Floor drain brick and floor drain structure

A technology for floor drain and floor drain cover, which is applied to drainage structures, building structures, waterway systems, etc., can solve the problems of increasing the economic investment in decoration, the overall effect affecting the appearance of decoration, etc., and achieving the effect of facilitating drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

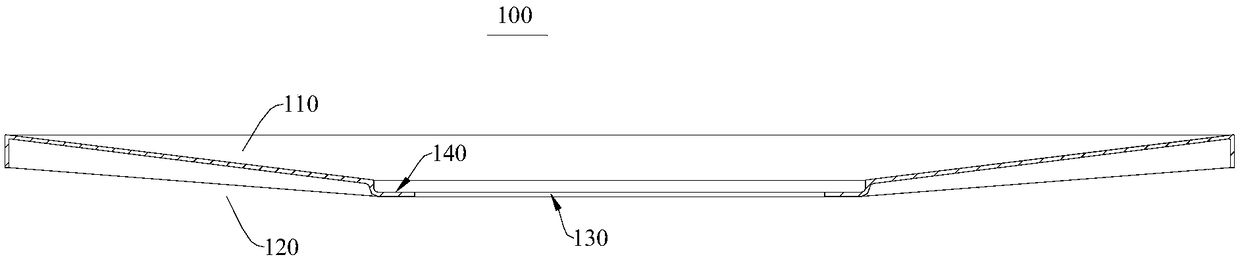

[0042] This embodiment provides a floor drain tile 100, please refer to figure 1 . figure 1 A schematic structural diagram of the floor drain tile 100 from a first viewing angle is shown.

[0043] In this embodiment, the floor drain tile 100 has an integral structure, and the floor drain tile 100 includes opposite first sides 110 and second sides 120 . Such as figure 1 As shown, the floor drain tile 100 includes an upper side and a lower side.

