Patents

Literature

39results about "Liquid fuel engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

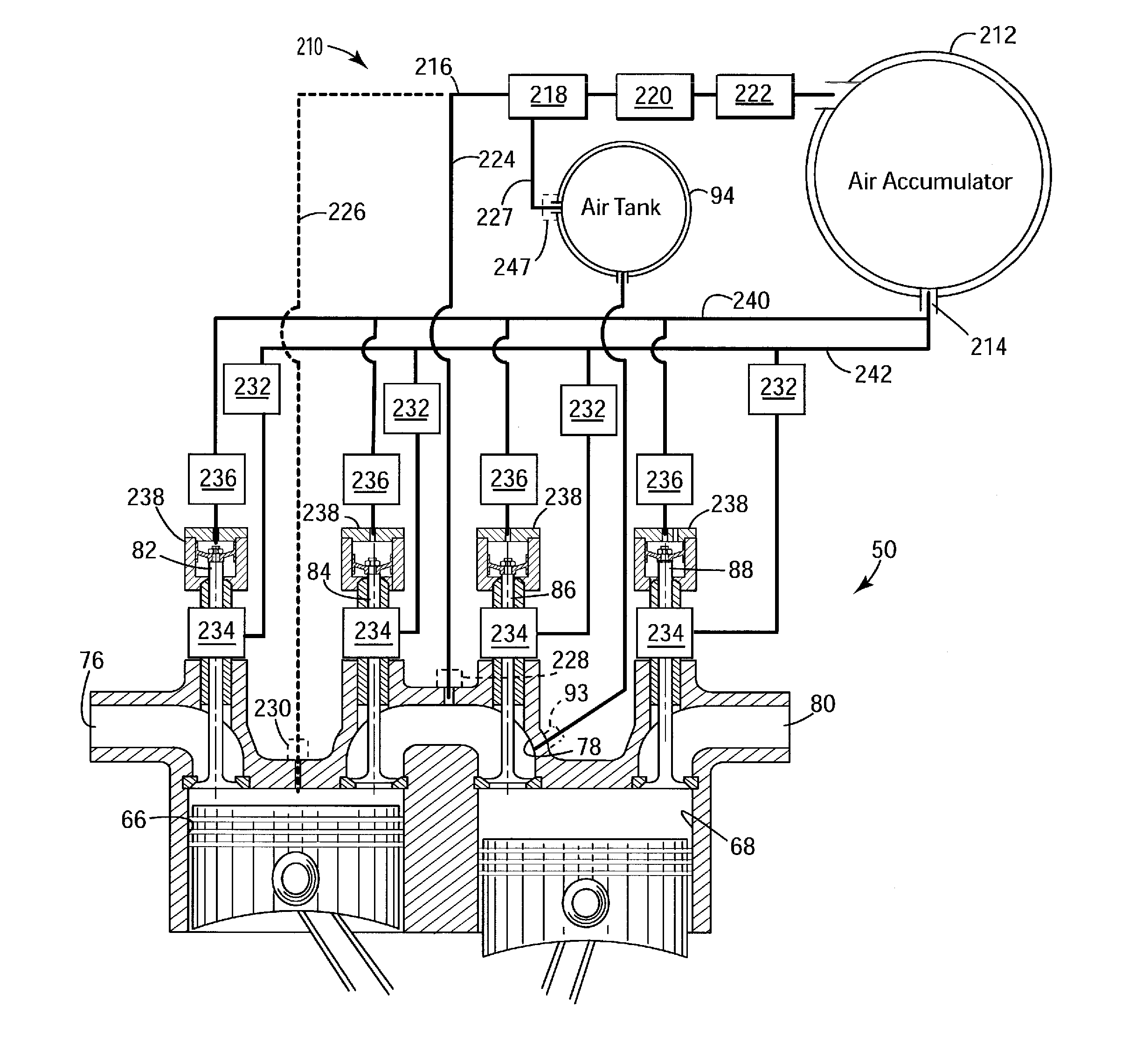

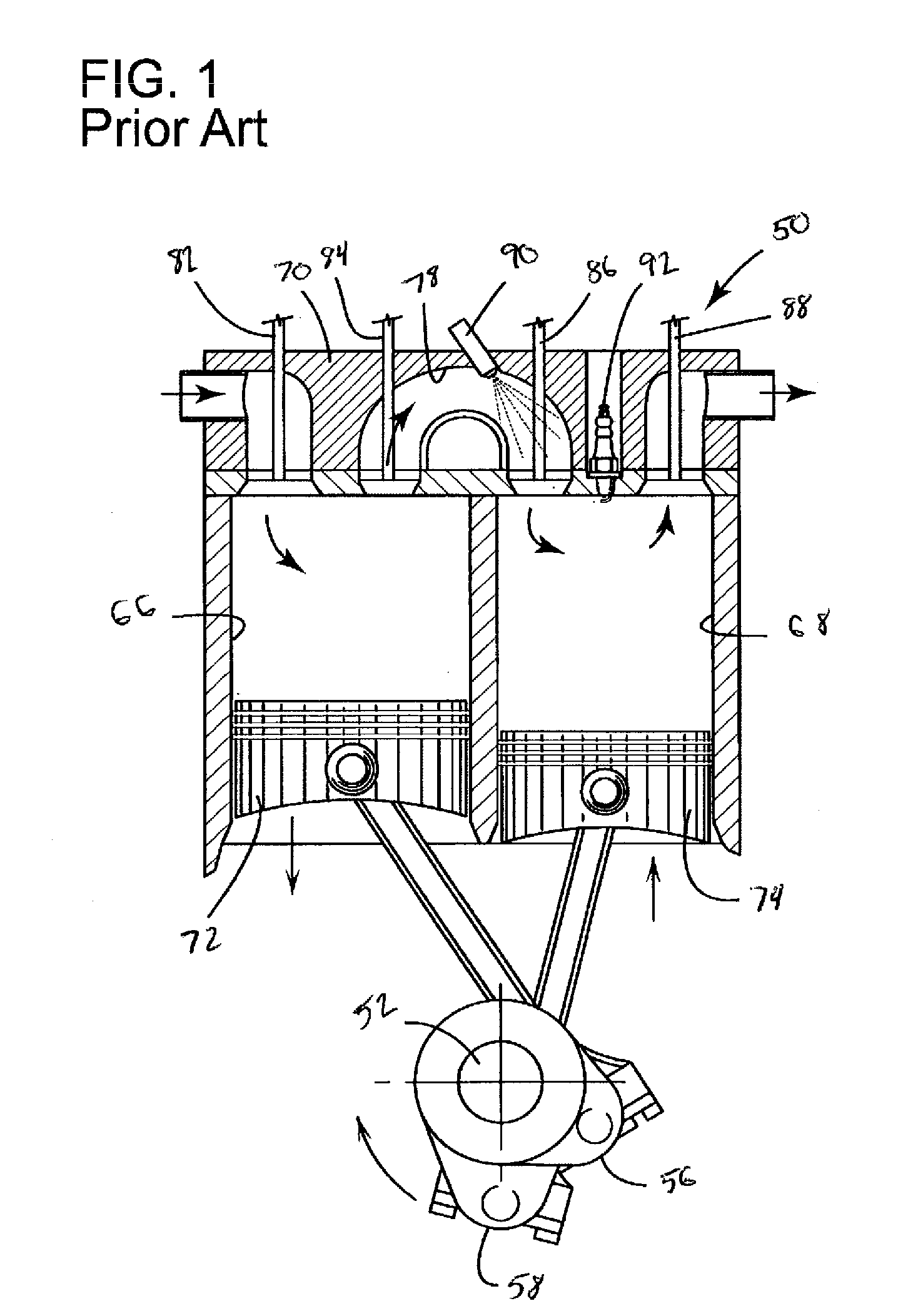

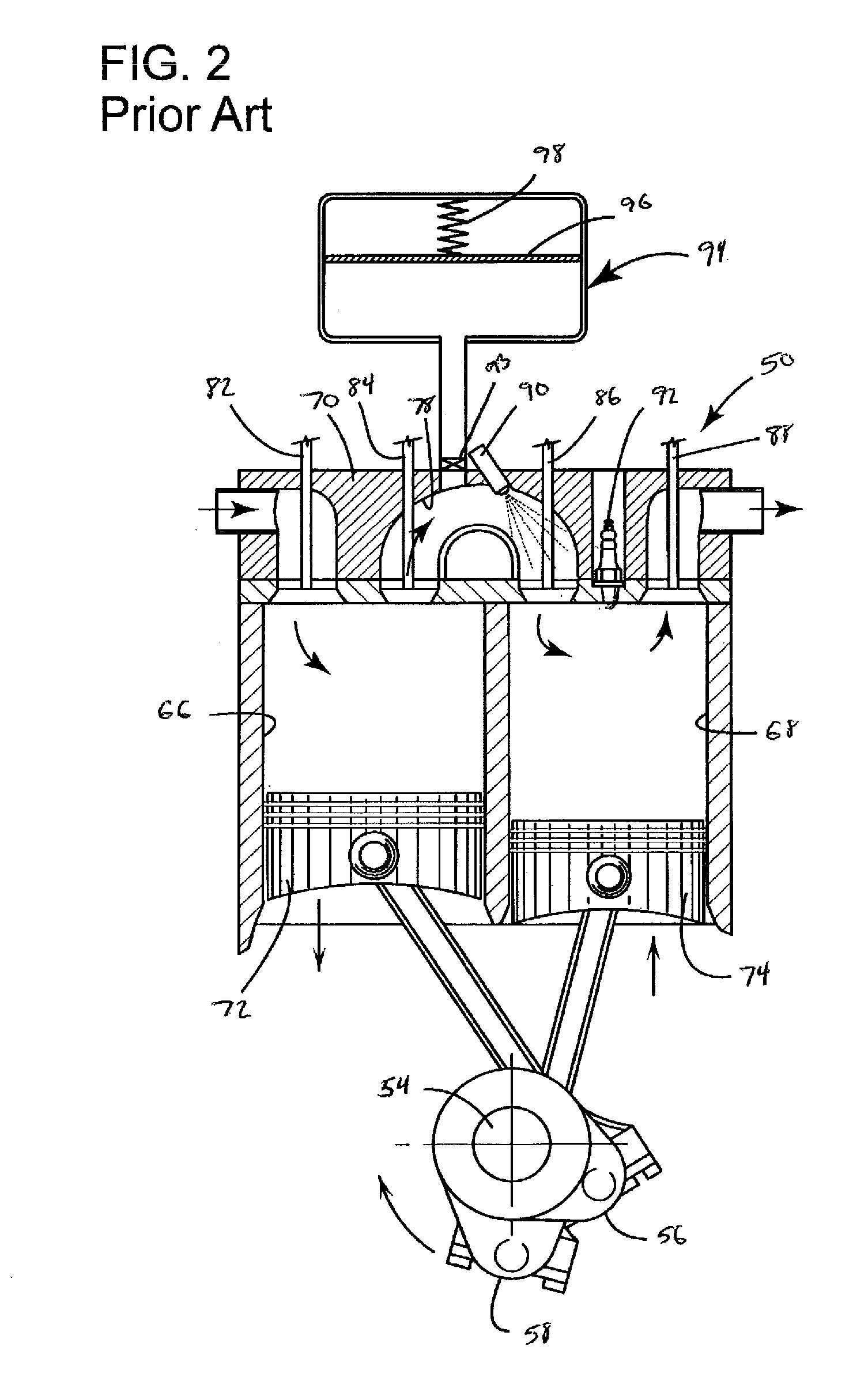

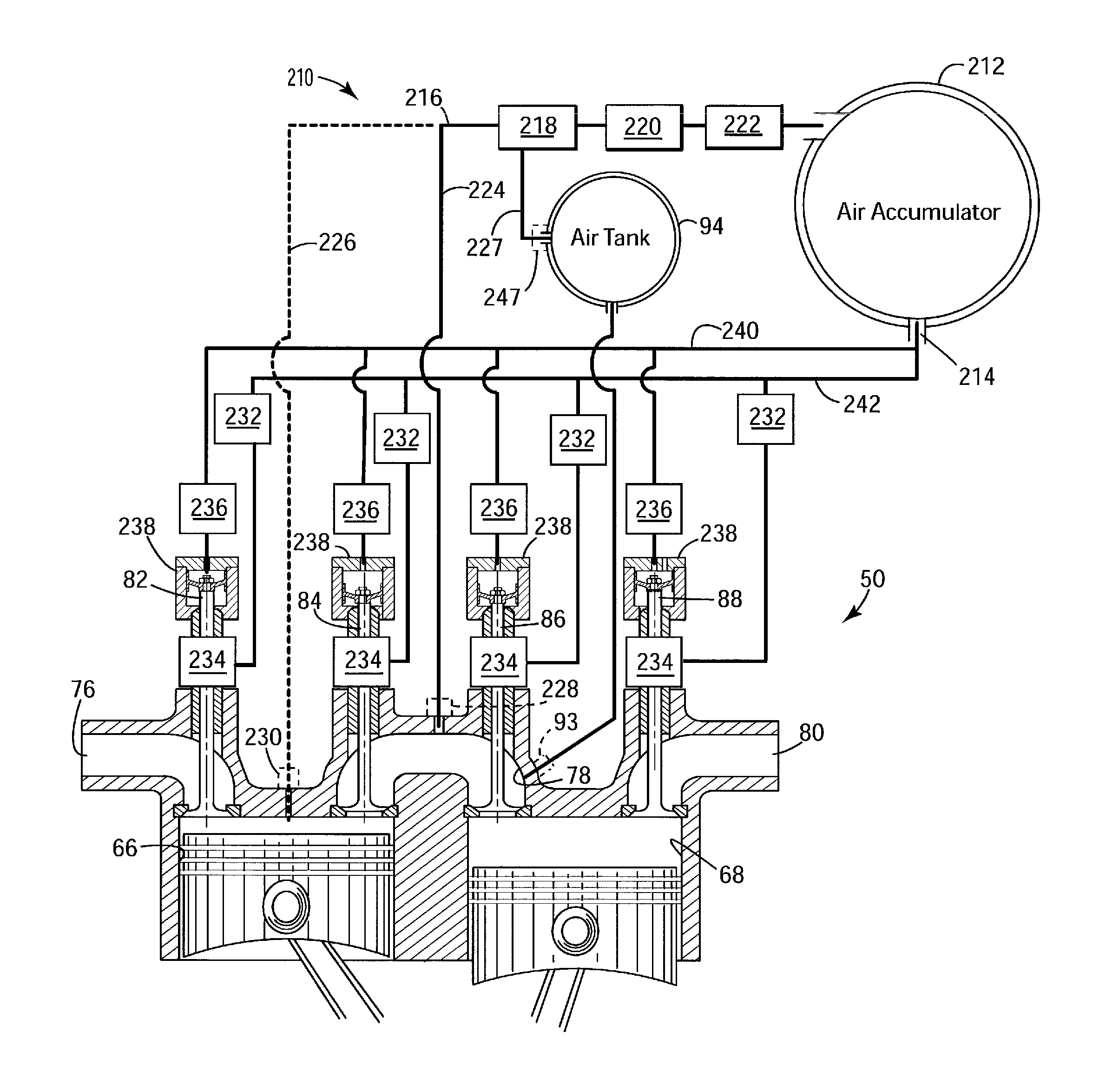

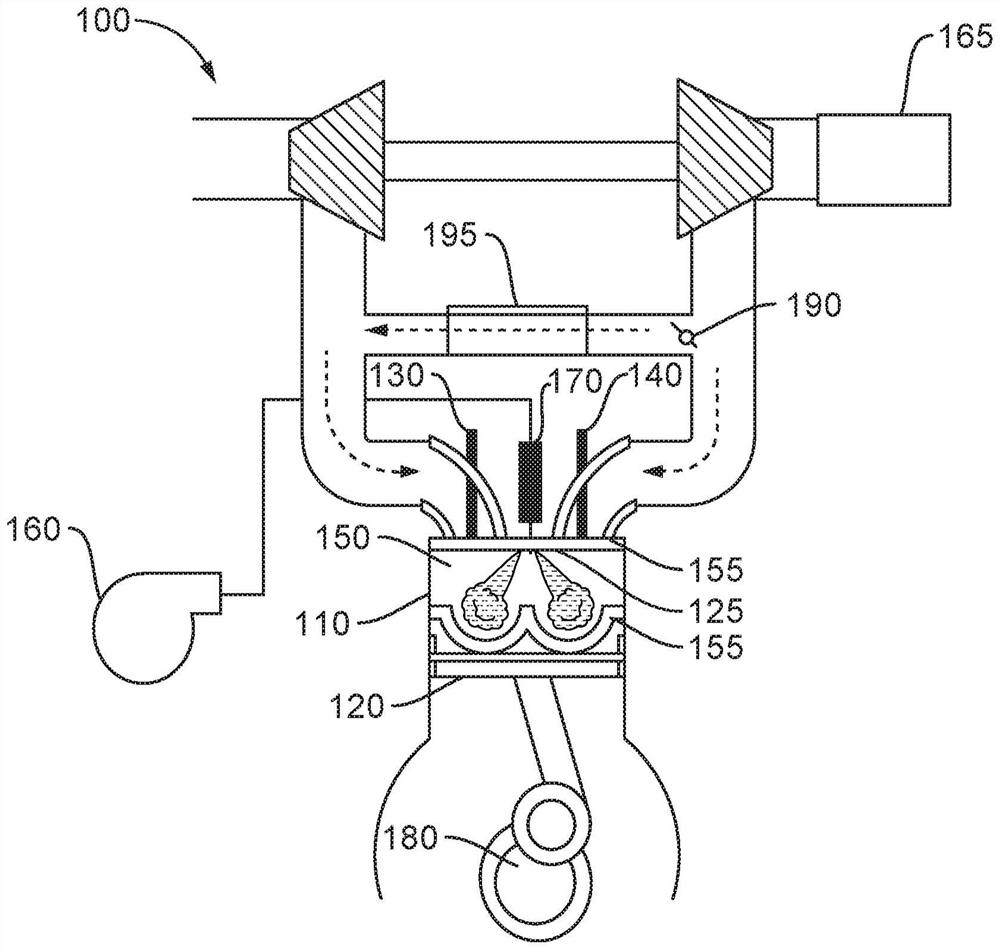

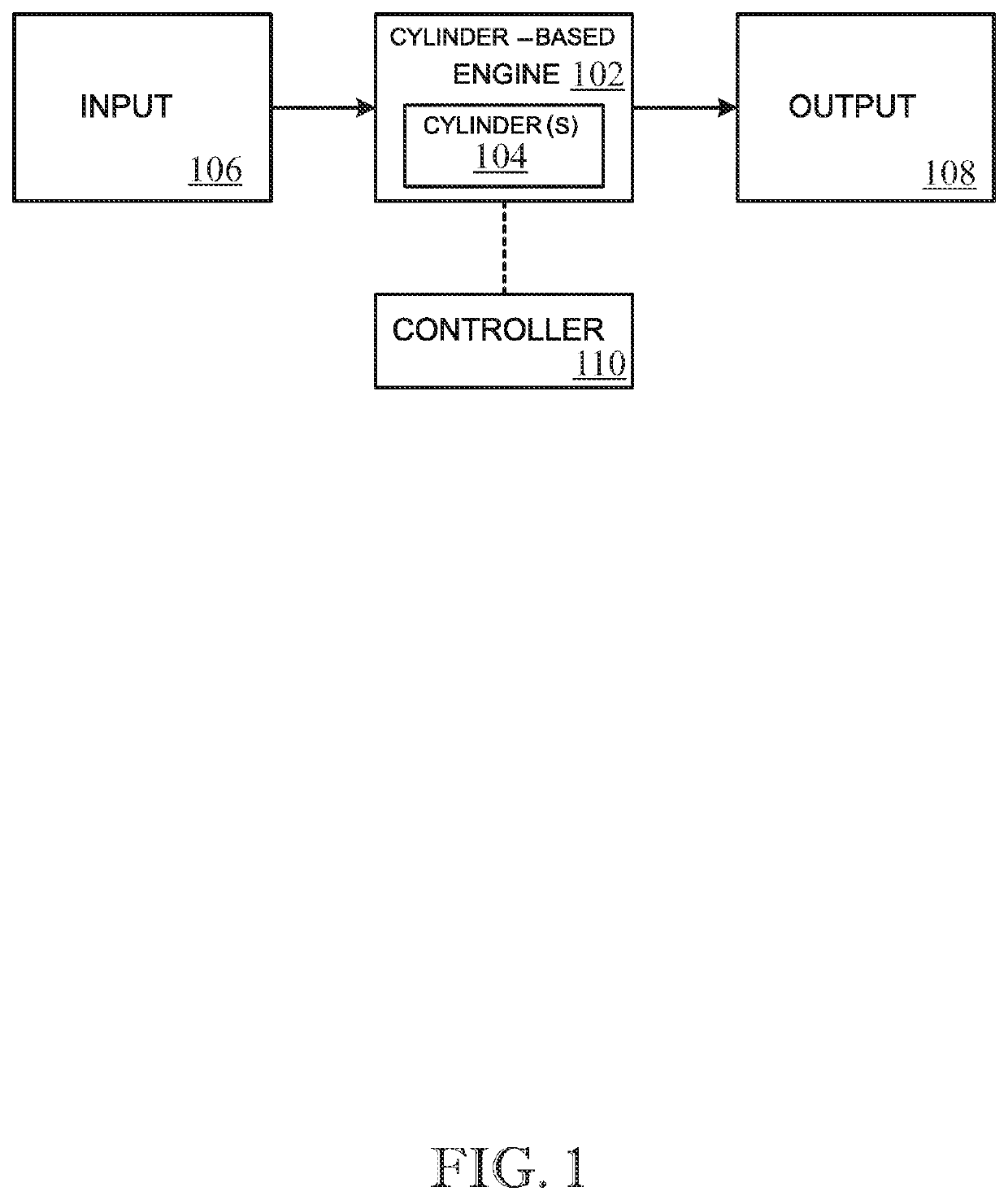

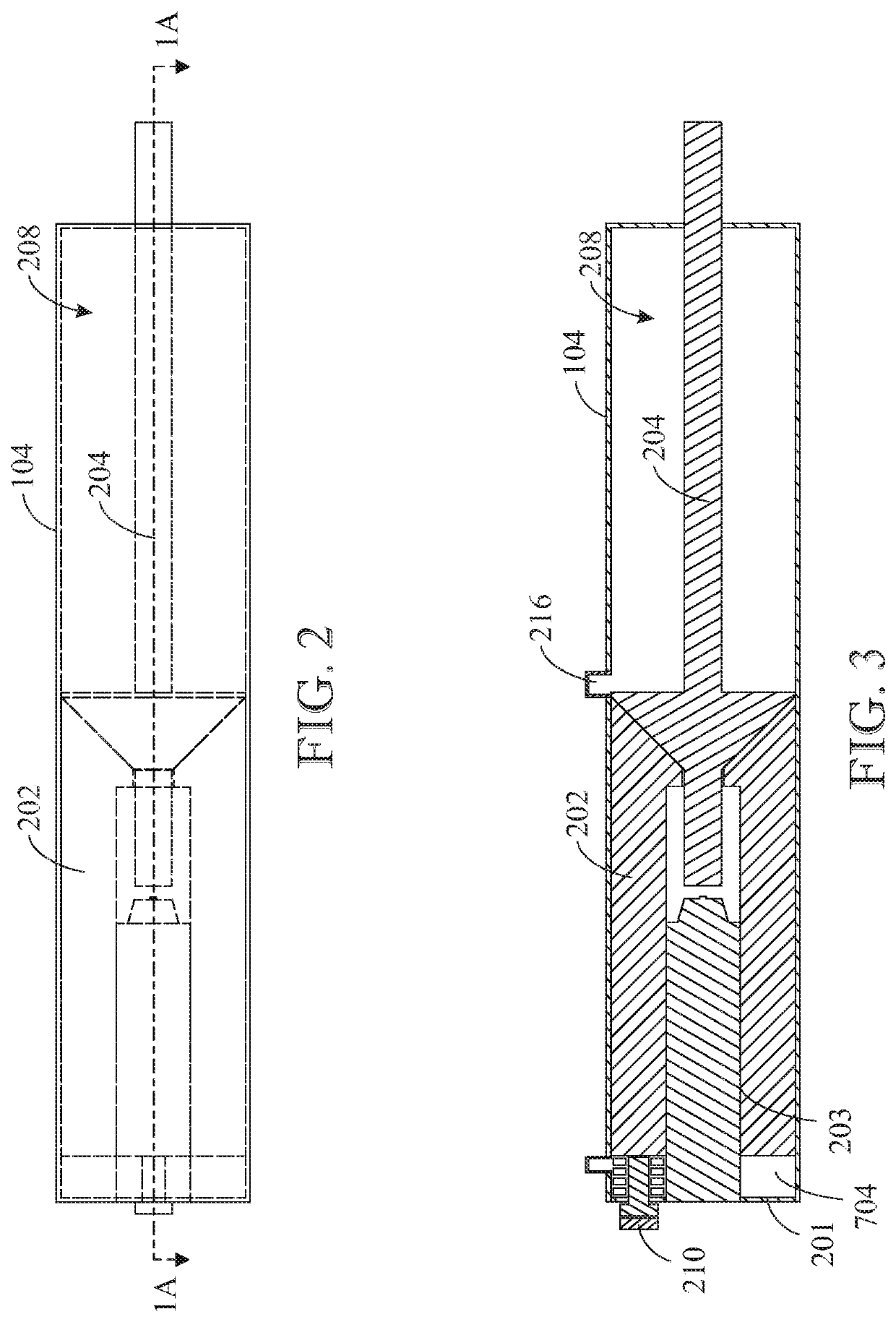

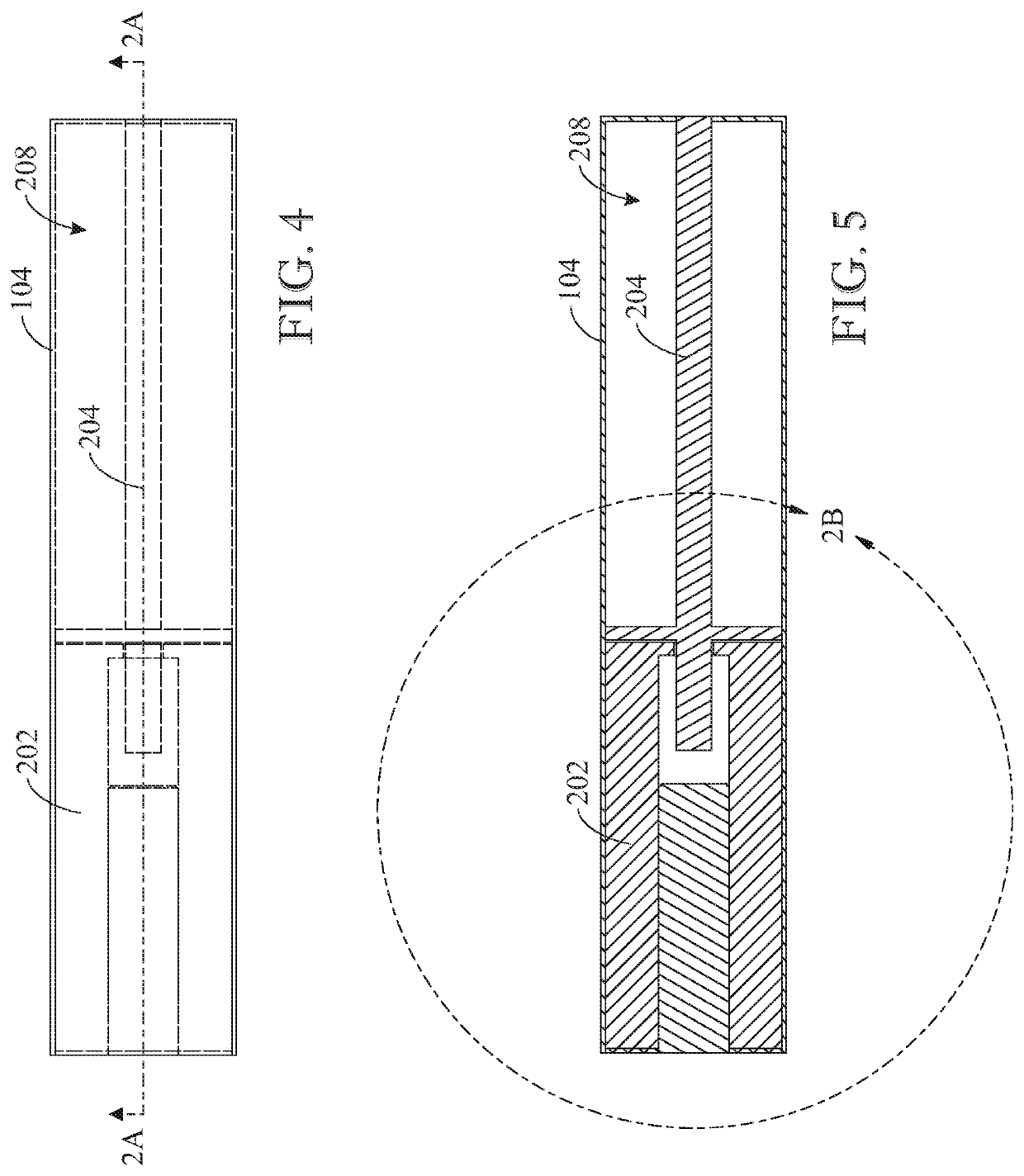

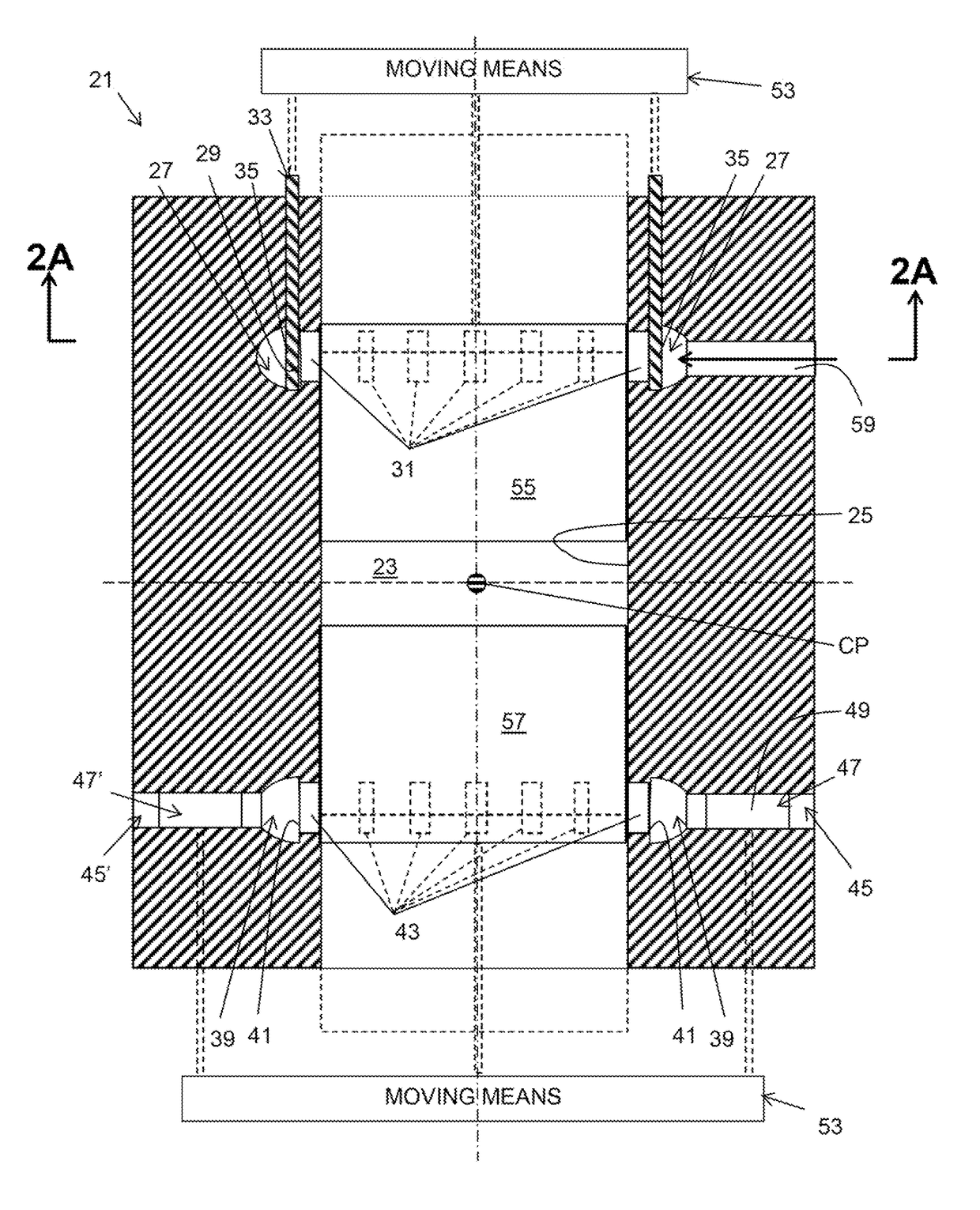

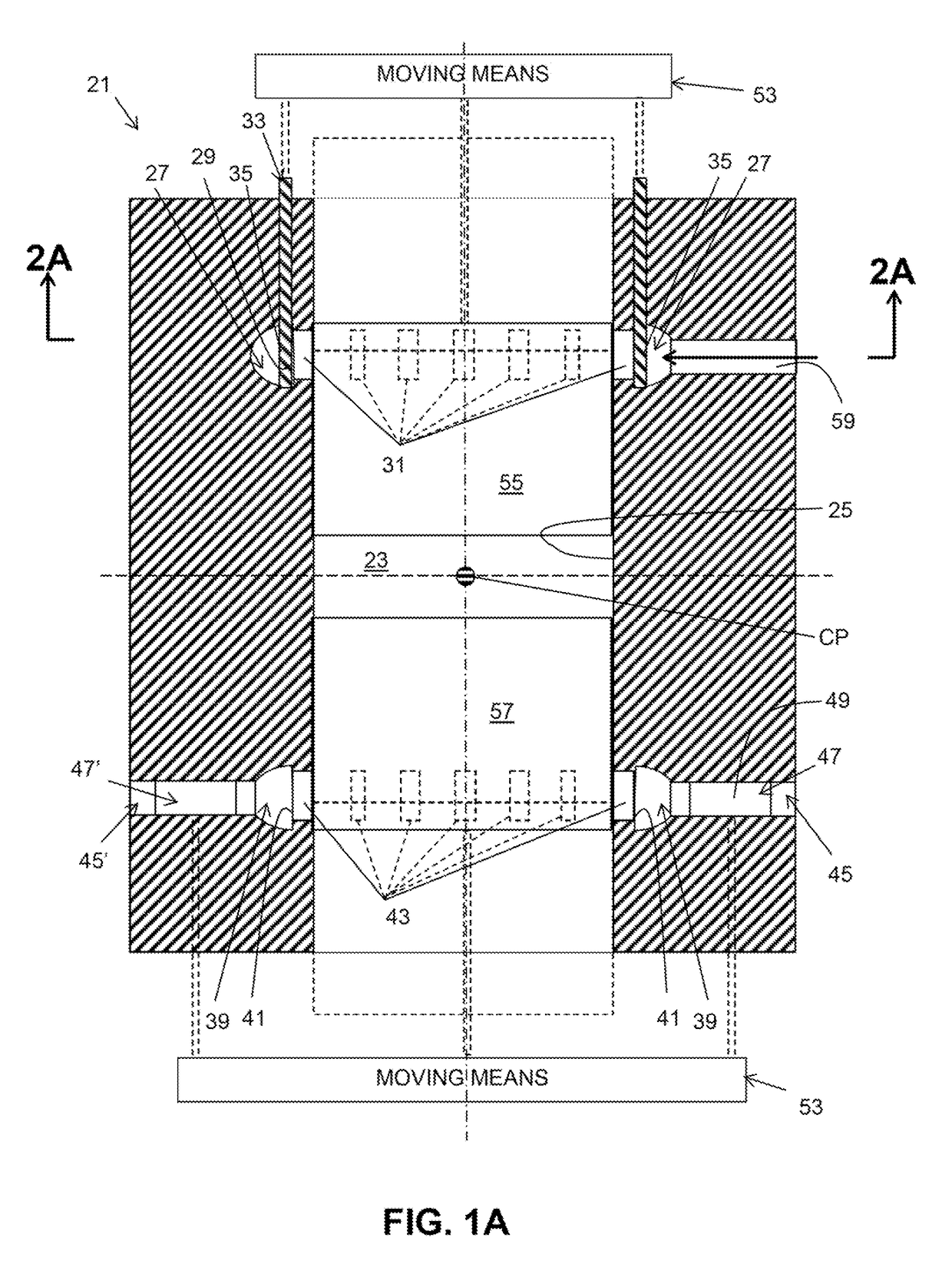

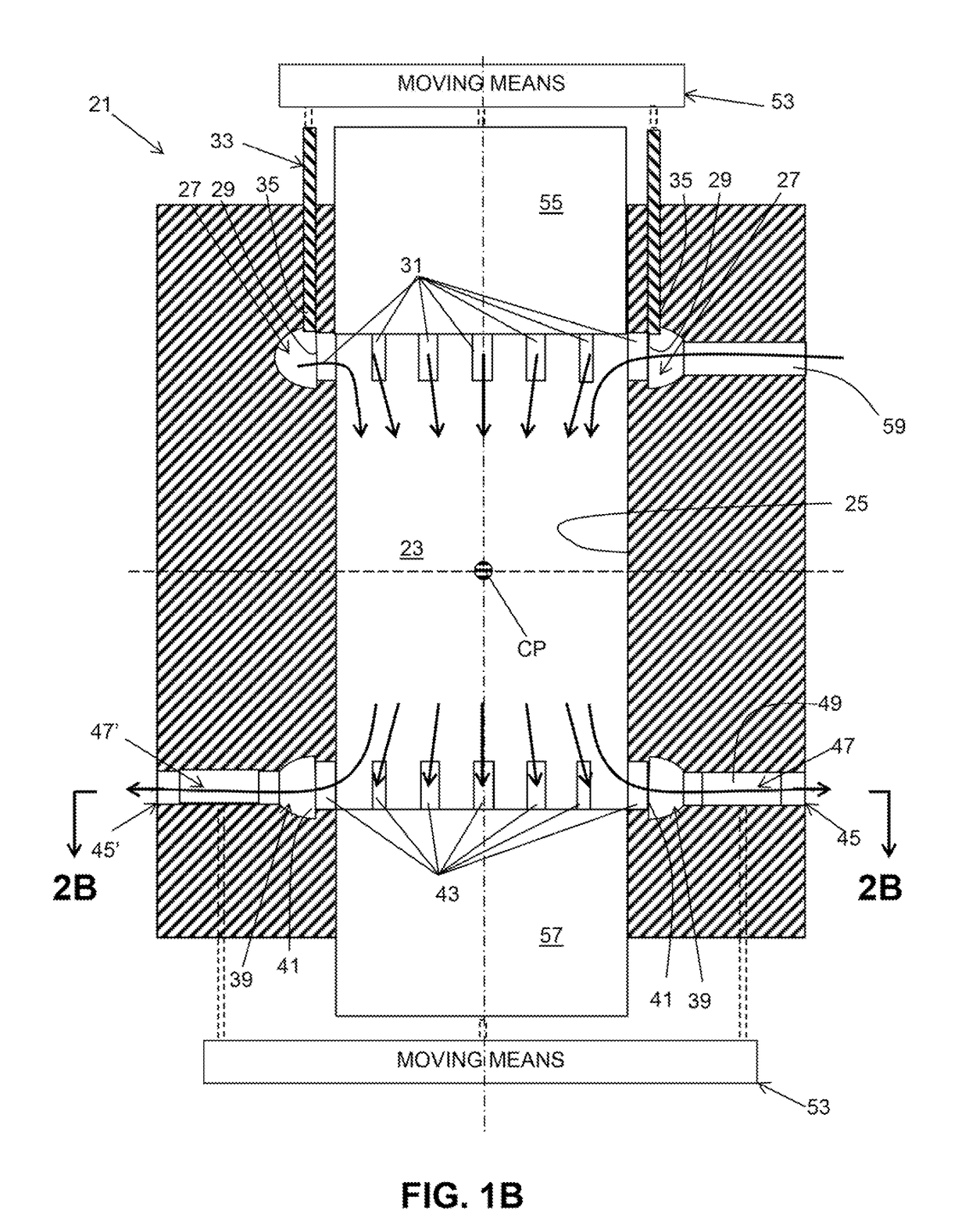

Air Supply for Components of a Split-Cycle Engine

InactiveUS20100282225A1Operating means/releasing devices for valvesNon-fuel substance addition to fuelAir springPower component

