Down coat manufacturing technology

A preparation process and technology for down jackets, which are applied to sewing tools, clothing, clothing, etc., can solve problems such as troublesome production process, uneven down, and affecting thermal performance, etc., and achieve simple preparation method, convenient preparation, and down filling effect uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

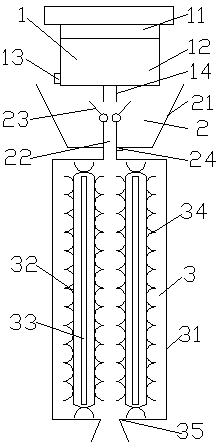

Image

Examples

Embodiment 1

[0028] A down jacket preparation process, through the steps of cutting, making, down ball preparation, down ball stuffing and sewing steps, completes down jacket preparation; the specific steps are as follows:

[0029] (1) Cutting: Cut the lining and fabric according to the pattern, and cut it into: front piece, back piece, sleeves, collar, hat, pocket;

[0030] (2) Production: Arrange lines according to drawings and samples, needle pitch: 11-13 needles / 3cm open stitches, 12-14 needles / 3cm dark stitches; The color thread of the same color of the fabric; the line of each part should be straight, there should be no single jump or continuous skip stitches within 30cm of the sewing stitches, no skip stitches are allowed in the overlock stitches, the upper and lower threads should be tight and suitable, and the ups and downs must be stitched Back stitch;

[0031] (3) Preparation of down balls: After pre-treatment of down, compression of down, preparation of water-soluble adhesive,...

Embodiment 2

[0042] A down jacket preparation process, through the steps of cutting, making, down ball preparation, down ball stuffing and sewing steps, completes down jacket preparation; the specific steps are as follows:

[0043] (6) Cutting: Cut the lining and fabric according to the pattern, and cut it into: front piece, back piece, sleeves, collar, hat, pocket;

[0044] (7) Production: Arrange lines according to drawings and samples, needle pitch: 11-13 needles / 3cm open stitches, 12-14 needles / 3cm dark stitches; The color thread of the same color of the fabric; the line of each part should be straight, there should be no single jump or continuous skip stitches within 30cm of the sewing stitches, no skip stitches are allowed in the overlock stitches, the upper and lower threads should be tight and suitable, and the ups and downs must be stitched Back stitch;

[0045] (8) Preparation of down balls: After pre-treatment of down, compression of down, preparation of water-soluble adhesive, w...

Embodiment 3

[0056] A down jacket preparation process, through the steps of cutting, making, down ball preparation, down ball stuffing and sewing steps, completes down jacket preparation; the specific steps are as follows:

[0057] (11) Cutting: Cut the lining and fabric according to the pattern, and cut it into: front piece, back piece, sleeves, collar, hat, pocket;

[0058] (12) Production: Arrange lines according to drawings and samples, needle pitch: 11-13 needles / 3cm open stitches, 12-14 needles / 3cm dark stitches; The color thread of the same color of the fabric; the line of each part should be straight, there should be no single jump or continuous skip stitches within 30cm of the sewing stitches, no skip stitches are allowed in the overlock stitches, the upper and lower threads should be tight and suitable, and the ups and downs must be stitched Back stitch;

[0059] (13) Preparation of down balls: After down pretreatment, down compression, preparation of water-soluble adhesive, dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com