Multifunctional pipe joint

A kind of pipe joint, multi-functional technology, applied in the direction of pipe/pipe joint/pipe fitting, hose connection device, mechanical equipment, etc., can solve the problem that the pipe joint cannot be reused, increase the cost of use, waste resources, etc. The effect of repeated use, improved sealing, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

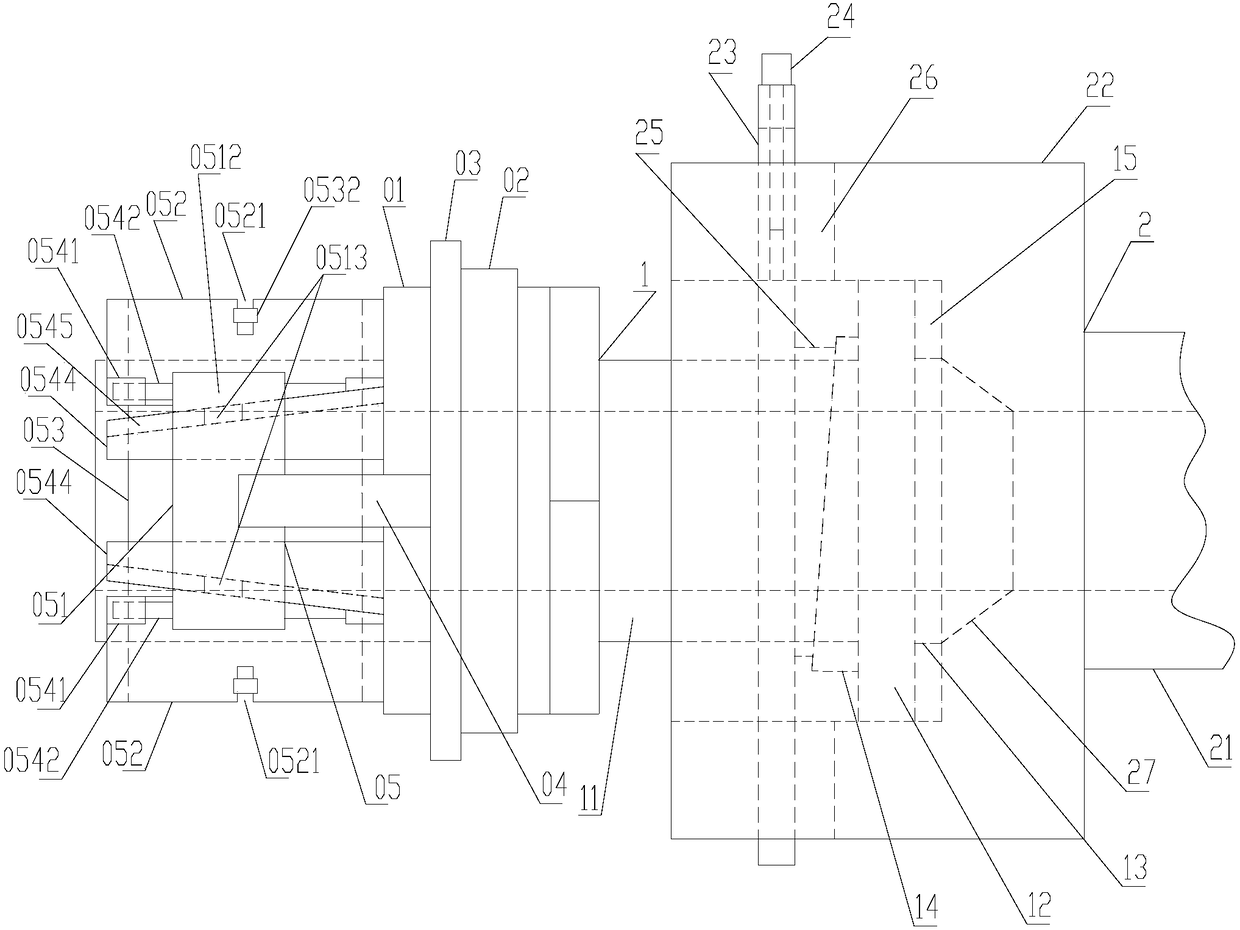

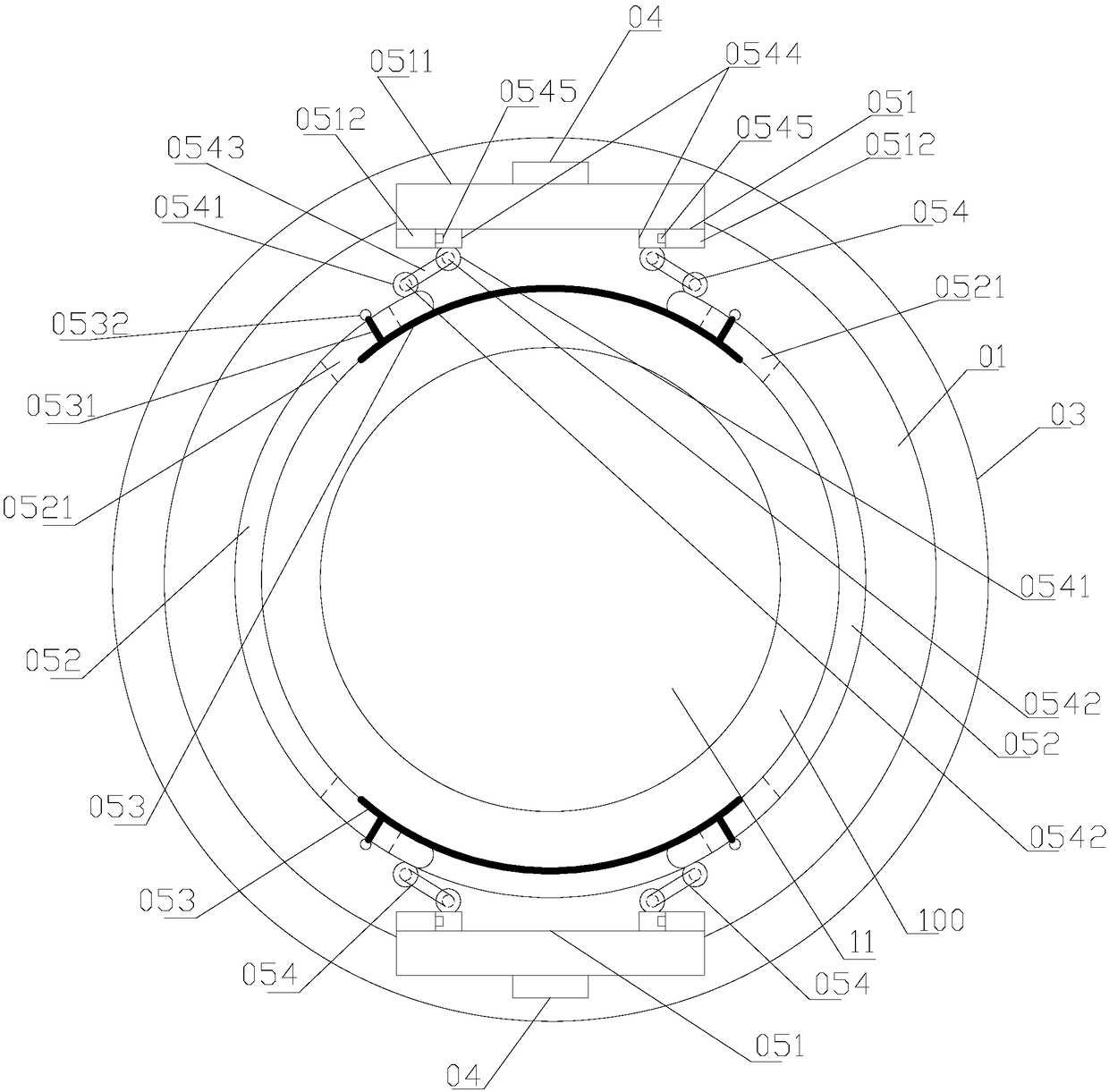

[0017] refer to figure 1 , 2 , a multifunctional pipe joint of the present invention, comprising a first connector 1 and a second connector 2 detachably connected to the first connector 1, the first connector 1 includes a pipe body 11 integrally formed on the pipe body The blocking step 12 on the rear end of the 11 and the plug-in body 13 integrally formed on the rear end of the blocking step 12, the through hole of the tube body 11 extends backward and passes through the blocking step 12 and the plug-in body 13 in turn, the blocking The front end of the step 12 is provided with two protrusions 14 respectively located on both sides of the pipe body 11. The front ends of the protrusions 14 are inclined surfaces, and the rear end of the insertion body 13 is a conical surface. An annular protrusion 01 is provided, and a fastening nut 02 threaded on the said annular protrusion 01 is provided. There are two symmetrically arranged pull rods 04, and the front ends of the two pull r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com