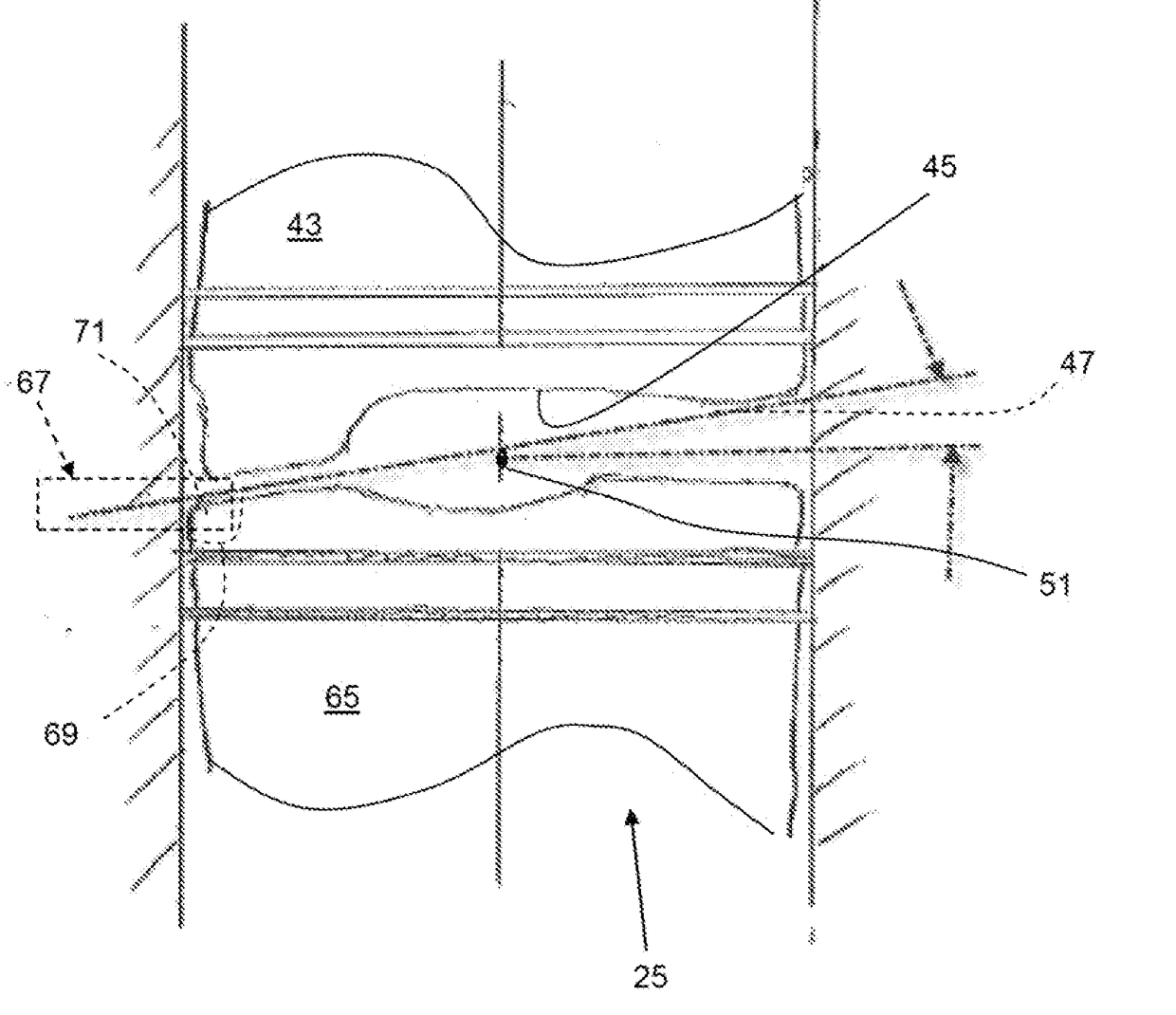

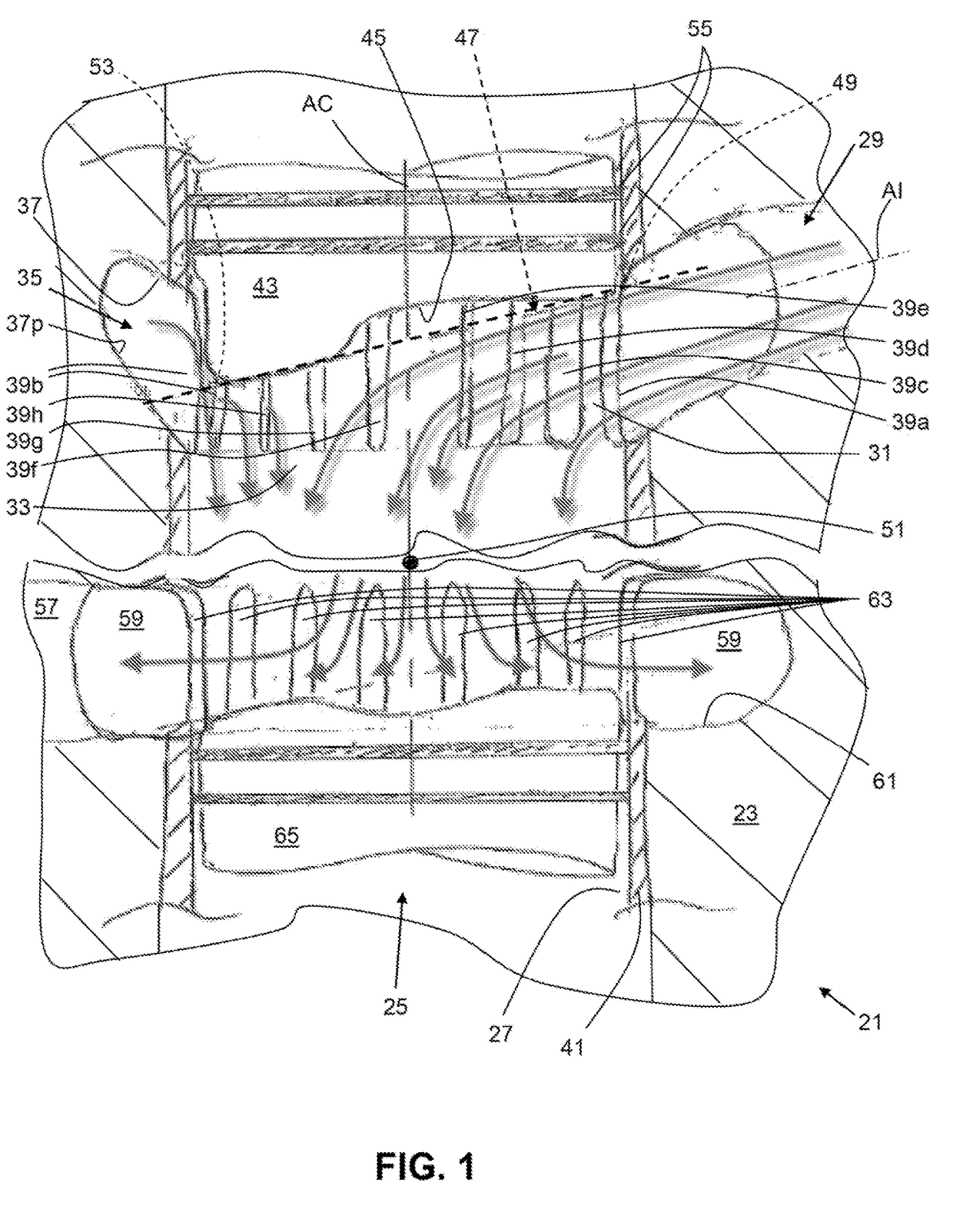

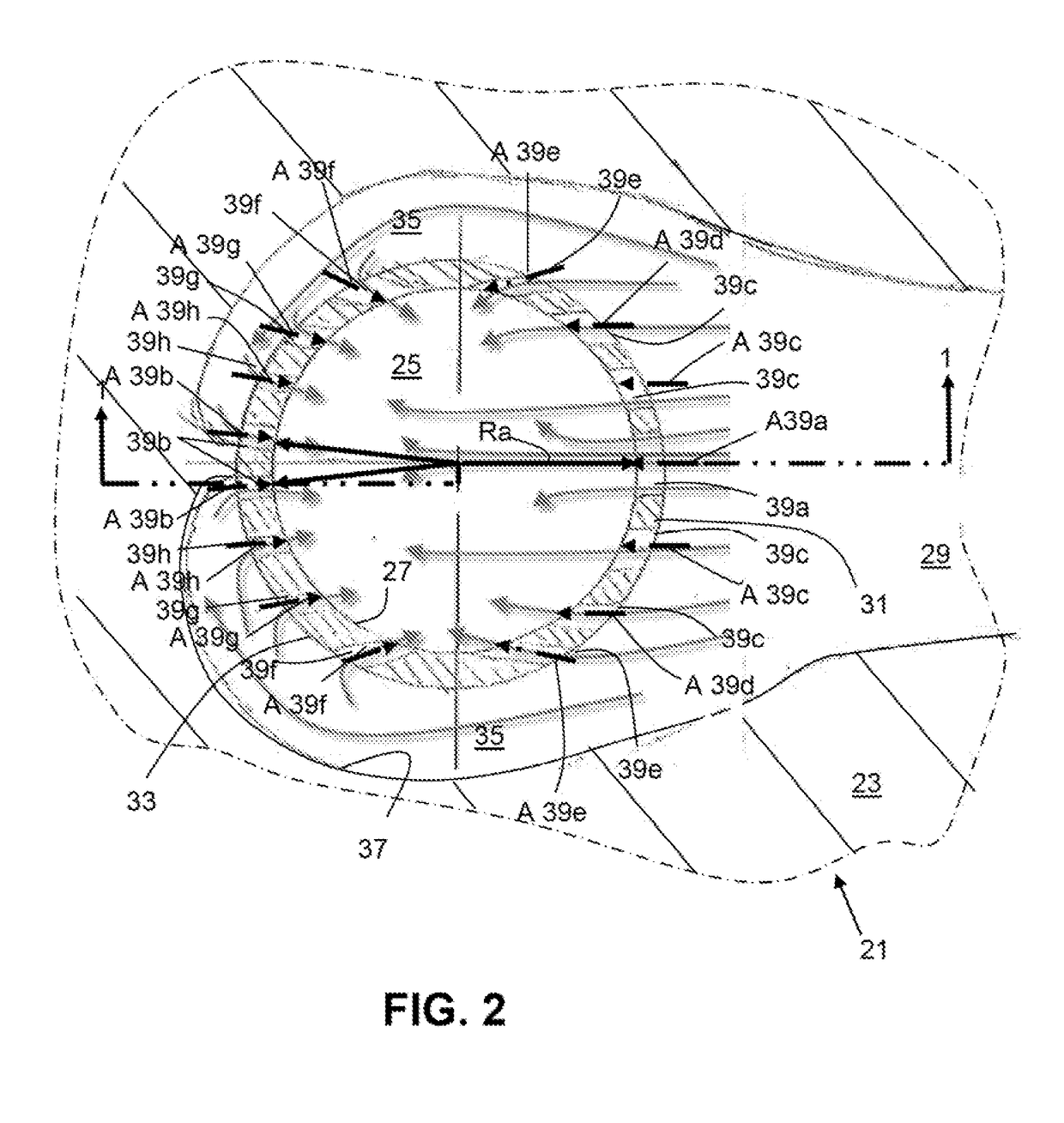

The present invention generally relates to providing an air supply for components associated with an engine. More particularly, the present invention relates to a system and method for using compressed air generated by a split-cycle engine to power components such as valves or air springs associated with the split-cycle engine.

Owner:SKADERI GRUP LLC

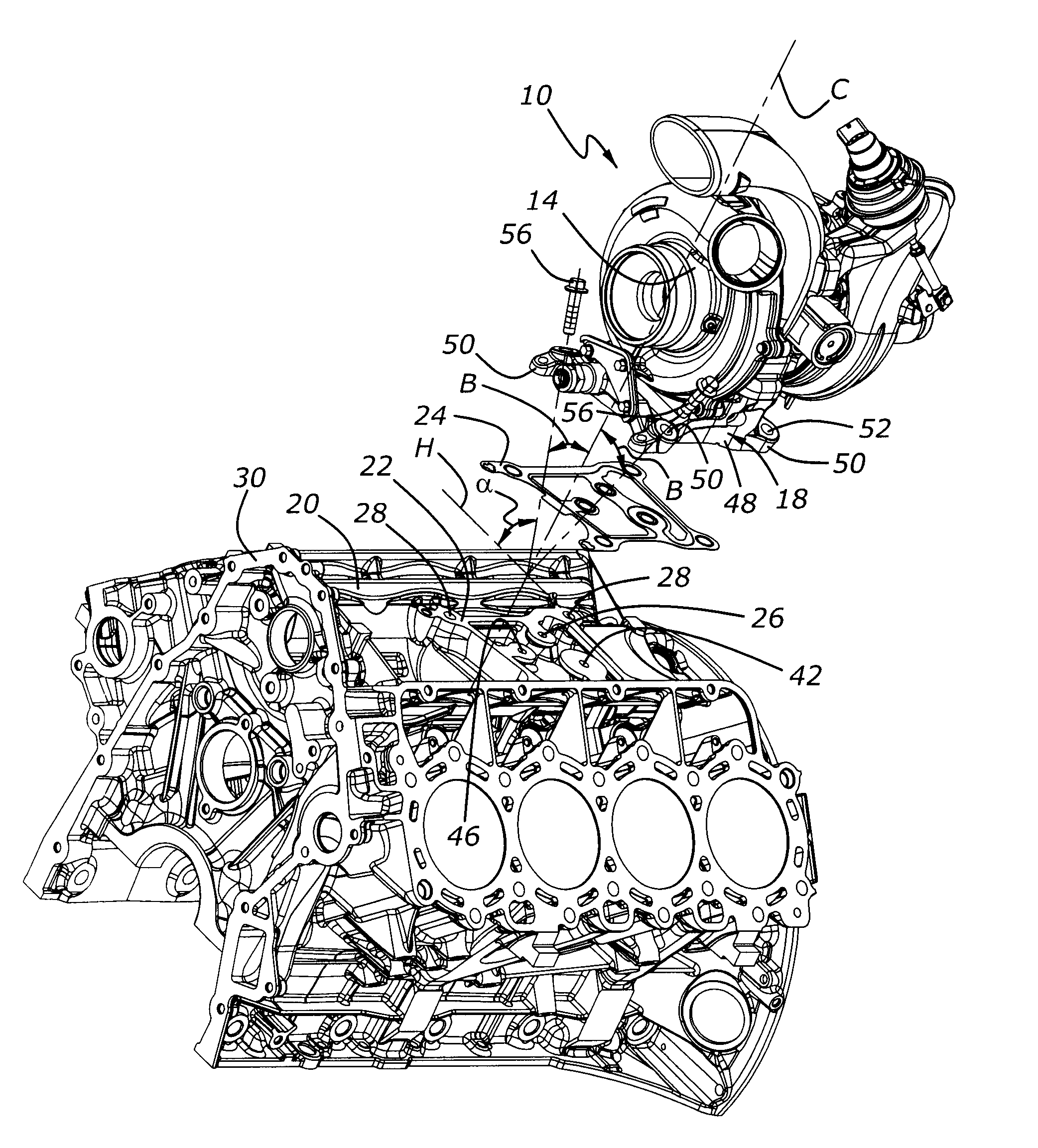

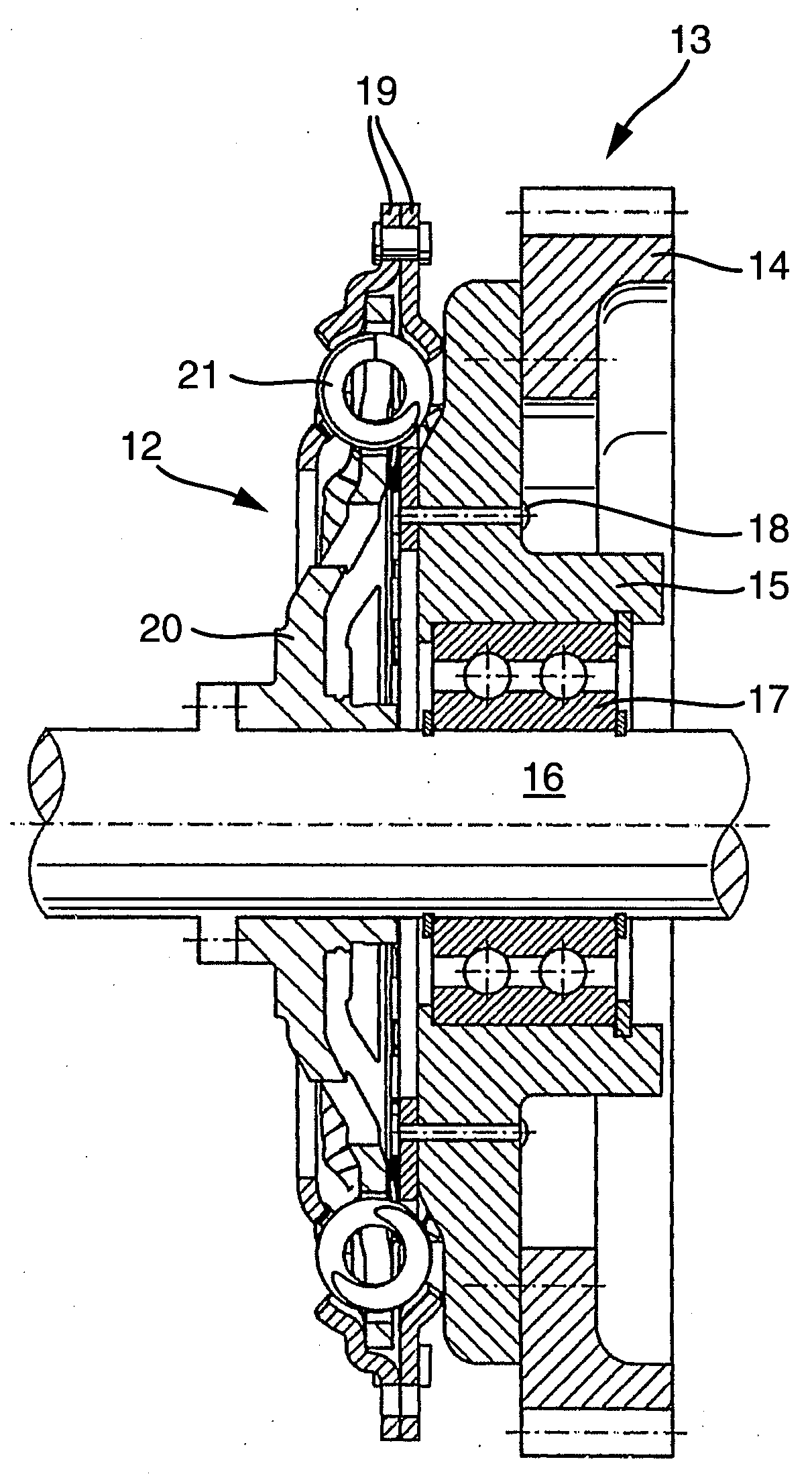

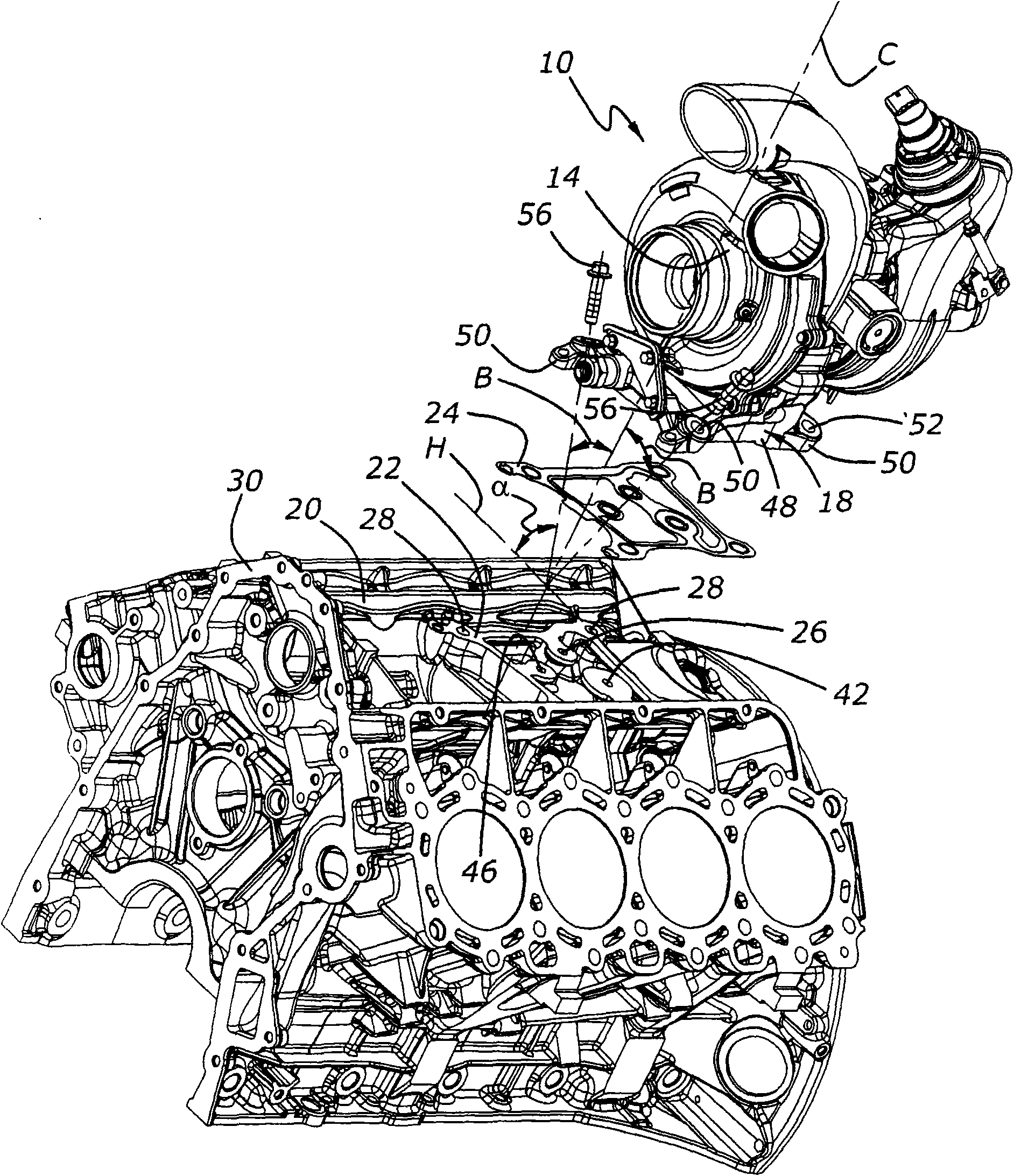

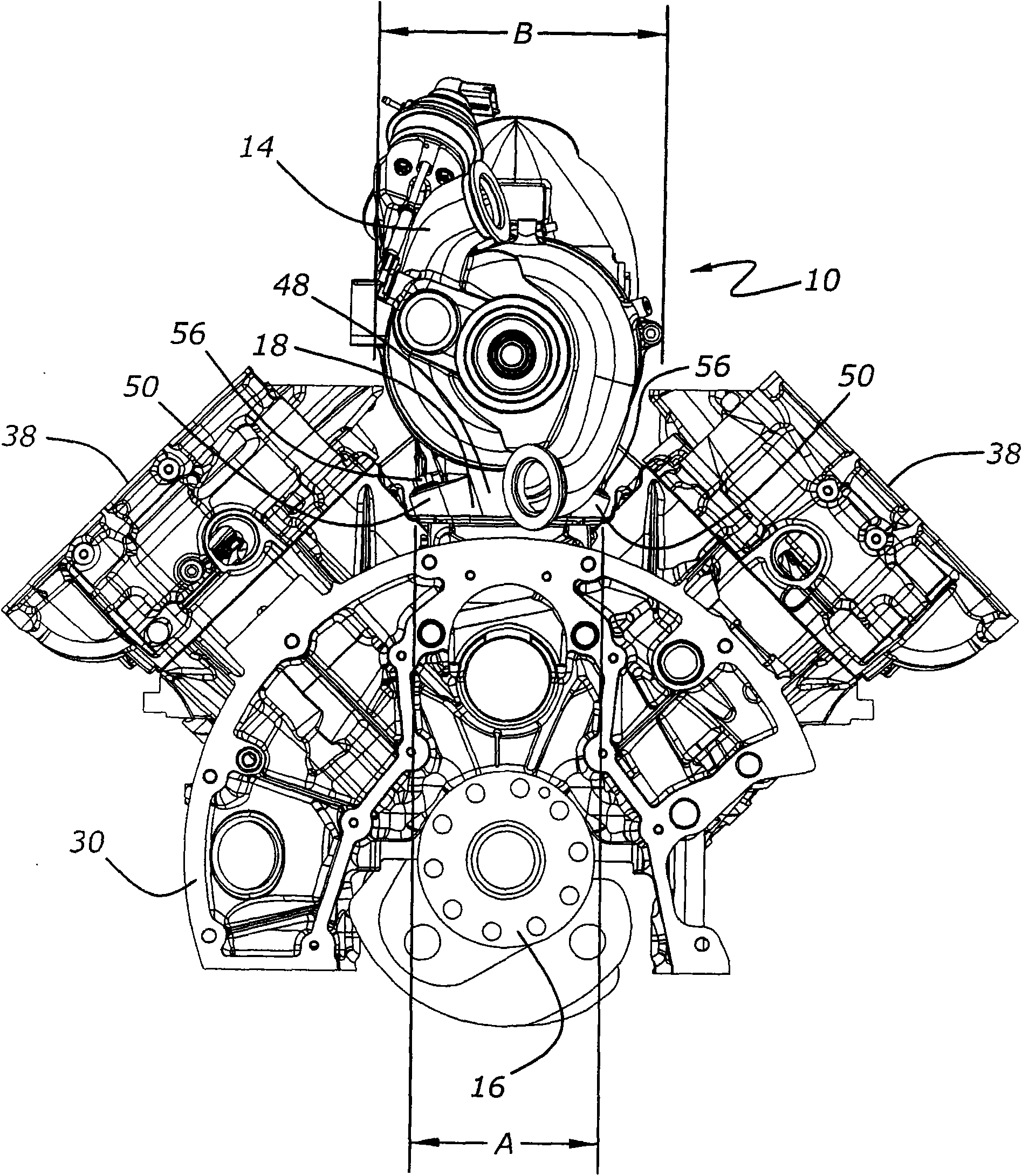

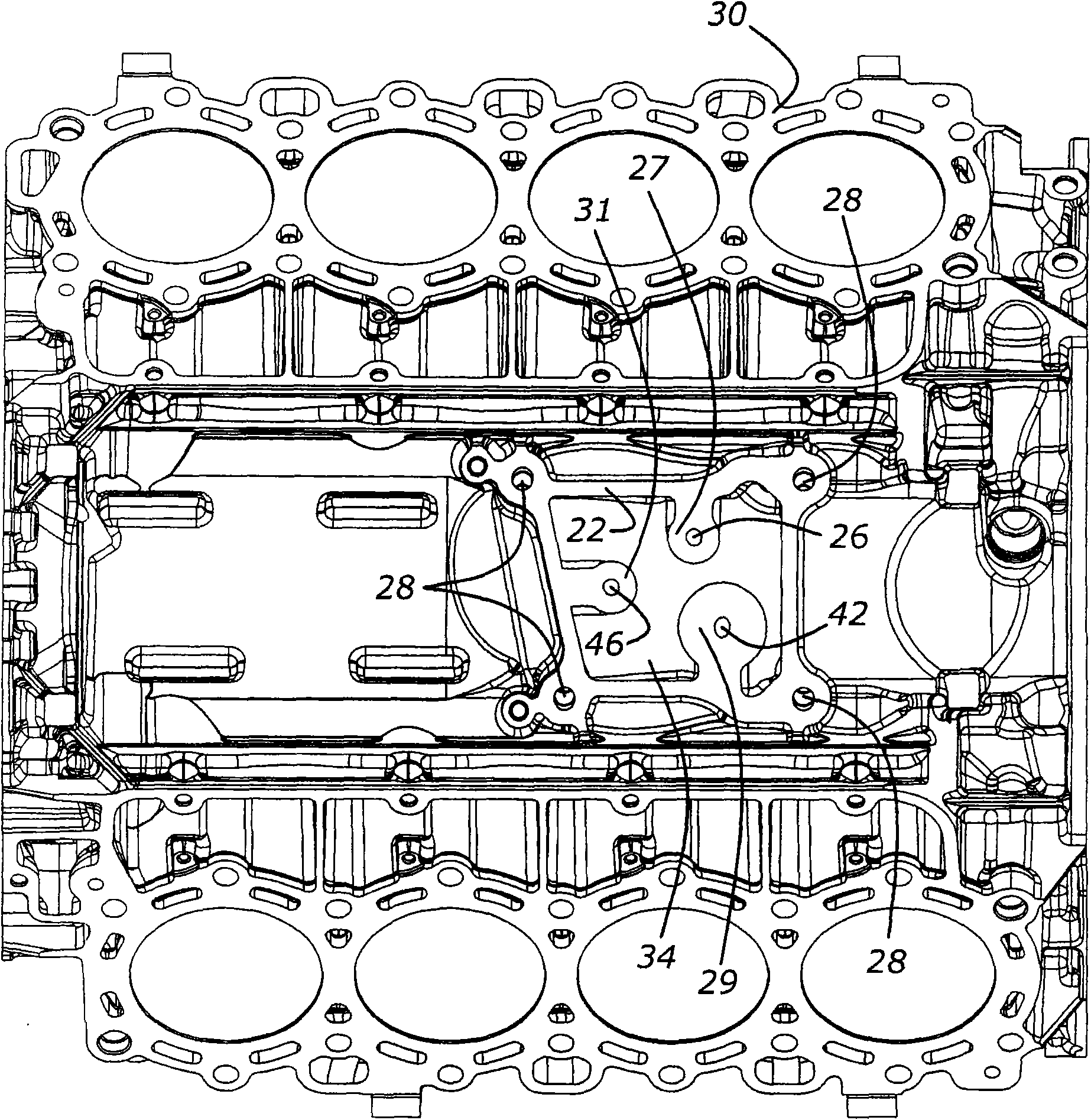

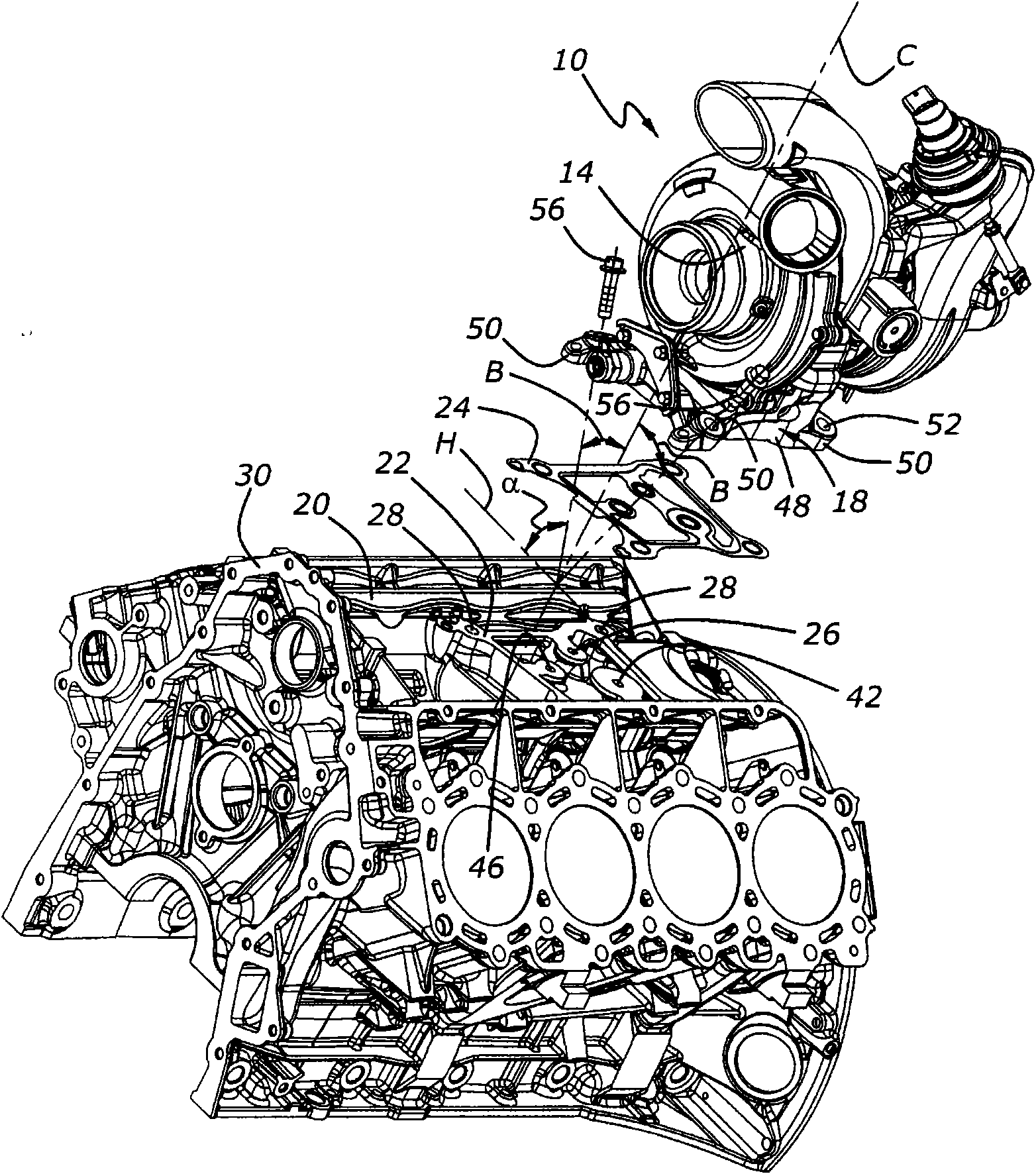

Turbocharger system for internal combustion engine with internal isolated turbocharger oil drainback passage

A turbocharger system for an internal combustion engine includes a turbocharger with a utility pedestal extending between the turbocharger and the hard point associated with the cylinder block. The utility pedestal includes a mounting pad for attaching the combined turbocharger and pedestal assembly to an engine, as well as oil and coolant supply passages for supplying the turbocharger with coolant and lubricating oil under pressure. An internal, isolated, turbocharger oil drainback passage conducts waste oil from the turbocharger to a crankcase sump without permitting the waste oil to contact the engine's moving parts.

