Method for conducting a vibration diagnostic monitoring of a machine

A technology of machines and machine parts, which is applied in the field of devices implementing the method, can solve problems such as the difficulty in estimating the source of vibration behavior, the correlation of operating parameters of machine vibration behavior that cannot be measured in discontinuous motion, and the complexity of motion patterns, etc., to save calculations Effects of Time and Computing Power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The following will refer to Figure 1 to Figure 11 The invention is explained in detail, wherein the same reference numerals refer to the same structural and / or functional features.

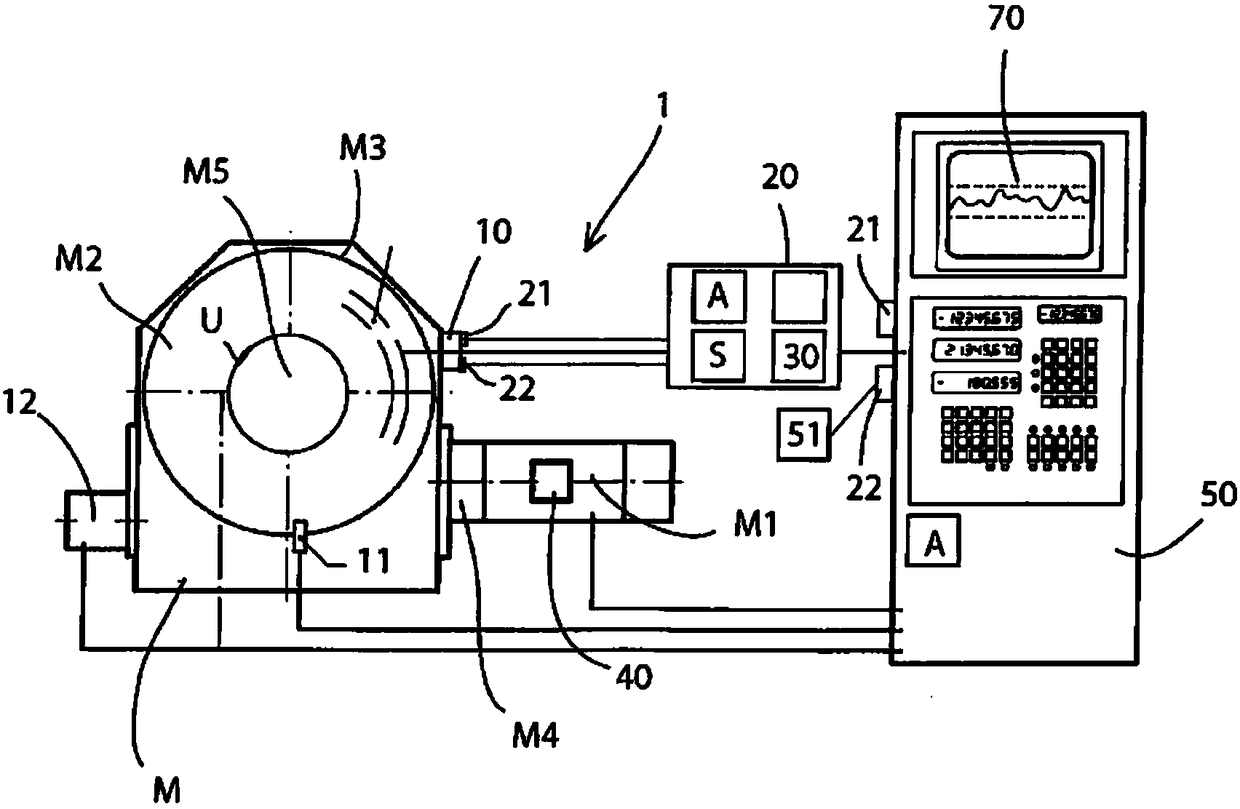

[0083] figure 1 A schematic diagram of a machine M (here a rotary table) is shown with machine components M1 , . . . , M5 and a device 1 with a vibration sensor 20 for measuring vibrations.

