Pipe cutting device

A technology for cutting devices and pipes, which is applied to sawing machines, attachments of sawing machines, metal sawing equipment, etc., can solve the problems of increasing the labor intensity of operators, complicated cutting processes, and low work efficiency, so as to ensure fixed-length cutting. , novel structure, high work efficiency

Active Publication Date: 2019-04-09

安徽酷勒威拉丝模有限公司

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When cutting in this way, the steel pipe needs to be pre-clamped, and the steel pipe needs to be loosened when the steel pipe is removed. The whole cutting process is complicated, which increases the labor intensity of the operator, and the work efficiency is low.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

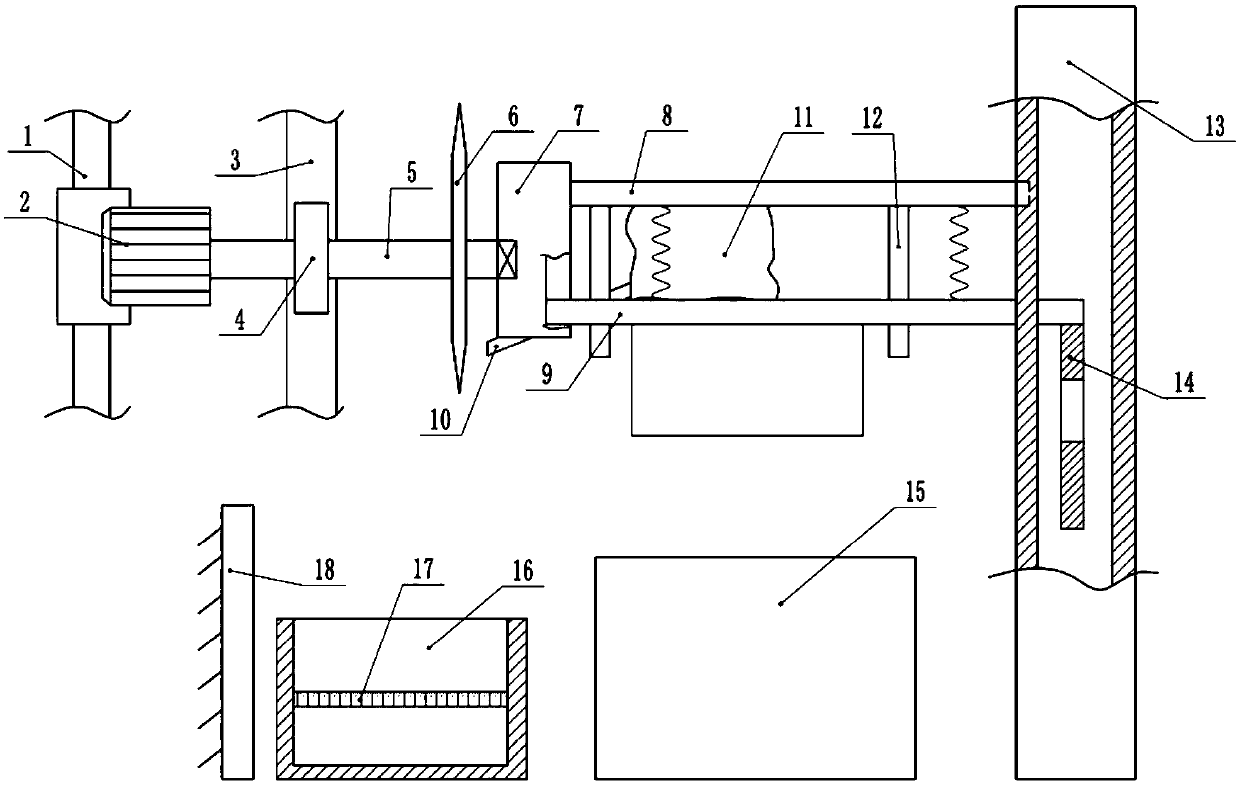

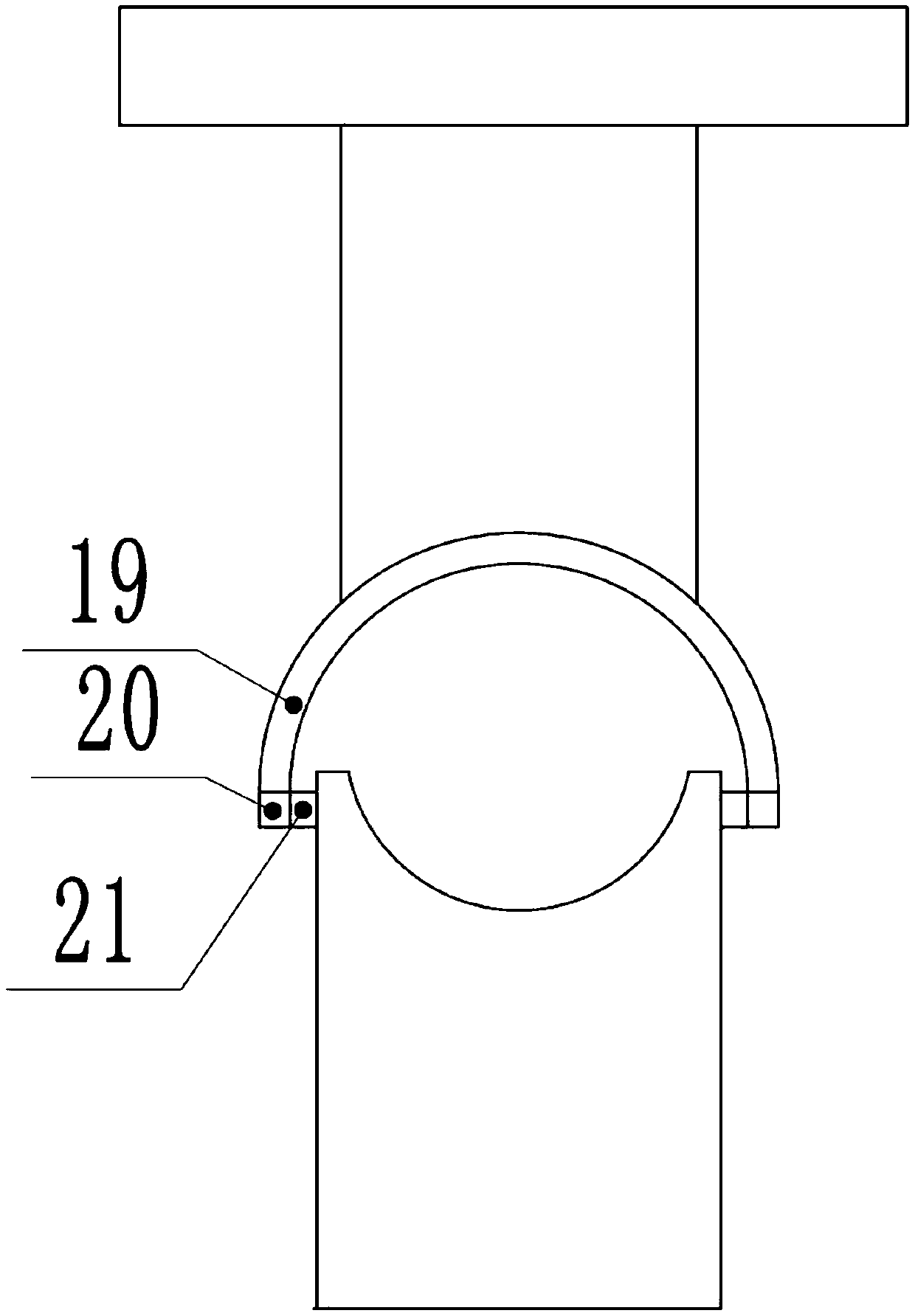

The invention belongs to the technical field of cutting equipment, and particularly discloses a pipe cutting device. The pipe cutting device comprises a sliding rail and a motor in sliding connectionwith the sliding rail. A transmission gear and a rotating shaft are connected to an output shaft of the motor, a machine frame is provided with a rack engaged with the transmission gear, a cutting sawblade is fixedly connected to the rotating shaft, and a sliding plate is rotationally connected to the end of the rotating shaft. A fixed plate is arranged on the right of the sliding plate, a lifting plate is arranged between the sliding plate and the fixed plate, a clamping plate is arranged below the lifting plate, the two ends of the clamping plate are in sliding connection with the sliding plate and the fixed plate correspondingly, a