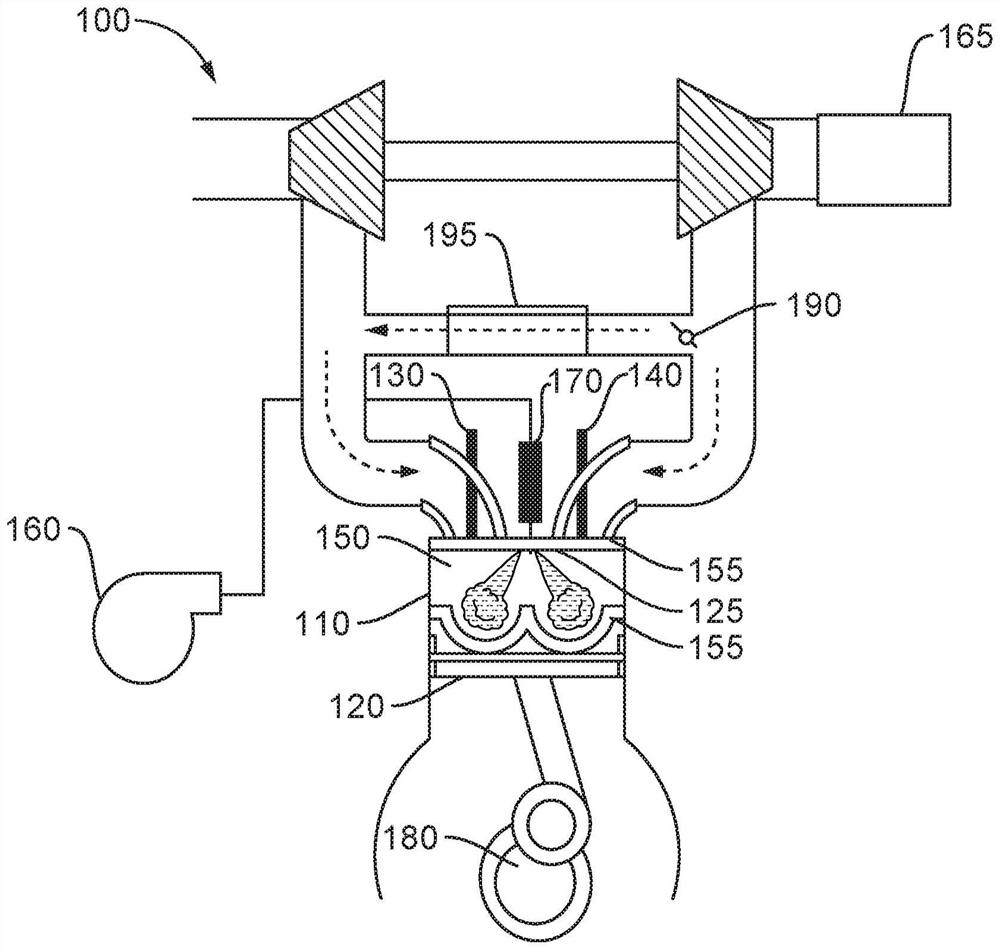

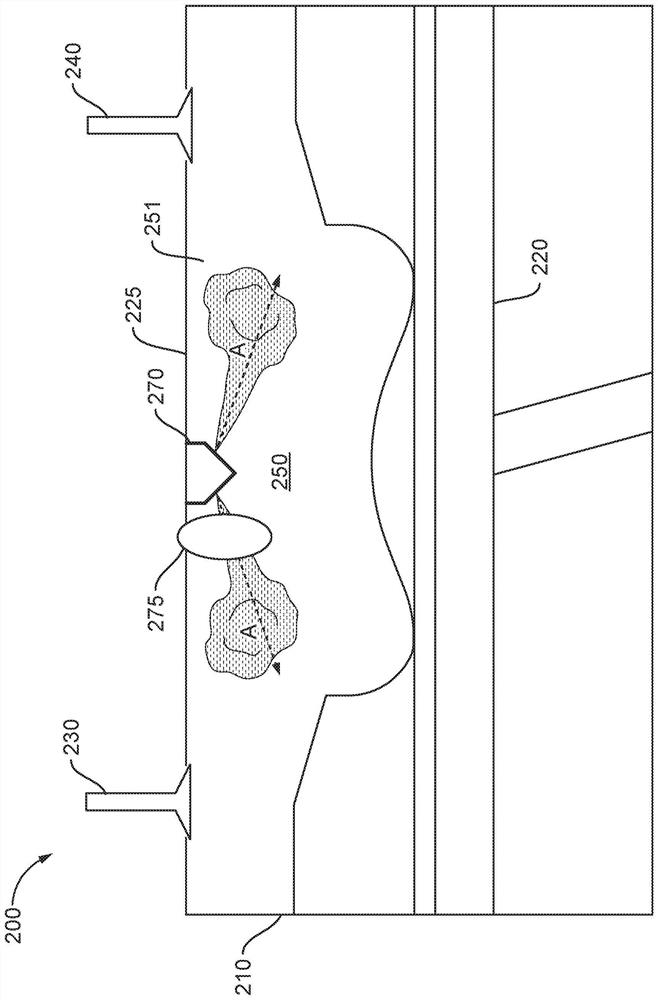

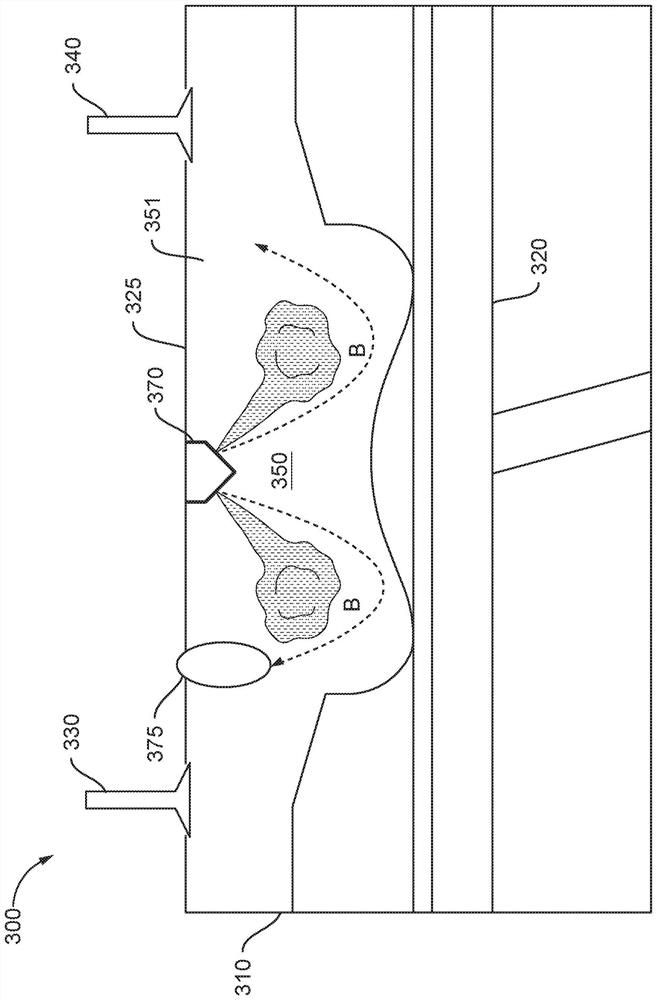

Cold start for high octane fuel in diesel engine architecture

A technology of engines and engine cylinders, applied in the direction of incandescent ignition of engines, engine components, combustion engines, etc., can solve the problems of high initial cost and difficulty in starting diesel engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Chemical fuels (petroleum, alcohols, biodiesel, etc.) are still important for heavy road transport. Their high energy density is important for users who need to travel long distances and refuel quickly. As a result, the demand for chemically fueled diesel engines will continue for decades. However, diesel fuel prices have risen substantially over the past three decades, and diesel fuel is a significant contributor to greenhouse gas emissions. In addition, for nitrogen dioxide and nitric oxide (collectively referred to as NO x ) and smoke emission standards are becoming more and more stringent.

[0012] The use of cleaner, low-carbon alternative fuels such as methanol, ethanol, dimethyl ether (DME) and natural gas has become increasingly common in the US energy sector over the past two decades. From 2000 to 2018, U.S. ethanol production increased tenfold from 1.6 billion gallons per year to 16.1 billion gallons. During the same period, natural gas production in the U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com