Owner:FORD GLOBAL TECH LLC

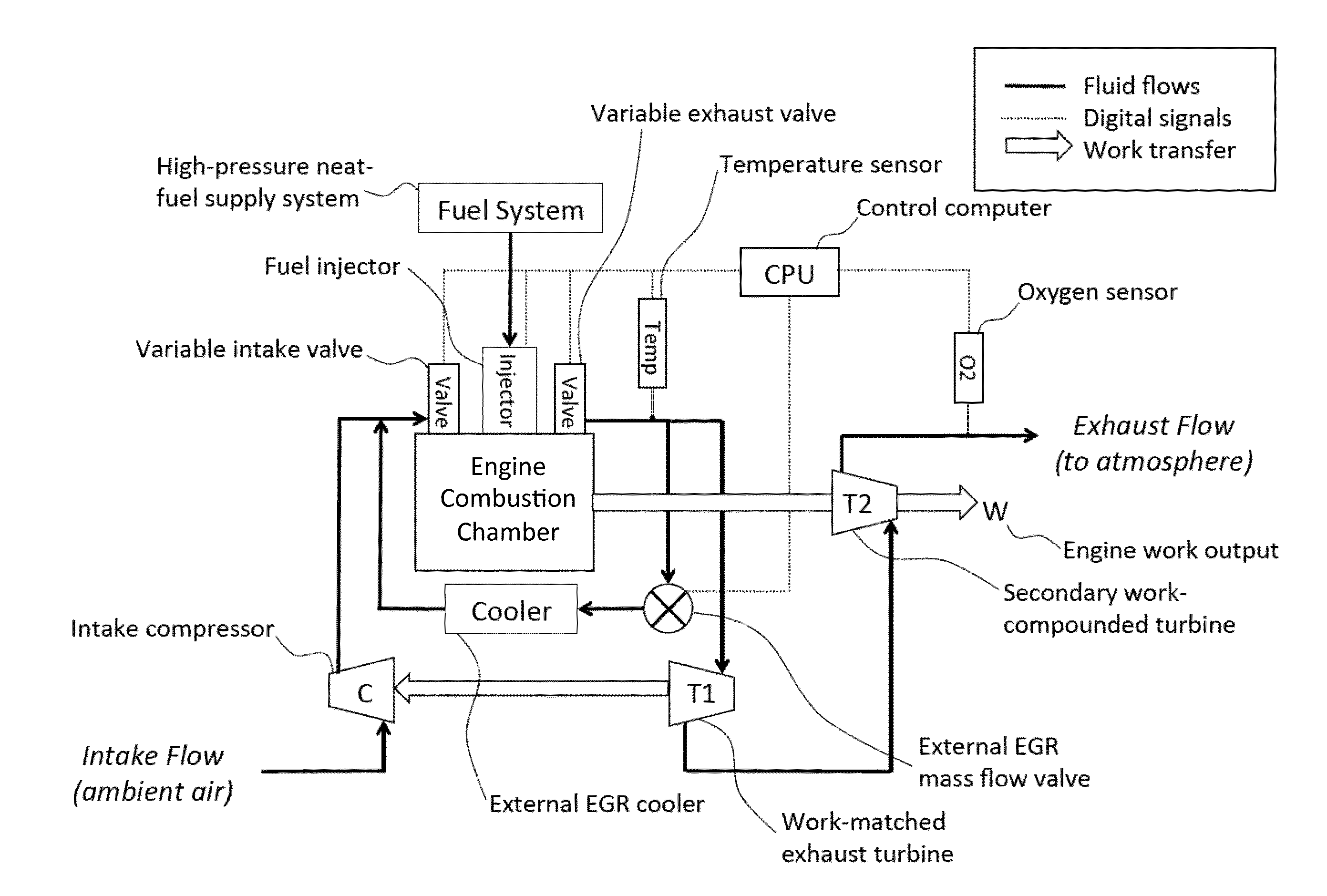

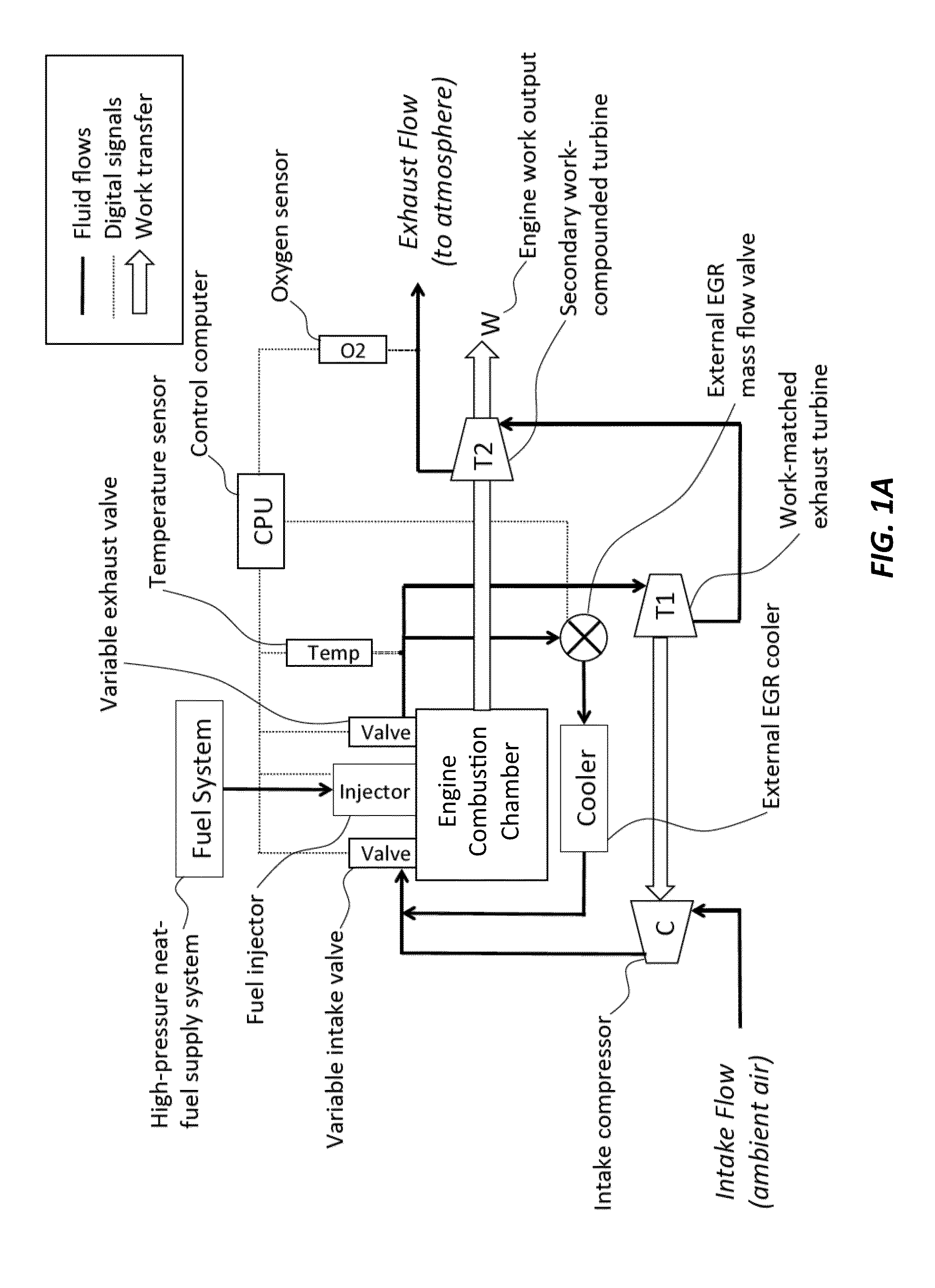

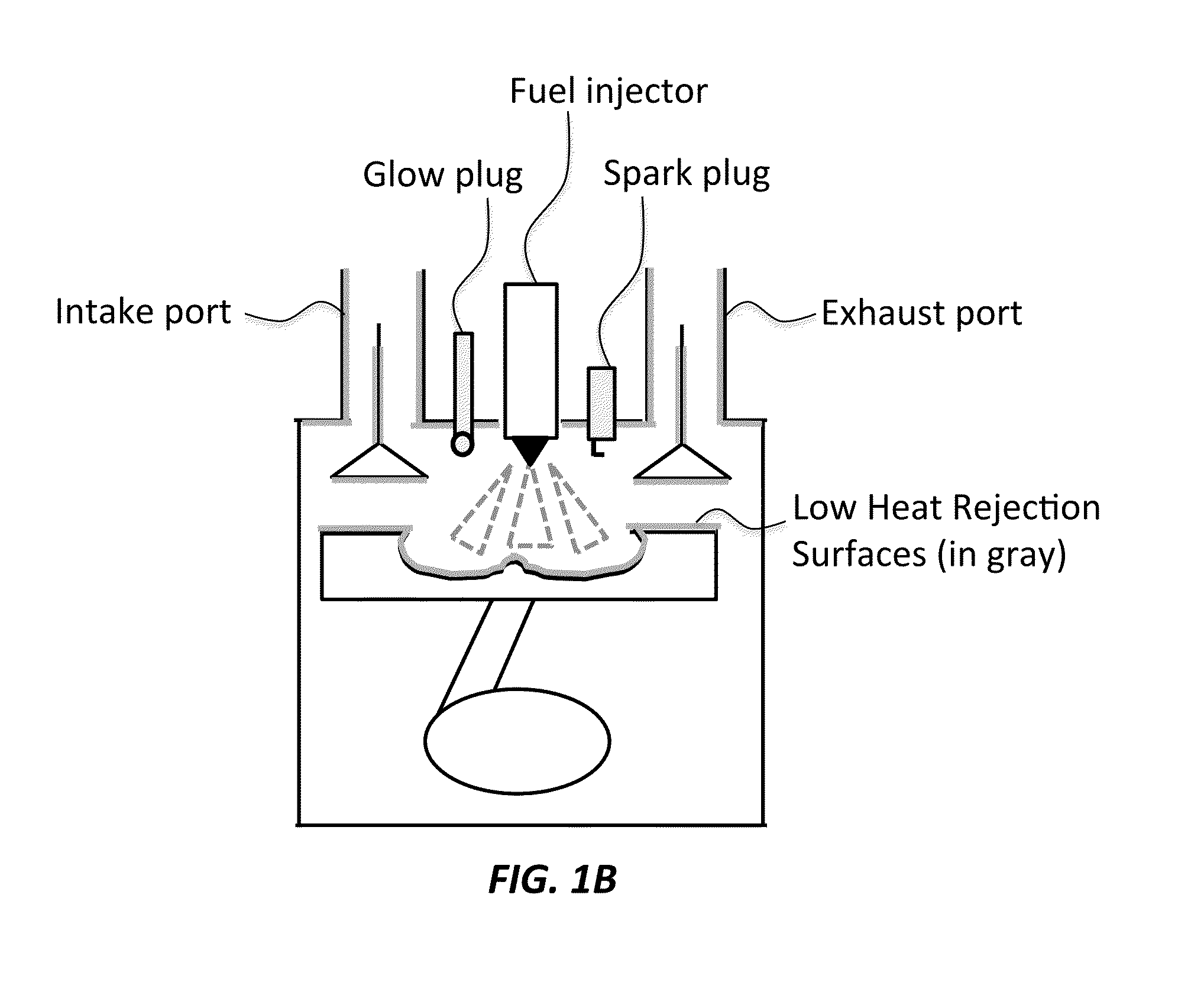

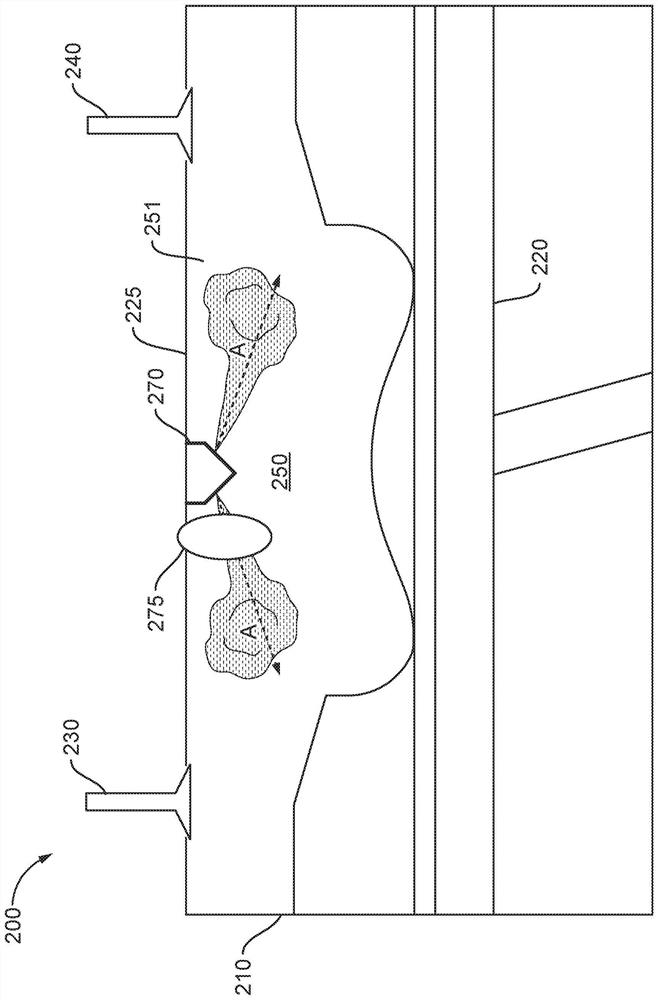

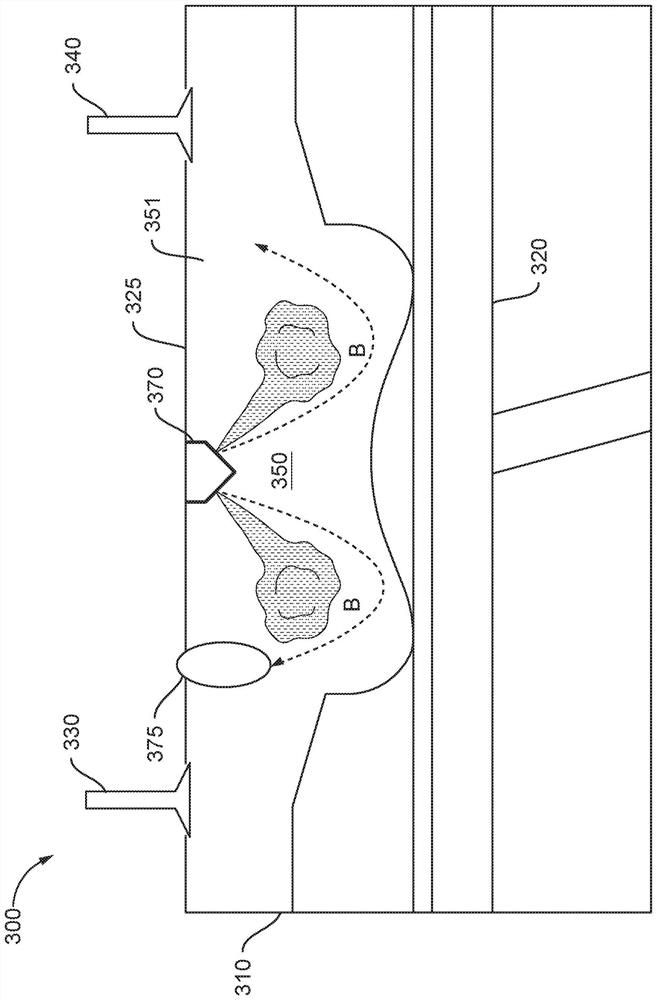

Stoichiometric high-temperature direct-injection compression-ignition engine

ActiveUS9903262B2Electrical controlInternal combustion piston enginesExhaust valveCombustion chamber

