Locking mechanism for hub bearing and use method thereof

A locking mechanism and wheel bearing technology, applied in the direction of wheel hub, transportation and packaging, vehicle parts, etc., can solve the problems of vehicle performance and safety impact, inconvenient maintenance, large fluctuation of preload force, etc., and achieve relative positional relationship. Stable, easy maintenance, flexible disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

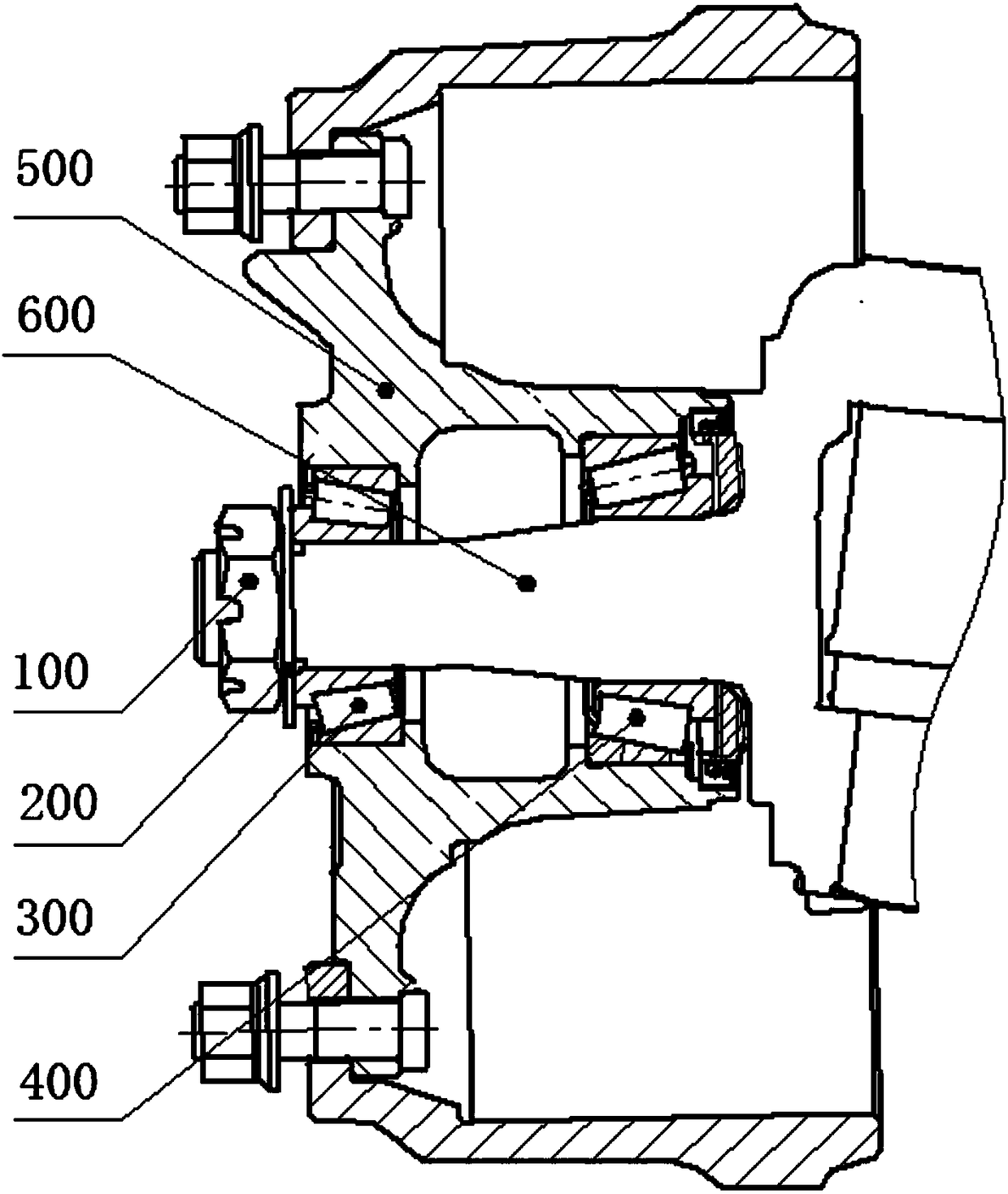

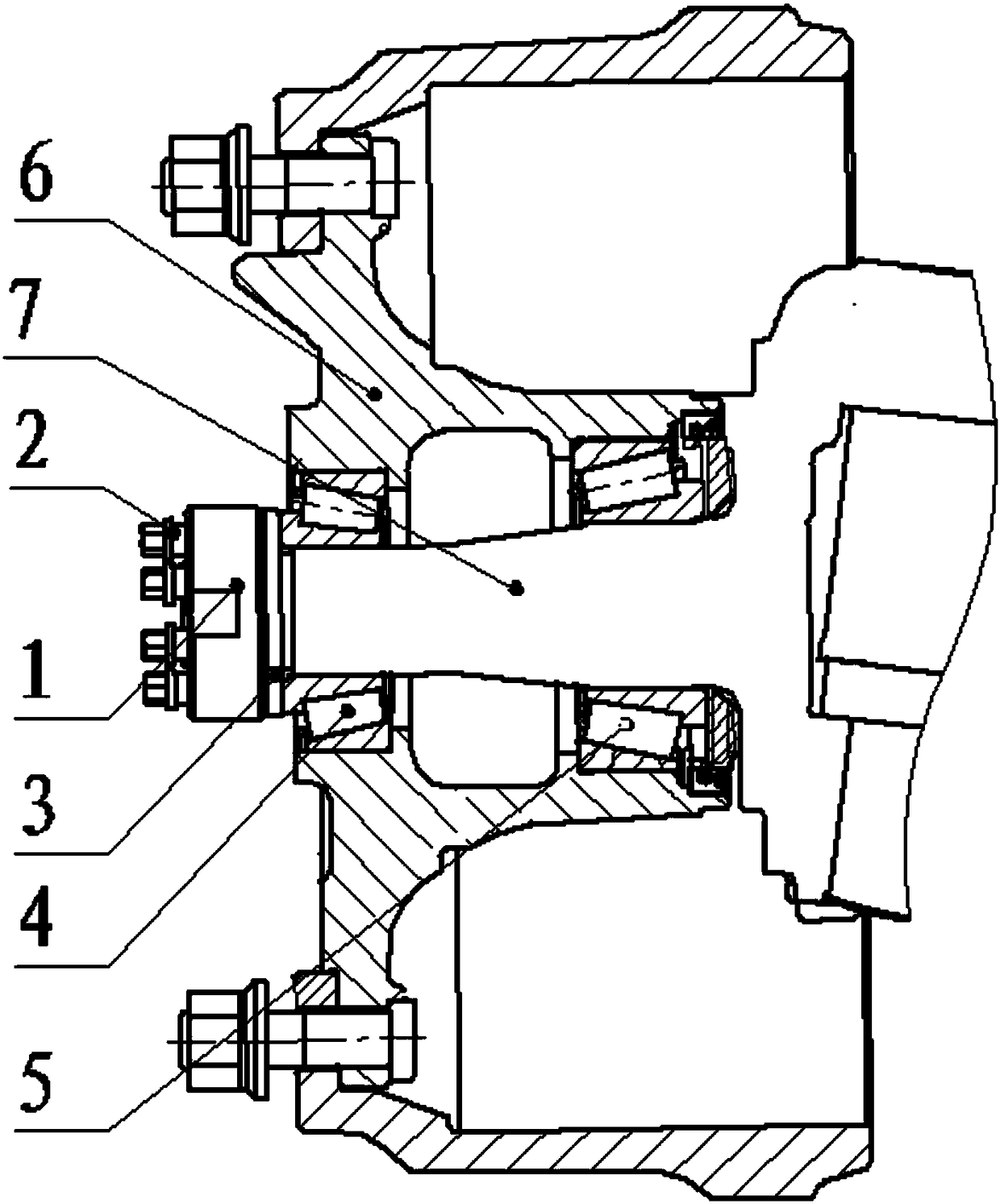

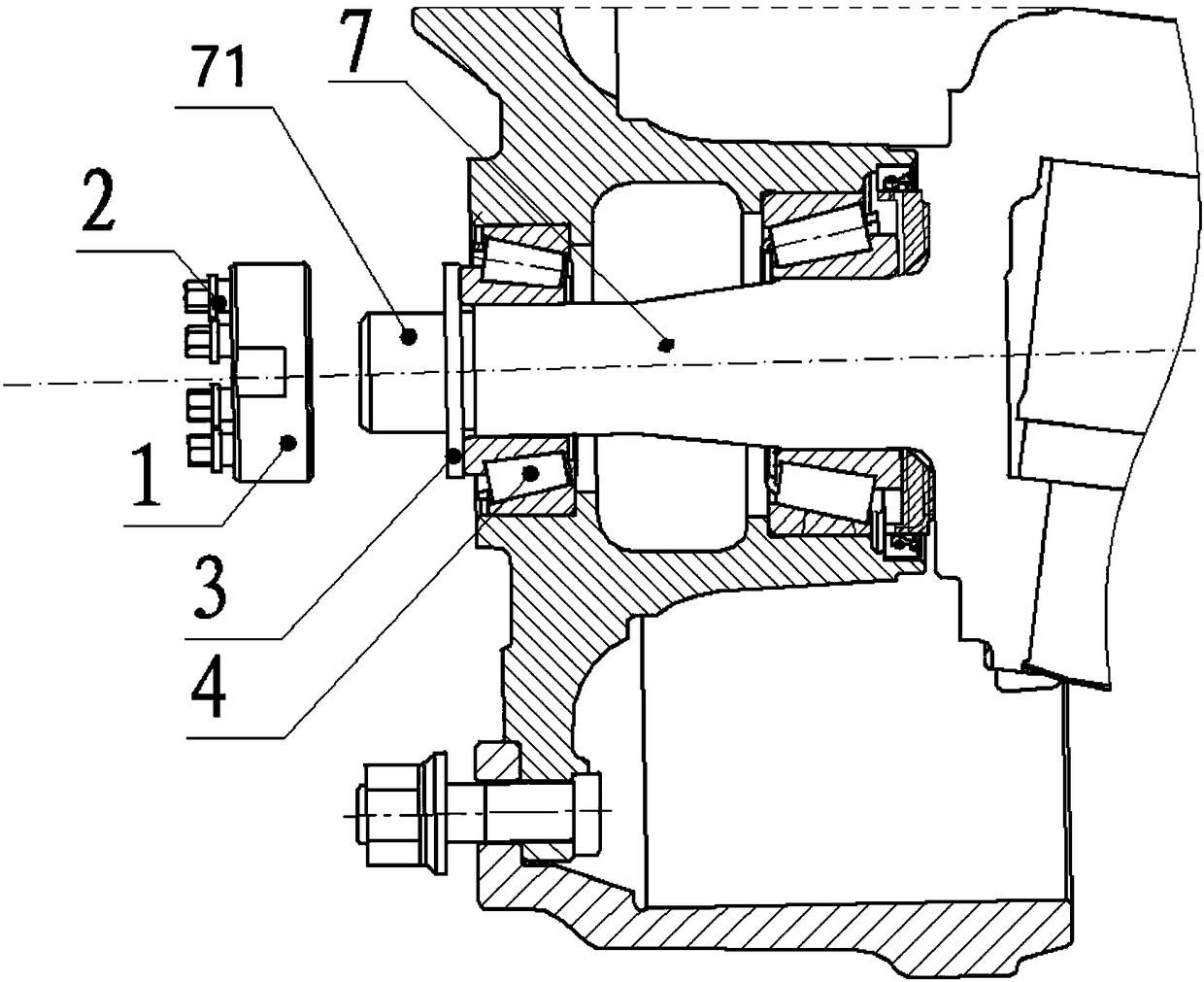

[0047] Such as Figure 2 to Figure 6 As shown, the embodiment of the present invention provides a locking mechanism for hub bearings, including a steering knuckle 7, the steering knuckle 7 has a rotating shaft 71, and the inner hub bearing 5, The hub 6, the outer hub bearing 4, the outer circumference of the end of the rotating shaft 71 is distributed with external threads, and also includes a lock nut 1 and a push bolt 2, the lock nut 1 has a threaded hole 101, and the lock nut 1 is connected to the rotating shaft through the threaded hole 101 The outer circumference of 71 is threaded; the edge of the lock nut 1 is provided with several mounting holes 102 in the axial direction, and the mounting holes 102 are arranged in a circular array with the threaded hole 101 as the center; the number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com