Internal combustion engine and method for controlling such internal combustion engine

An internal combustion engine, fuel technology, applied in engine control, internal combustion piston engine, combustion engine and other directions, can solve problems such as low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

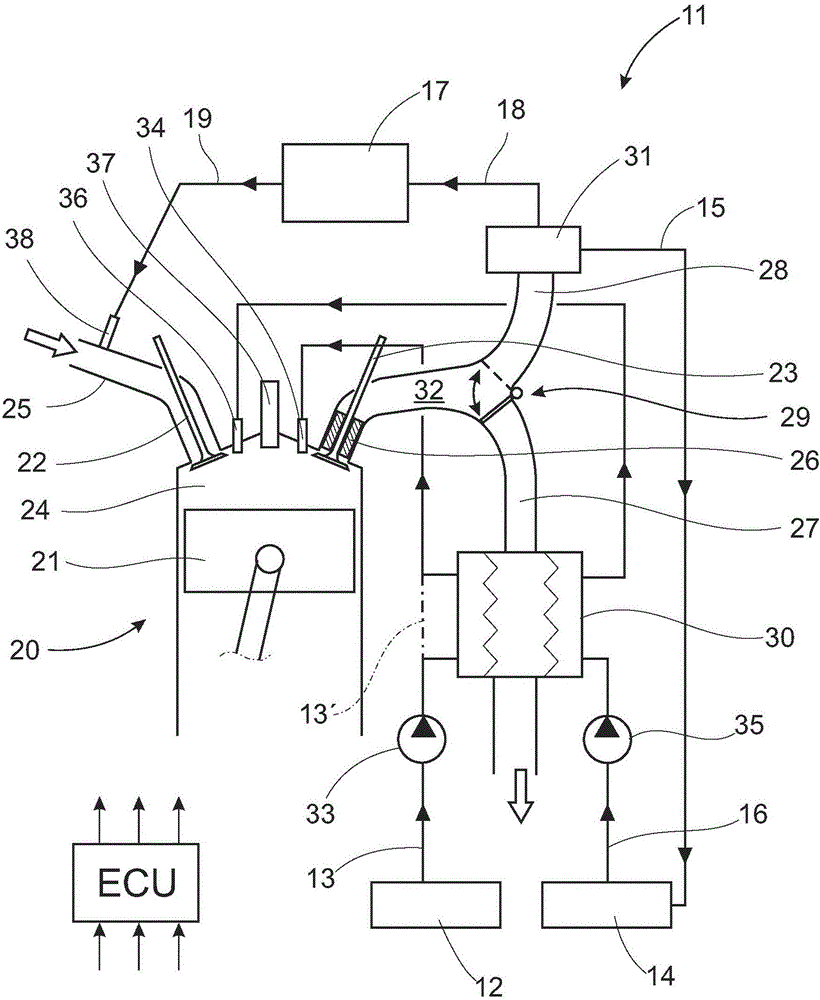

[0052] figure 1 There is shown a schematically represented vehicle 10 comprising an internal combustion engine 11 connected in this example to a transmission (not shown) for driving a pair of front wheels. The vehicle 10 includes a first fuel tank 12 connected to an engine 11 via a first fuel supply line 13 . The engine 11 is further connected to the water tank 14 through a water supply pipeline 15 and a water return pipeline 16 . Finally, the engine 11 is connected to a second fuel tank 17 for the reformed fuel produced by the engine 11 , said connection comprising a fuel collection line 18 and a second fuel supply line 19 .

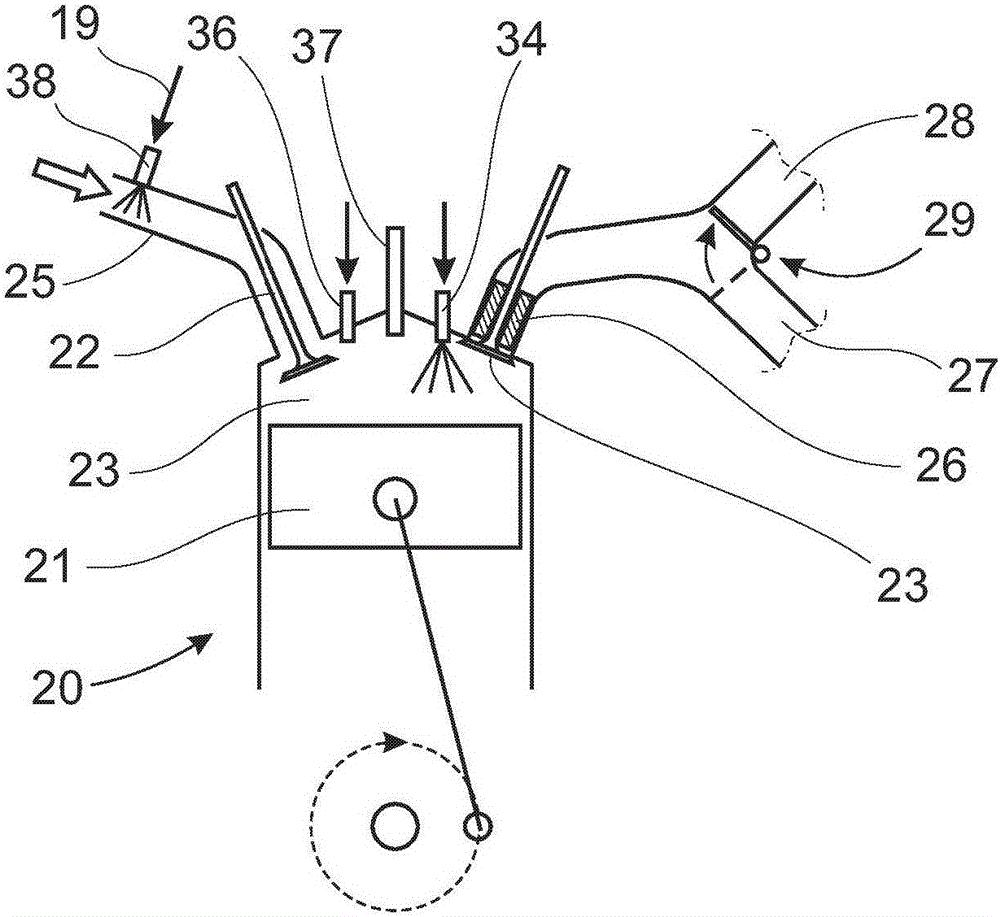

[0053] figure 2 A schematically illustrated internal combustion engine according to the invention is shown, the engine 11 being operable in six-stroke mode. The engine 11 includes at least one cylinder 20 (one shown) with an intake duct 25 and an exhaust duct 32, each cylinder 20 having a reciprocating piston 21 and at least one intake port for intr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com