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

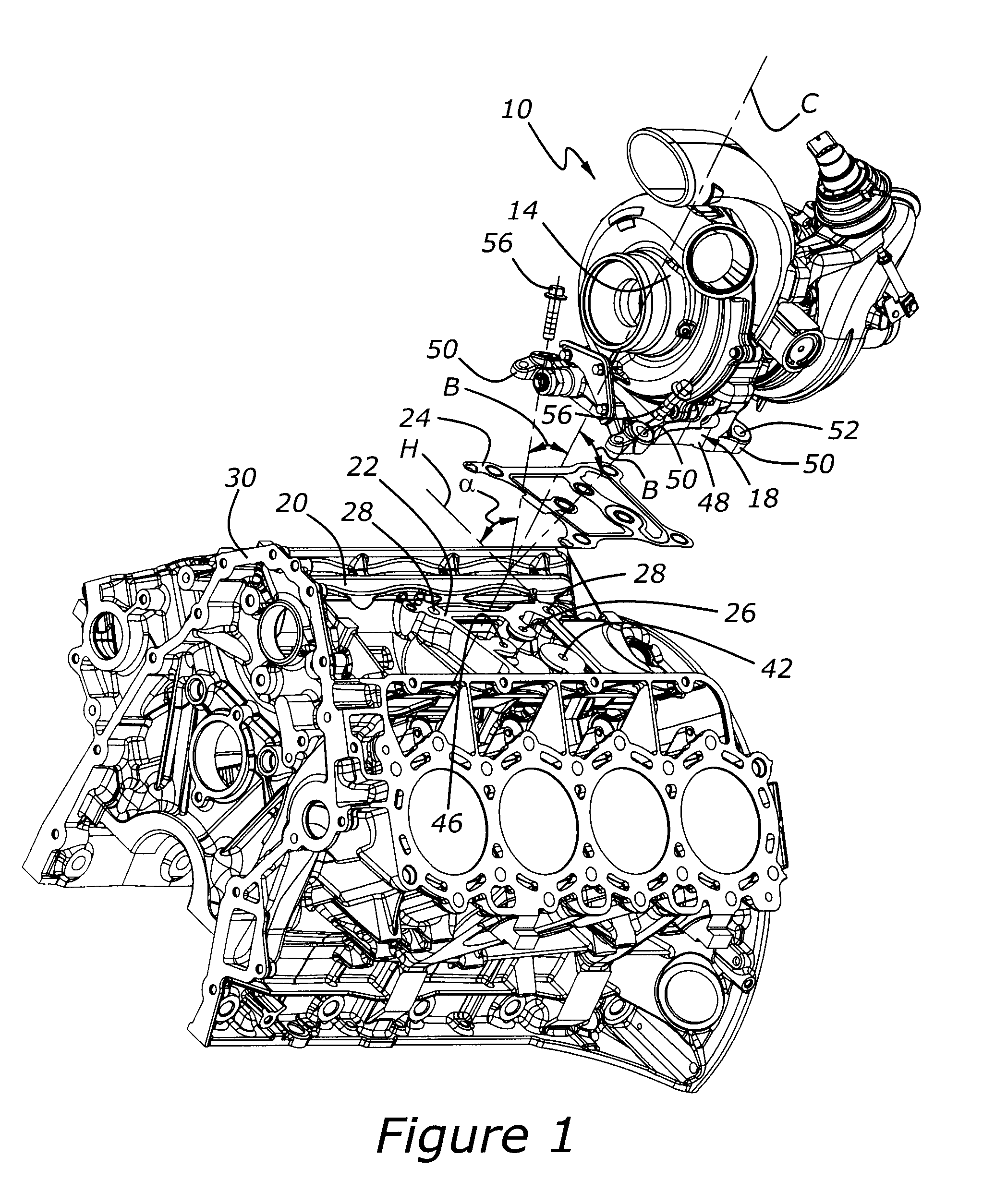

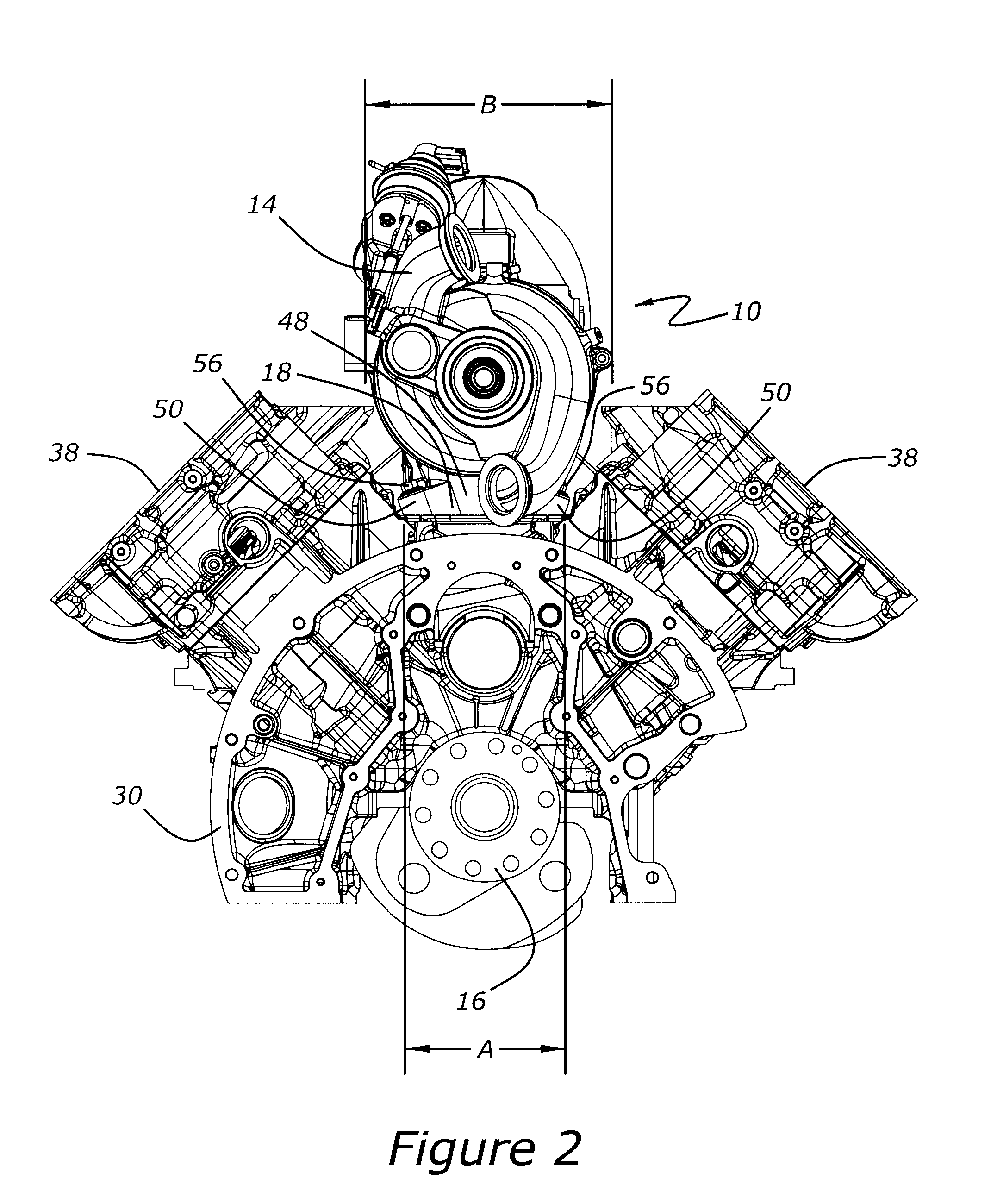

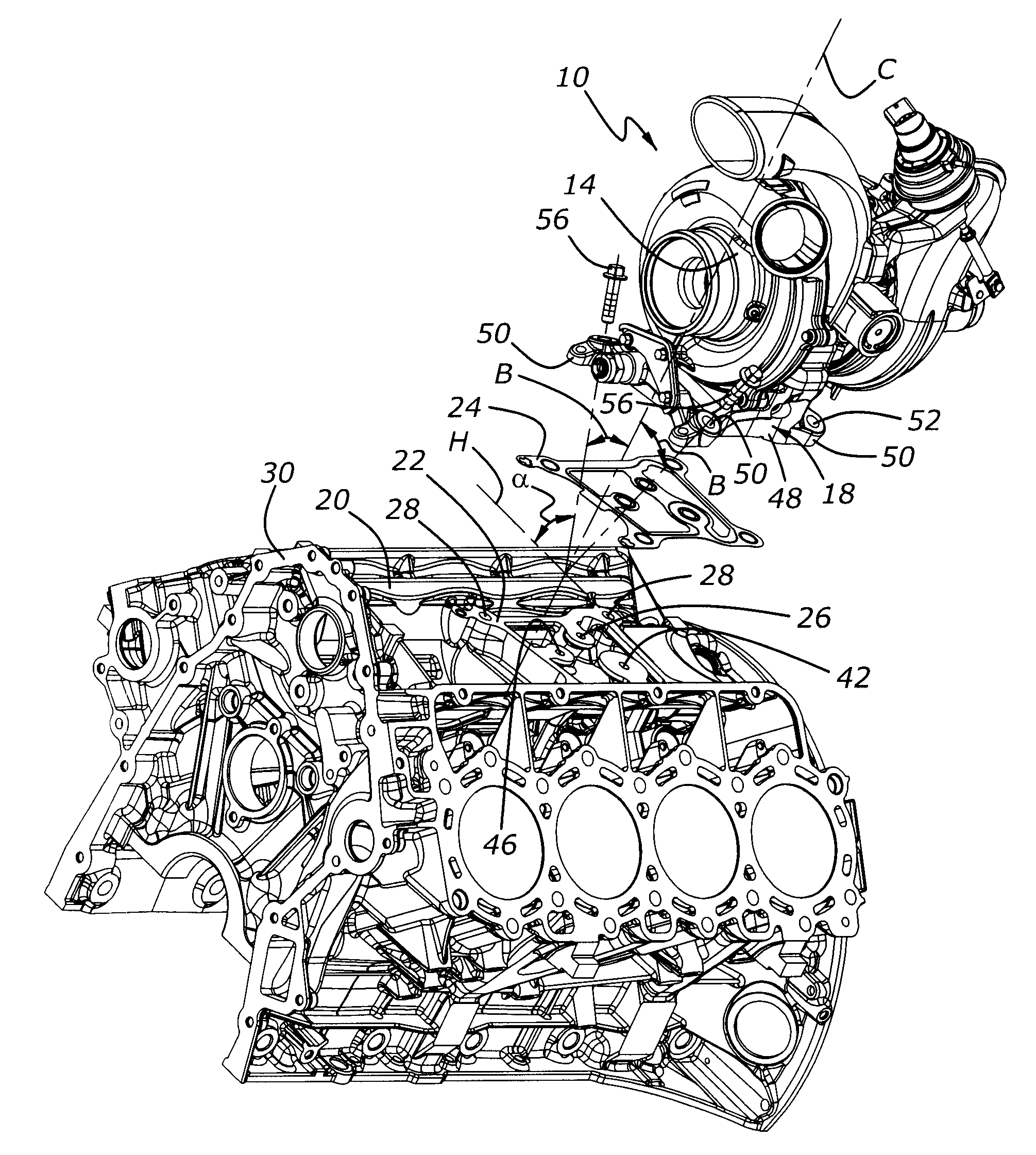

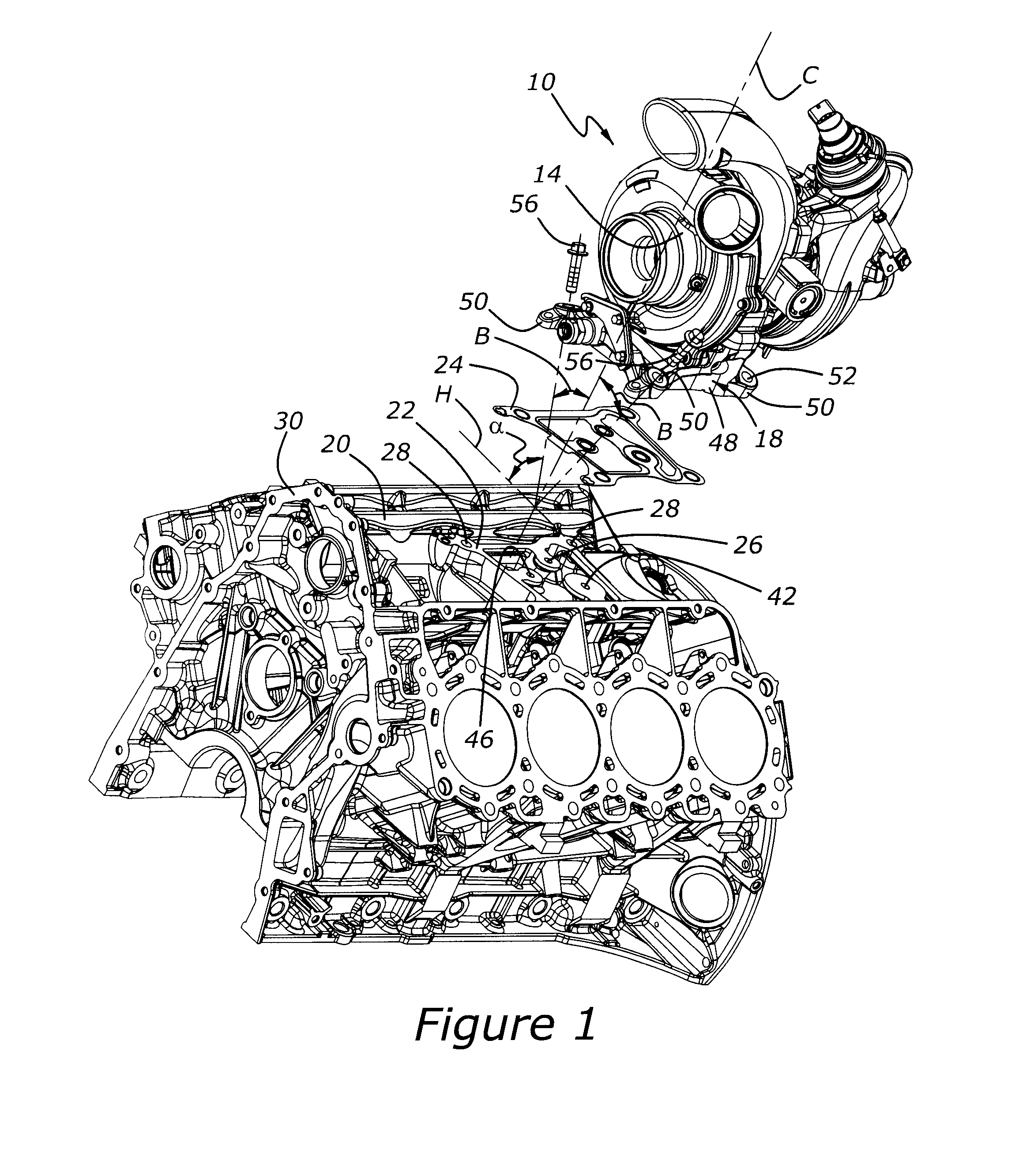

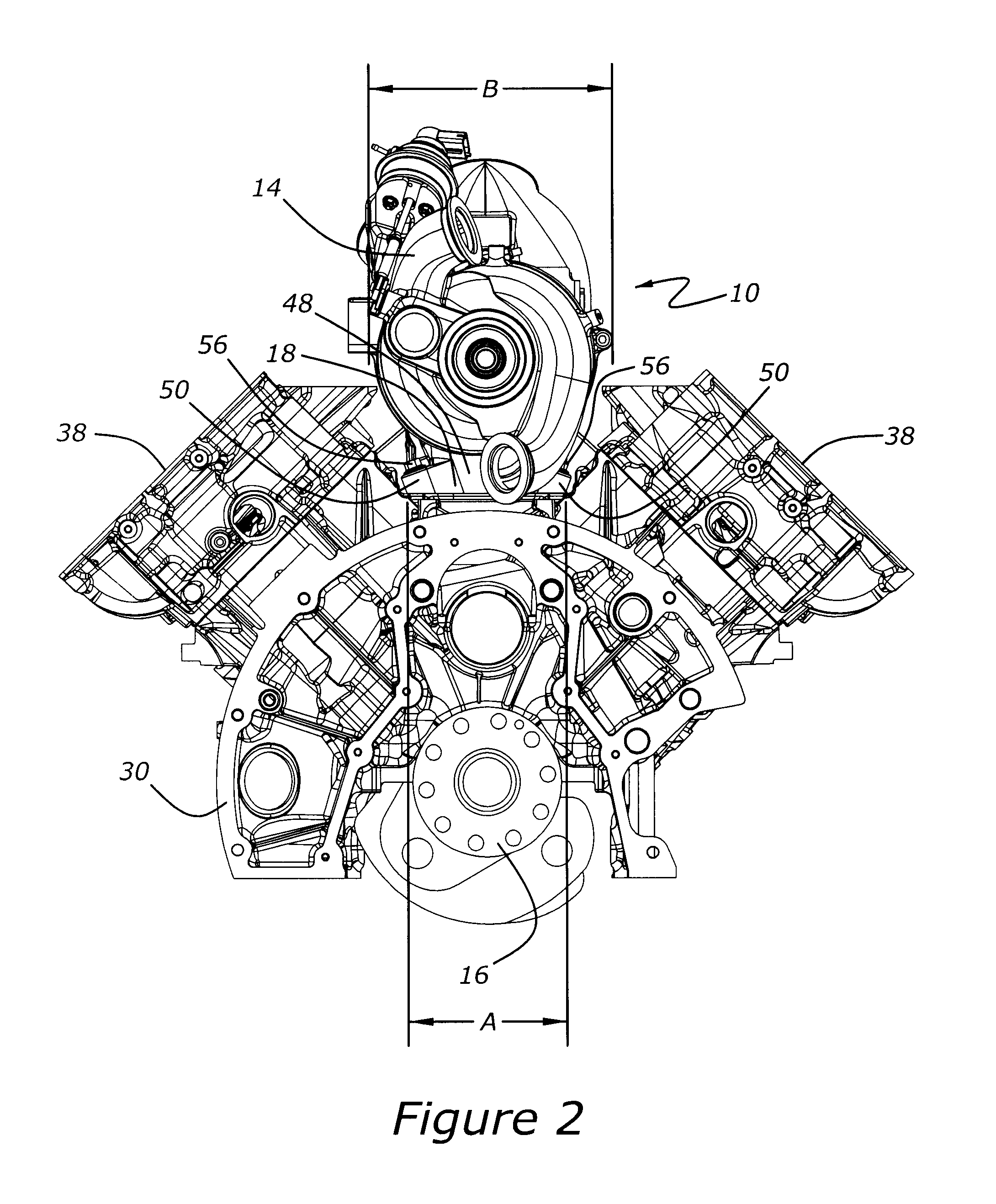

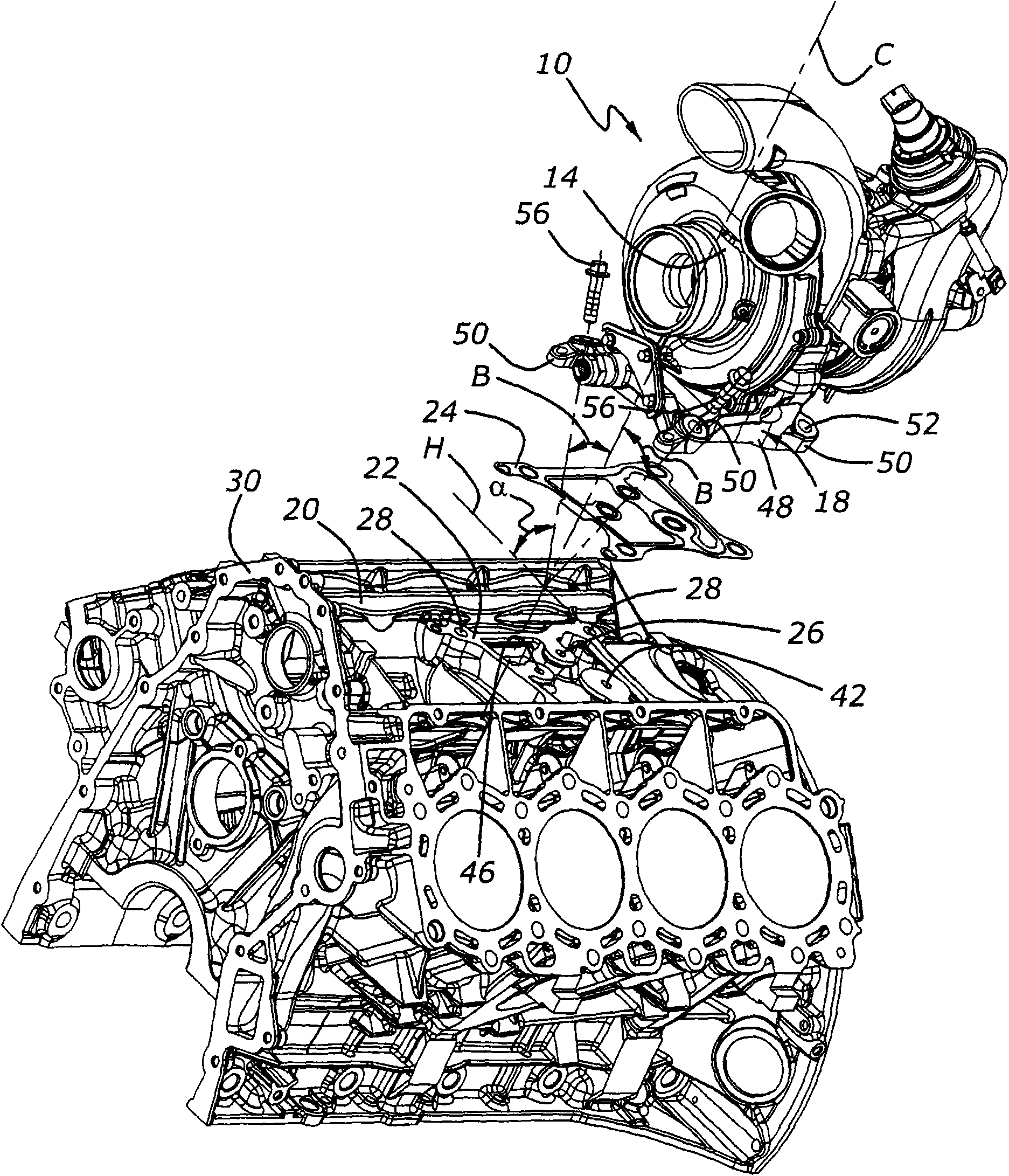

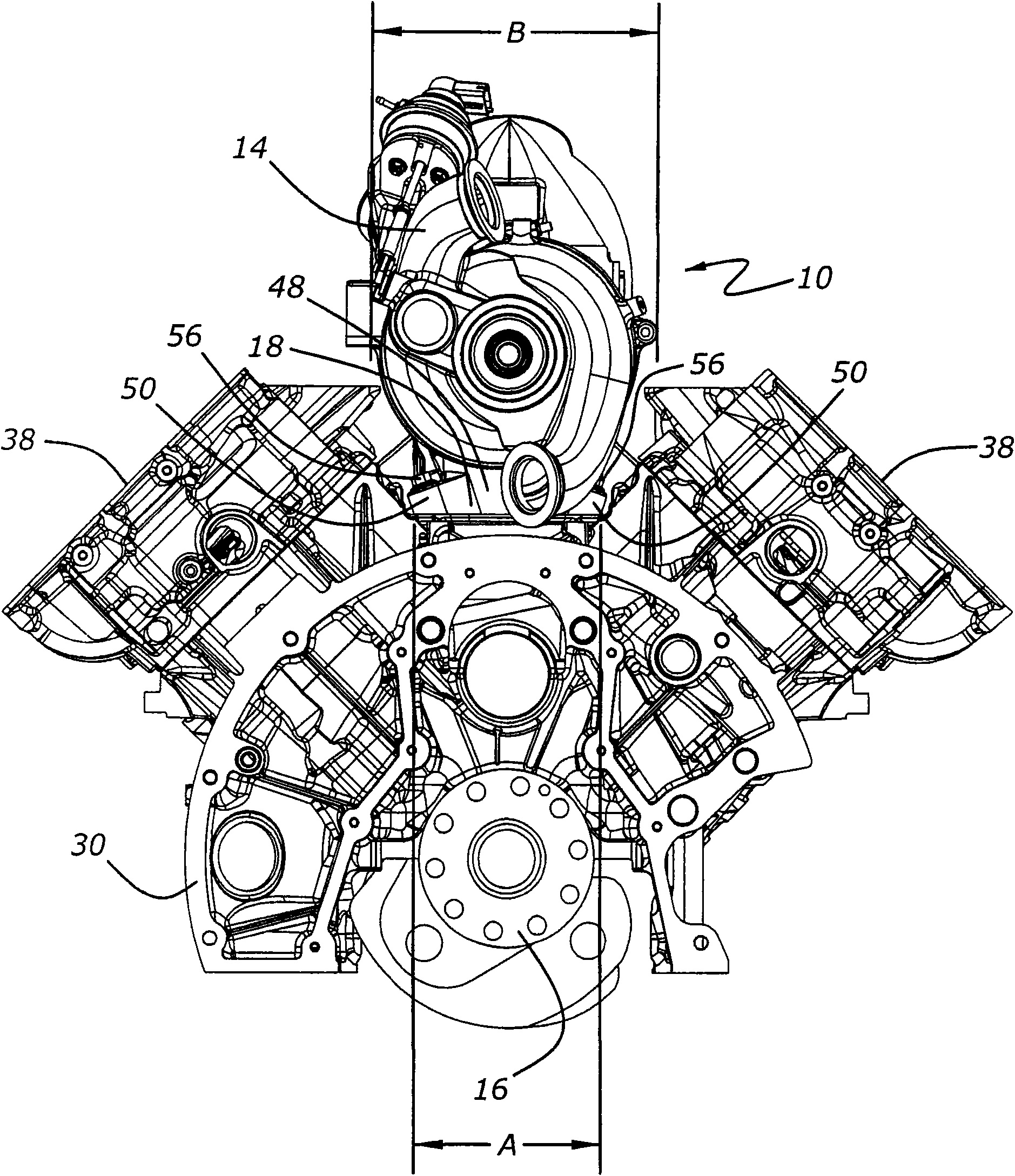

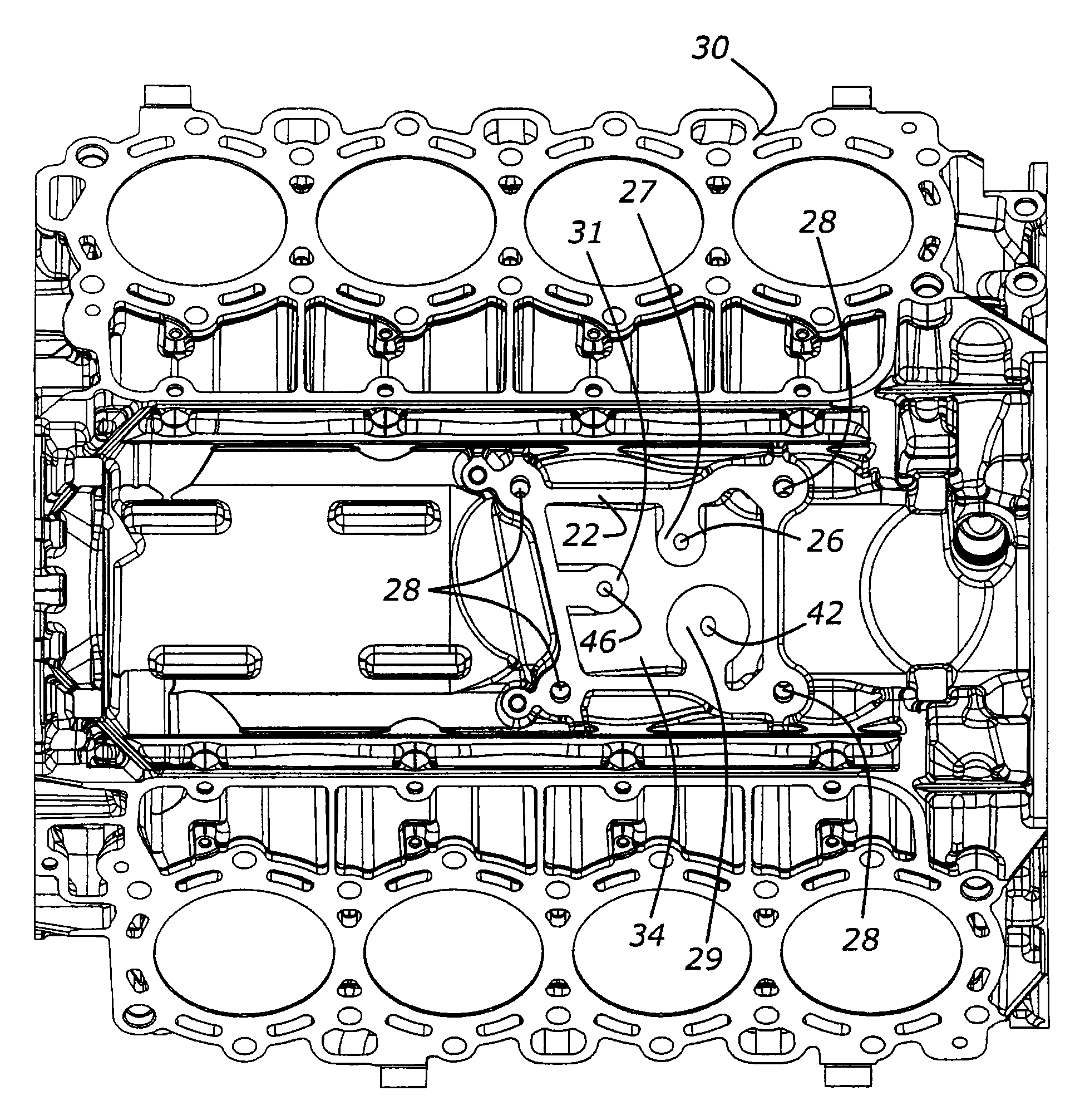

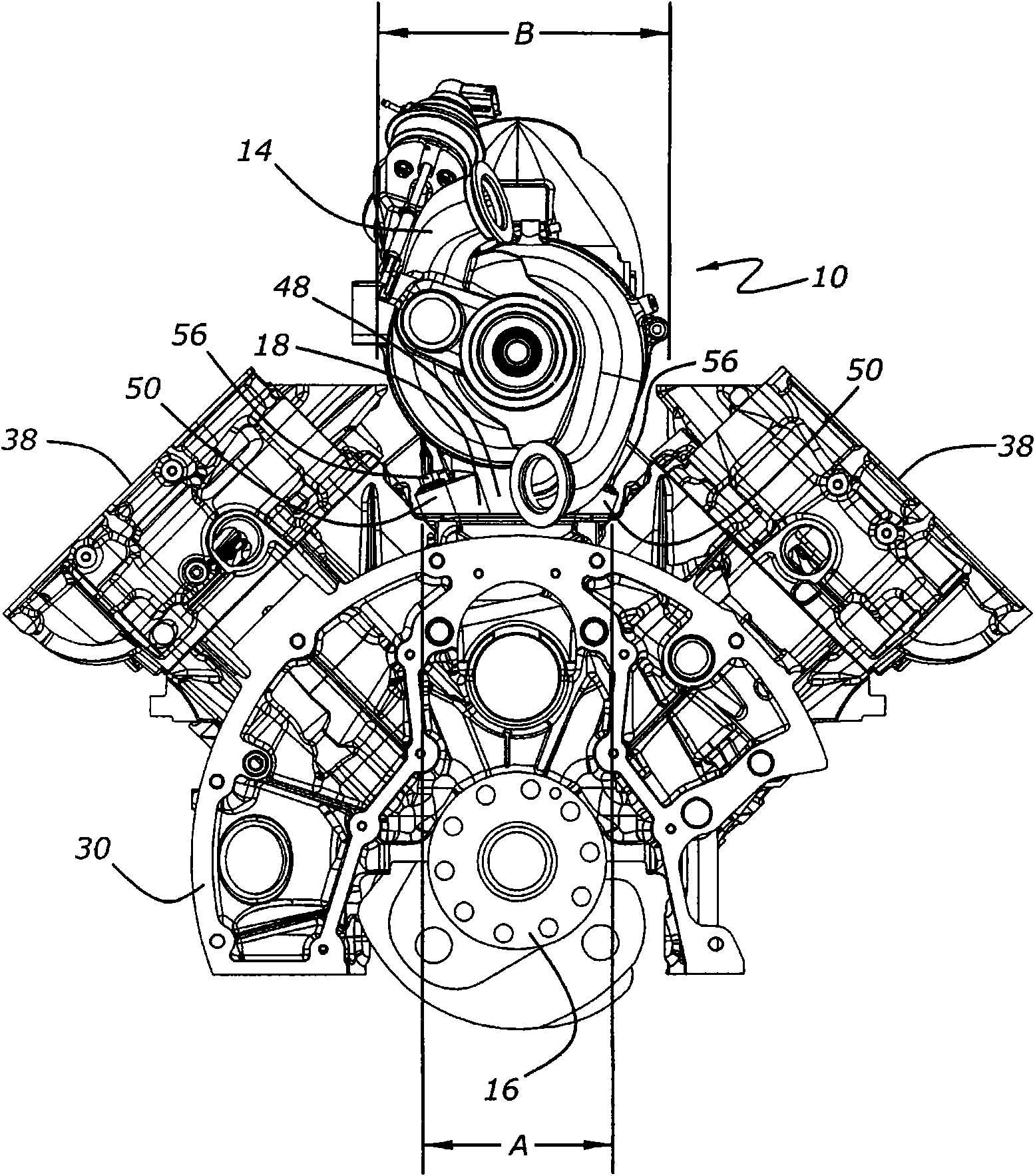

Cylinder block mounted pedestal and turbocharger system for internal combustion engine

A turbocharger system for an internal combustion engine includes a turbocharger with a utility pedestal extending between the turbocharger and hard point associated with the cylinder block. The utility pedestal includes a mounting pad for attaching the combined turbocharger and pedestal assembly to an engine, as well as internal oil and coolant supply passages for supplying the turbocharger with coolant and lubricating oil under pressure.

Owner:FORD GLOBAL TECH LLC

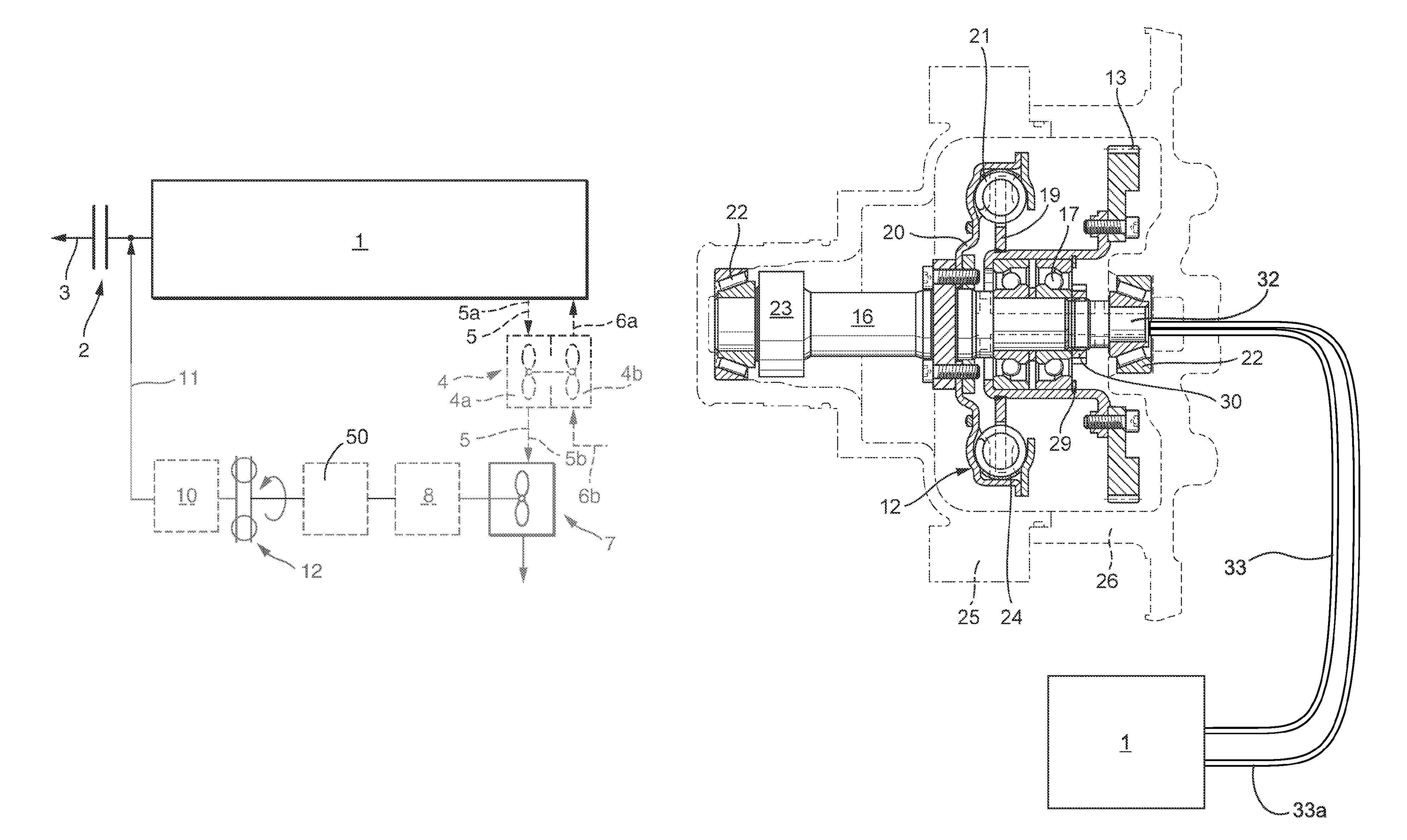

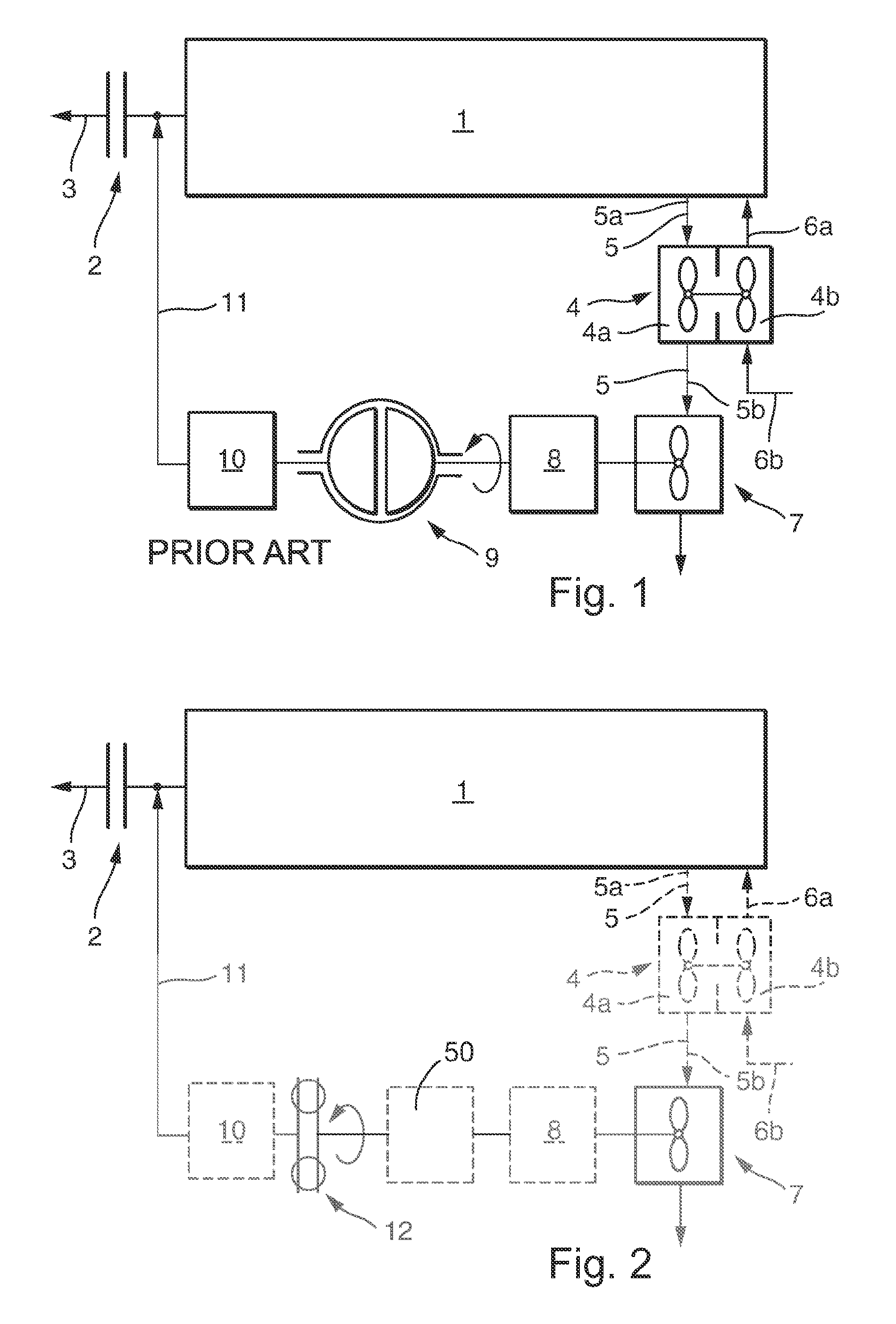

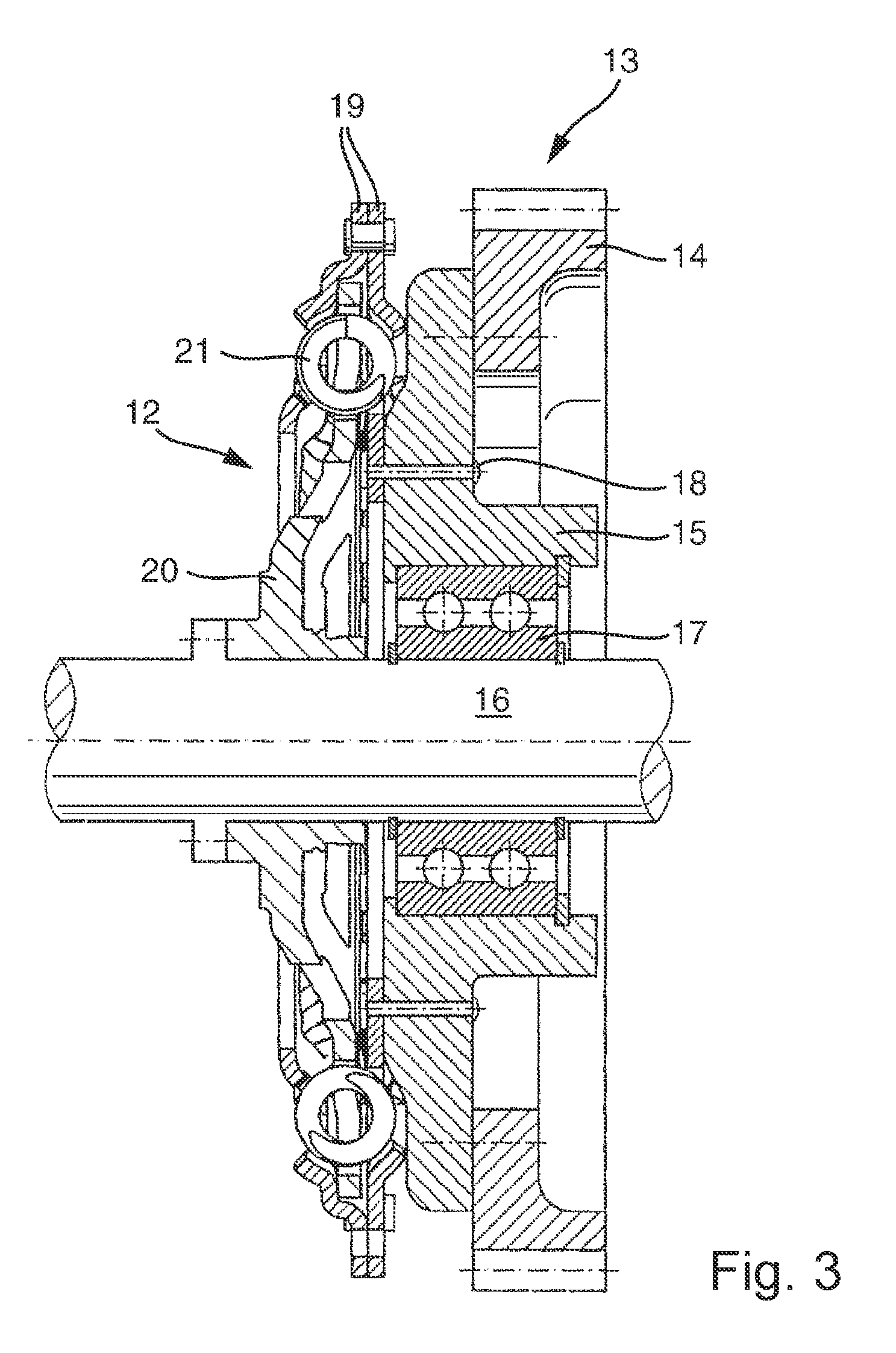

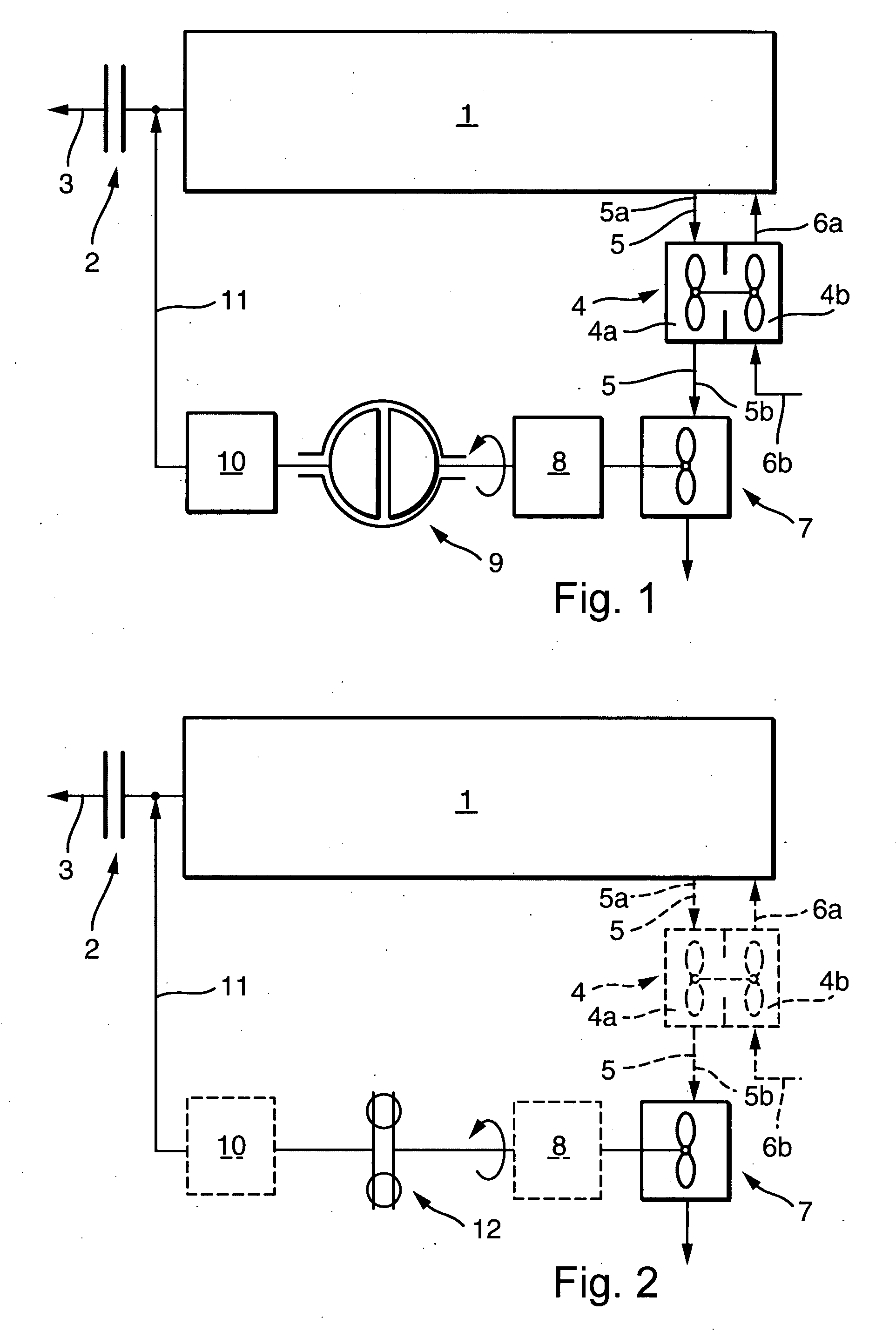

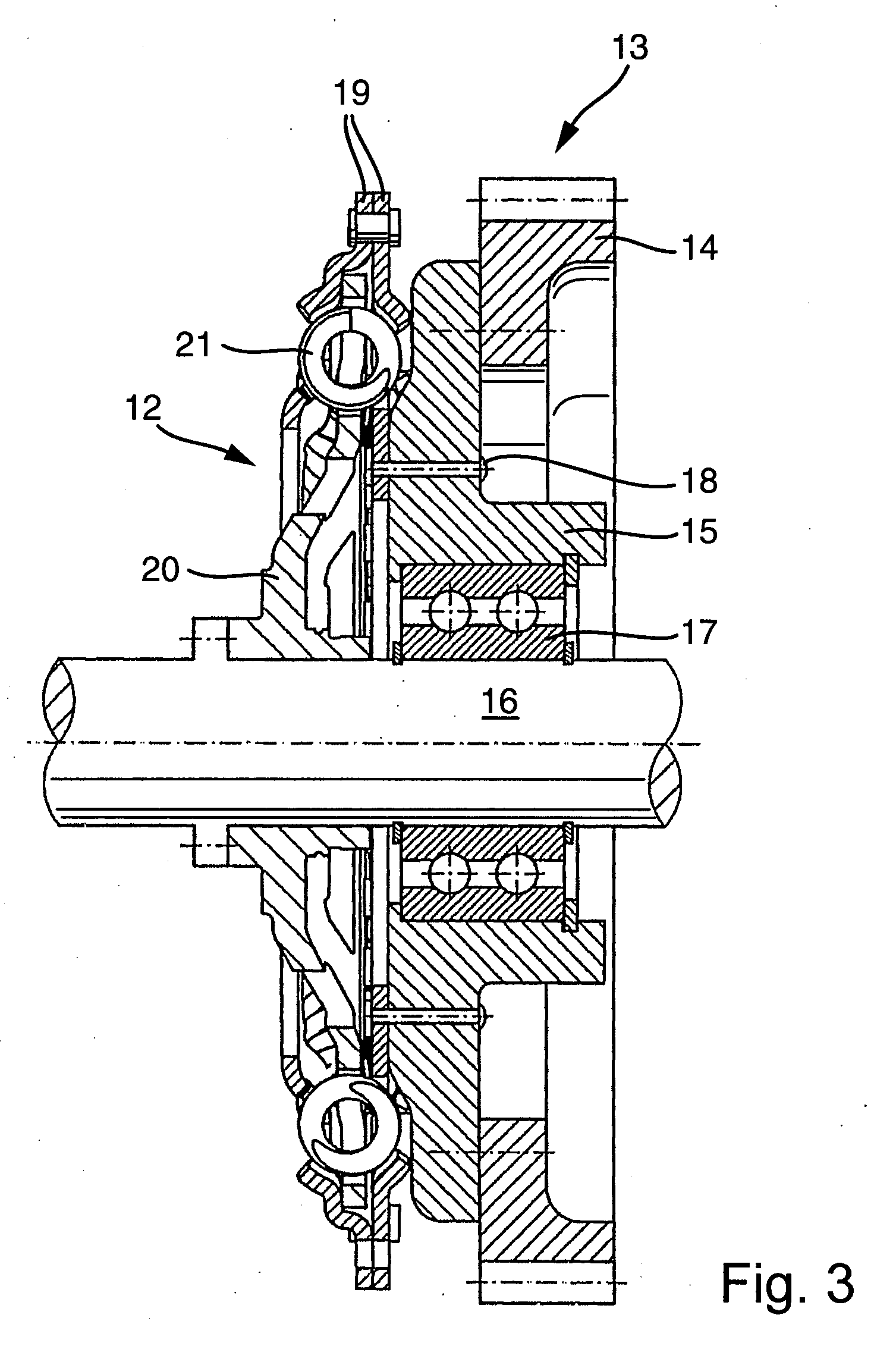

Compound transmission

InactiveUS7966817B2Vibration minimizationEliminate torsional vibrations—atYielding couplingInternal combustion piston enginesTransmitted powerCoupling

An internal combustion engine comprises includes a turbo-compound and the known Föttinger-coupling is replaced by a torsion vibration damper. The Föttinger-coupling, which is used to transmit power, has high losses in power when it is necessary to have a differential rotational speed between the input side and the output side, that is, the appearance of a slip. The losses are not used in a torsion vibration damper which has at least the same quality as a Föttinger-coupling.

