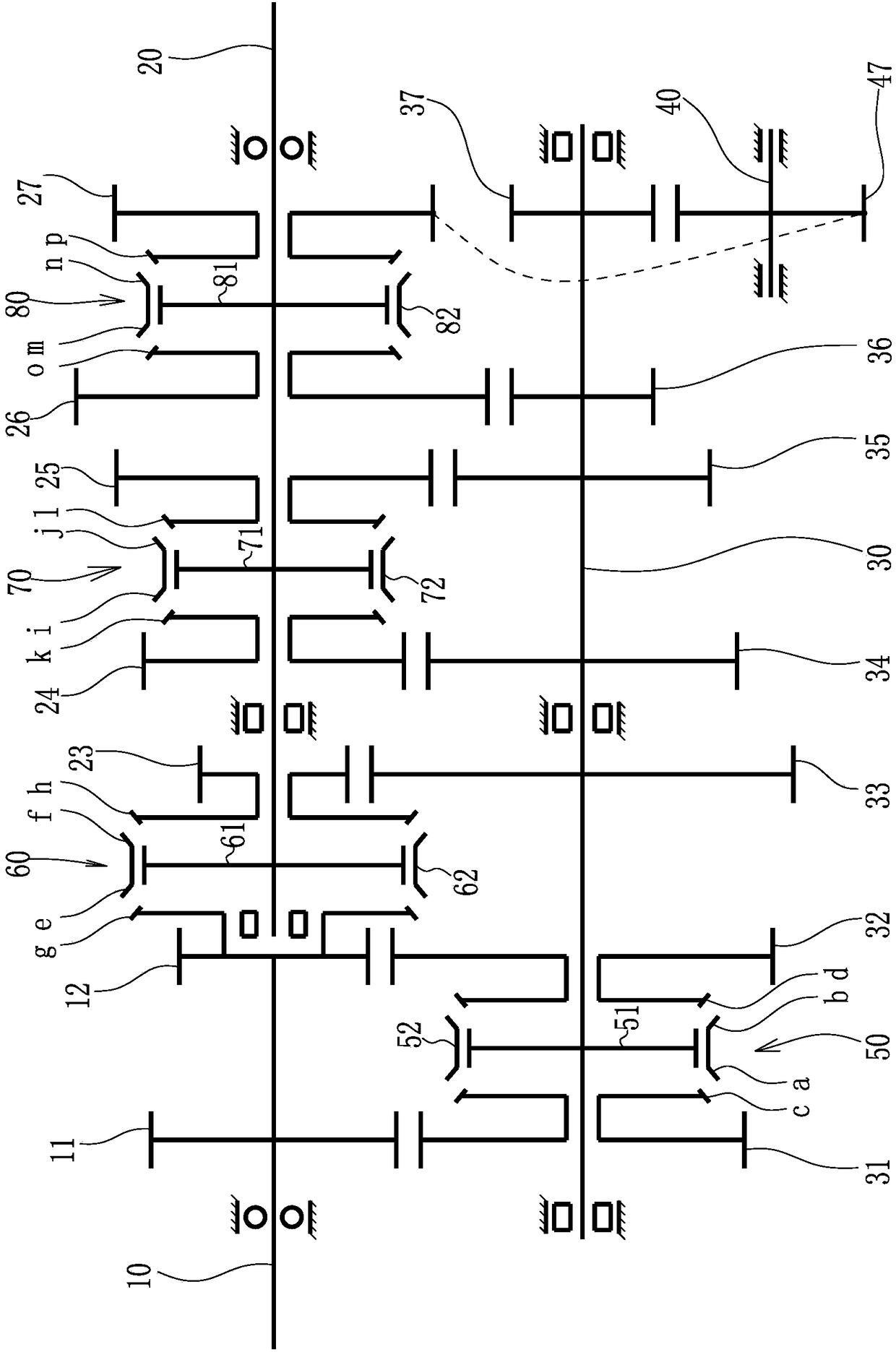

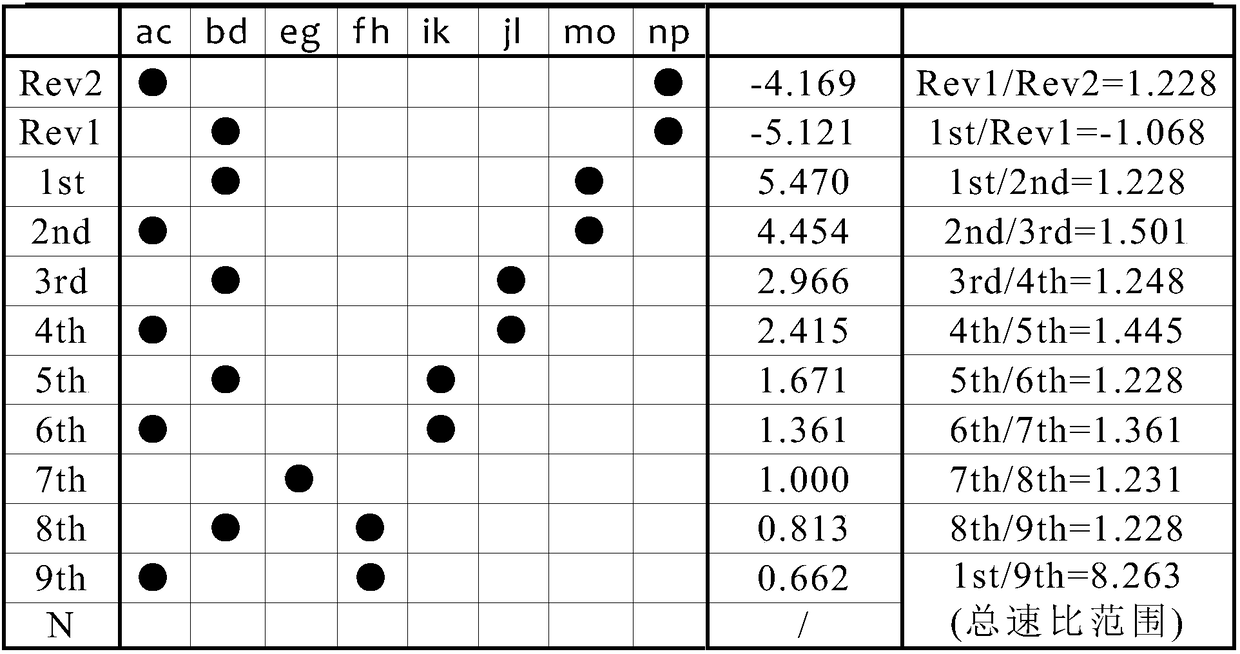

[0028] Such as figure 1 In the shown multi-speed transmission, eight forward gears can be realized through two first-stage deceleration structures and four two-stage deceleration structures, and the direct connection between the input shaft 10 and the output shaft 20 can be realized under the action of the synchronous structure 260 to realize Ninth forward gear; two one-stage deceleration structures cooperate with one reverse gear structure to realize two reverse gear outputs.

[0029] Such as figure 1The multi-speed transmission shown includes an input shaft 10, an intermediate shaft 30, an output shaft 20 and a reverse gear shaft 40. The input shaft 10 is coaxially connected with a driving gear 1 11 and a driving gear 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com