Closed type low-emission backflow scavenging passage air cylinder for small gasoline engine

A small gasoline engine and scavenging passage technology, which is applied in the field of gasoline engine cylinders, can solve problems such as unreasonable heat dissipation structure and unstable scavenging, and achieve the effects of novel cylinder structure, avoiding deflagration and premature combustion, and stabilizing the scavenging direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

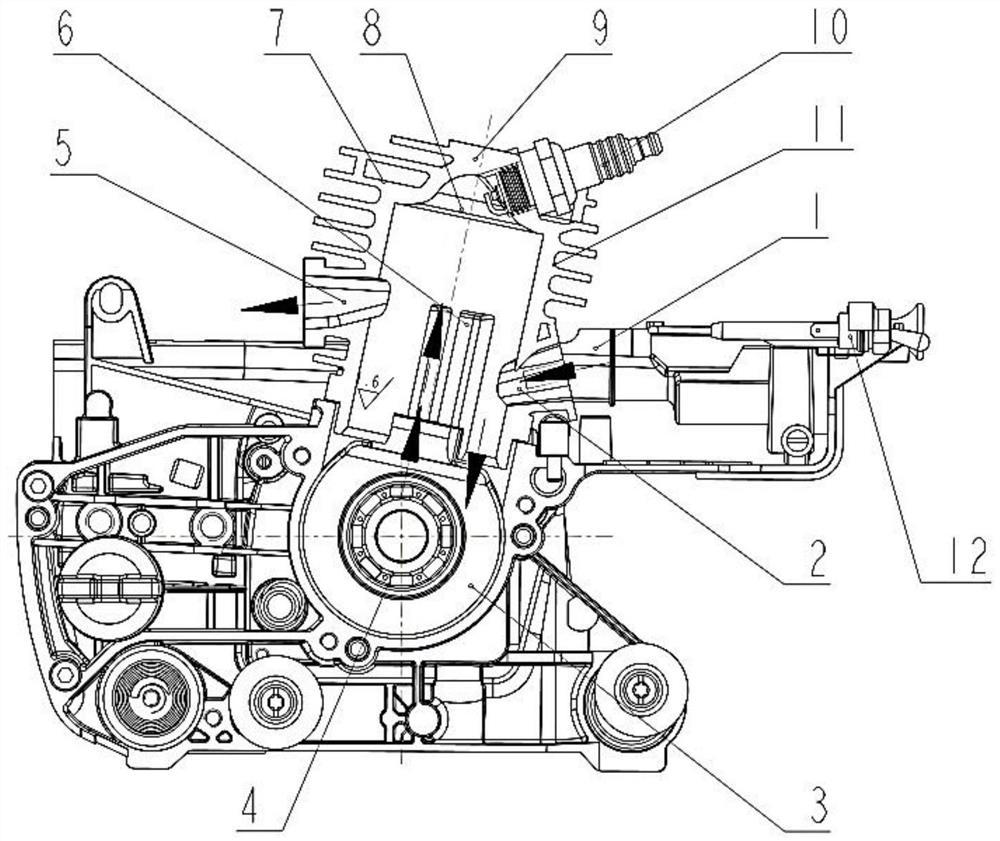

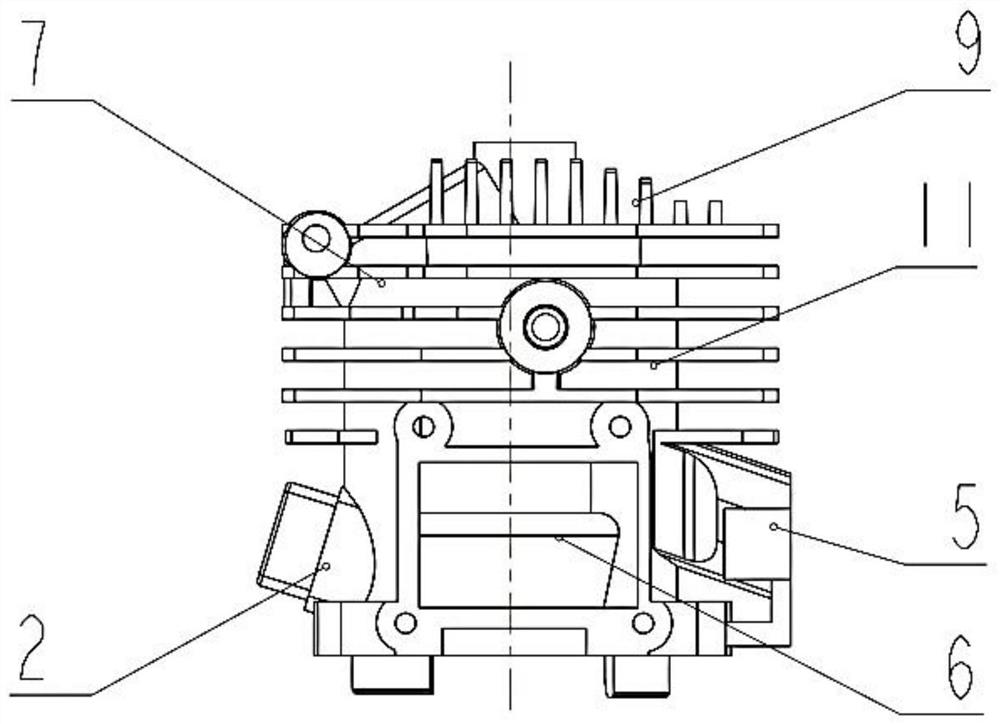

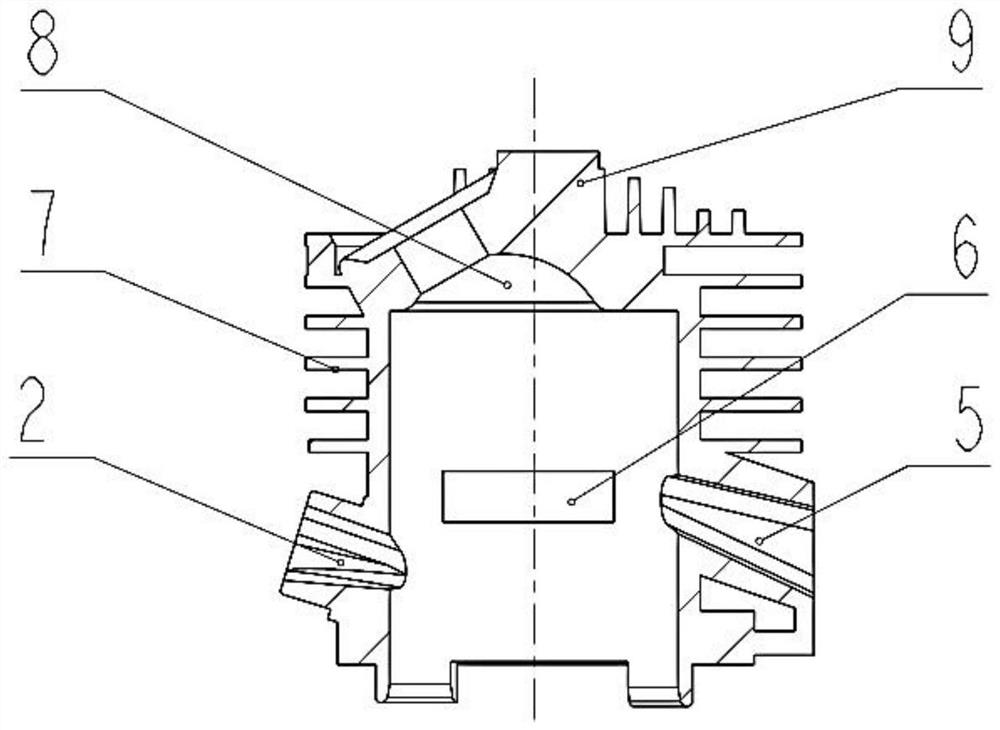

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] like Figure 1-Figure 7 As shown, a closed low-emission backflow scavenging channel cylinder for a small gasoline engine of the present invention includes a cylinder block 11, the bottom of the cylinder block 11 is open, and the top of the cylinder block 11 is closed, and the bottom of the cylinder block 11 is open and fixedly connected to the crankshaft. Case 3, the crankshaft installed in the crankcase 3 through deep groove ball bearing rotation, the piston 15 is slidably installed in the inner cavity of the cylinder body 11, and the crankshaft in the crankcase 3 is connected with the piston 15 in the cylinder body 11 by a connecting rod.

[0034] There are multiple layers of horizontal cooling fins 7 fixed on the outer surface of the upper cylinder wall of the cylinder block 11, wherein the top surface of the uppermost horizontal cooling fin i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com