Owner:SCHAEFFLER TECH AG & CO KG

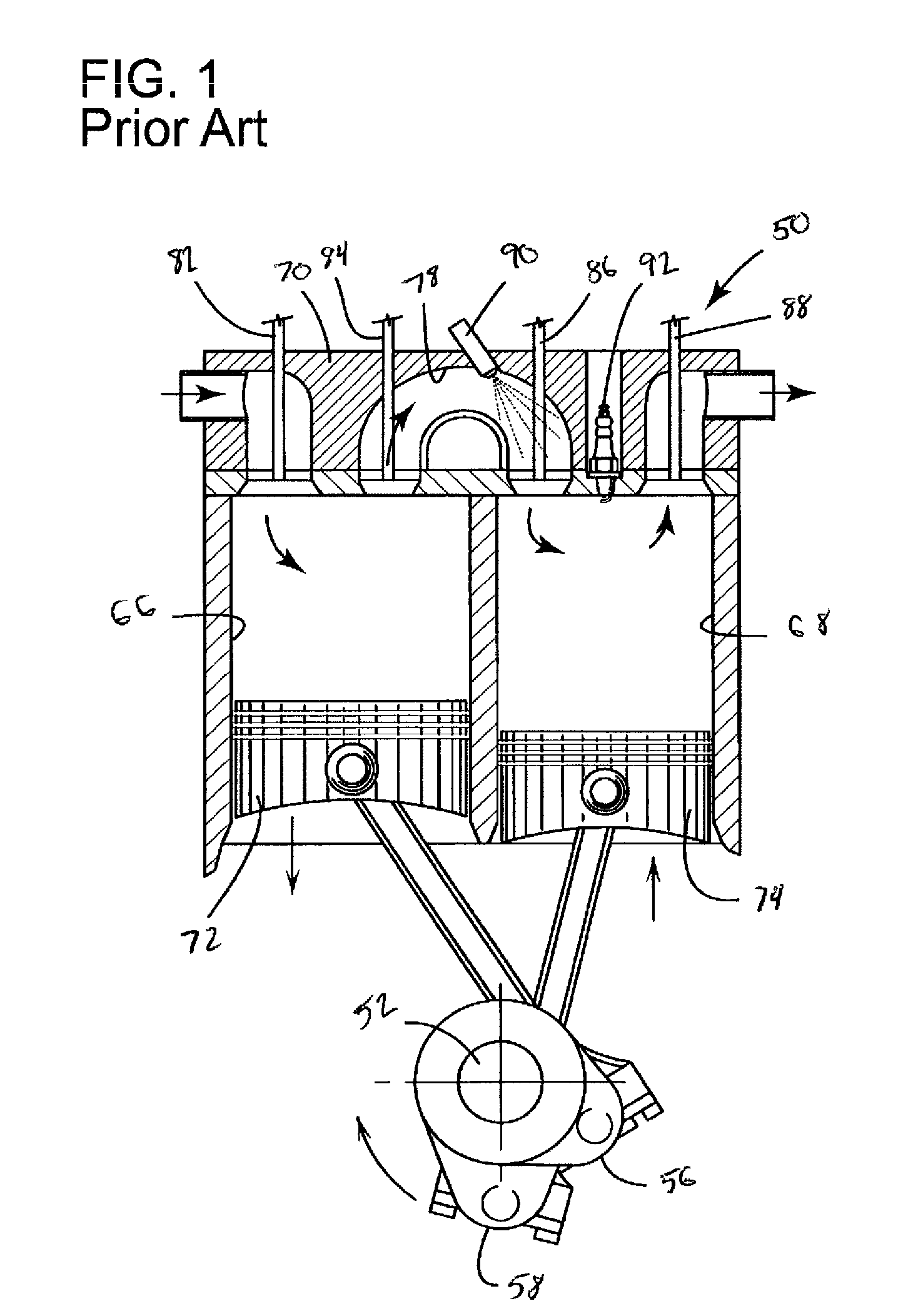

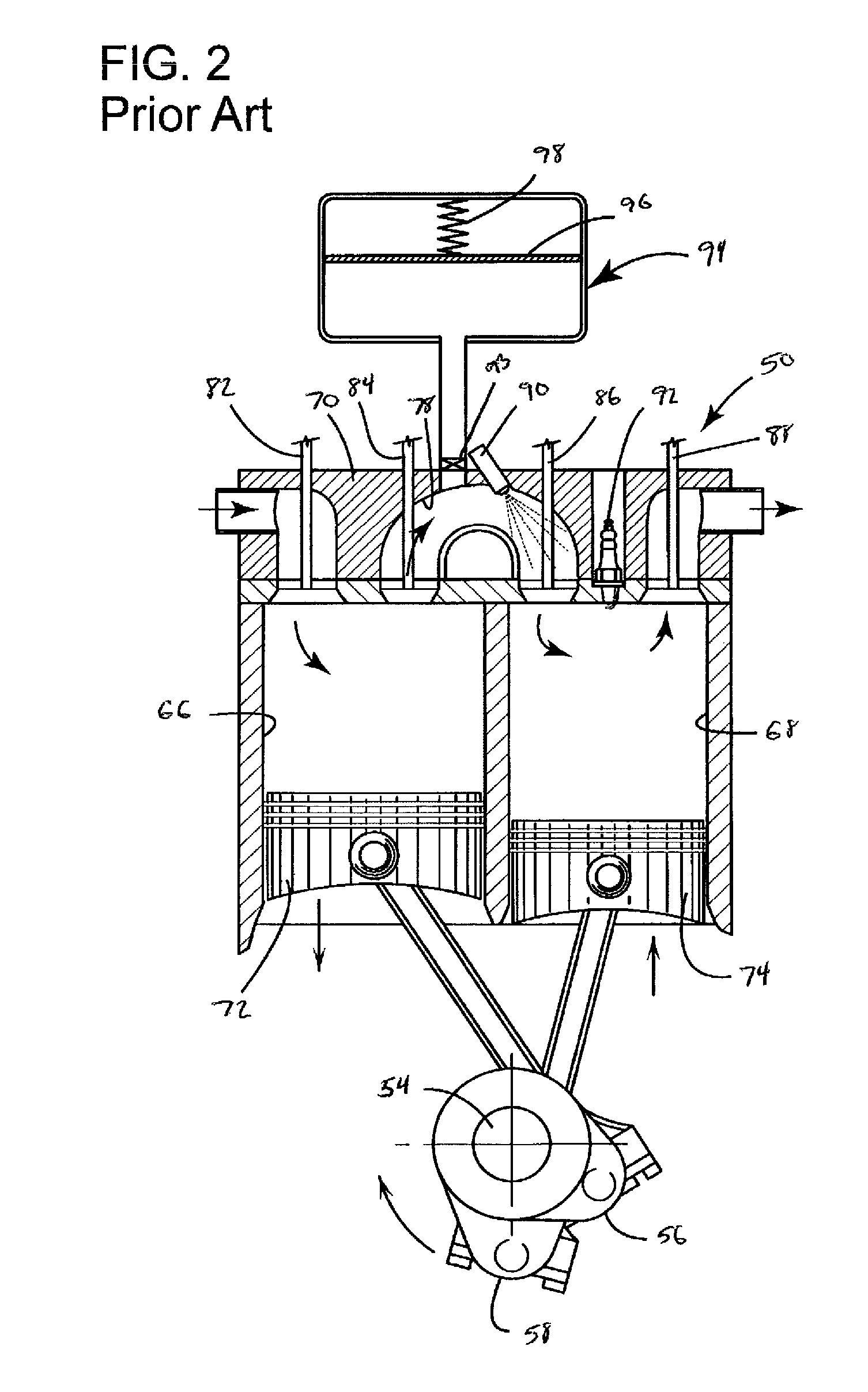

Stoichiometric High-Temperature Direct-Injection Compression-Ignition Engine

ActiveUS20150285139A1Electrical controlNon-fuel substance addition to fuelCombustion chamberExhaust valve

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

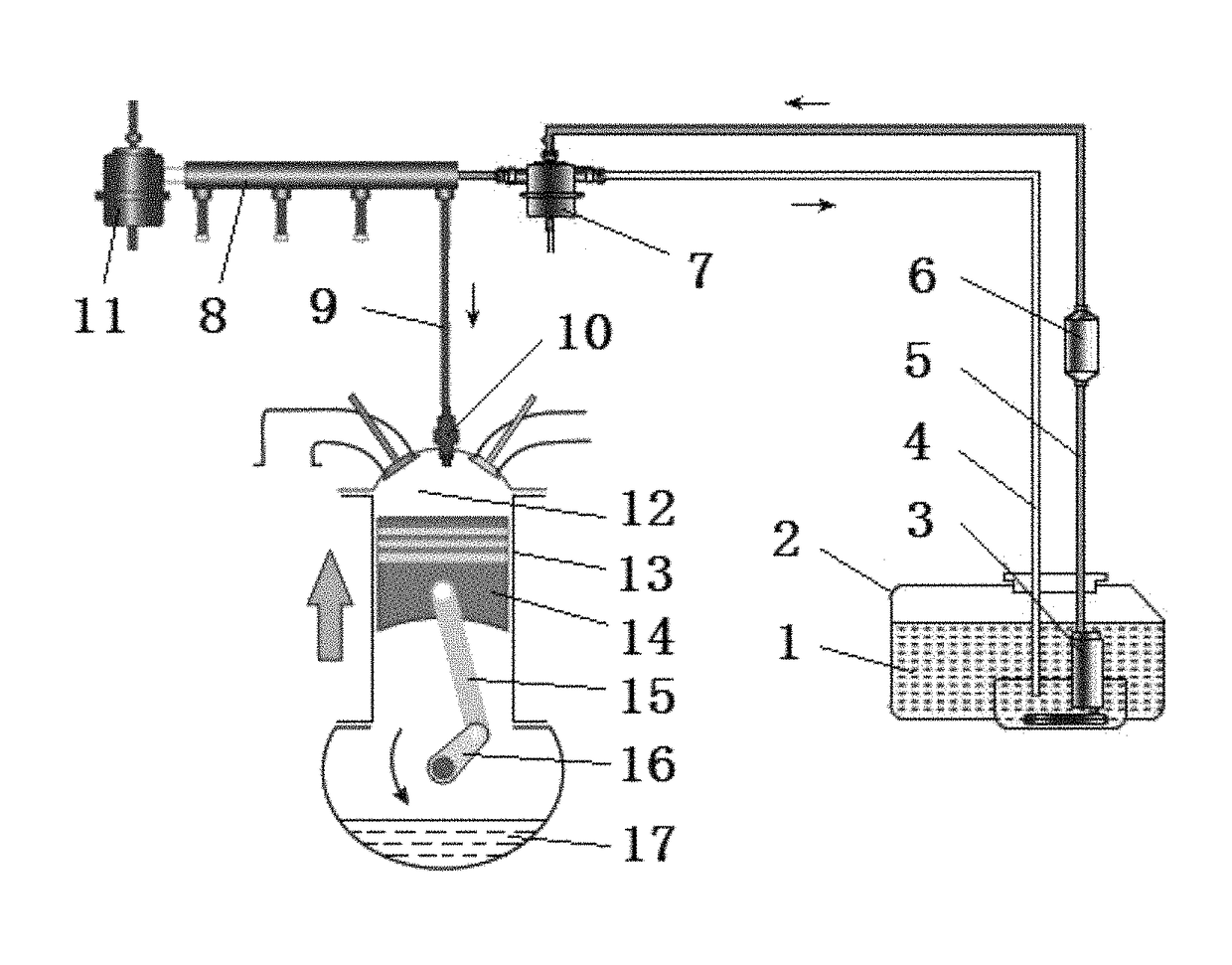

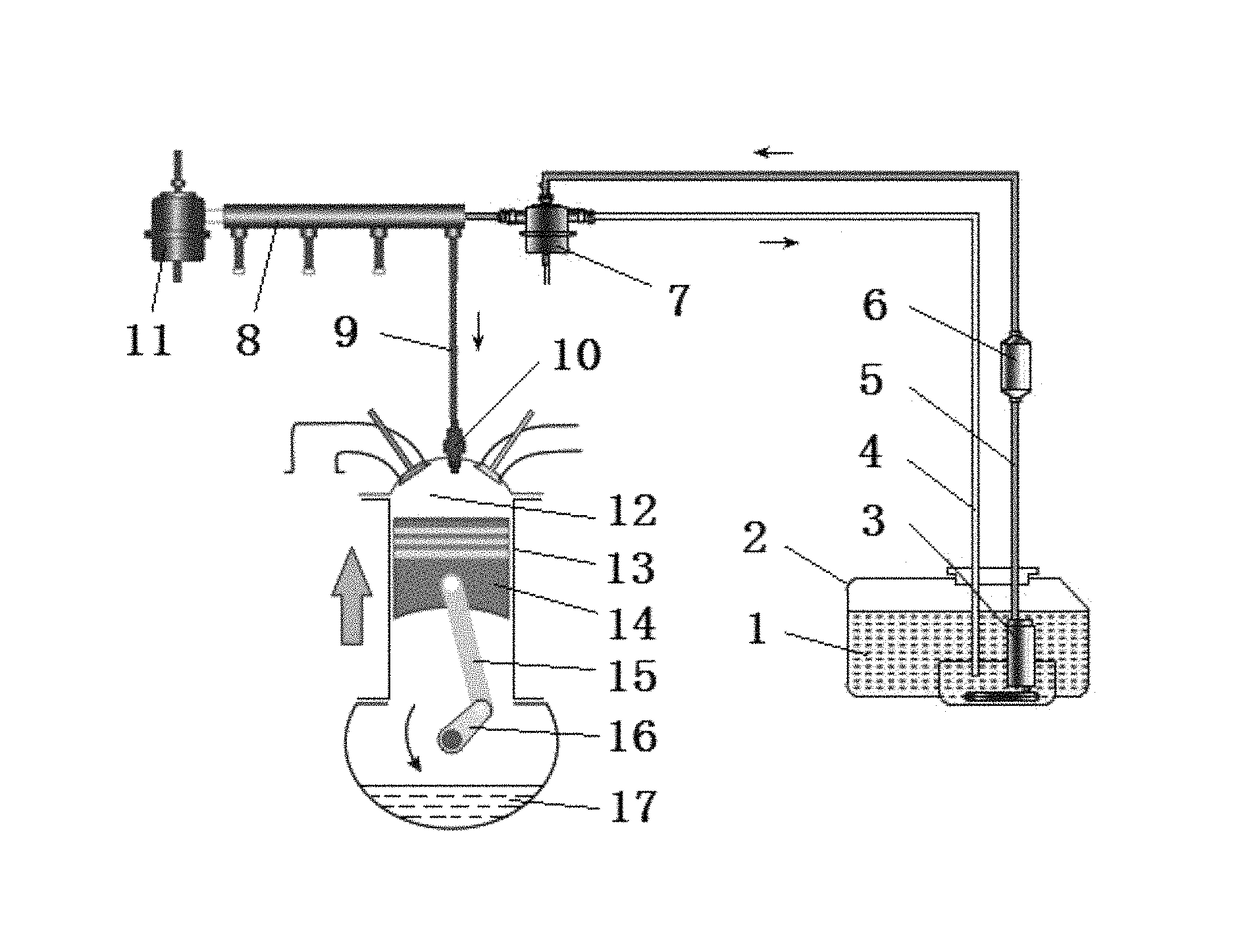

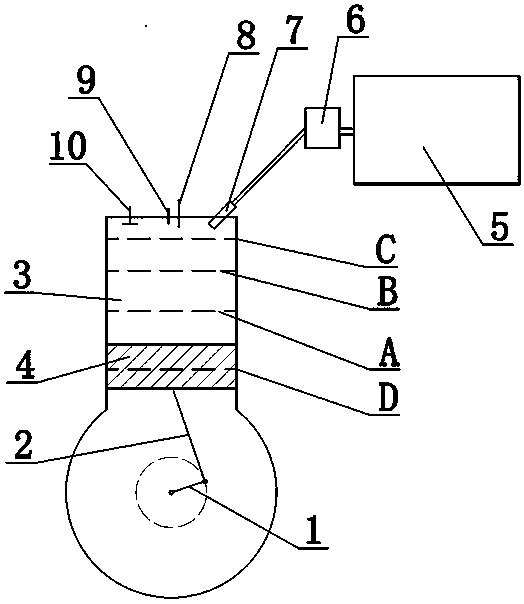

Compression-ignition low octane gasoline engine

ActiveUS20130160729A1Reduce injection pressureLow ignition temperatureElectrical controlNon-fuel substance addition to fuelFailure rateHomogeneous charge compression ignition

A compression-ignition low octane gasoline engine. The engine uses low octane gasoline and a compression-ignition method, does not require a spark plug, and compared with ordinary gasoline engines, increases thermal efficiency by approximately 40% and reduces green-house effects caused by emissions by approximately 45%. The “compression-ignition” of the low octane gasoline engine is a diffusion charge compression-ignition, differing from a homogeneous charge compression-ignition. The compression ratio in a cylinder can be 14 to 22, while an ordinary gasoline engine has a compression ratio of 7 to 11. The low octane gasoline engine has a simple structure, easy combustion control, a low noise level, and a low failure rate. As the low octane gasoline can be free of aromatic hydrocarbons, and not require the addition of antiknock agents such as MTBE and MMT, the present novel gasoline engine is a highly efficient, clean, and environmentally friendly internal combustion engine.

Owner:ZHOU XIANGJIN

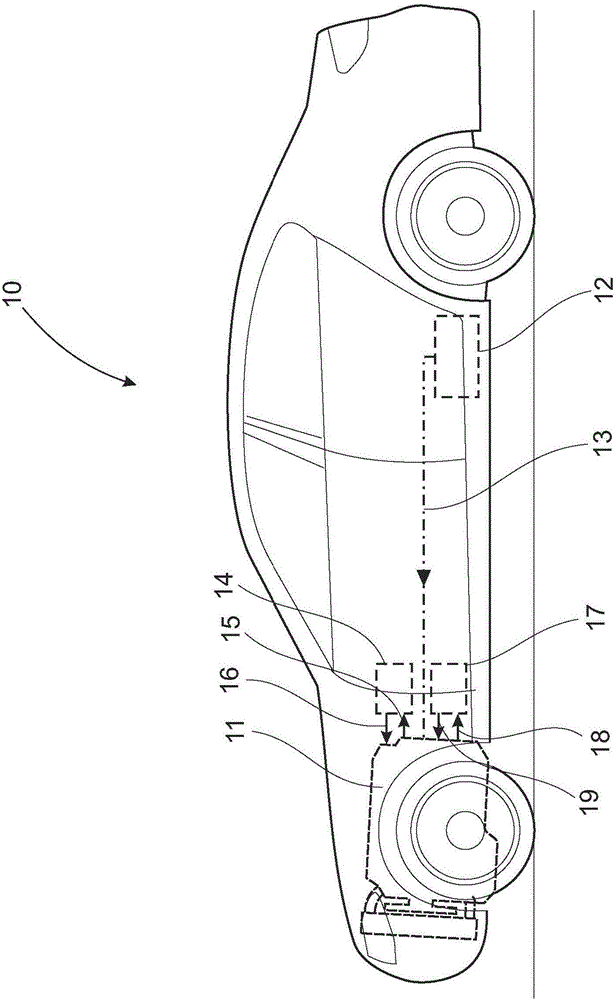

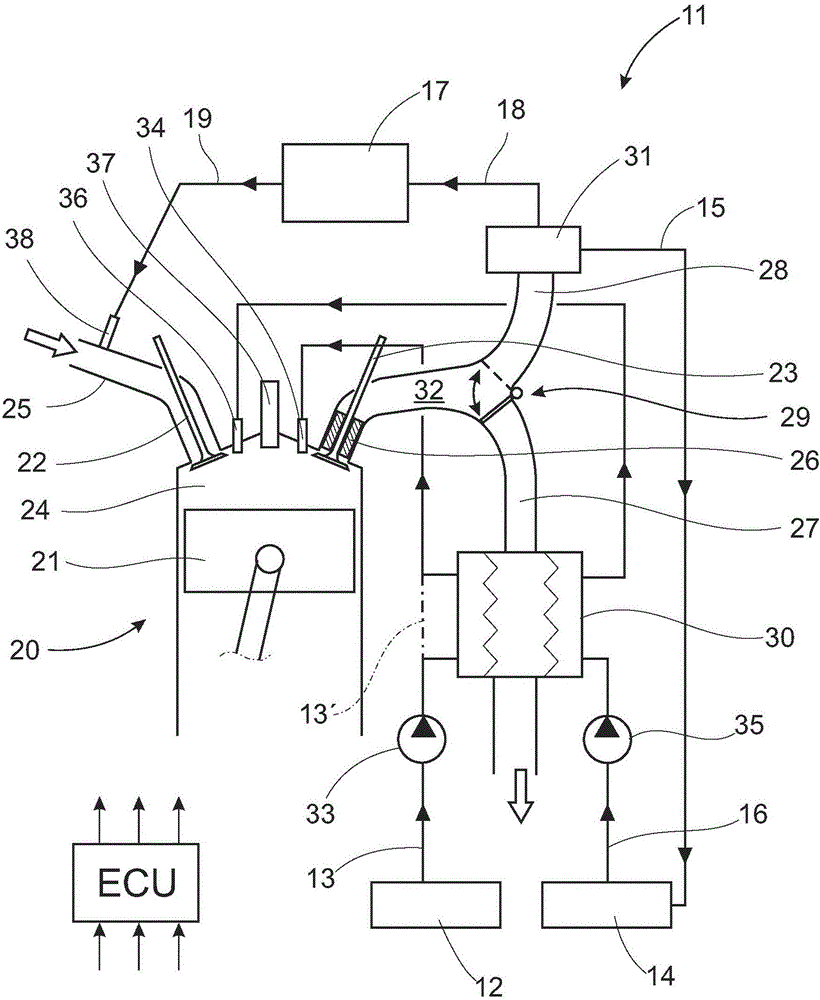

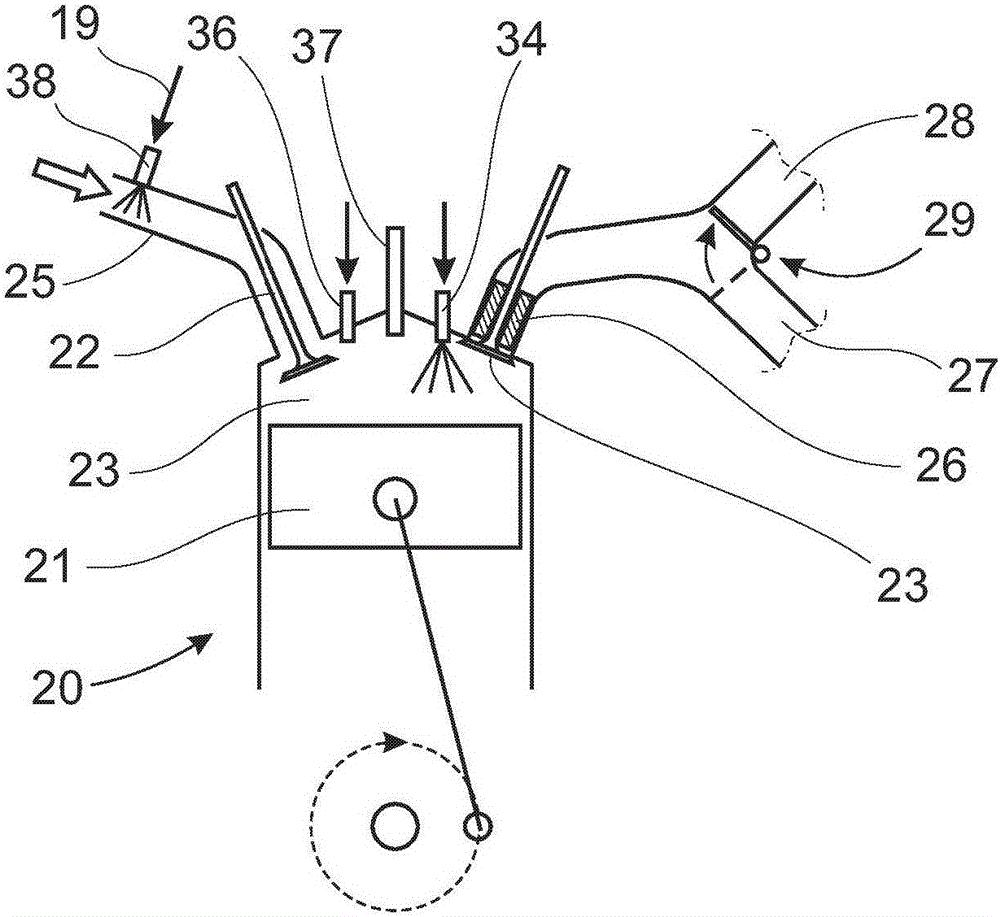

Internal combustion engine and method for controlling such internal combustion engine

ActiveCN106168161AHigh thermal efficiencyElectrical controlInternal combustion piston enginesExternal combustion engineReciprocating motion

The disclosure relates to a method for operating an internal combustion engine in a six-stroke mode, wherein the engine comprises at least one cylinder (20) with a reciprocating piston (21), each cylinder having at least one inlet and outlet valve (22, 23). The method involves performing a first stroke where a gas comprising at least air is induced into a combustion chamber (24) from an intake conduit (25); a second stroke where the gas and injected fuel is compressed; a third stroke where the compressed fuel / gas mixture is expanded following an ignition; a fourth stroke where combusted exhaust gas is expelled through a catalyst body (26) into a first exhaust conduit (27); a fifth stroke where pressurized fuel and pressurized heated water is injected into the combustion chamber (24) to be expanded; and a sixth stroke where steam and gaseous fuel mixture is expelled through the catalyst body (26) into a second exhaust conduit (28).

Owner:VOLVO CAR CORP

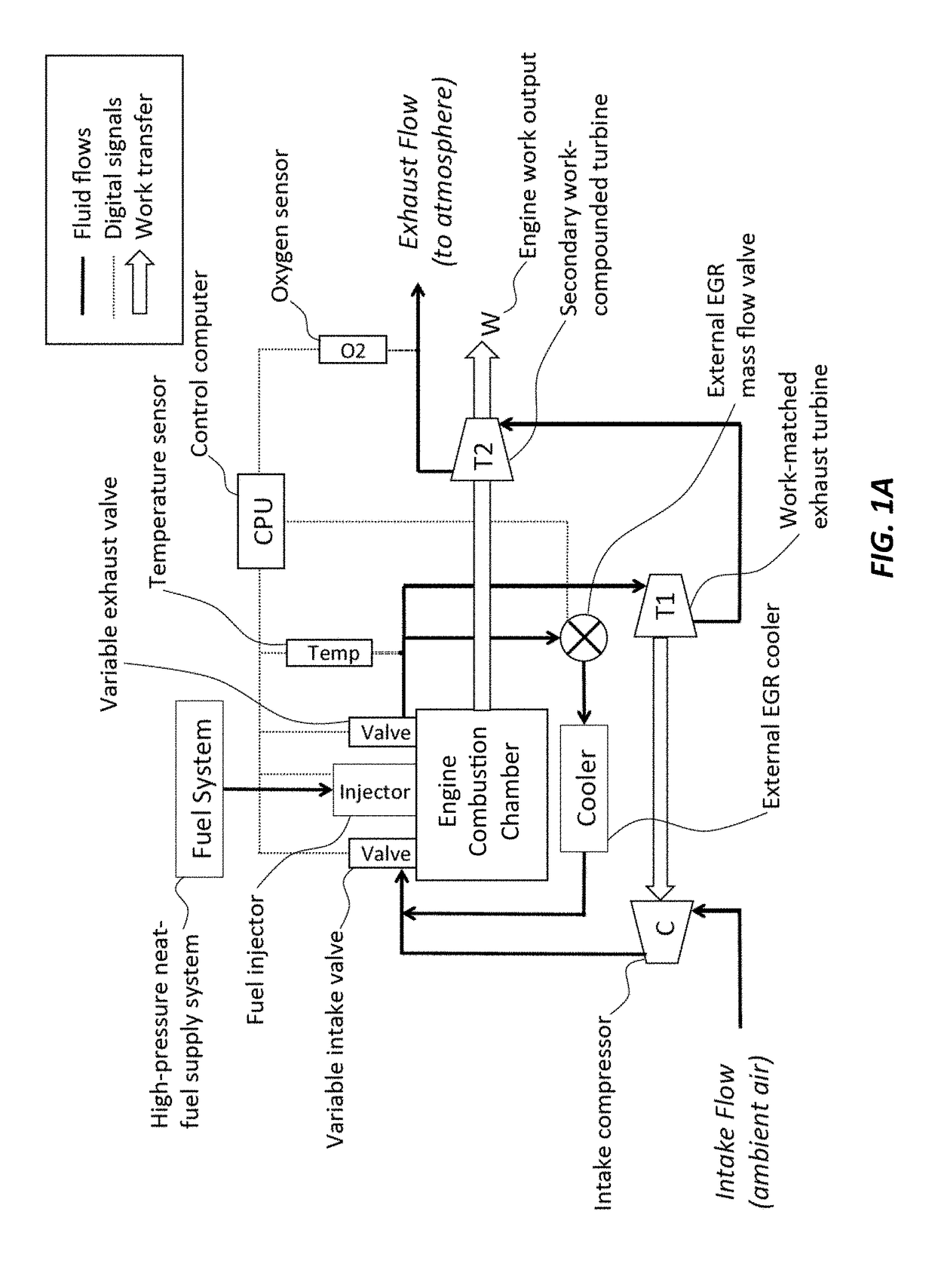

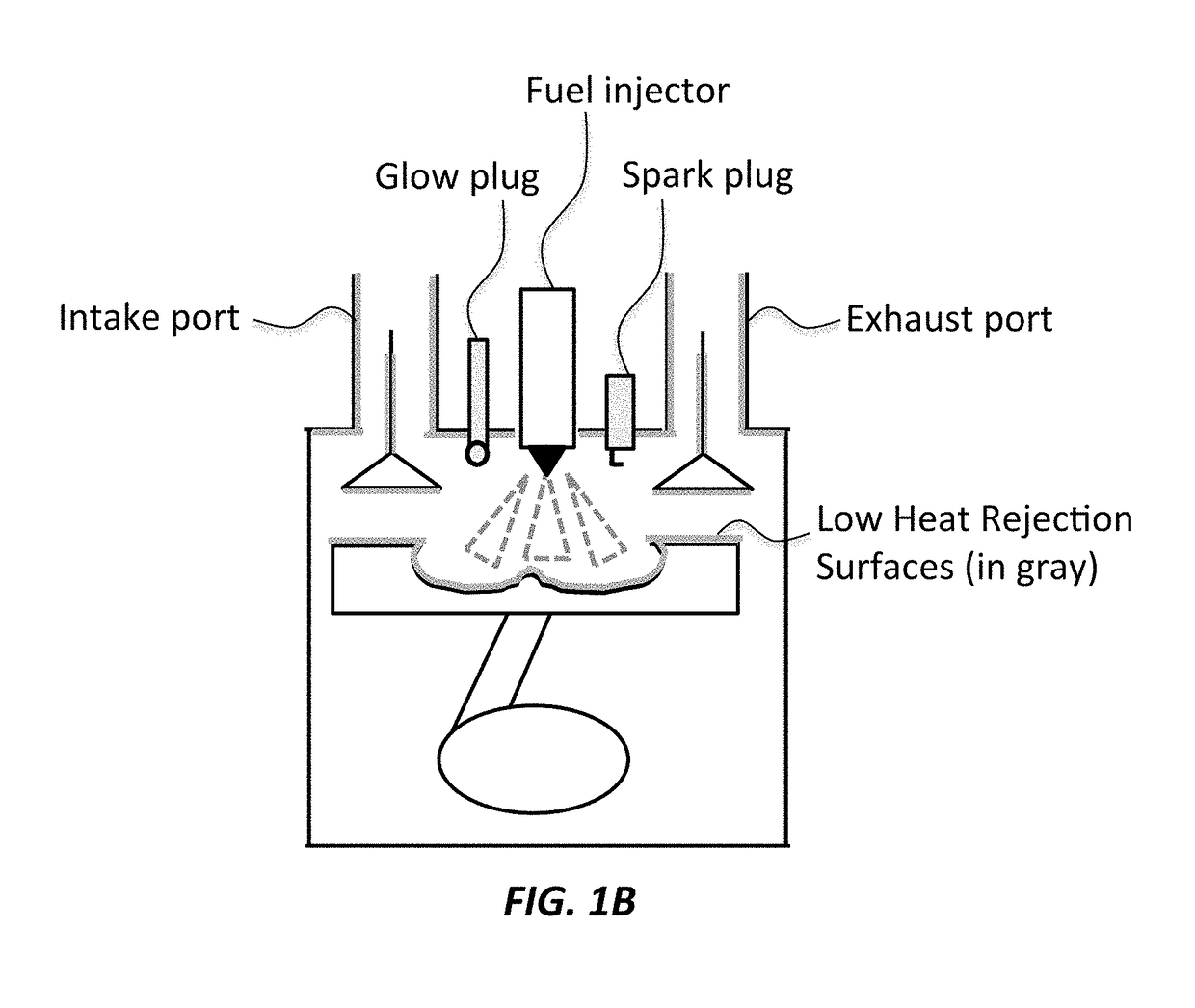

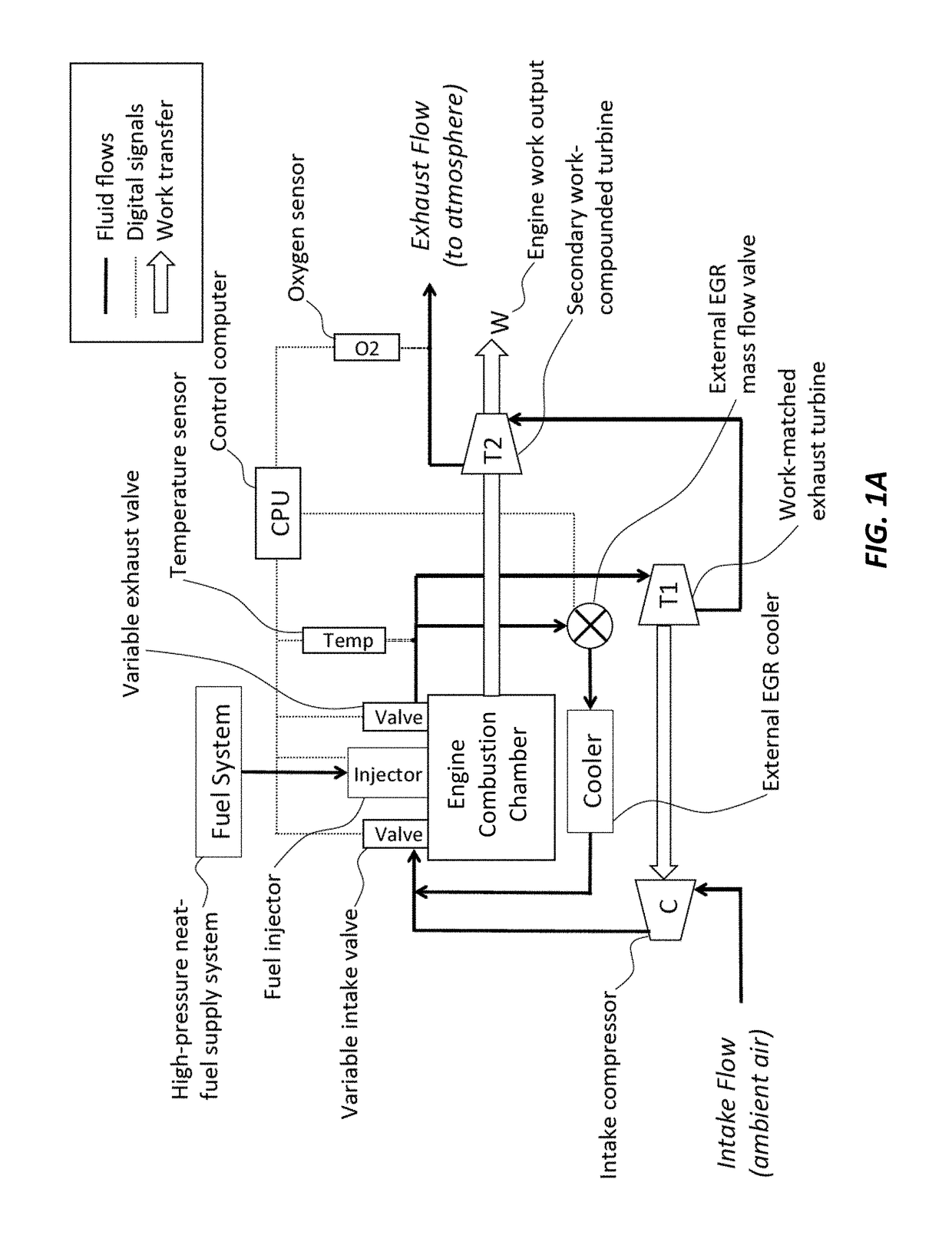

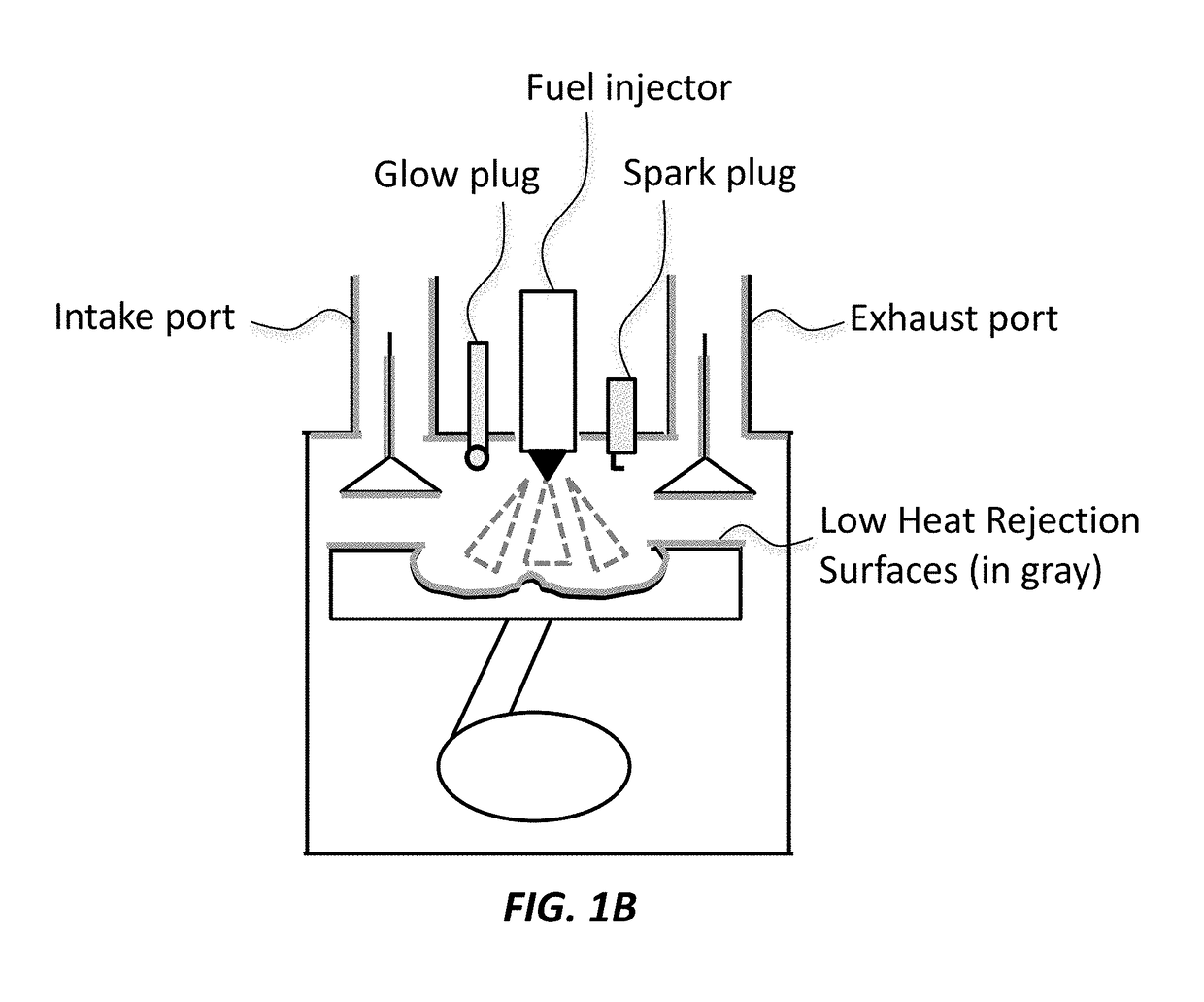

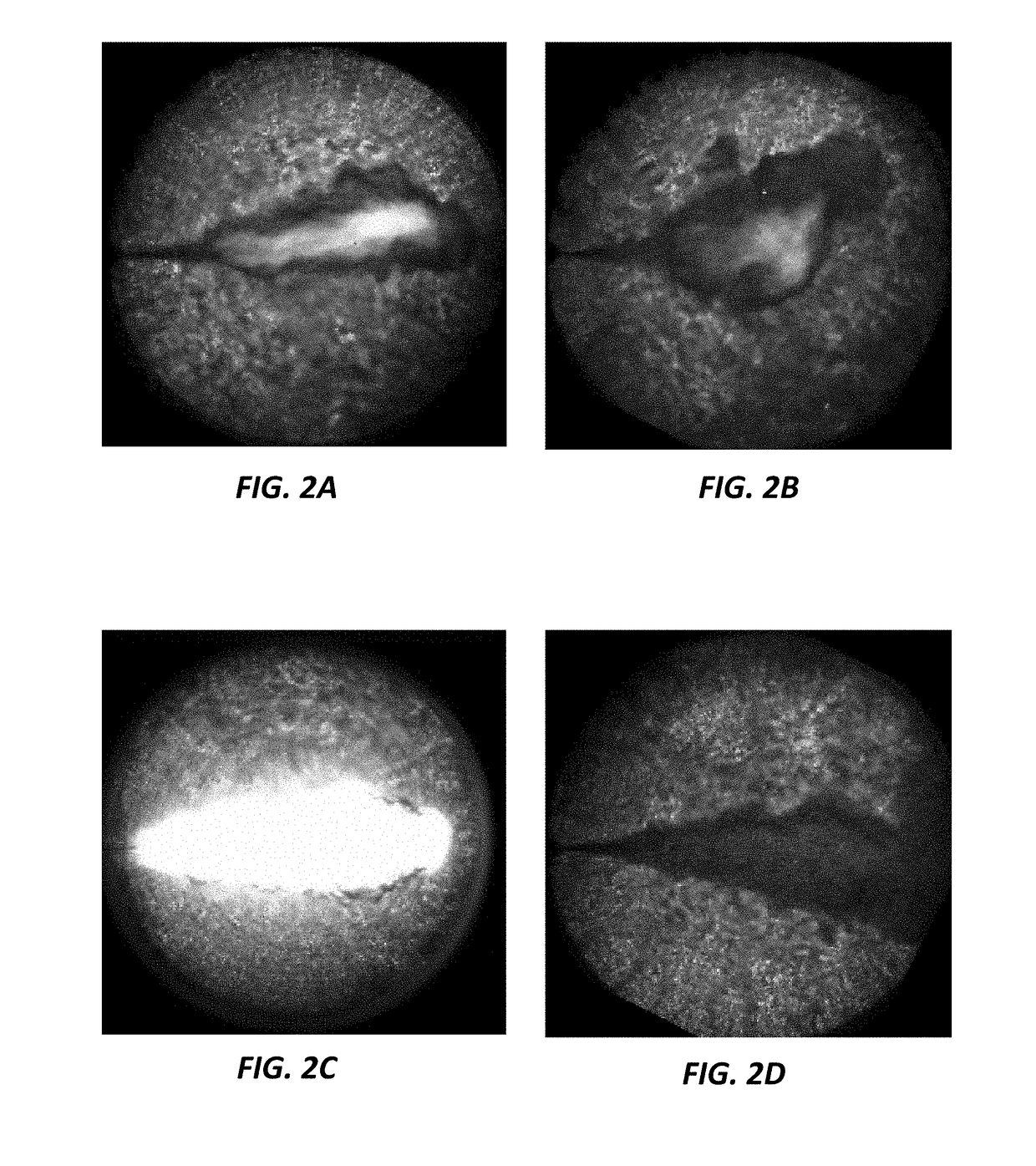

Stoichiometric High-Temperature Direct-Injection Compression-Ignition Engine

ActiveUS20180306098A1Electrical controlInternal combustion piston enginesCombustion chamberExhaust valve