water bag is arranged between the lifting plate and the clamping plate, and the water bag is connected with a water pipe. A push plate with a through hole is in sliding connection with the interior of the fixed plate, the push plate is fixedly connected with the clamping plate, a base is arranged below the clamping plate, and one side of the base is provided with a trough and a baffle. A steel pipe is rapidly cut, and working efficiency is improved.

Description

technical field [0001] The invention belongs to the technical field of cutting equipment, and in particular relates to a pipe material cutting device. Background technique [0002] At present, due to the simple, convenient and fast process of steel processing and production, construction and installation, it has become an important material component required in various fields and is widely used in various fields of national economic construction; especially steel pipes, in our industrial production The application is more and more extensive. Now in the production of automobiles, steel pipes are also an indispensable material, and steel pipes for automobiles are used as the necessary connection and fixing parts for the parts produced by automobiles. [0003] At present, in the production process of the enterprise, when the steel pipe is too long to affect the use, it is necessary to cut the steel pipe. In the prior art, one of the methods for cutting steel pipes is by manu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23D45/02B23D45/12B23D47/04B23D47/08B23D59/00B23D59/02

CPCB23D45/022B23D45/12B23D47/04B23D47/08B23D59/001B23D59/02

Inventor 李志华

Owner 安徽酷勒威拉丝模有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com