Special anti-explosion bag dust collector used in underground coal mine

A bag-type dust collector, explosion-proof technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of equipment explosion, large equipment footprint, high equipment resistance, etc., and achieve the effect of preventing explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

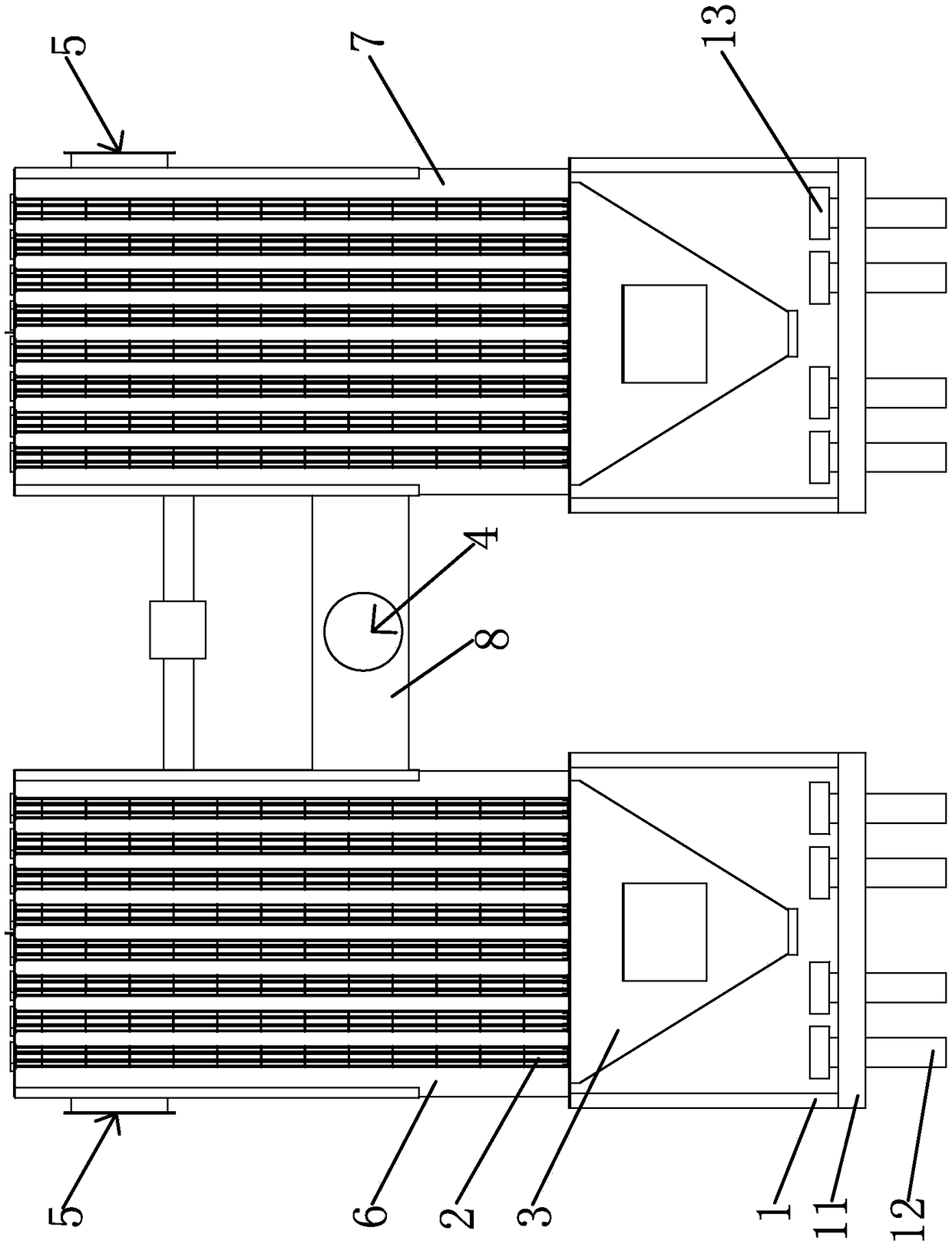

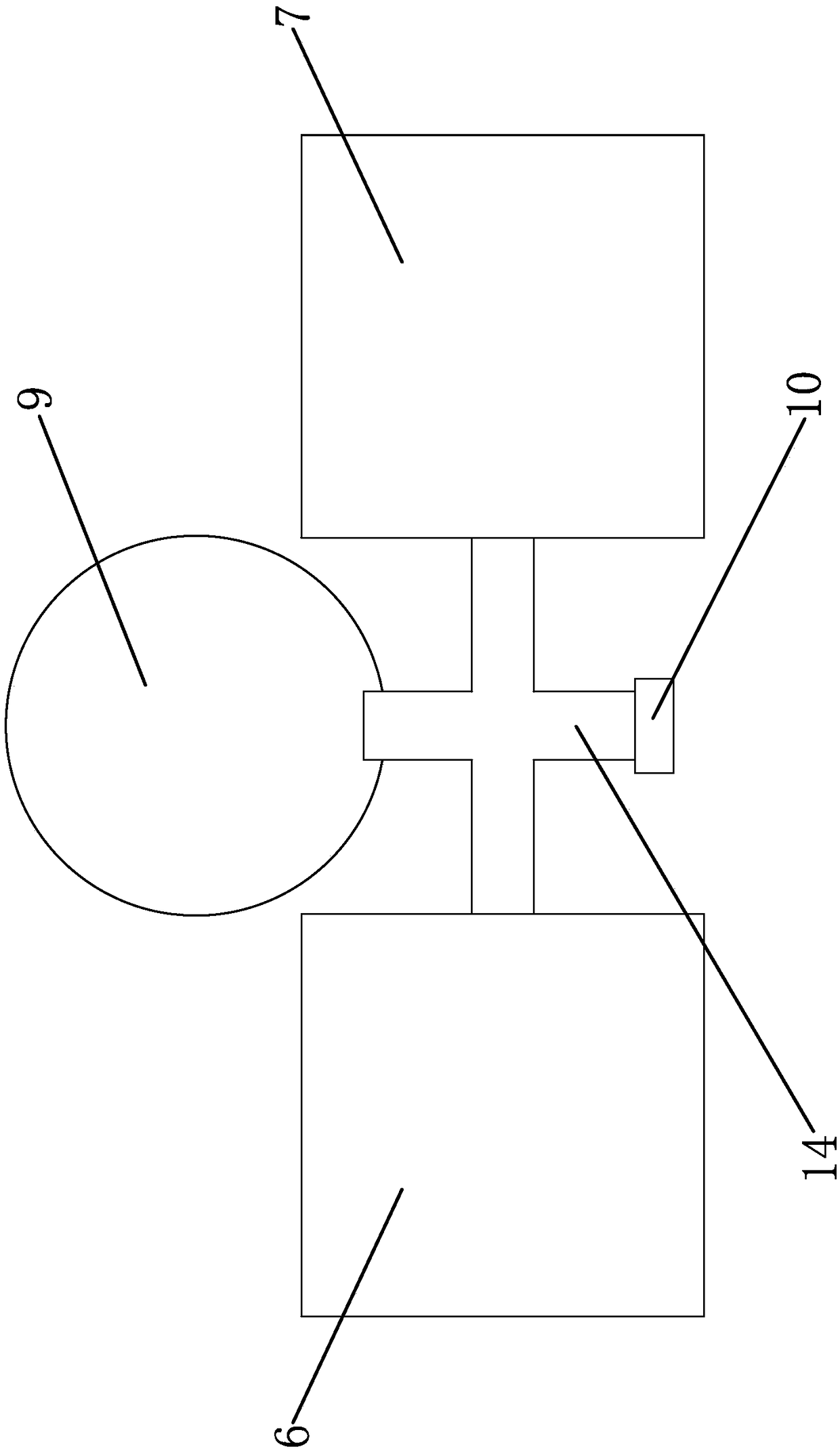

[0020] Such as Figure 1-2 As shown, the special explosion-proof bag filter for underground coal mines includes a frame 1, a main box is fixed on the frame 1, a number of bag cages 2 are fixed by bolts in the main box, and filter bags are set on the bag cage 2. There is an ash collecting hopper 3 connected to the bottom of the box, and the main box has an "H" shape structure. The main box includes a left working part 6, a right working part 7, and a welding connection part 8 between the left working part 6 and the right working part 7. The connecting part 8 is a connecting pipe, and the connecting pipe is provided with an air inlet 4, and the left working part 6 and the right working part 7 have air leakage ports and are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com