A neat-fuel direct-injected compression ignition engine having a thermal barrier coated combustion chamber, an injection port injects fuel that satisfies a stoichiometric condition with respect to the intake air, a mechanical exhaust regenerator transfers energy from exhaust gas to intake compression stages, an exhaust O2 sensor inputs to a feedback control to deliver quantified fuel, a variable valve actuation (VVA) controls valve positions, an exhaust gas temperature sensor controls exhaust feedback by closing the exhaust valve early according to the VVA, or recirculated to the chamber with an exhaust-gas-recirculation (EGR), heat exchanger, and flow path connecting an air intake, a load command input, and a computer operates the EGR from sensors to input exhaust gas according exhaust temperature signals and changes VVA timing, the load control is by chamber exhaust gas, the computer operates a fuel injector to deliver fuel independent of exhaust gas by the O2 signals.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Uniflow engine with fluid flow arrangement

ActiveUS20170335752A1Minimize turbulenceMinimize heat transferInternal combustion piston enginesCylinder headsInlet channelEngineering

A uniflow engine includes a cylinder having a cylinder wall, an inlet channel, an extension of a central axis of the inlet channel first intersecting the cylinder wail in a first portion of the cylinder and next intersecting the cylinder wail in a second portion of the cylinder opposite the first portion of the cylinder, an intake air gallery, the intake air gallery having a gallery wall and being in flow communication with the inlet channel, and a plurality of intake ports extending between the cylinder wail and the gallery wall, at least some of the intake ports having different areas at the cylinder wall measured perpendicular to longitudinal axes of the intake ports, and wherein an area of at least one in take port in the first portion of the cylinder is larger than an area of at least one intake port in the second portion of the cylinder.

Owner:VOLVO LASTVAGNAR AB

Compound Transmission

InactiveUS20090031725A1Vibration minimizationEliminate torsional vibrations—atRotating vibration suppressionYielding couplingCouplingTransmitted power

An internal combustion engine comprises a turbo-compound and the known Föttinger-coupling is replaced by a torsion vibration damper. The Föttinger-coupling, which is used to transmit power, has high losses in power when it is necessary to have a differential rotational speed between the input side and the output side, i.e., the appearance of a slip. The losses are not used in a torsion vibration damper which has at least the same quality as a Föttinger-coupling.

Owner:SCHAEFFLER TECH AG & CO KG

Pedestal installed on cylinder body and turbocharger system for internal combustion engine

ActiveCN101614150AReduce noise featuresCylinder headsCombustion enginesTurbochargerInternal combustion engine

The invention relates to a pedestal installed on a cylinder body and a turbocharger system for an internal combustion engine. The invention provides a turbocharger system of an internal combustion engine. The system comprises a turbocharger system with a practical pedestal, wherein the practical pedestal extends between the turbocharger and a hard point associated with the cylinder body. The practical pedestal comprises a mounting pad which connects the combined turbocharger and pedestal assembly to the engine, an inner lubricating oil supply passage and a coolant supply passage which supply the pressurized lubricating oil and coolant to the turbocharger. According to the invention, the turbocharger system can be directly connected to the cylinder body of the internal combustion engine, so as to reduce external pipes and noise of the turbocharger.

Owner:FORD GLOBAL TECH LLC

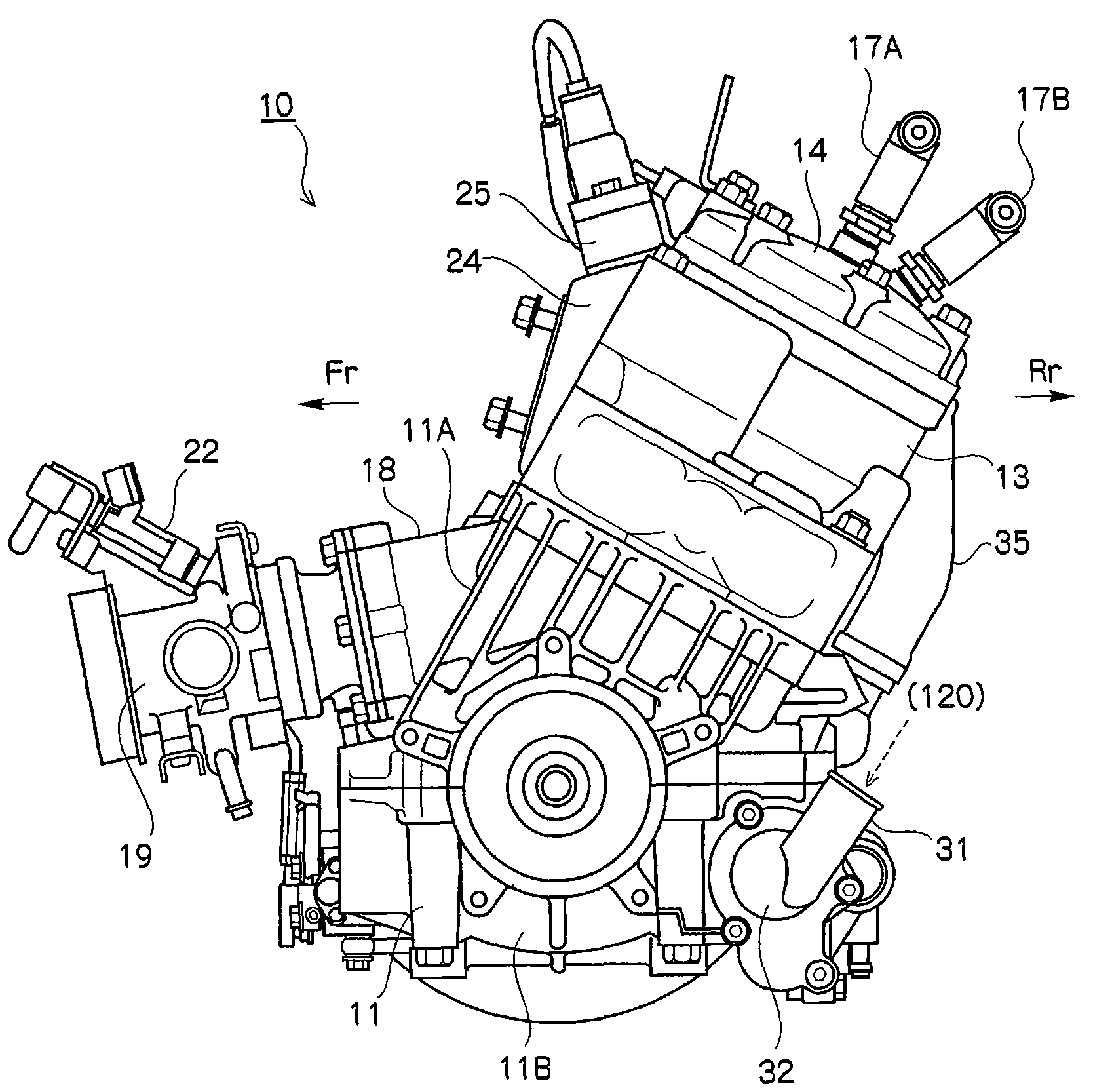

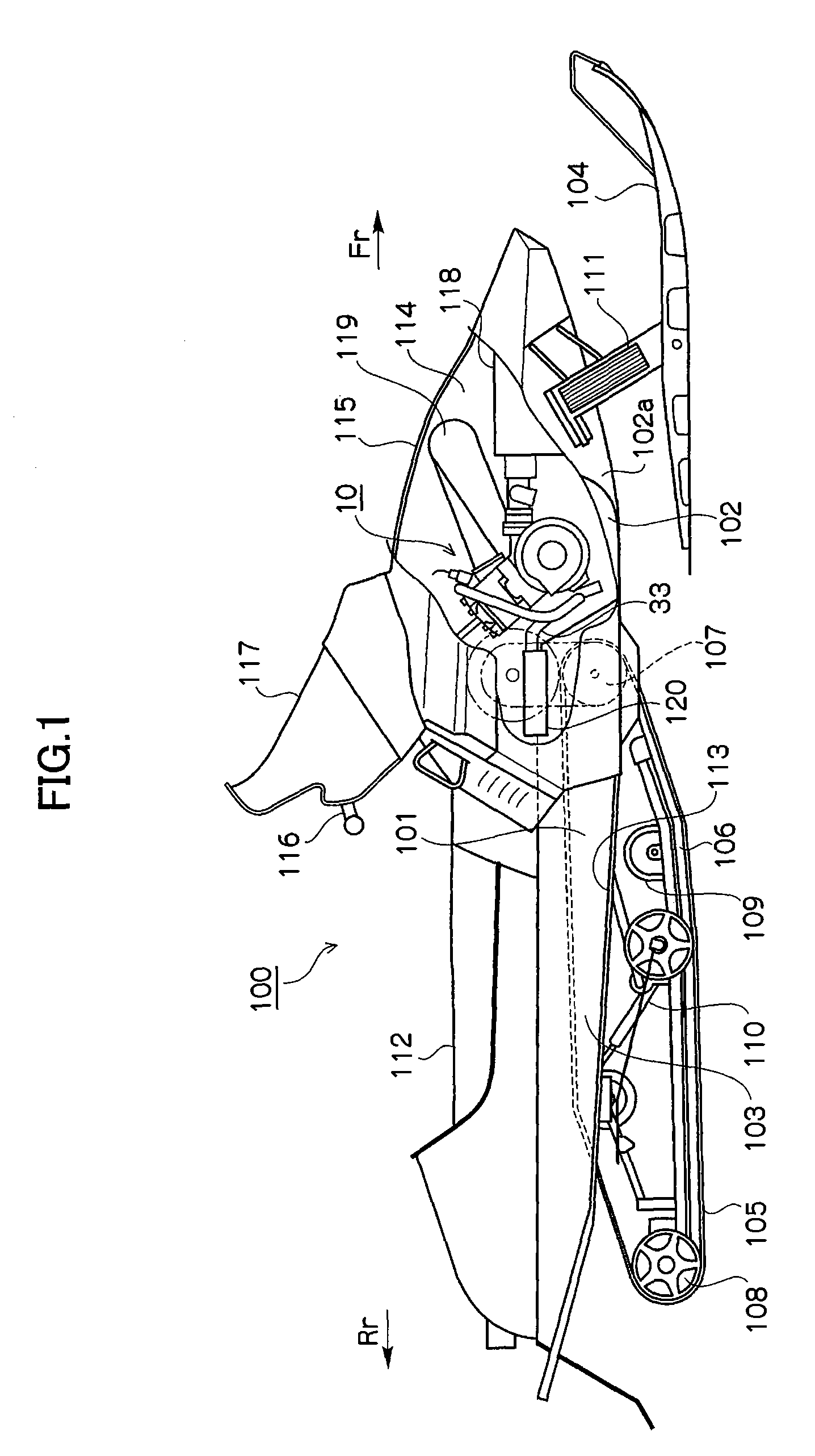

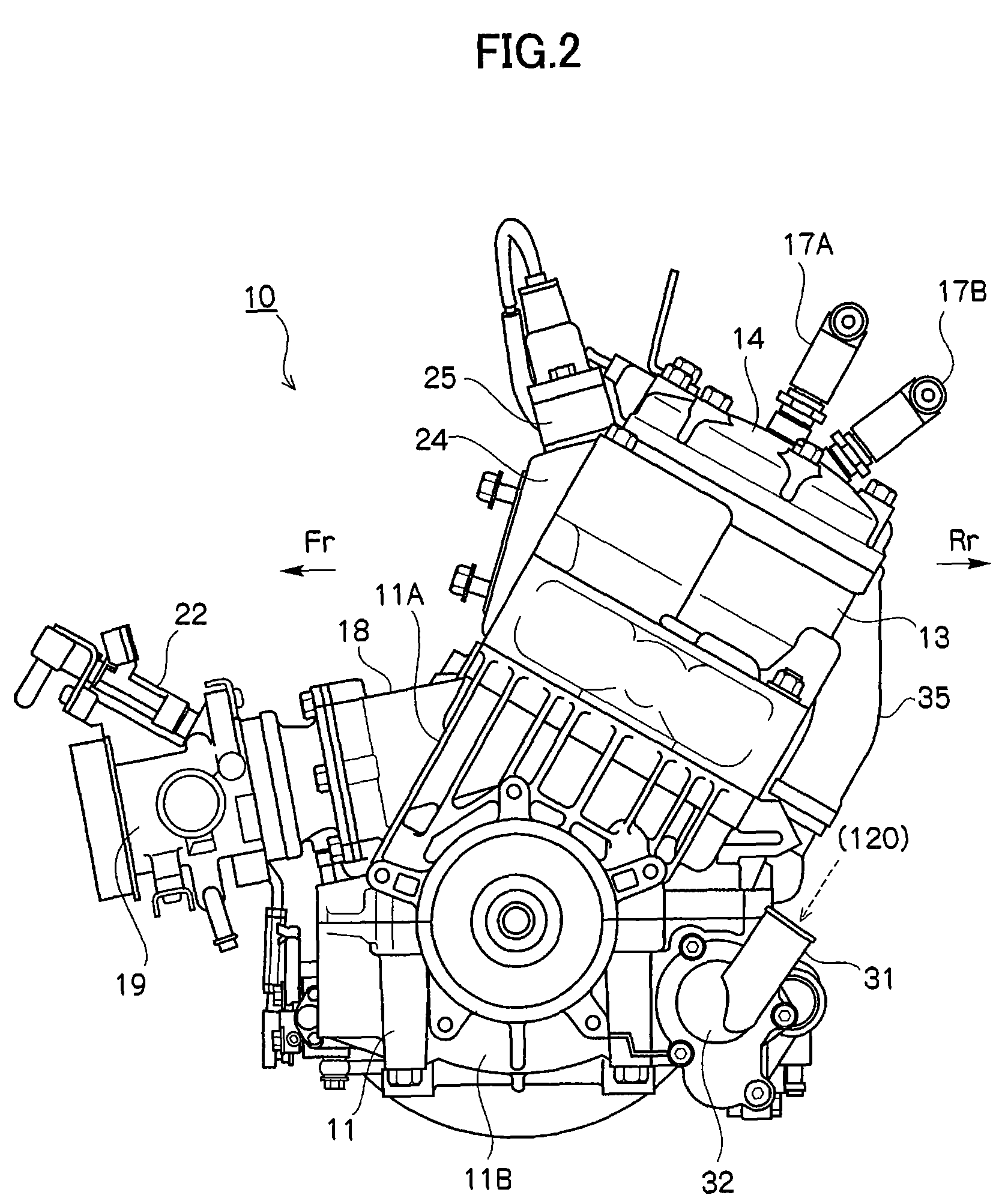

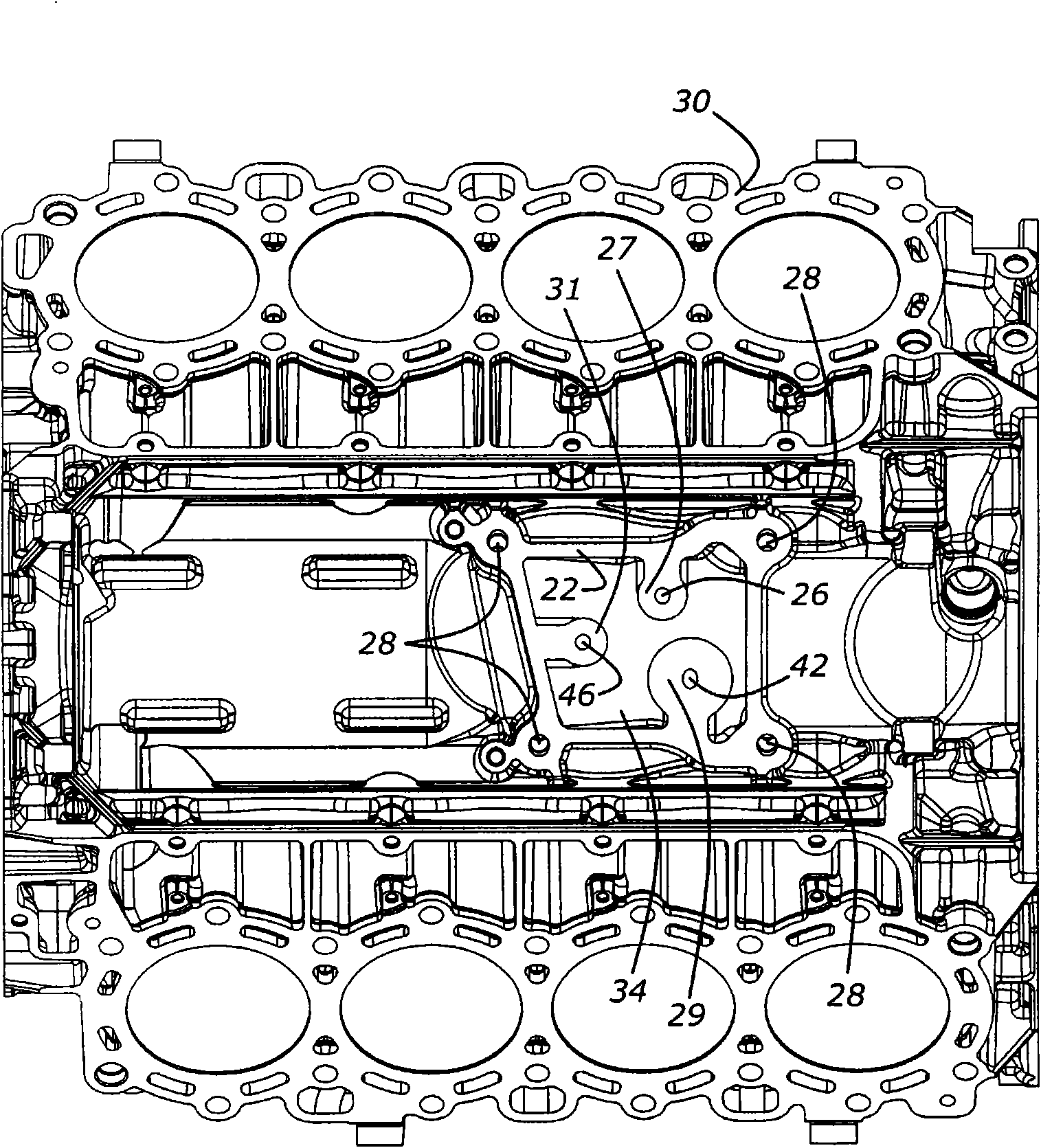

Water-cooled two-cycle engine

ActiveUS7278382B1Promote combustionImprove cooling effectAir coolingCylinder headsWater dischargeCylinder head

A cooling structure of a water-cooled two-cycle parallel multicylinder engine includes: an exhaust port in a cylinder block; an air intake port disposed in a crankcase below the exhaust port; a water pump disposed in the crankcase in an opposite side of the exhaust port; a first cooling water passage introducing cooling water discharged from the water pump to a cooling water jacket of a cylinder head; and a second cooling water passage introducing a part of the cooling water discharged from the water pump to a cooling water jacket below the exhaust port, the second cooling water passage being provided in the crankcase.

Owner:SUZUKI MOTOR CORP

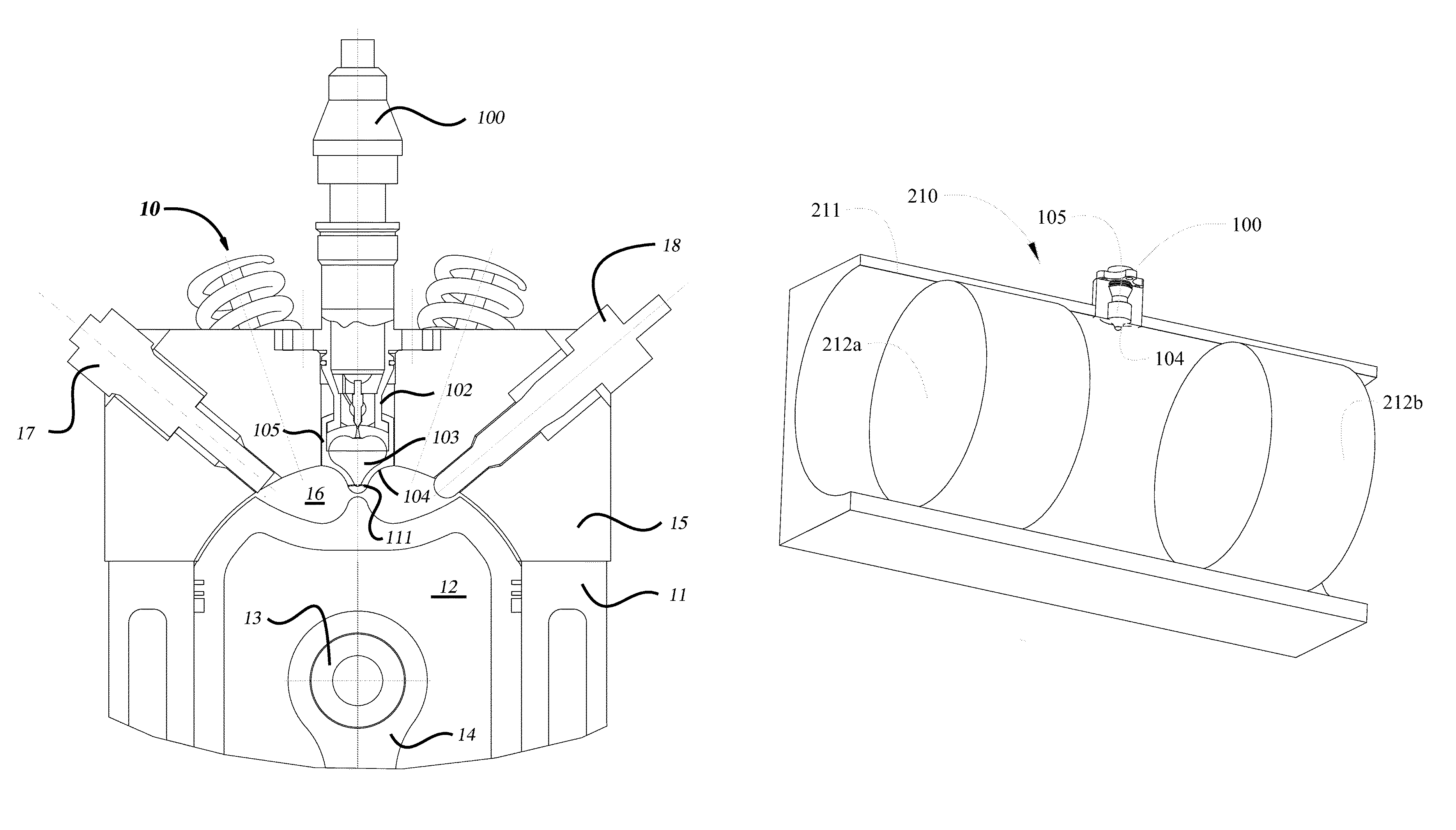

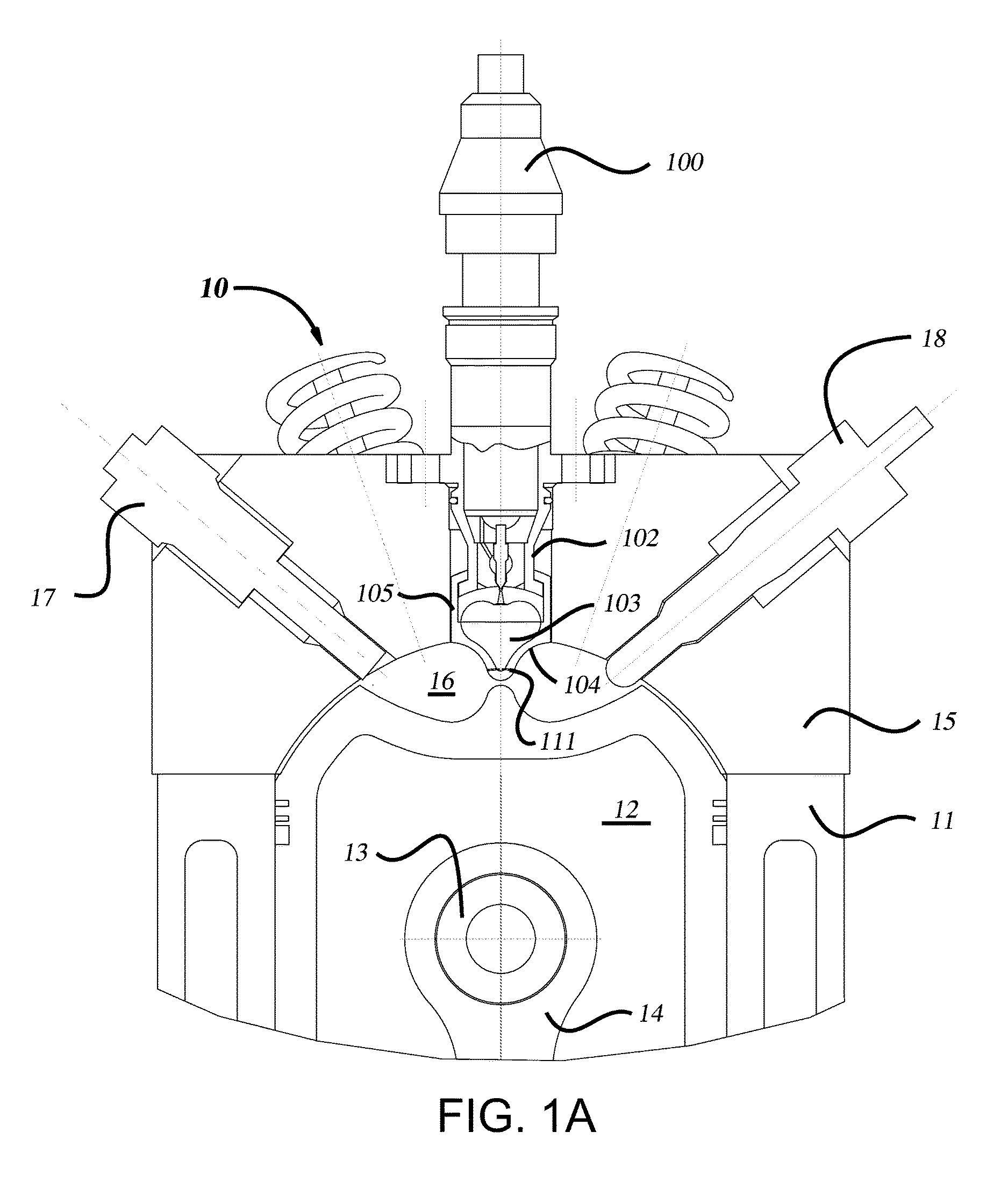

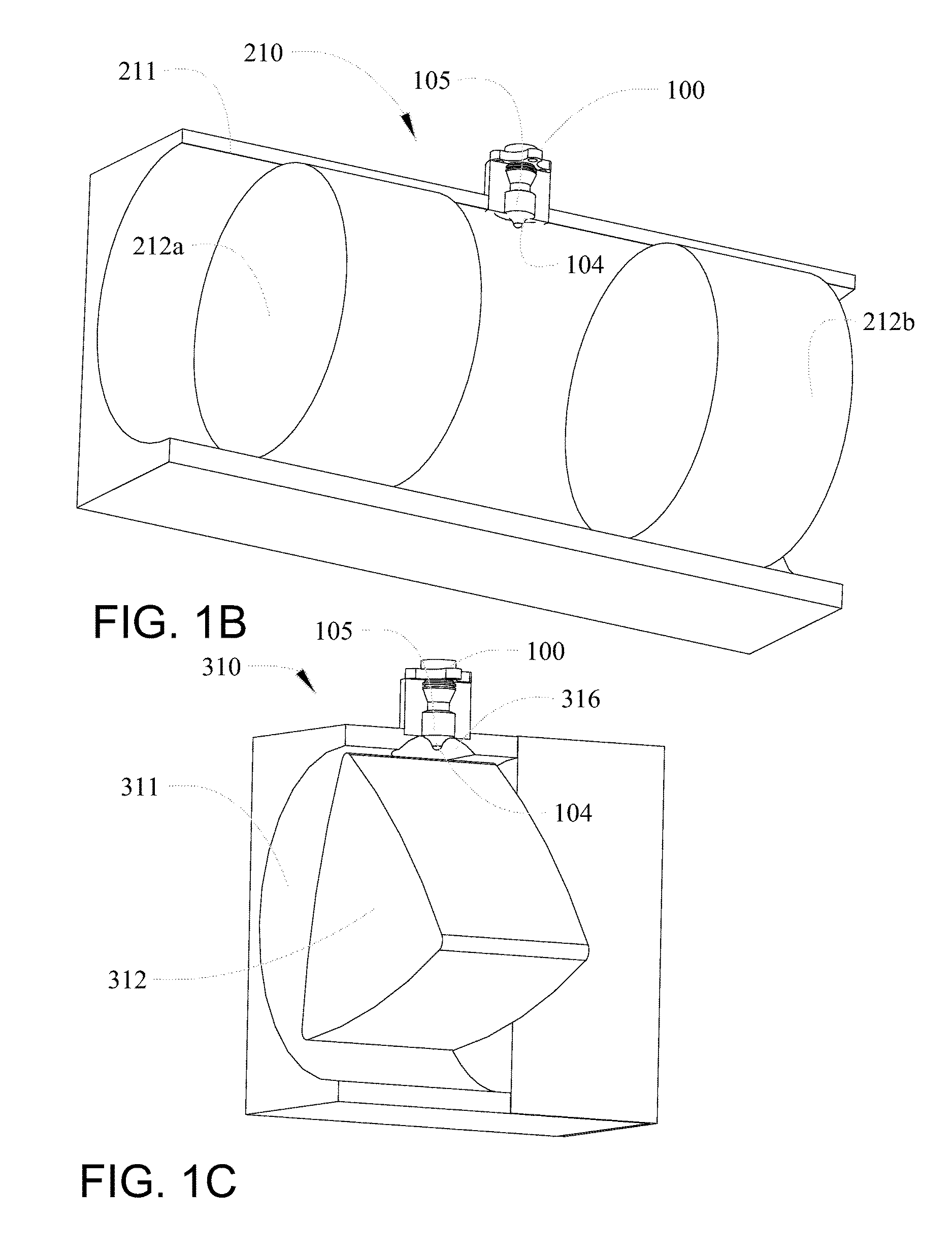

Adiabatic fuel injection-ignition method and device

An internal combustion engine having a combustion chamber incorporates a fuel conditioner and injector employs a vessel having a wall exposed within the combustion chamber to be heated by combusting fuel. The vessel encompasses an expansion chamber and has at least one open fuel injection passage through the wall into combustion chamber. An inlet conduit receives liquid fuel at a predetermined pressure from a fuel delivery system. A nozzle interconnects the inlet conduit and the expansion chamber. A pin operably seals the nozzle for timed injection of liquid fuel into the expansion chamber. An operator actuates the pin from a closed position sealing the nozzle to an open position placing the fuel injection volume in fluid communication with the expansion chamber. Liquid fuel injected into the expansion chamber at a predetermined time is simultaneously adiabatically heated, and pressurized to a state above a critical point using heat in the vessel wall and self-injects through the at least one open fuel injection passage into the combustion chamber of the engine.

Owner:SERGIN ALEXANDER

Air supply for components of a split-cycle engine

InactiveUS8763571B2Operating means/releasing devices for valvesCombustion enginesAir springPower component

The present invention generally relates to providing an air supply for components associated with an engine. More particularly, the present invention relates to a system and method for using compressed air generated by a split-cycle engine to power components such as valves or air springs associated with the split-cycle engine.

Owner:SKADERI GRUP LLC

Compression-ignition low octane gasoline engine

ActiveUS10072558B2Low ignition temperatureImprove heating efficiencyElectrical controlInternal combustion piston enginesLow noiseHomogeneous charge compression ignition

A compression-ignition low octane gasoline engine. The engine uses low octane gasoline and a compression-ignition method, does not require a spark plug, and compared with ordinary gasoline engines, increases thermal efficiency by approximately 40% and reduces green-house effects caused by emissions by approximately 45%. The “compression-ignition” of the low octane gasoline engine is a diffusion charge compression-ignition, differing from a homogeneous charge compression-ignition. The compression ratio in a cylinder can be 14 to 22, while an ordinary gasoline engine has a compression ratio of 7 to 11. The low octane gasoline engine has a simple structure, easy combustion control, a low noise level, and a low failure rate. As the low octane gasoline can be free of aromatic hydrocarbons, and not require the addition of antiknock agents such as MTBE and MMT, the present novel gasoline engine is a highly efficient, clean, and environmentally friendly internal combustion engine.

Owner:ZHOU XIANGJIN

Oxygen-injection double-stroke internal combustion engine and running method thereof

ActiveCN108869027AEliminate emissionsGuaranteed ventilation efficiencyLiquid engine fuelsEngine controllersExhaust valveExternal combustion engine

The invention discloses an oxygen-injection double-stroke internal combustion engine and a running method thereof. The oxygen-injection double-stroke internal combustion engine comprises a high-pressure oxygen pipe and a pressure stabilizing device; a high-pressure nozzle, a spark plug, an oil injector and an exhaust valve are fixed to the top end of the cylinder; the high-pressure oxygen pipe isconnected with the high-pressure nozzle; a pipeline where the high-pressure oxygen pipe is connected with the high-pressure nozzle is provided with the pressure stabilizing device; when the rotation angle of a crank is changed from 230 degrees to 360 degrees, a piston is sequentially subjected to compression, oil injection and spark plug ignition processes; and when the rotation angle of the crankis changed from 0 to 230 degrees, the piston sequentially does work and executes an exhausting process. According to the oxygen-injection double-stroke internal combustion engine disclosed by the invention, an existing four-stroke internal combustion engine is changed into a double-stroke internal combustion engine, a gas feed stroke is canceled, a compression stroke and an exhaust stroke of theoriginal four-stroke internal combustion engine are integrated as one stroke, thus zero emission of NOx is realized, and the emission load of HC is remarkably reduced.

Owner:ANYANG INST OF TECH

Turbocharger system with internally isolated turbocharger oil drainback passage

ActiveCN101614152AAvoid damageContact minimizationLiquid coolingCombustion enginesTurbochargerCrankcase

The invention relates to a turbocharger system with internally isolated turbocharger oil drainback passage. The invention provides a turbocharger system of an internal combustion engine. The system comprises a turbocharger system with a practical pedestal, wherein the practical pedestal extends between the turbocharger and a hard point associated with the cylinder body. The practical pedestal comprises a mounting pad which connects the combined turbocharger and pedestal assembly to the engine, an inner lubricating oil supply passage and a coolant supply passage which supply the pressurized lubricating oil and coolant to the turbocharger. The turbocharger system with internally isolated turbocharger oil drainback passage conveys waste oil from the turbocharger to a crankcase sump without permitting the waste oil to contact moving parts of the engine.

Owner:FORD GLOBAL TECH LLC

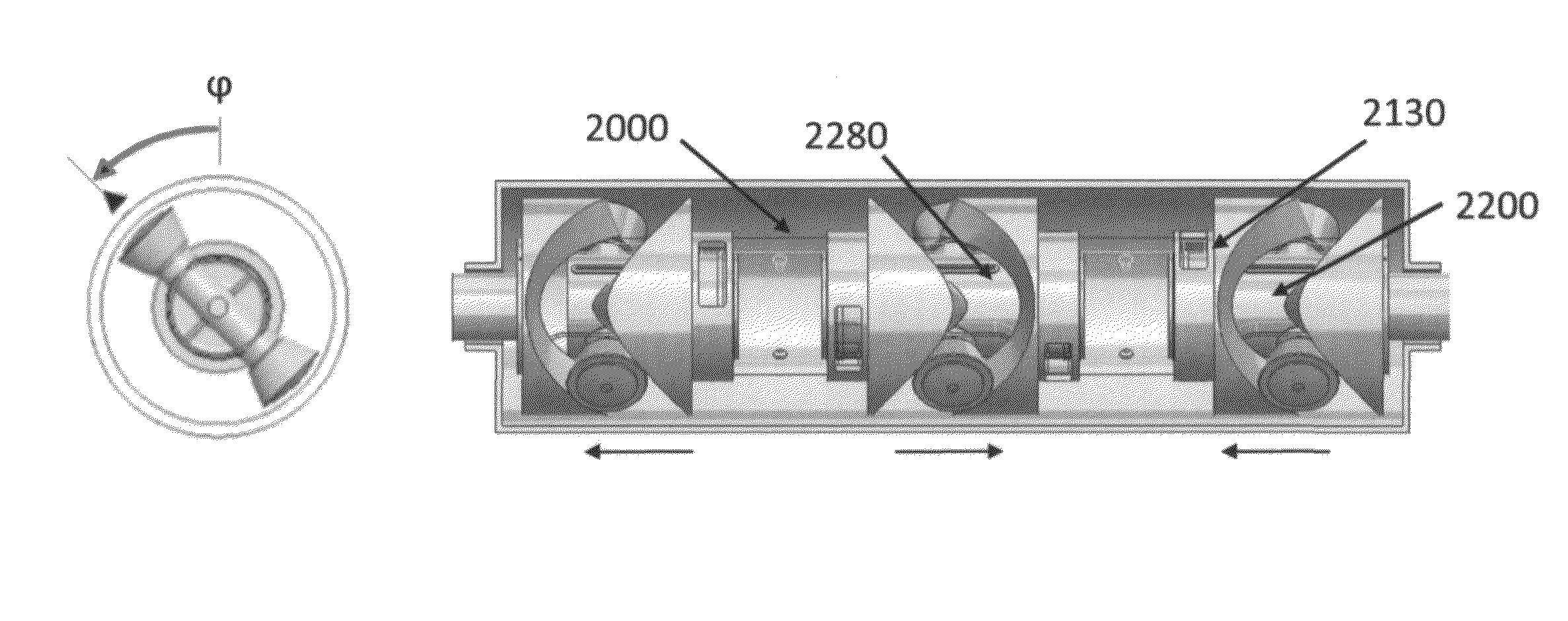

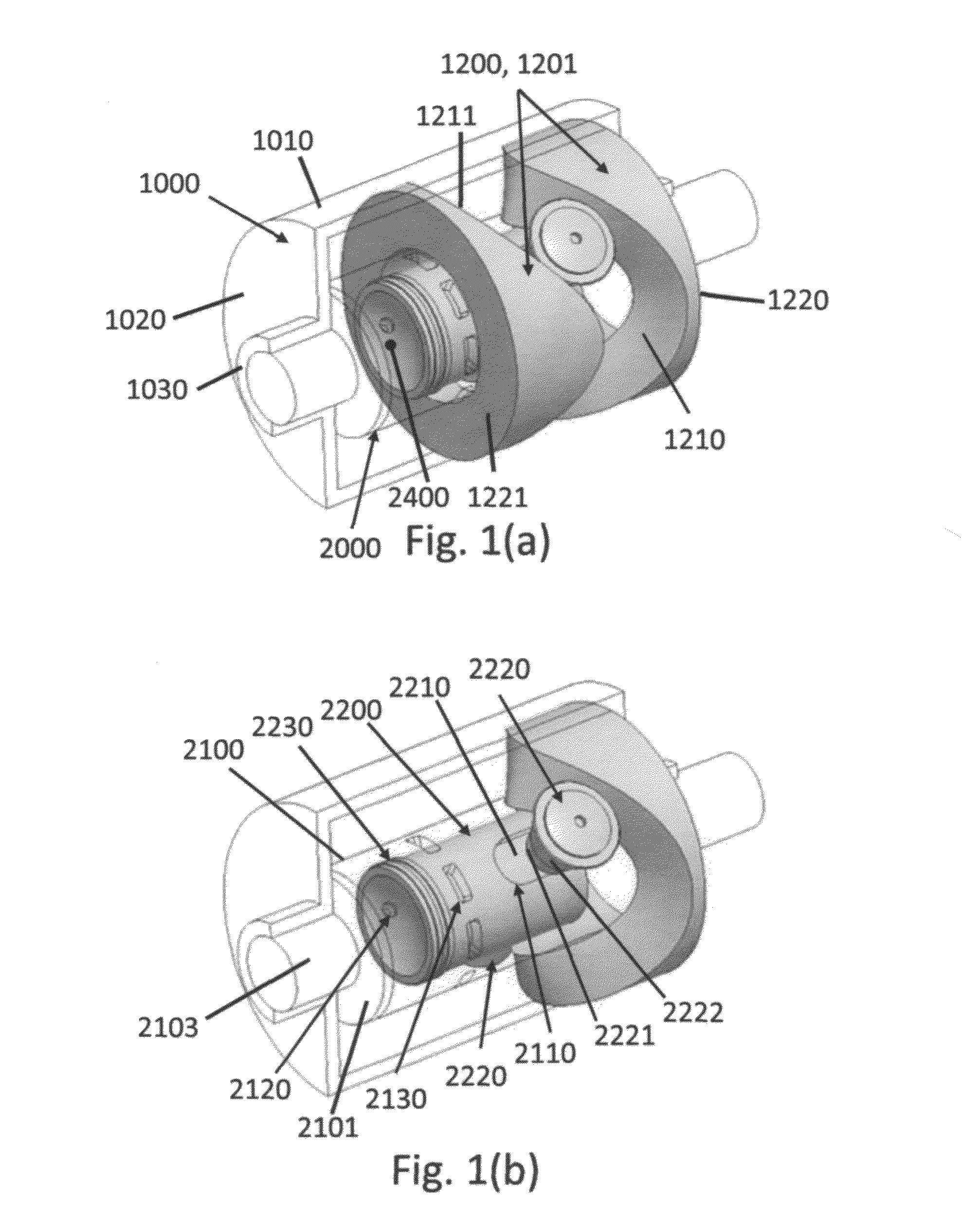

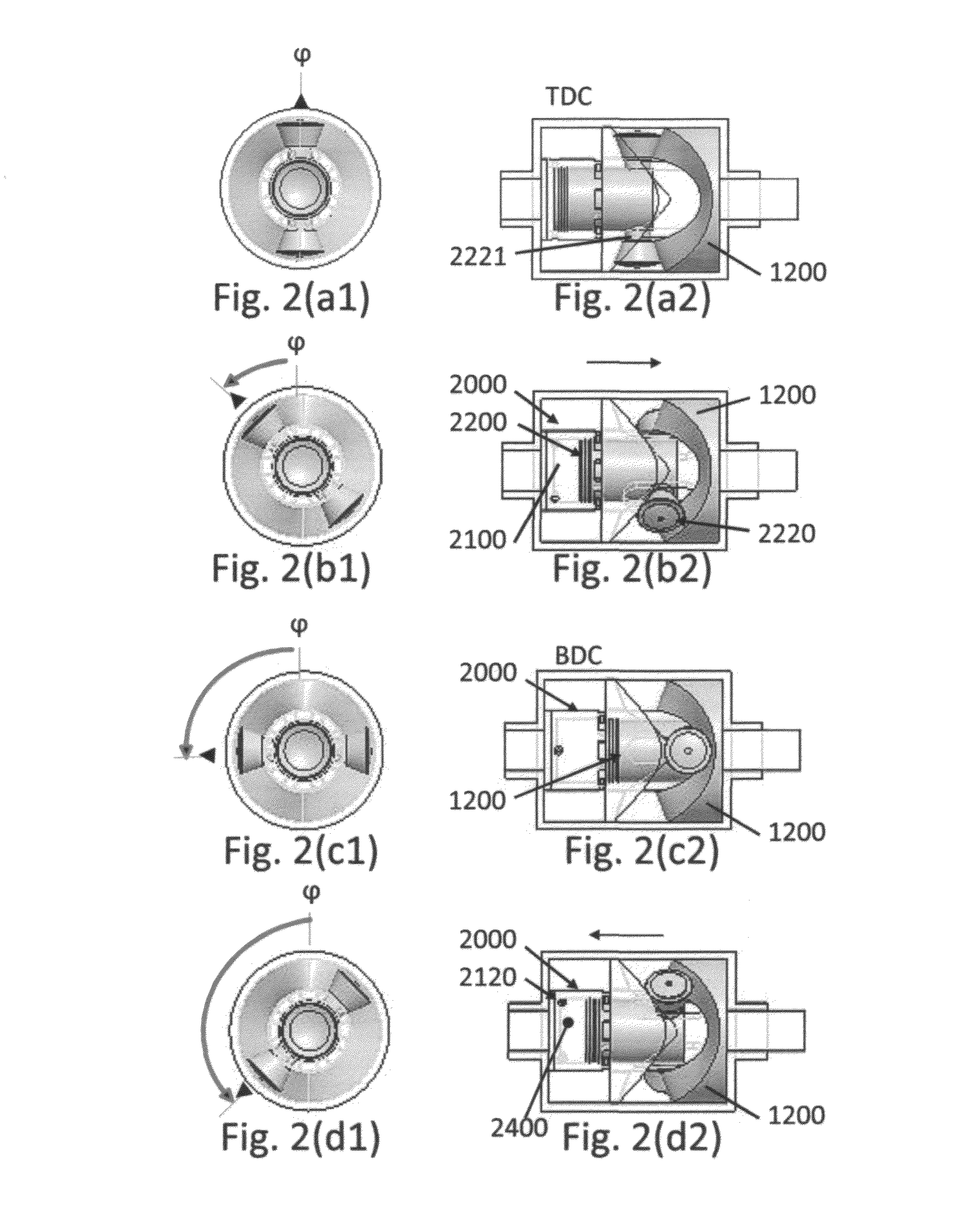

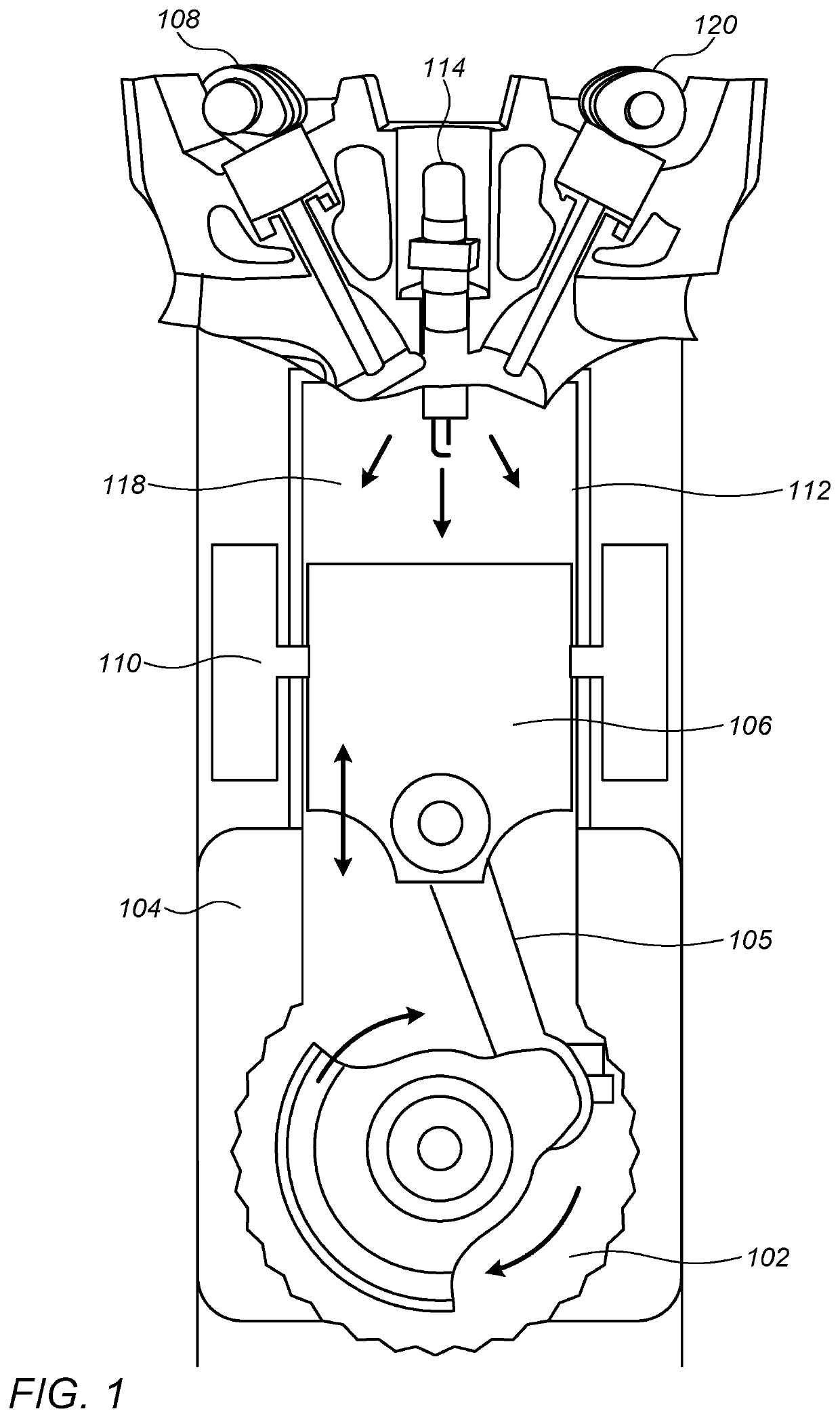

Barrel cam rotating cylinder engine

The present disclosure is directed toward implementations of internal combustion engines. The disclosure describes various embodiments of internal combustion engines where most of the internal elements rotate. Such engines allow for more efficient transfer of the energy created by combustion to the motive components of a vehicle such as wheels or propellers. One specific embodiment includes a rotating cylinder with a single piston which both reciprocates and rotates. The rotating motion of the piston is transferred to the cylinder, which in turn is connected to a driveshaft. Various embodiments of the invention employ differing numbers and configurations of pistons. All embodiments have the advantage of decreasing engine volume and increasing efficiency over traditional internal combustion engines.

Owner:MCNITT MARK

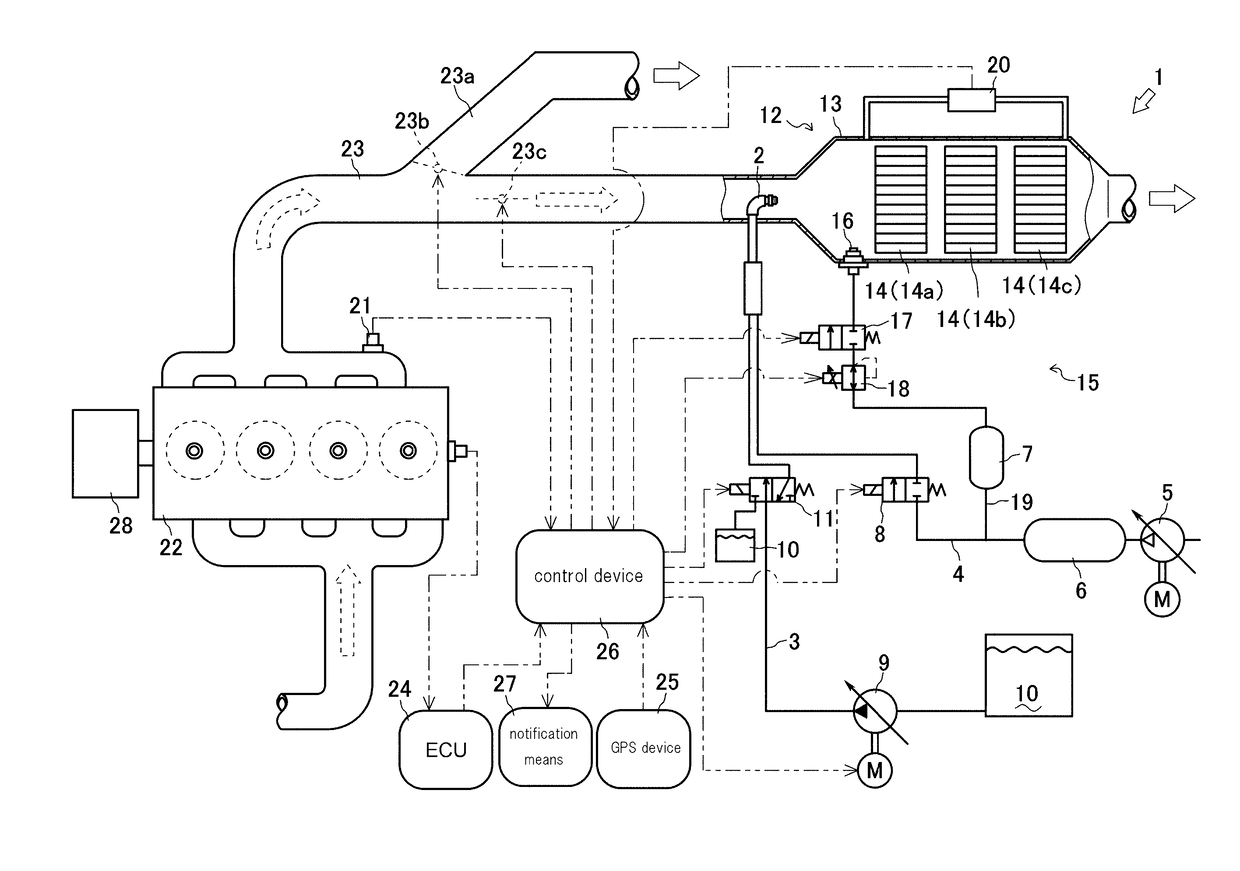

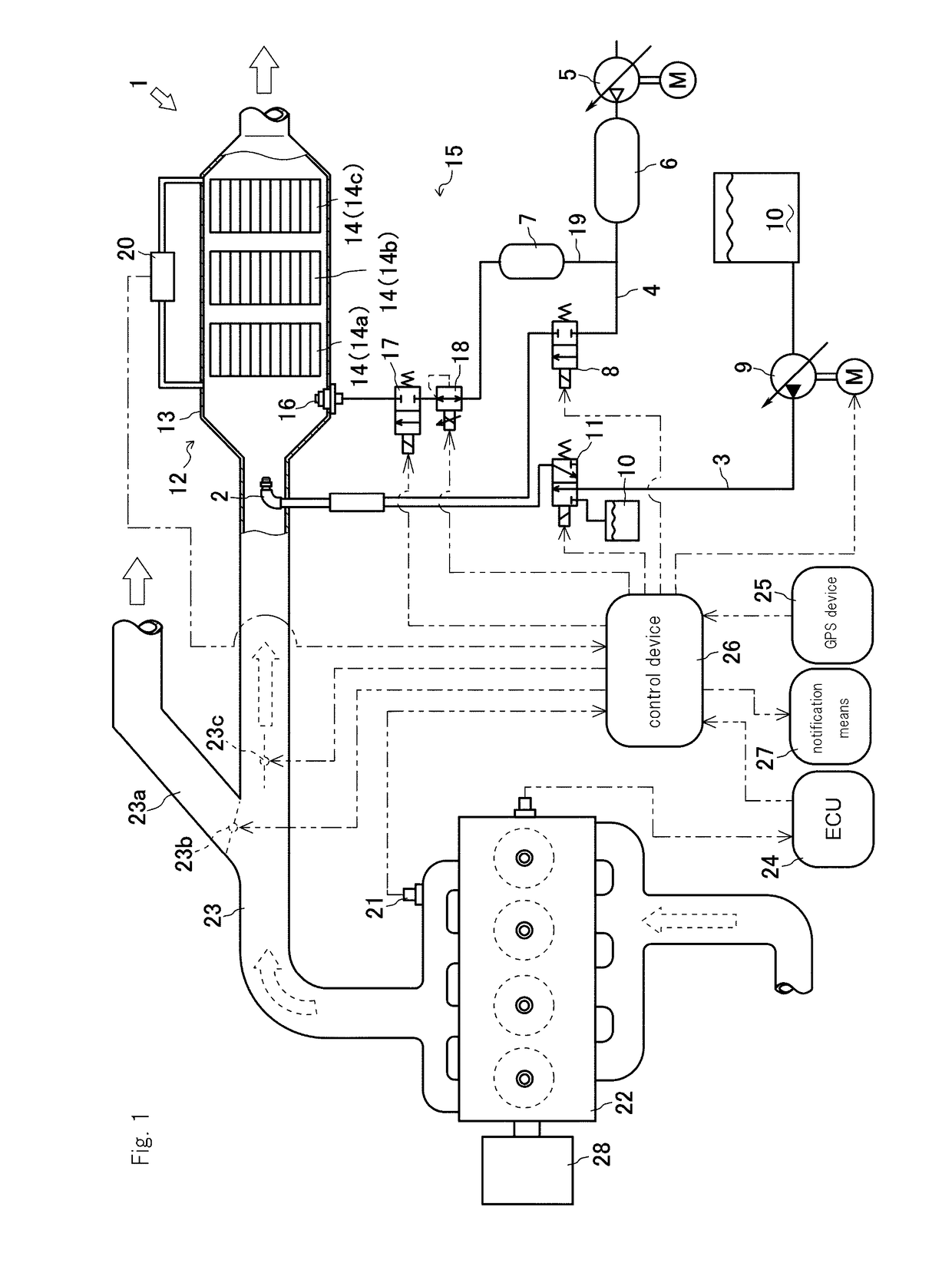

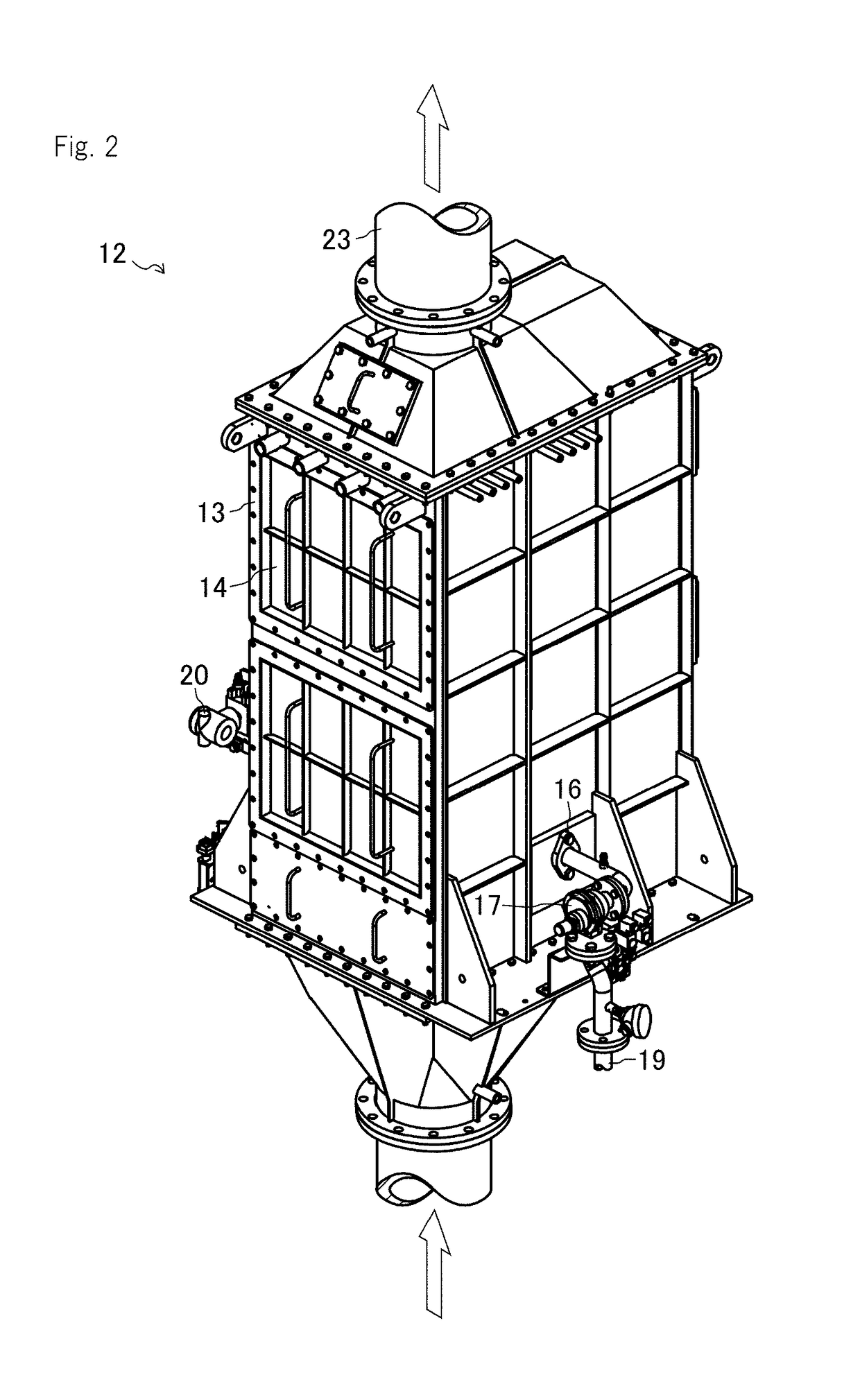

Exhaust purification device

InactiveUS20170145884A1Reduce loadReduce rateElectrical controlInternal combustion piston enginesEngineeringPressure difference

The invention provides an exhaust purification device capable of suppressing the temporal decrease in NOx catalyst removal efficiency due to soot accumulation. The invention provides an exhaust purification device using an air injection nozzle to inject pressurized air into a casing of a catalyst reactor containing an NOx catalyst as a catalyst and removing soot adhering to the NOx catalyst, wherein it is determined and externally notified that there is abnormal deterioration in the NOx catalyst when the pressure difference ΔP in exhaust between the upstream and downstream sides of the NOx catalyst has increased by at least a first reference pressure difference increase ΔPt1, which is the allowable amount of pressure difference increase, above the pressure difference ΔPi in exhaust between the upstream and downstream sides of the catalyst in the initial state at the same exhaust flow rate Ve.

