A fully automatic self-service pattern custom clothing equipment and method

A fully automatic, ready-to-wear technology, which is applied to sewing tools, electrical program control, program control in sequence/logic controllers, etc., can solve the problems that cannot meet the application needs of service and sales environments, increase manpower and management costs, Unable to satisfy customers and other problems, achieve the effect of realizing service and sales application needs, reducing manpower and management costs, and improving delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

[0042] It should be noted that, unless otherwise specified, the technical or scientific terms used in this application shall have the usual meaning understood by those skilled in the art to which the present invention belongs.

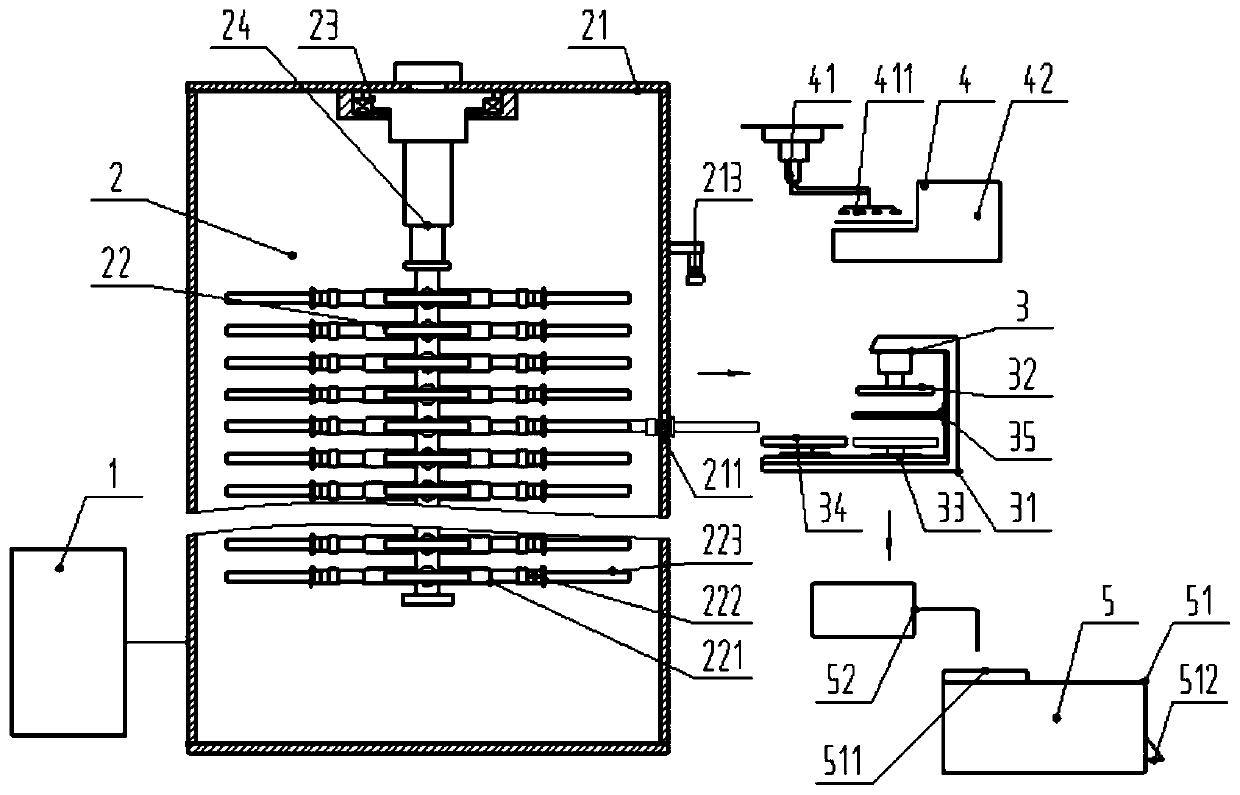

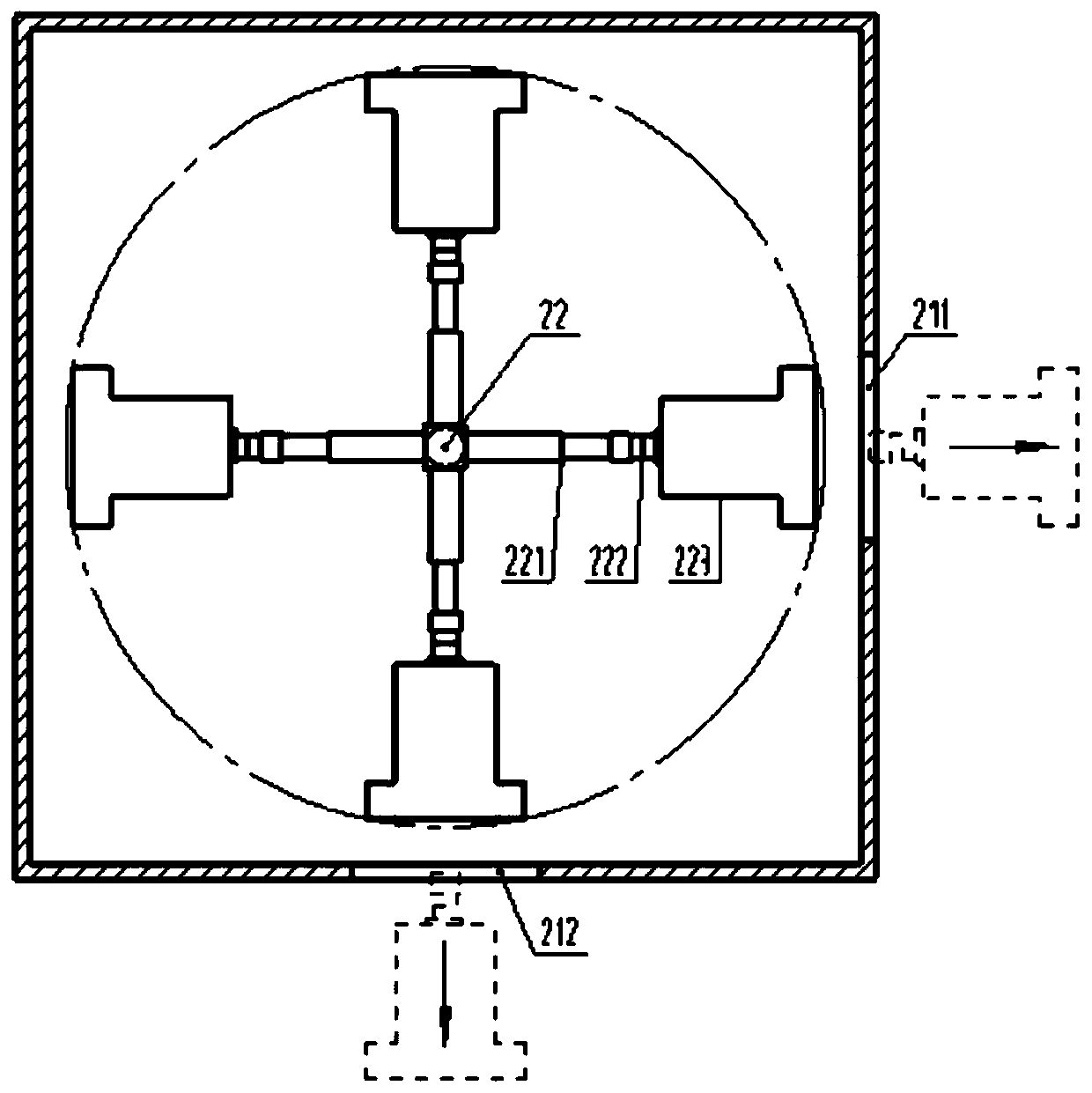

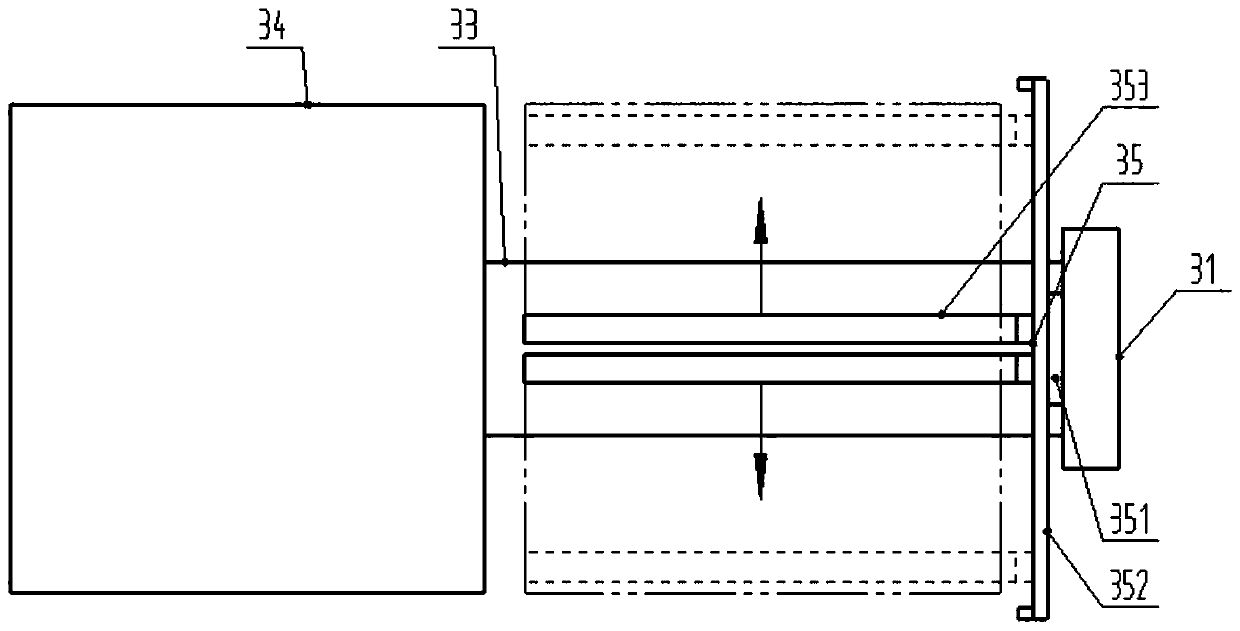

[0043] Such as Figure 1-3 As shown, a fully automatic self-service pattern customization garment equipment includes a control unit 1, a number selection unit 2, a transfer unit 3, a printing unit 4, and a plastic packaging unit 5. It also includes a frame for installing the above-mentioned units (in the drawings) Not shown); The number selection unit includes a wardrobe body 21, a clothing assembly 22 arranged in the inner cavity of the wardrobe and having several layers of clothing tables, and a rotating mechanism 23 and a lifting mechani...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap