Scaffold mounted turbocharger system for internal combustion engine

An internal combustion engine, turbocharger technology, applied in combustion engines, engine lubrication, engine cooling, etc., can solve problems such as increased noise and lack of rigidity, and achieve the effect of reducing noise signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

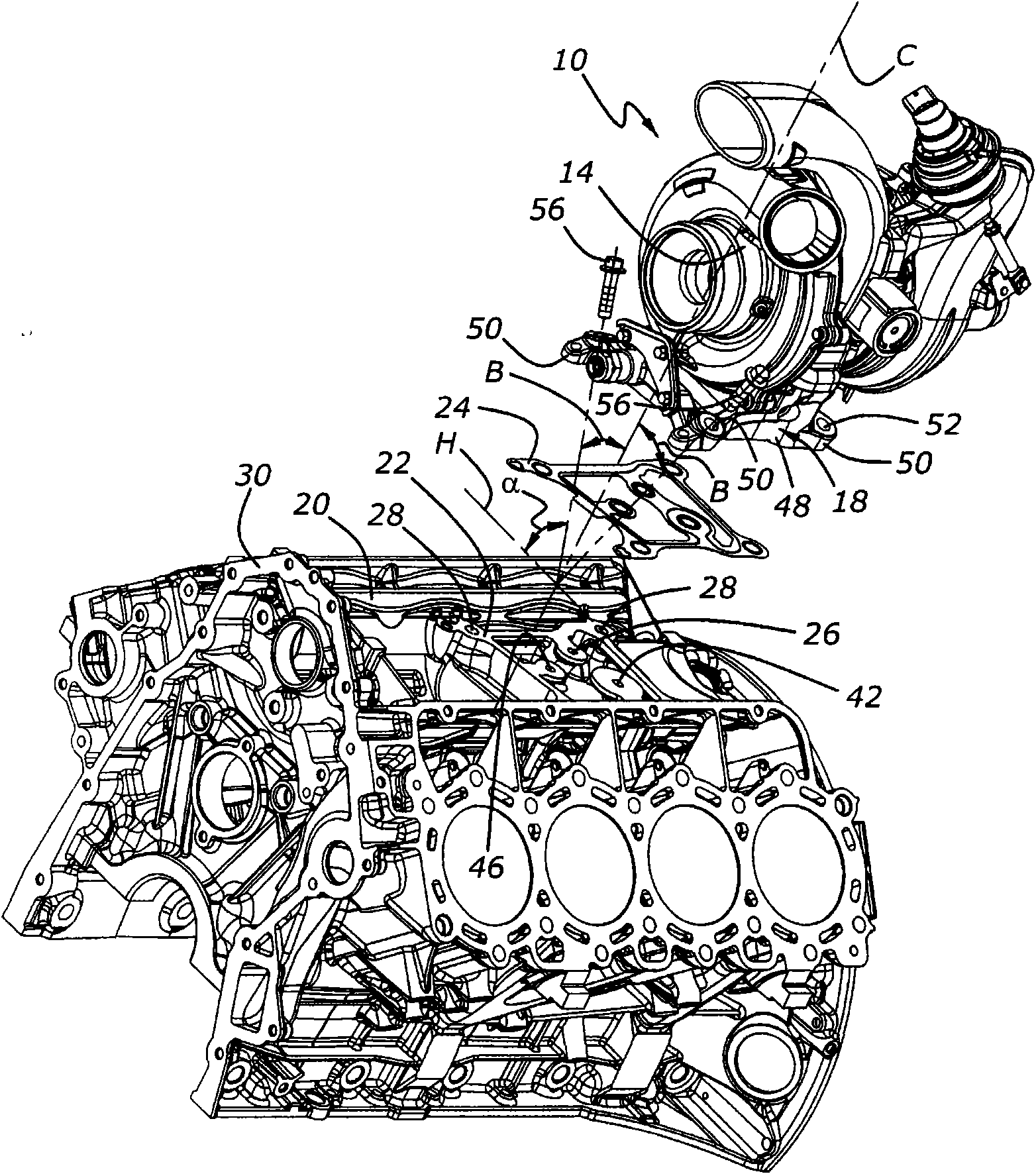

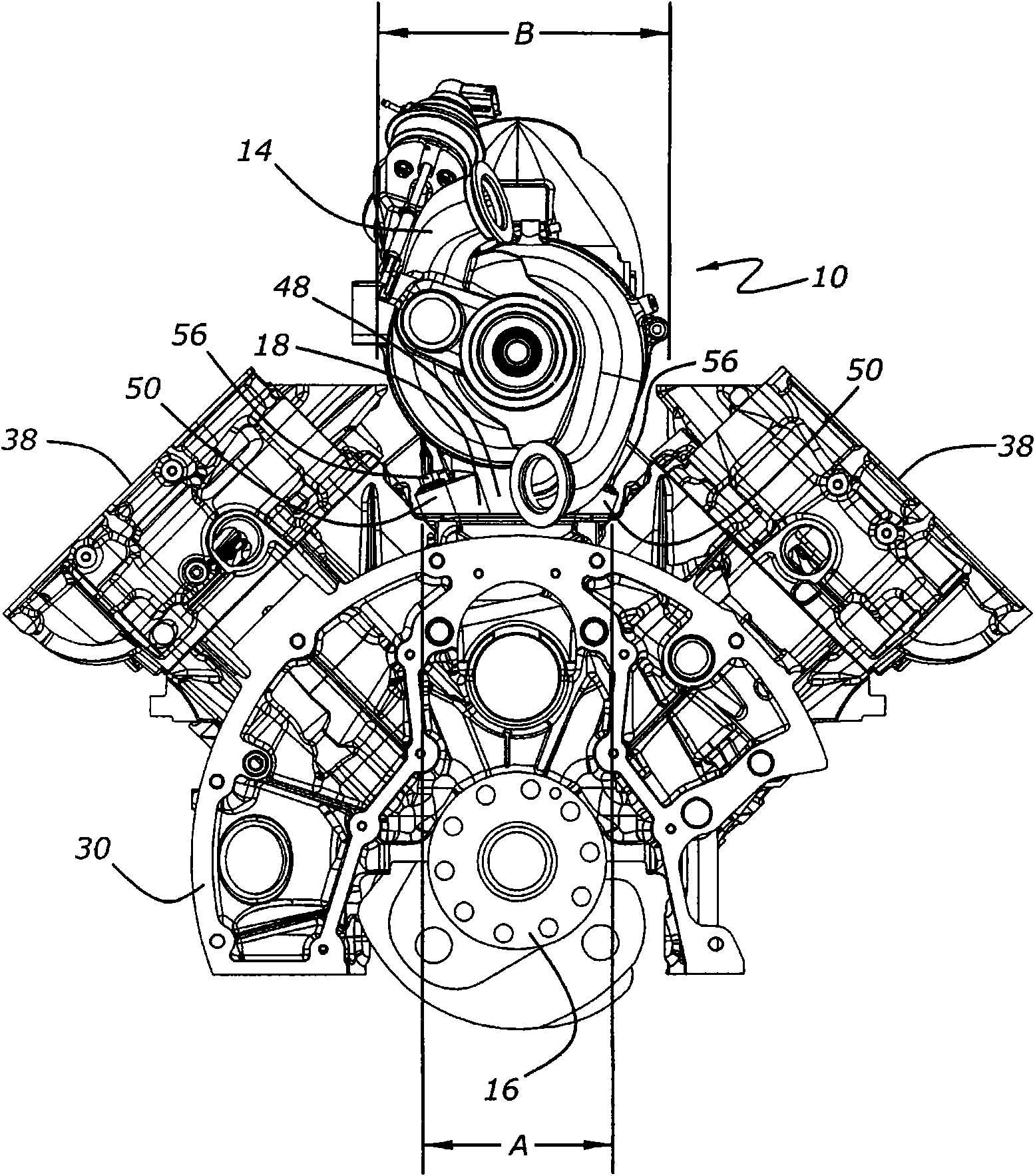

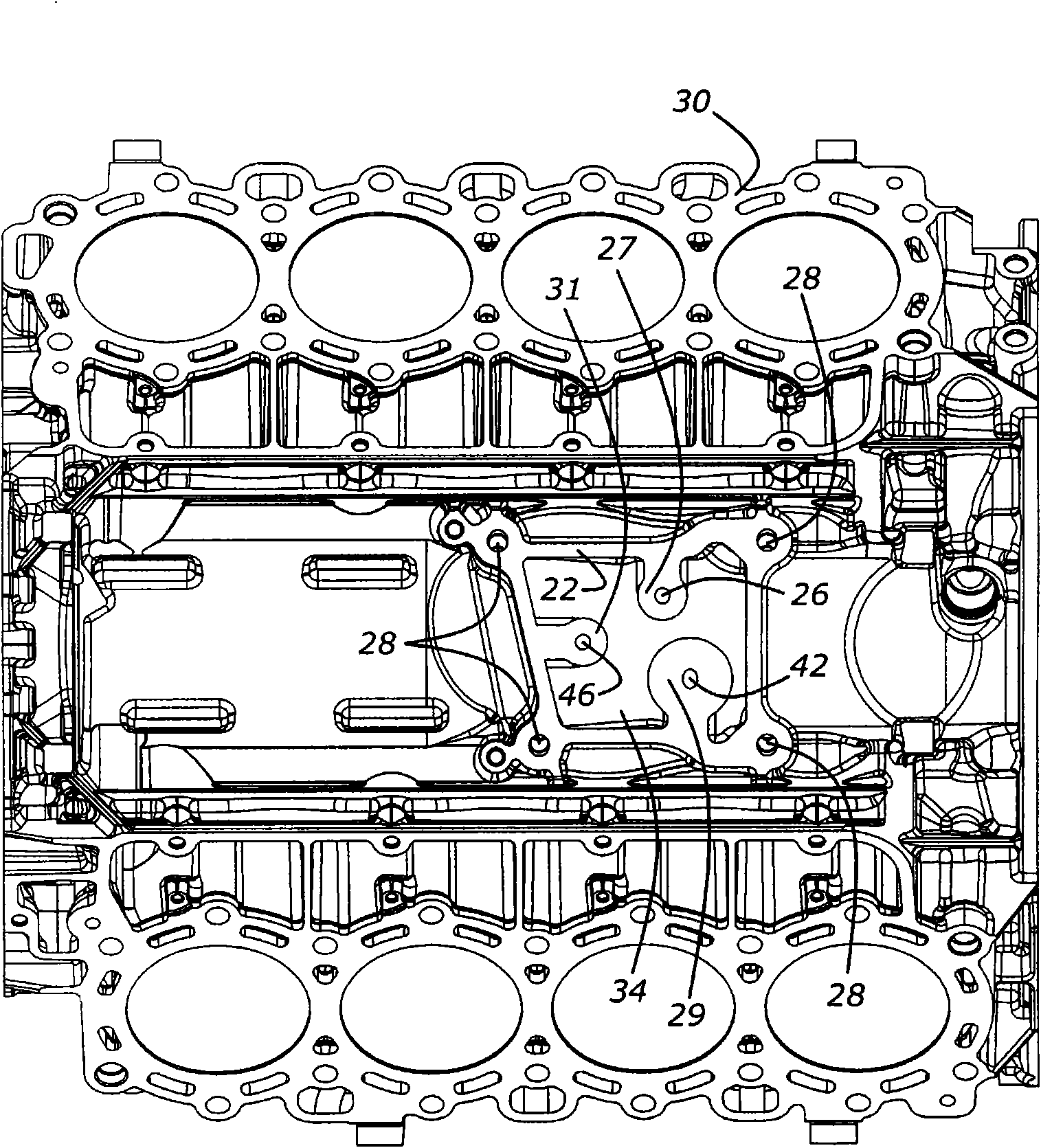

[0025] like figure 1 As shown in , a turbocharging system 10 includes a turbocharger 14 and an equipment stand 18 . The turbocharger 14 is preferably mounted to the equipment rack 18 before the turbocharger 14 is mounted on the engine. figure 1 Also shown is an engine block 30 having a valley 20 into which the turbocharging system 10 rests by way of a hard point, shown as a generally planar mounting pad 22 . The equipment stand 18 provides rigid structural support for the turbocharger 14, which helps reduce unwanted engine noise emissions, as well as reduce unwanted vibrations associated with the turbocharger. Those skilled in the art will understand from the present invention that the word "hard point", as used herein means a structurally rigid mounting location, such as a cylinder block gasket machined into the base material of the cylinder block, or a split gasket, such as Image 6 Shown at 100. Mounting spacer 100 is intended to be attached to the engine by bolting, wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com