Owner:YANMAR POWER TECHNOLOGY CO LTD

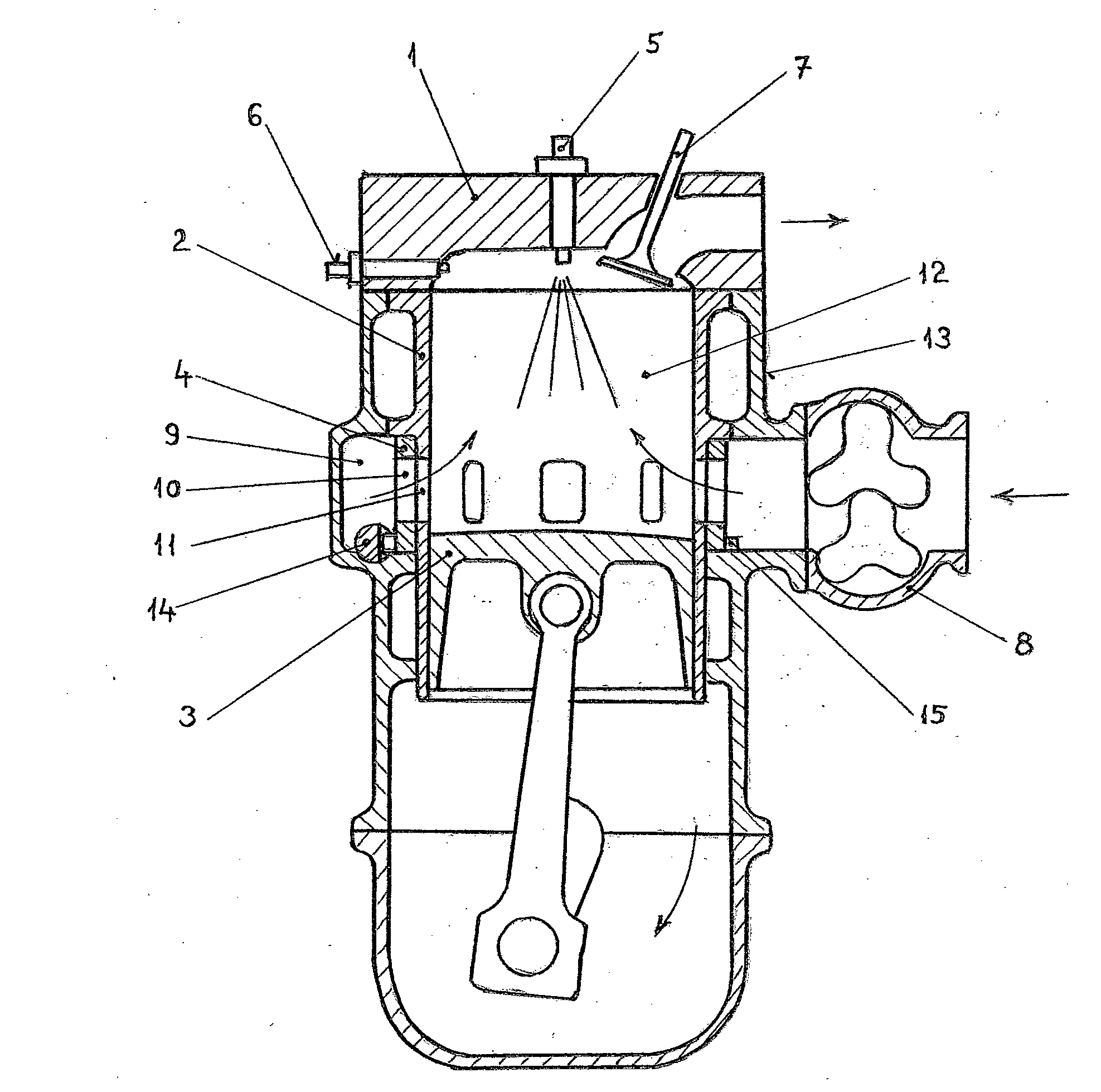

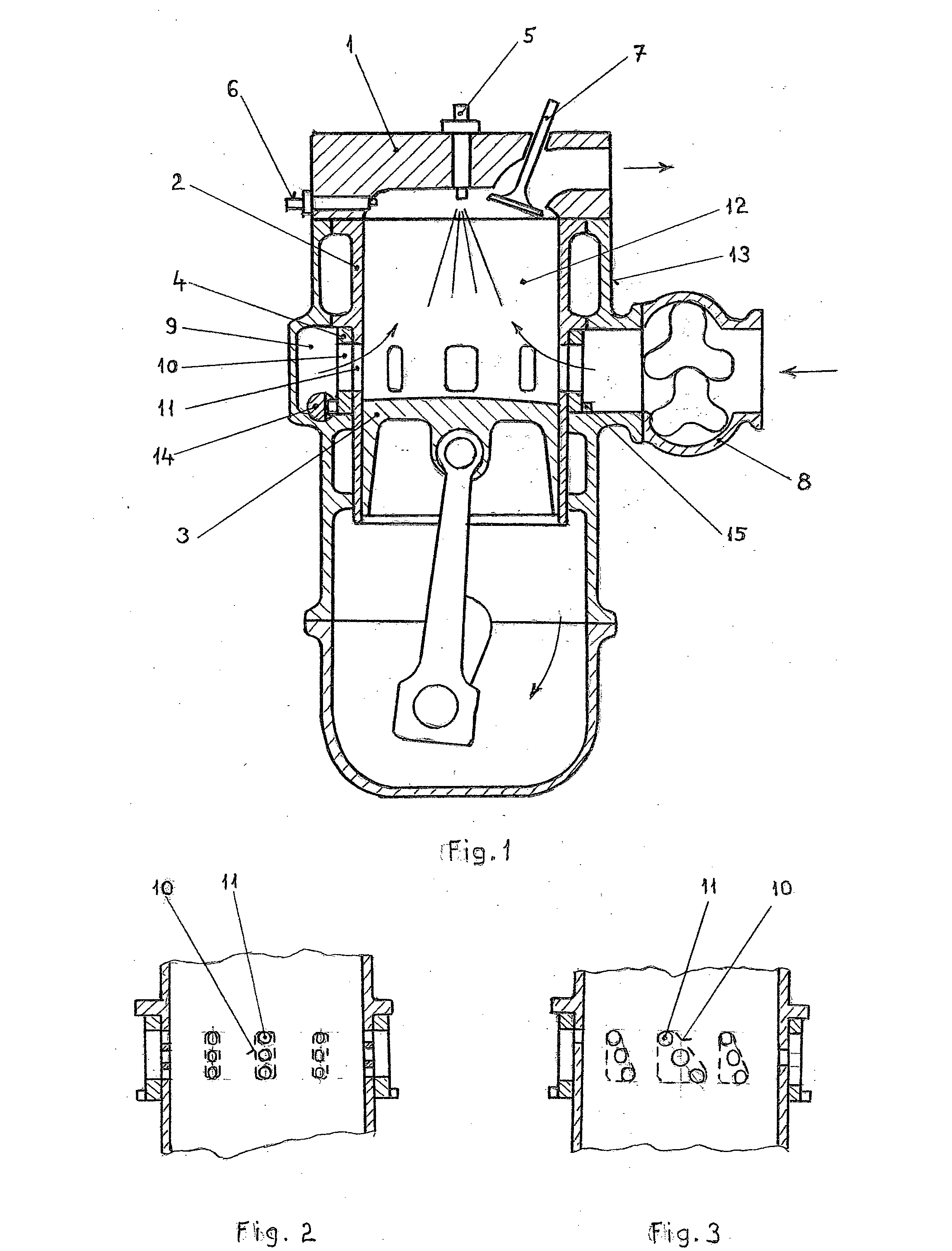

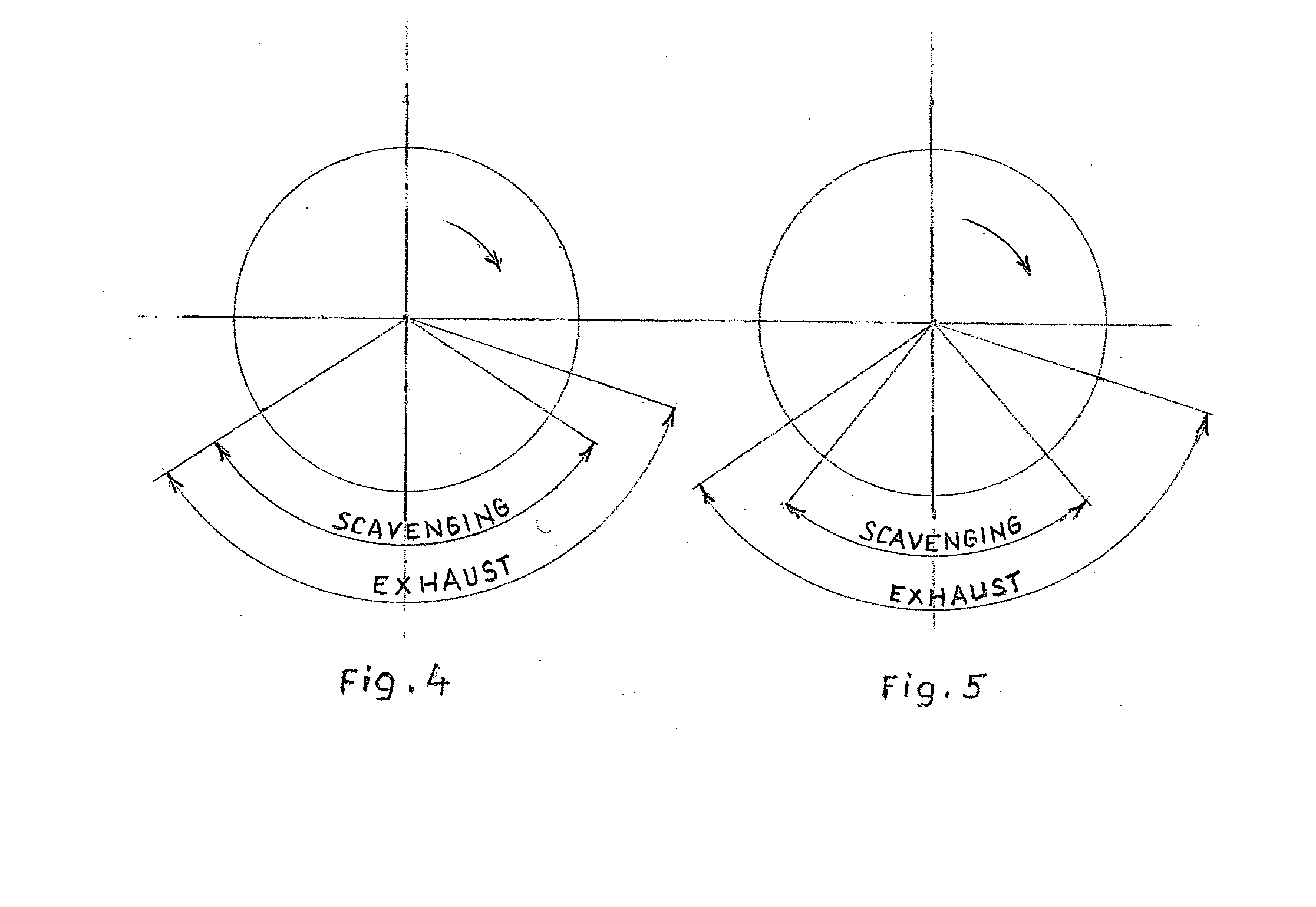

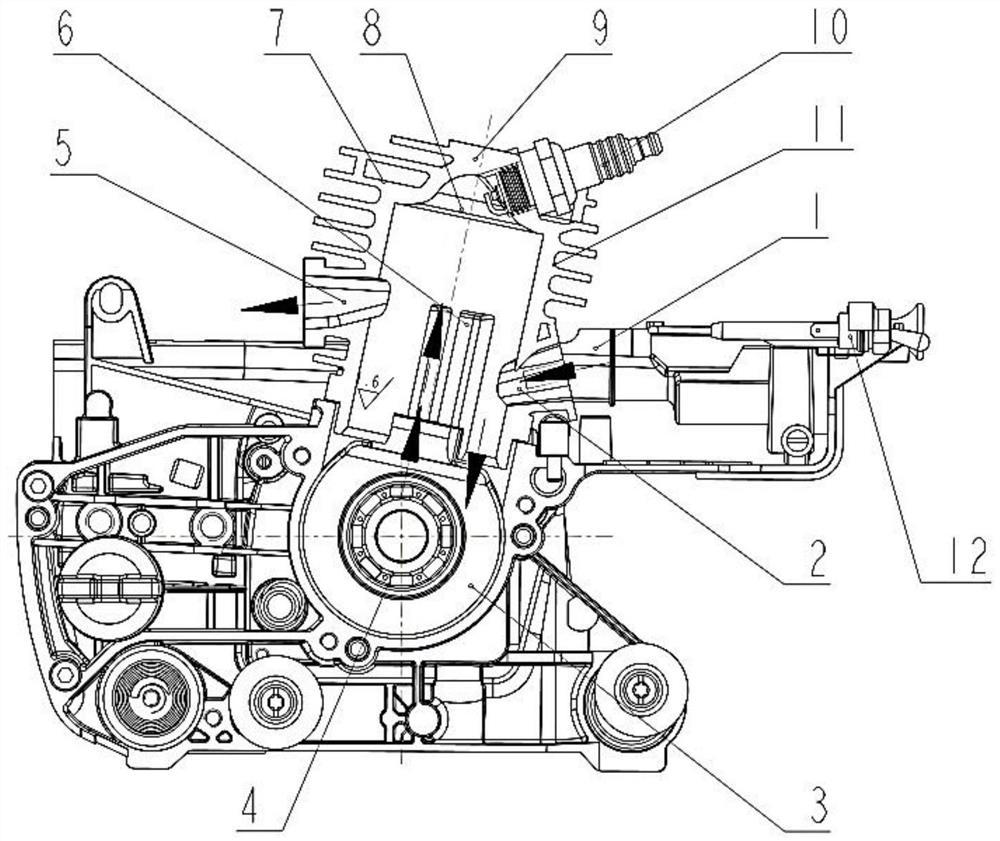

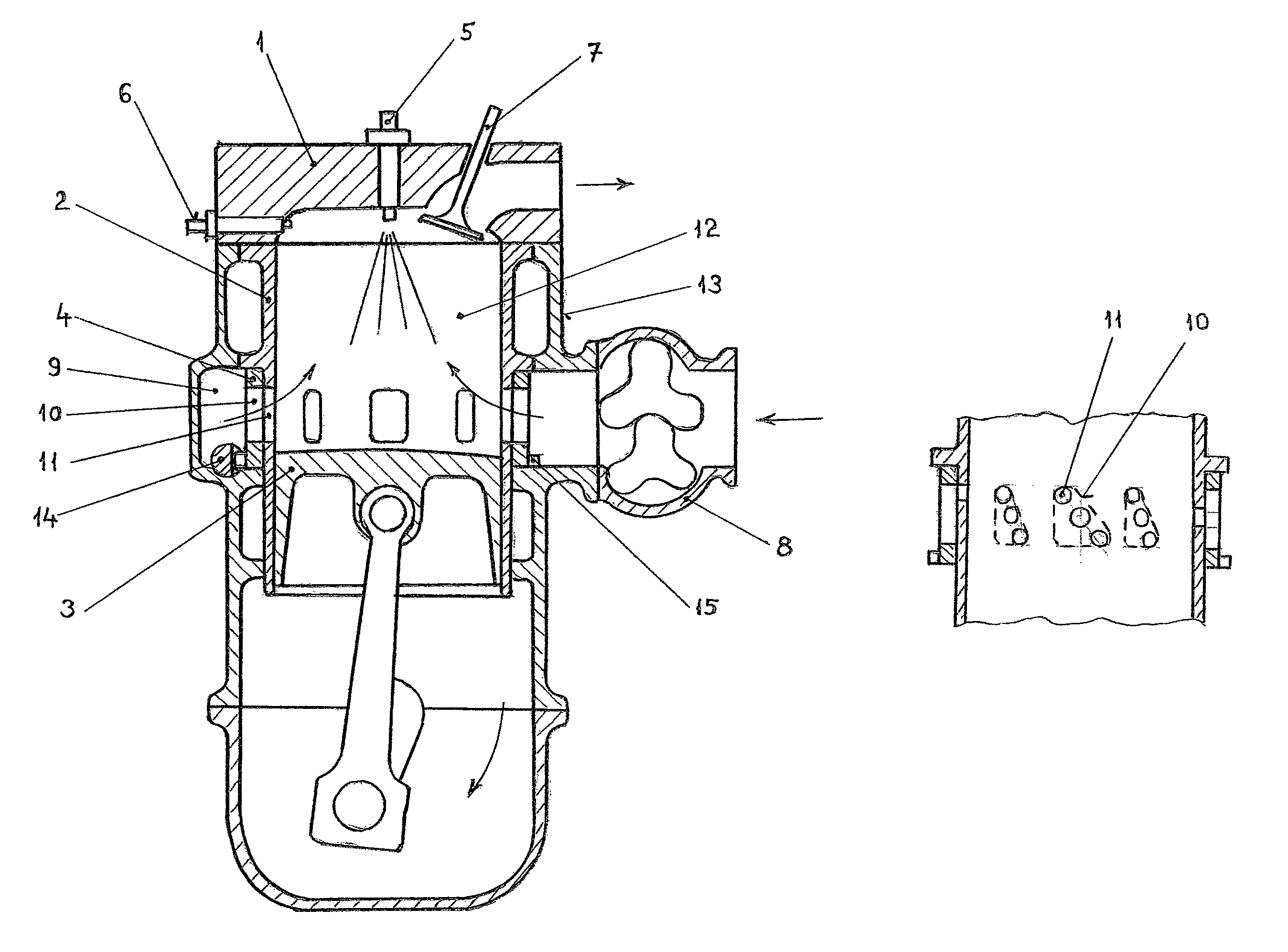

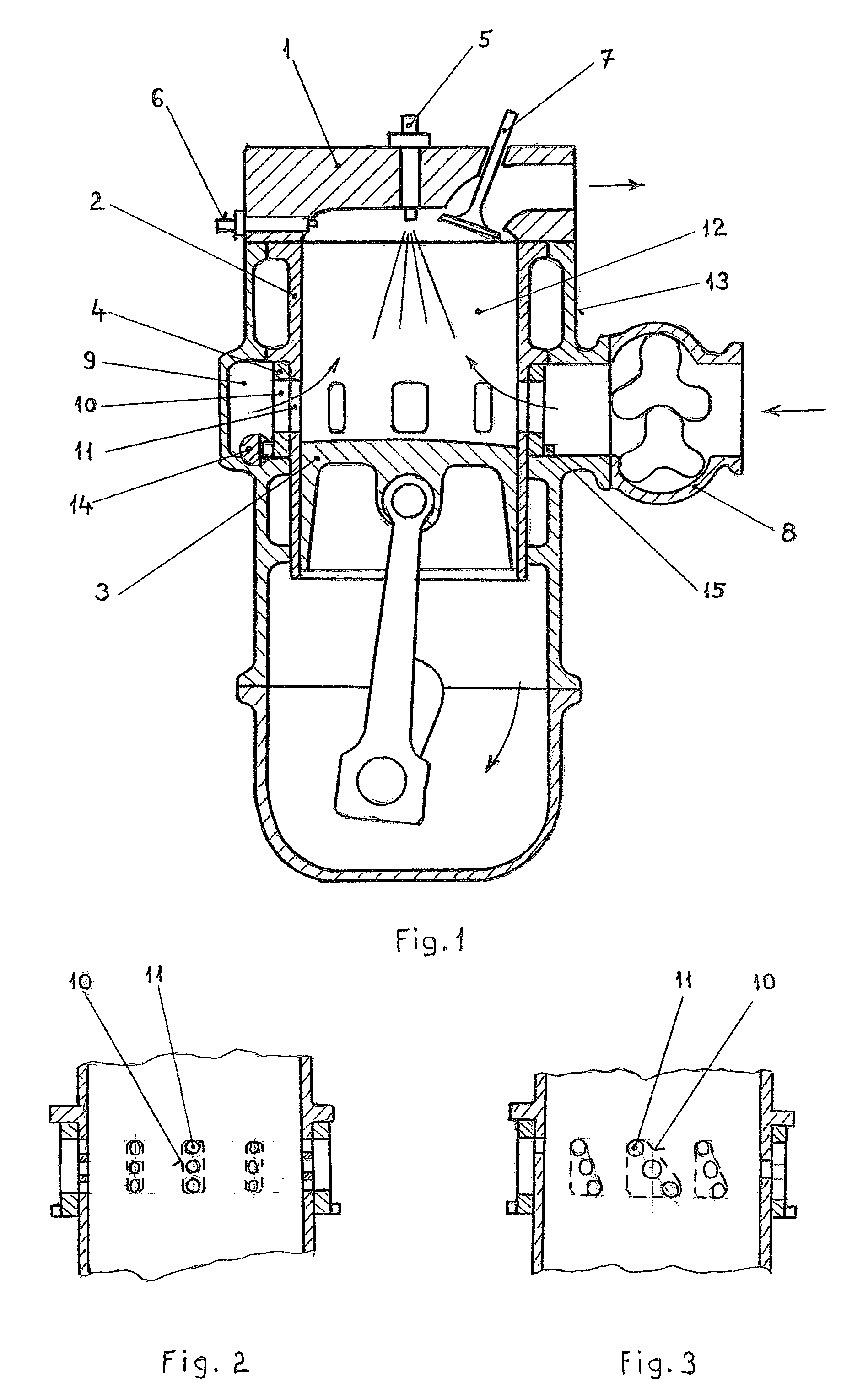

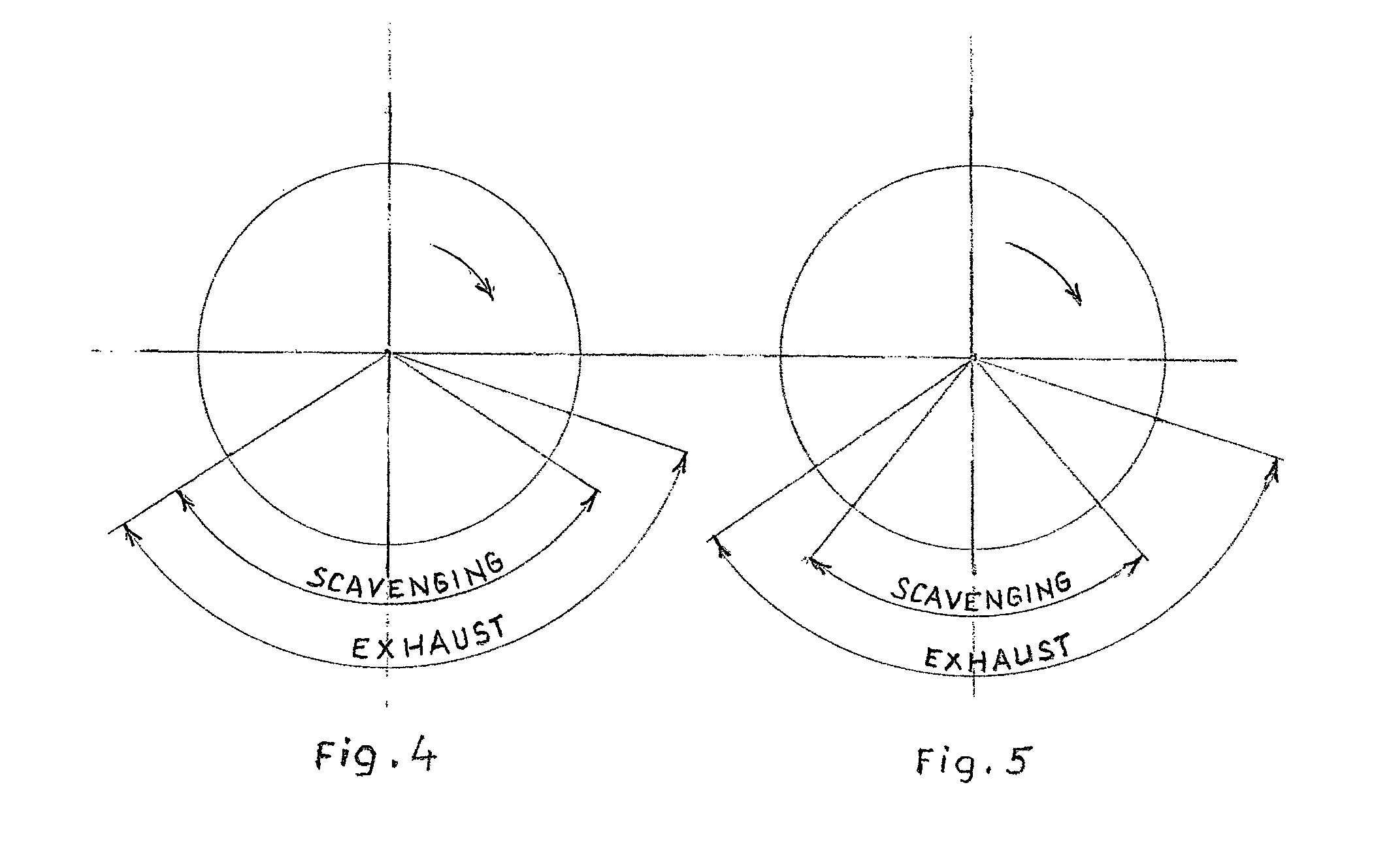

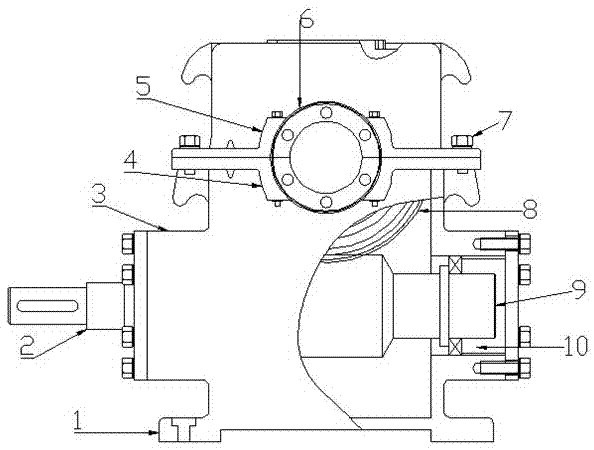

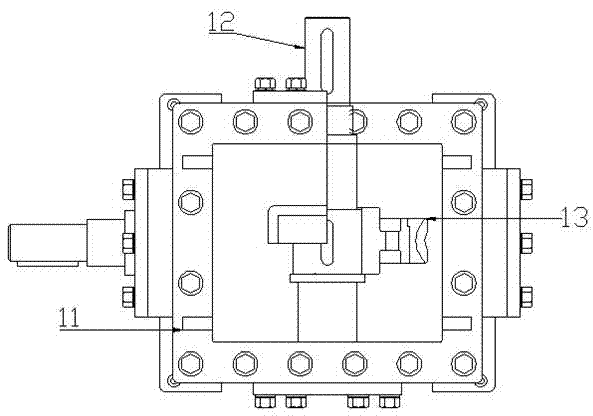

Two-stroke spark-ignition engine

ActiveUS20150083076A1Reduce penetrationReduce blowingCylinder headsLiquid engine fuelsExhaust valveTurbocharger

A two-stroke spark-ignition engine with through scavenging, exhaust valves (7), an injection nozzle (5) and sparking plug (6) in the cylinder head is characterized by higher volume efficiency and higher volume output with the possibility of gradual change of timing of air inlet into the engine cylinder (2) from the idle run to the full power. The use of a charger or turbocharger is convenient. Higher volume efficiency is achieved by a limitation of flow of exhaust gas back to the suction part through a gradual change of the inlet section to the engine cylinder (2) and by ensuring a higher air pressure before the inlet section. The change of the inlet section is achieved by a rotary bushing (4) on the cylinder (2) or insert of the engine cylinder (2), the bushing (4) being controlled with a control rod (14) from the throttle pedal.

Owner:NOVOTNY ZDEN K

Cold start for high octane fuel in diesel engine architecture

PendingCN114341477AElectrical controlInternal combustion piston enginesCombustion chamberTop dead center

Embodiments disclosed herein relate generally to systems and methods of operating an internal combustion (IC) engine, and more particularly to systems and methods of starting a compression ignition (CI) engine (i.e., "cold start") when the ambient environment is significantly lower than the normal operating temperature of the engine. In some embodiments, the CI engine may include an ignition assist. In some embodiments, a method of operating a CI engine during a cold start may include opening an intake valve to draw a volume of air into a combustion chamber; moving the piston from a bottom dead center position to a top dead center in the combustion chamber at a compression ratio of between about 15 and about 25; injecting a volume of fuel, the fuel having a cetane number of less than about 30; closing an intake valve; and burning substantially all of the volume of fuel.

Owner:CLEARFLAME ENGINES INC

Four stroke relative motion cylinder with dedicated compression space

ActiveUS11248521B1Cooling effectVibration minimizationInternal combustion piston enginesCylinder headsInterior spaceReciprocating motion

Implementations are disclosed herein that relate to a cylinder occupying structure. An example provides a cylinder system comprising a mechanical cylinder including an internal space in which a fluid is introduced, and a piston configured for reciprocating motion in the internal space, and a cylinder occupying structure including an insertion rod acting as a second piston, wherein the insertion rod is variably inserted into, and retracted from, the internal space of the cylinder in correspondence with the reciprocating motion of the piston and where parts of the insertion rod and the piston may surround the combustion space, and where fluid compression and fluid combustion is conducted within separate spaces.

Owner:HANNA IBRAHIM

Scaffold mounted turbocharger system for internal combustion engine

ActiveCN101614151AReduce noise signalHas intrinsic hardnessLiquid coolingLiquid engine fuelsTurbochargerInternal combustion engine

The invention discloses a scaffold mounted turbocharger system for an internal combustion engine, comprising a turbocharger and a device scaffold extending between the turbocharger and a mounting surface associated with the engine. The device scaffold comprises a mounting pad connecting the combined turbocharger and scaffold to the engine, an inner lubricating oil supply passage and a coolant supply passage which supply the pressurized coolant and lubricating oil to the turbocharger. The turbocharger system provided by the invention comprises inner integrated supplying and returning passages of the lubricating and the oil, and has the advantages of compact design and reduced noise.

Owner:FORD GLOBAL TECH LLC

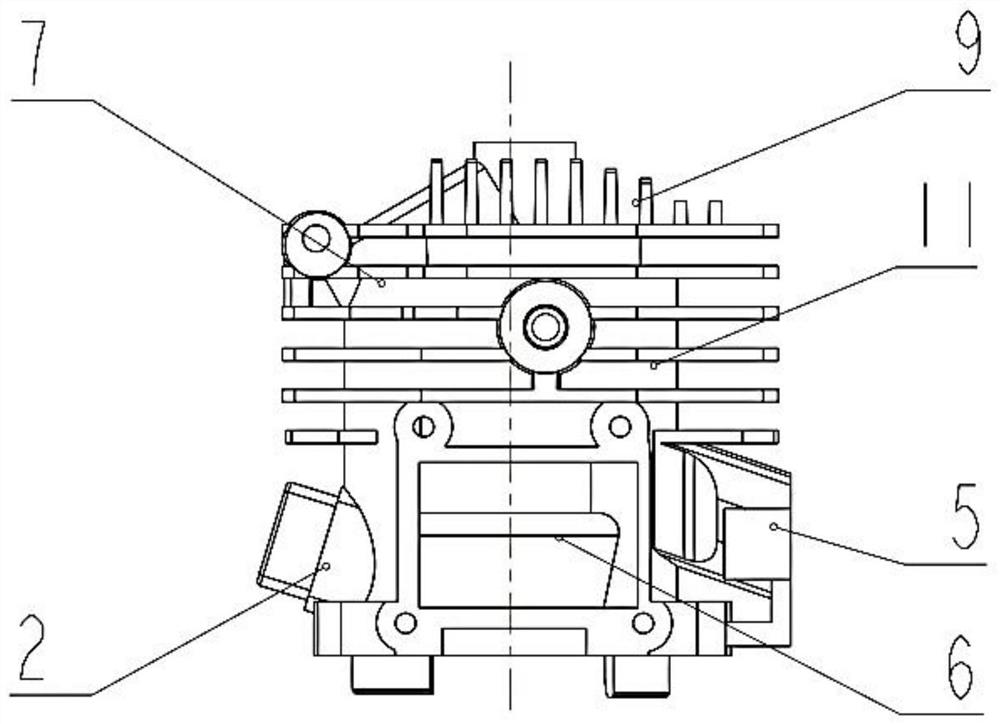

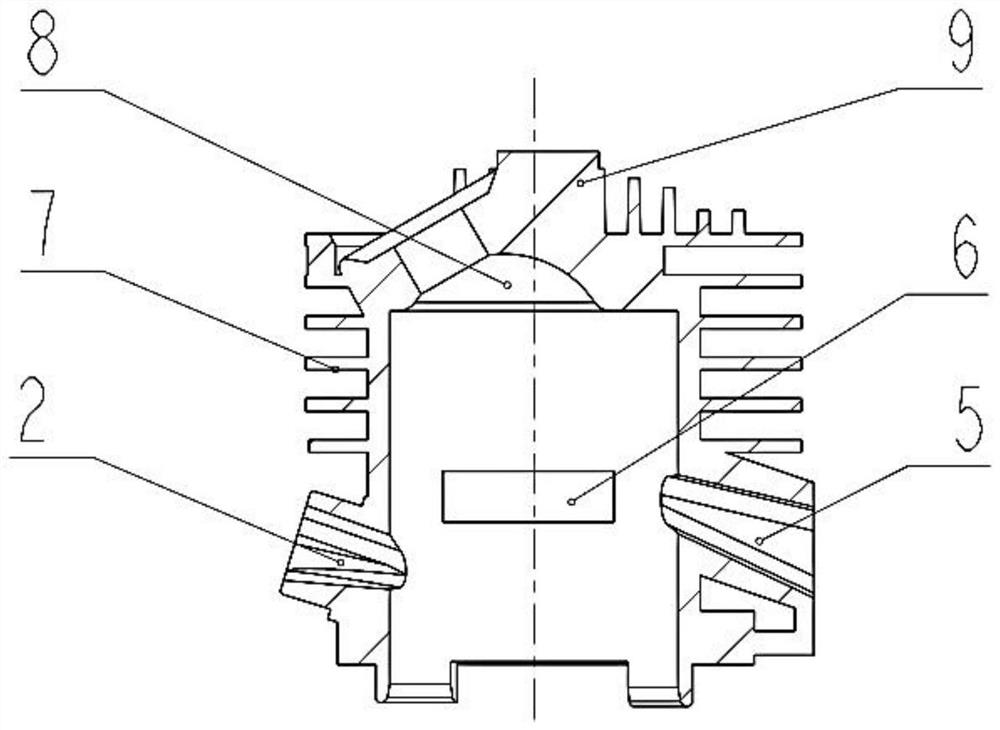

Closed type low-emission backflow scavenging passage air cylinder for small gasoline engine

PendingCN113503214AWell mixedIncrease powerInternal combustion piston enginesCylinder headsCombustion chamberGasoline

The invention discloses a closed type low-emission backflow scavenging passage air cylinder for a small gasoline engine. The closed type low-emission backflow scavenging passage air cylinder for the small gasoline engine comprises a cylinder body, and an inner cavity of the cylinder body is arched upwards to form a combustion chamber. An air inlet is formed in the lower portion of the cylinder wall on one side of the cylinder body, an exhaust port is formed in the cylinder wall on the other side of the cylinder body, scavenging ports are formed in the cylinder walls on the two sides of the cylinder body between the air inlet and the exhaust port separately, one scavenging port serves as a main scavenging port, the other scavenging port serves as an auxiliary scavenging port, side covers are fixed to the positions, corresponding to the scavenging ports, of the outer surface of the cylinder wall of the cylinder body in a covering mode separately, and scavenging ducts are defined by the side covers and the cylinder walls at the corresponding positions of the cylinder body. The air cylinder is novel in structure and reliable in performance, the requirements of reducing tail gas emission and meeting emission regulations are met, the working temperature of the air cylinder is lowered, and the power of the small gasoline engine is improved.

Owner:ZHEJIANG PIONEER MACHINERY & ELECTRON

Two-stroke spark-ignition engine

ActiveUS9175635B2Reduce blowingReduce penetrationCylinder headsCombustion enginesExhaust valveTurbocharger

Owner:NOVOTNY ZDEN K

Uniflow engine with intake and/or exhaust valves

ActiveUS20180328263A1Reduces potential cost advantageIncrease airflowCylinder headsCombustion enginesExhaust valveUniflow steam engine

Owner:VOLVO LASTVAGNAR AB

Power and miles per gallon for an automotive engine by using 2 stroke technology where the lubrication of the engine parts is independent of the fuel system.

InactiveUS20200291848A1Improve fuel efficiencyImprove power efficiencyInternal combustion piston enginesValve drivesCombustion chamberTurbocharger

The present invention provides a system and method for providing a wheel fuel efficiency improvement of at least 30% in a gasoline internal combustion engine, the system including a two-stroke engine, a crank case and oil pump in fluid communication with said two-stroke engine but independent of the fuel system of the engine and at least one of a turbocharger and / or another means of providing compressed air in fluid communication with a combustion chamber in said two-stroke engine, wherein camshafts are required to rotate at the same number of revolutions per minute as the crankshaft and that the gasoline can be injected directly into the combustion chamber and will not enter the combustion chamber via an intake manifold.

Owner:ROBINSON BARNETT JOEL

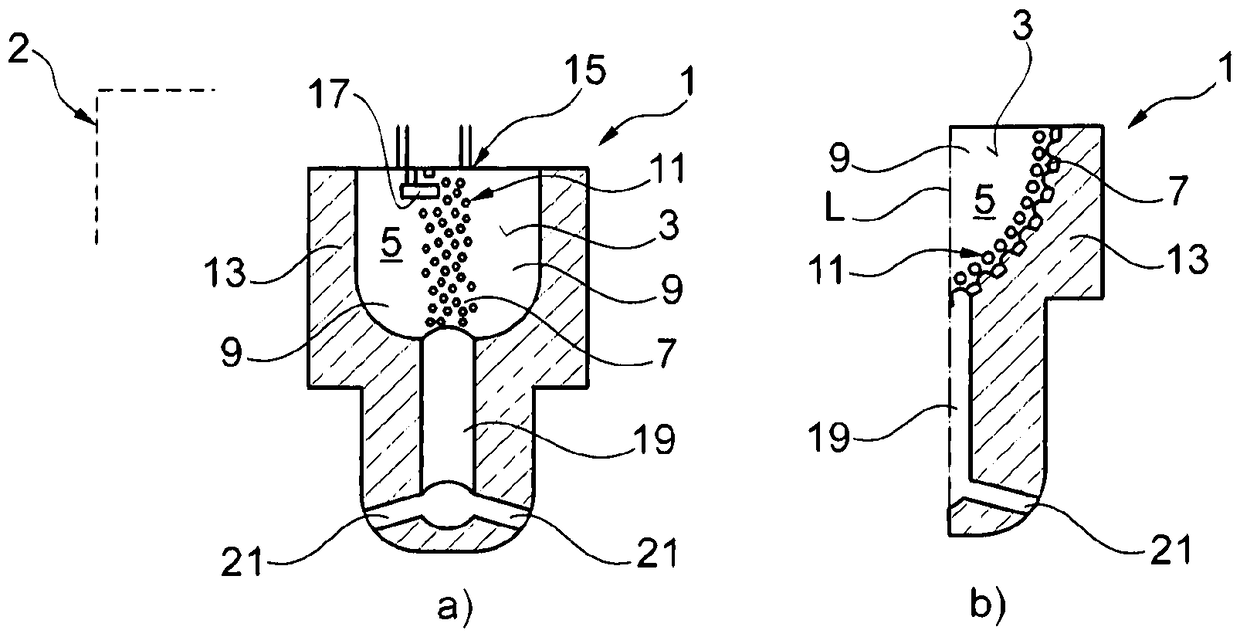

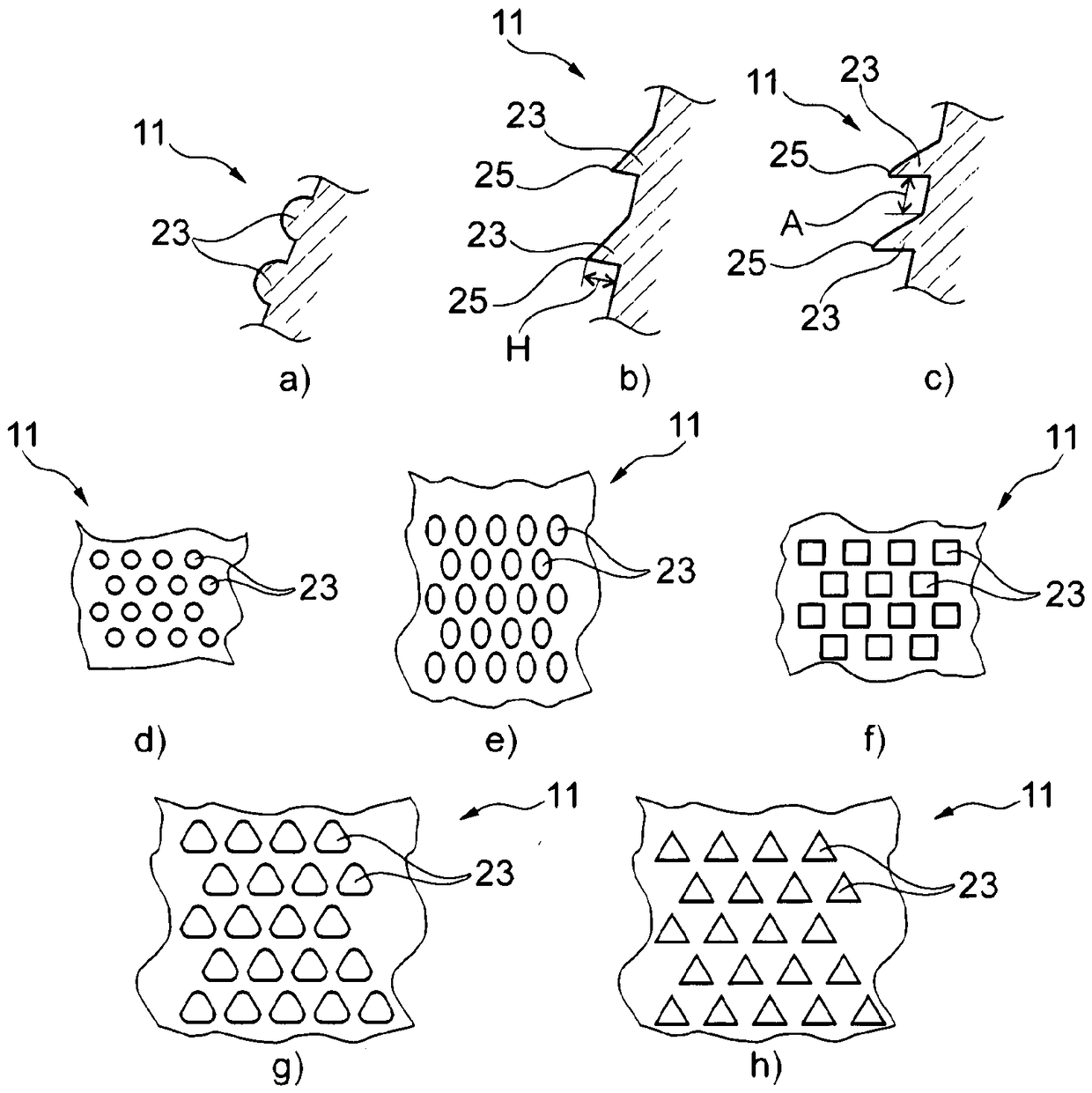

Prechamber for an internal combustion engine, internal combustion engine comprising a prechamber of this type and method for designing and/or producing a prechamber of this type

InactiveCN108474289AInternal combustion piston enginesFuel supply apparatusInternal combustion engine

The invention relates to a prechamber (1) for an internal combustion engine (2), comprising a surface (3) that is situated in the interior (5) of the prechamber (1) and that is impinged by a flow during the operation of the prechamber (1). According to the invention, the surface (3) has at least one first surface region (7) and at least one second surface region (9), wherein the first surface region (7) has a defined texture (11), whereas the second surface region (9) is untextured (11).

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

Four-stroke diesel engine on farming tractor

InactiveCN106855016AImprove fuel efficiencyIncrease kinetic energyLiquid engine fuelsLiquid fuel enginesGraphite carbonCombustion chamber

The invention discloses a four-stroke diesel engine on an agricultural tractor, which comprises a base, a protection crankshaft, a combustion chamber and graphite carbon rods, a connecting shaft is arranged above the base, and a pressure-resistant plate of a casing is installed above the connecting shaft. The pressure-resistant plate of the chassis is arranged between the connecting shaft and the protection crankshaft. A pressure crankshaft is installed above the protection crankshaft. The pressure crankshaft and the central axis of the cam are on the same straight line. The central axis is on the same straight line, the fixing bolt is installed above the combustion chamber, an air valve is arranged below the combustion chamber, and an oil groove is installed below the air valve. Beneficial effects: the four-stroke diesel engine can effectively improve the fuel value efficiency, improve equipment stability, reduce exhaust gas content, increase the kinetic energy of the tractor, effectively reduce noise, effectively clear the waste oil of the diesel engine, avoid blockage, and prolong the service life.

Owner:CHONGQING CHANGSHOU DISTRICT JUXIANG VEGETABLE GROWING SPECIALIZED COOP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com