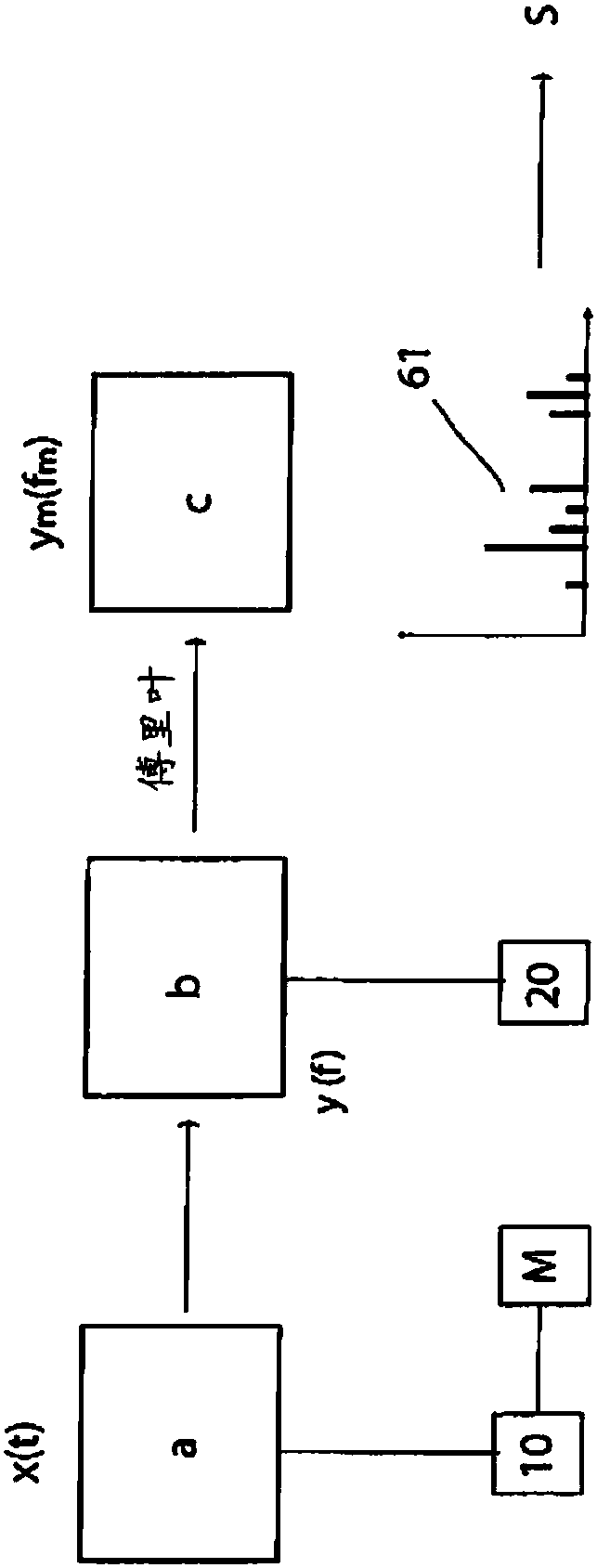

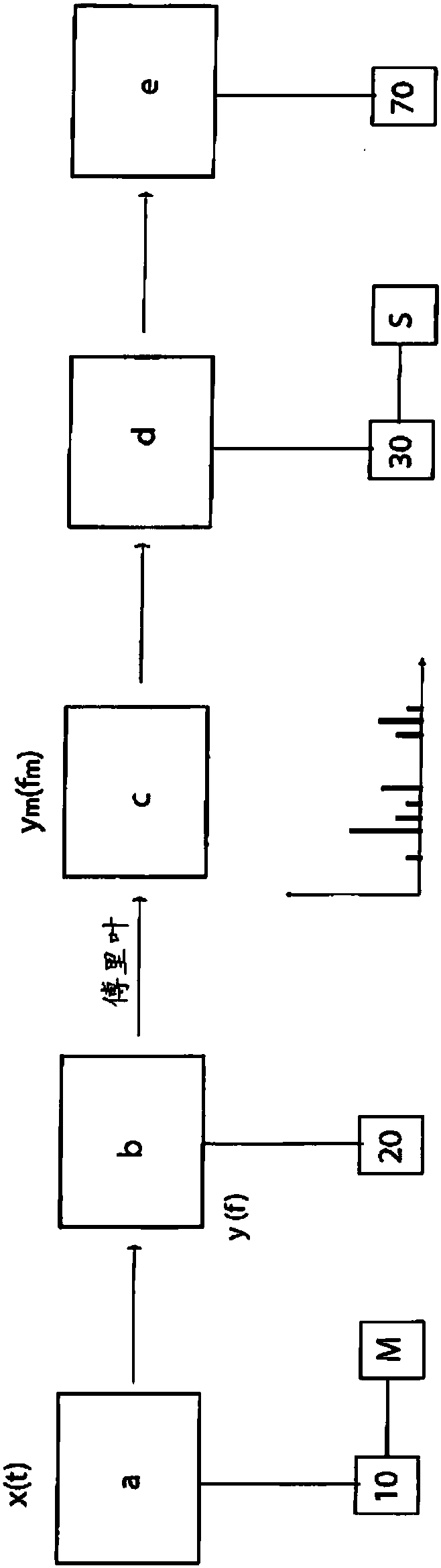

[0084] Device 1 is constructed to implement figure 2 and image 3 A method for vibration diagnostic monitoring and evaluation of individual machine parts M1, . . . , M5 of a machine M shown in the block diagram.

[0085] The machine M is equipped with a vibration sensor 10, which is used for discontinuous or continuous measurement and / or detection such as Figure 4 The time signal x(t) shown exemplarily in . Furthermore, other sensors not shown in detail in the figures (for example temperature sensors etc.) can be provided.

[0086] In this embodiment, the vibration sensor 10 detects the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com