Splitting machining method for shells of horizontal splitting type centrifugal compressor case

A centrifugal compressor and horizontal split technology, which is applied in the field of compressor shell processing, can solve the problems of tolerance and inability to guarantee the machining dimensional accuracy of each part of the shell, and achieve the goal of solving the limited load-bearing and ensuring the accuracy of machining dimensions and geometric tolerances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

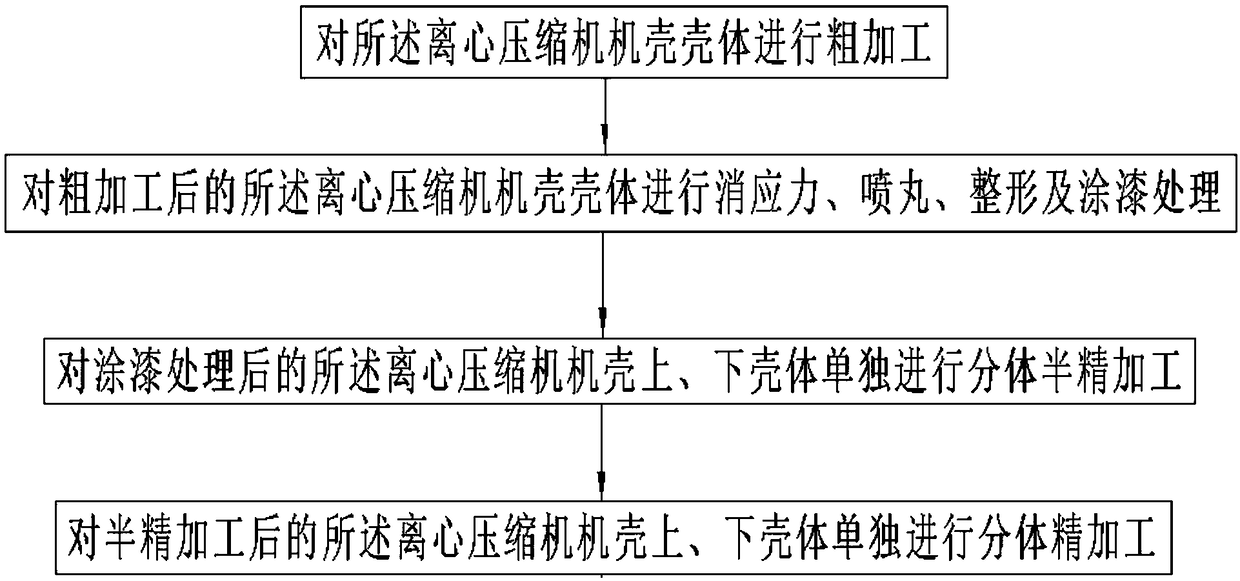

[0038] see figure 1 According to an embodiment of the present invention, a split processing method for a casing shell of a horizontally split centrifugal compressor includes the following steps:

[0039] Step 1, rough machining the shell of the centrifugal compressor.

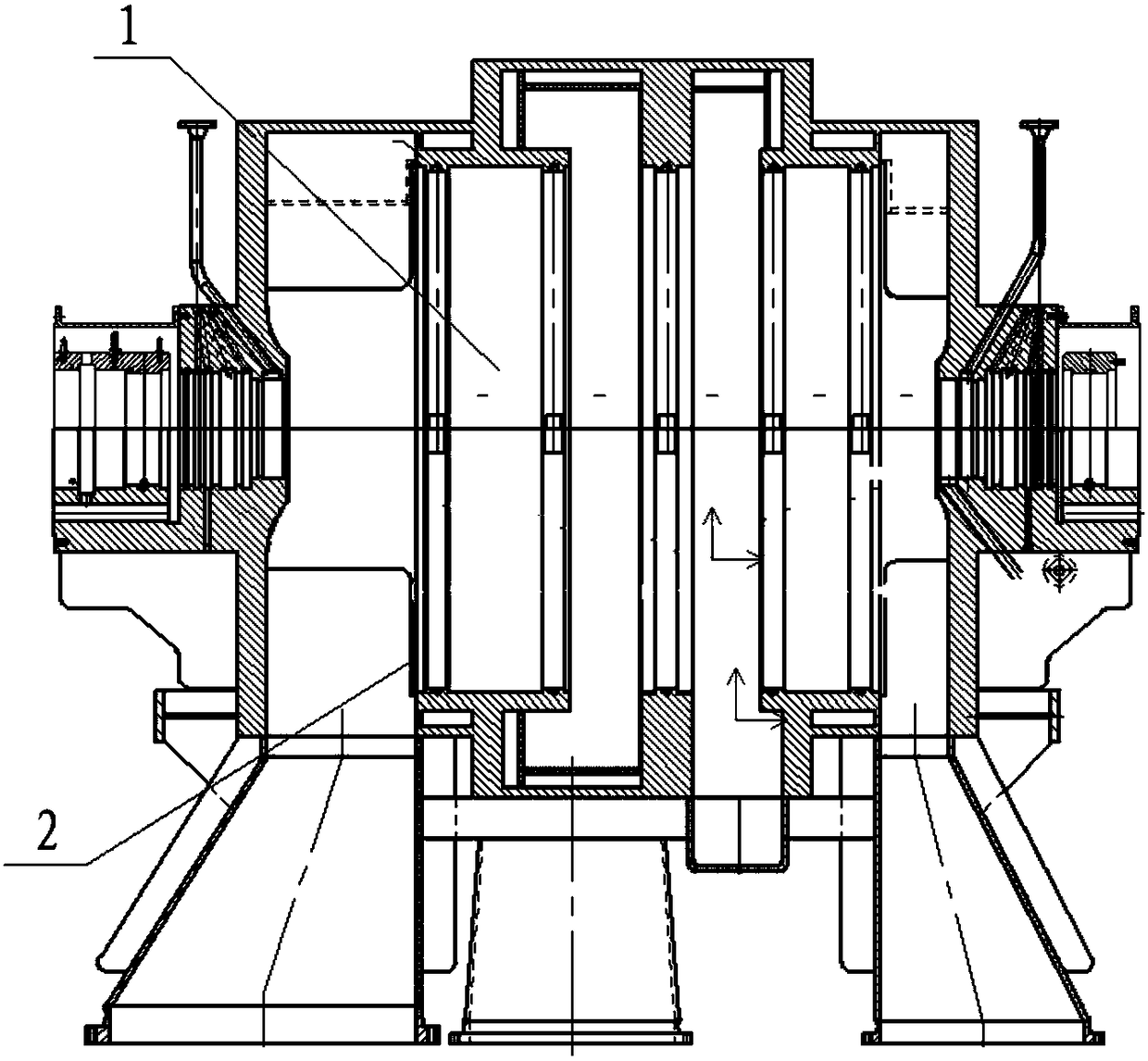

[0040] see figure 2 , the rough processing includes: the first scribing of the upper casing 1 and the lower casing 2 of the centrifugal compressor casing by gantry milling, checking the size margins of the upper casing 1 and the lower casing 2, and the upper casing 1 and the end faces of the sealing area of the lower casing 2 as a reference basis, the marking process draws the horizontal mid-section processing lines of the upper casing 1 and the lower casing 2 in the casing of the centrifugal compressor, and the inlet and outlet of the lower casing 2 Air outlet flange plane processing line, outrigger plane processing line, check the bearing area, sealing area, abdominal cavity axial and radial dimensions, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com