Prechamber for an internal combustion engine, internal combustion engine comprising a prechamber of this type and method for designing and/or producing a prechamber of this type

A pre-combustion chamber and internal combustion engine technology, applied to internal combustion piston engines, mechanical equipment, combustion engines, etc., can solve the problems of large periodic scattering and achieve the effect of improving eddy kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

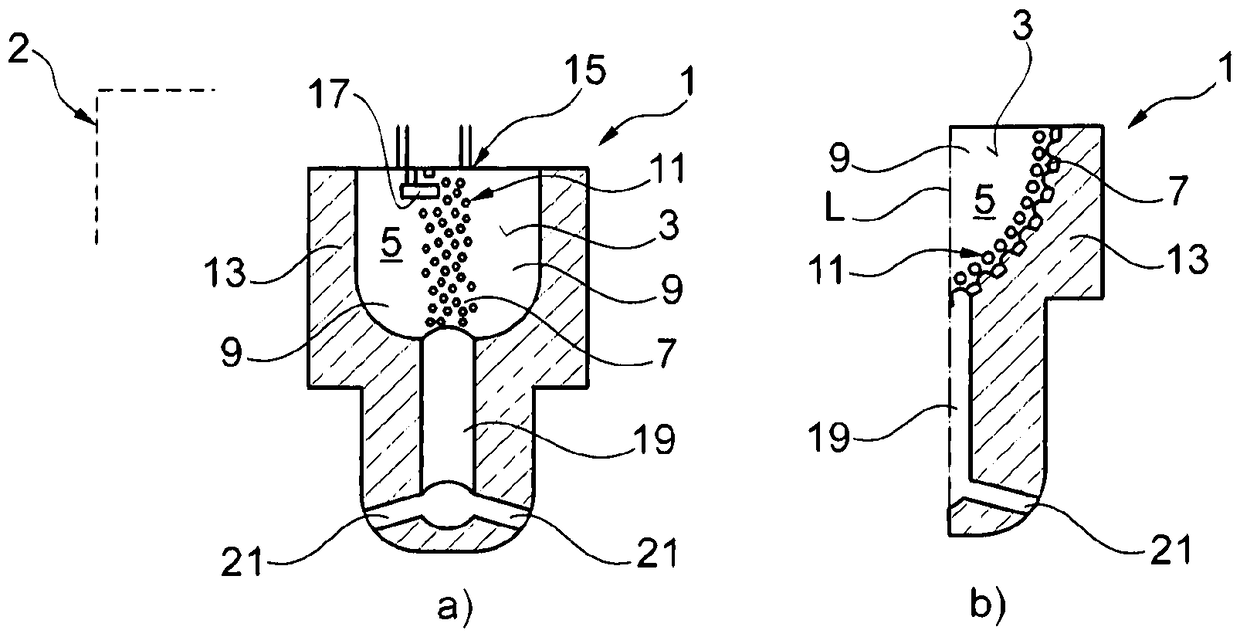

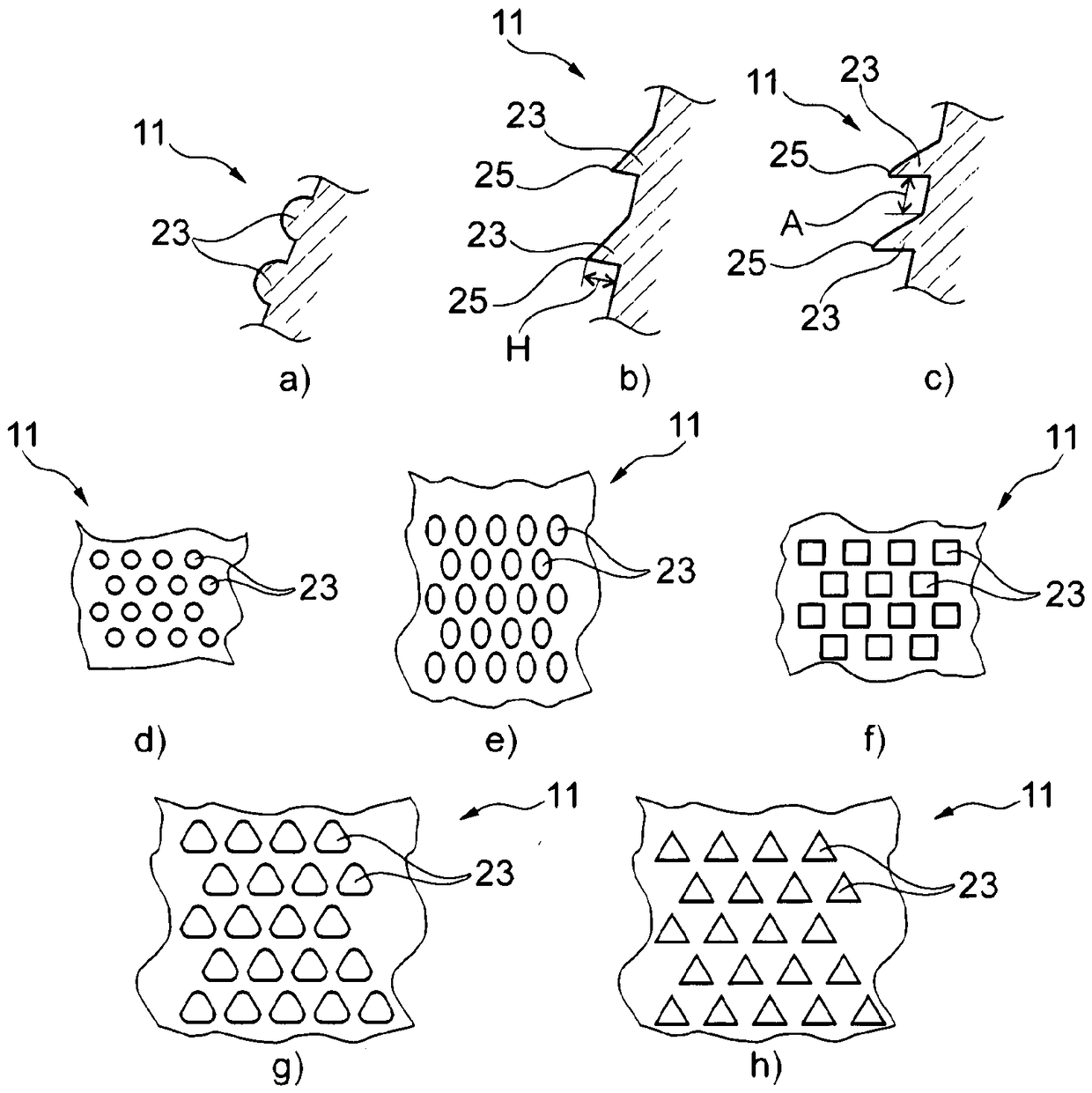

[0053] figure 1 An embodiment of a pre-chamber 1 of an internal combustion engine 2 is shown, wherein said pre-chamber 1 is figure 1 a) is shown in the first longitudinal section plane, and at figure 1 In b) it is shown in half section in a second longitudinal section plane rotated about the longitudinal axis relative to the first longitudinal section plane. The pre-chamber 1 for the internal combustion engine 2 has a surface 3 through which the pre-chamber 1 is in operation, which is arranged in the interior 5 of the pre-chamber 1 . The flow-through surface 3 has a first surface region 7 and a second surface region 9, wherein the first surface region 7 has specific structures 11, and wherein the second surface region 9 is free of the structures 11, wherein , the structure therefore does not have the defined structure 11 . Preferably, the surface 3 is not structured and / or smooth in the second surface region 9 .

[0054] The second surface area 9 is preferably - seen in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com