Oxygen-injection double-stroke internal combustion engine and running method thereof

A two-stroke internal combustion engine, oxygen tank technology, applied in liquid fuel engines, fuel systems, mechanical equipment, etc., can solve the problems of little improvement in engine combustion efficiency, inability to eliminate nitrogen oxide pollution, complex engine structure, etc. Conducive to variable valve timing, reduction of narrow gap effect, and reduction of valve drive power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

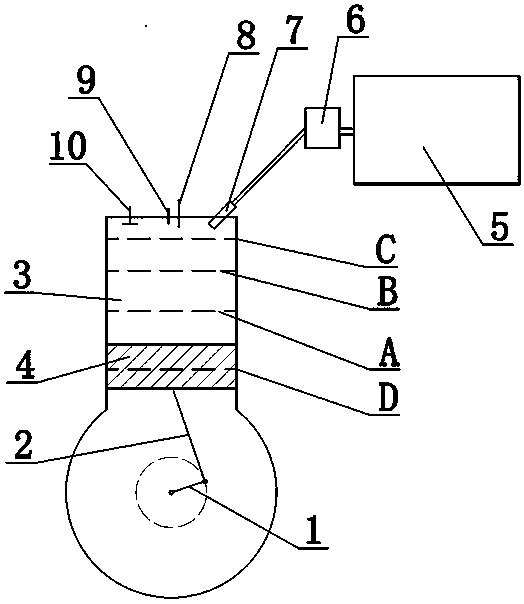

[0017] combine figure 1 , a kind of oxygen injection two-stroke internal combustion engine of the present invention comprises crankshaft 1, connecting rod 2, cylinder 3, piston 4, high-pressure oxygen pipe 5, voltage stabilizing device 6, high-pressure nozzle 7, spark plug 8, fuel injector 9, exhaust valve 10. The crankshaft 1 is hinged to one end of the connecting rod 2, and the other end of the hinged connecting rod 2 is hinged to the piston 4. The piston 4 is slidingly matched with the inner cylinder wall of the cylinder 3. The top of the cylinder 3 is fixed with a high-pressure nozzle 7, a spark plug 8, Fuel injector 9, exhaust valve 10, high-pressure oxygen tank 5 are connected to high-pressure nozzle 7 through pipelines, and the pipeline connecting high-pressure oxygen tank 5 and high-pressure nozzle 7 is provided with a voltage stabilizing device 6 for stabilizing the output pressure of oxygen and preventing The gas flows back into the high-pressure oxygen tank 5 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com