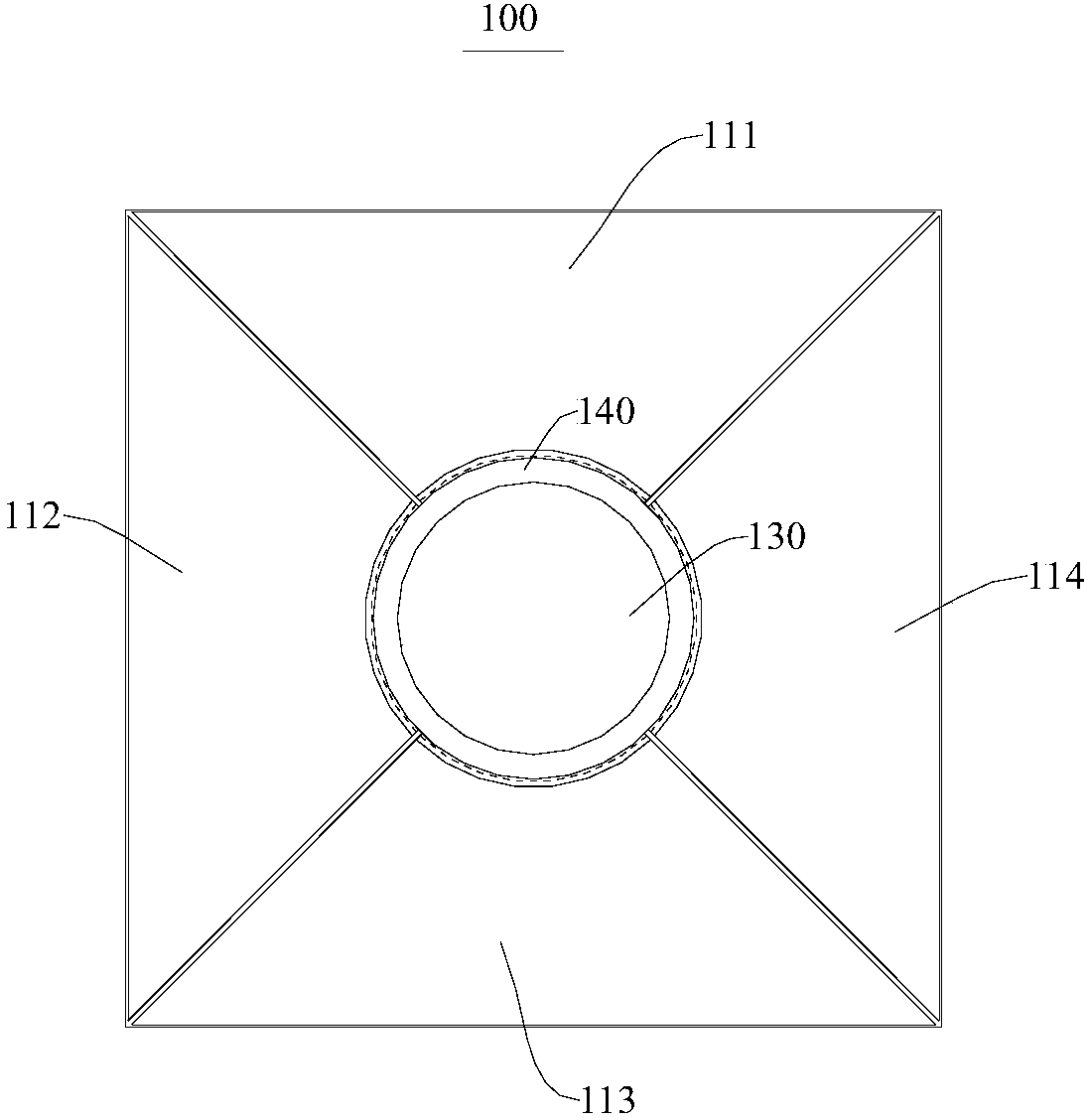

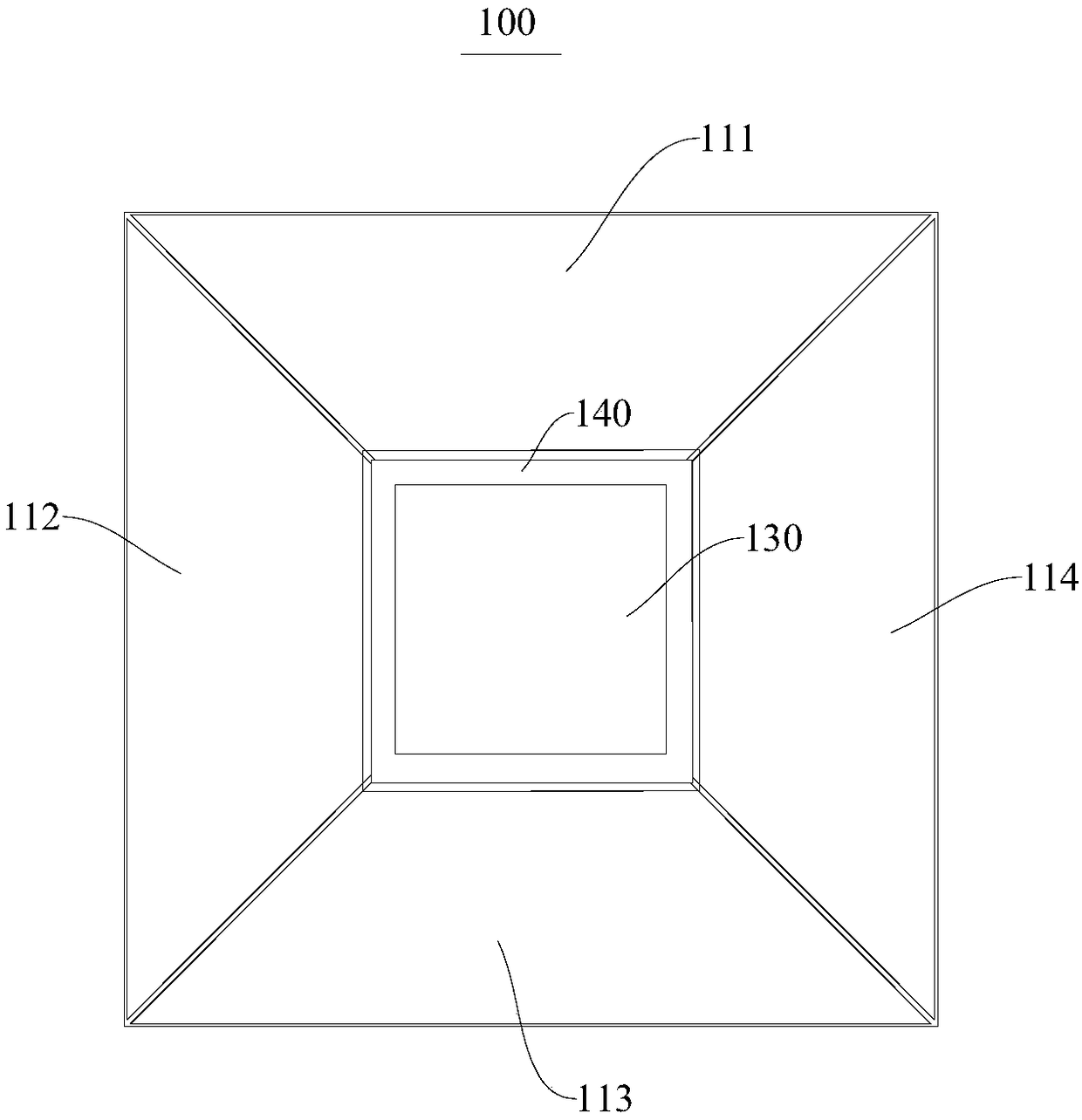

[0044] The floor drain tile 100 is provided with a floor drain installation hole 130 penetrating through the first side 110 and the second side 120, and the periphery of the floor drain installation hole 130 forms an installation step 140, wherein the size of the floor drain installation hole 130 matches the size of the floor drain main body 210. The surface of the first side 110 of the floor drain tile 100 and the installation step 140 have a preset inclination angle. That is, the surface of the first side 110 of the floor drain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com