Cartridge 2D servo valve with temperature compensated damping piston

A damping piston and temperature compensation technology, applied in servo motor components, valve operation/release devices, multi-way valves, etc., can solve problems such as damping reduction, and achieve increased stability, high power density ratio, and high application integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

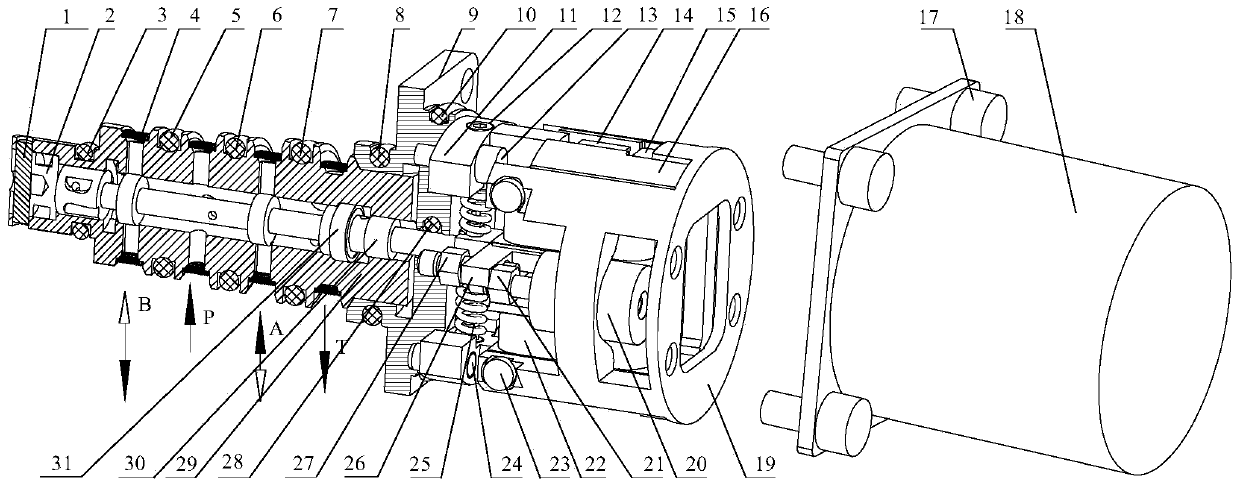

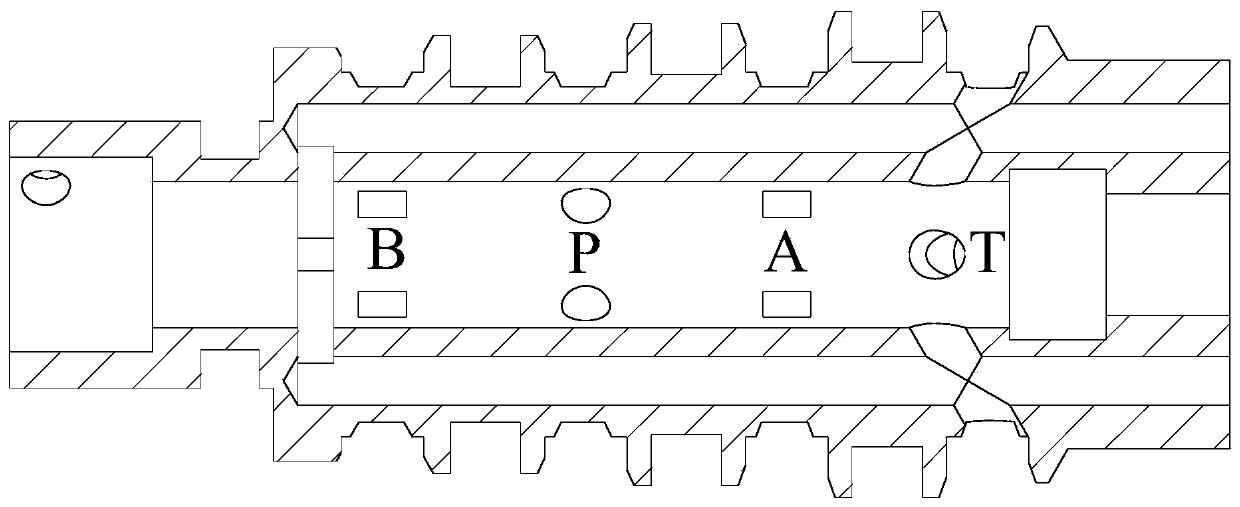

[0040] refer to Figure 1 to Figure 9 , a cartridge-type two-dimensional (2D) servo valve with a temperature-compensated damping piston, including a valve body module, an electro-mechanical converter module, and a position sensor module.

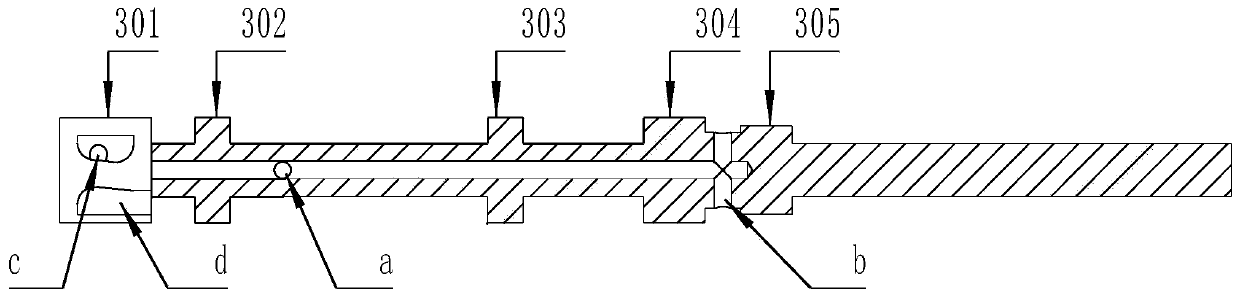

[0041] The valve body module includes a valve core 30, a valve sleeve 29, a damping piston 31, a valve sleeve pin 1, a left end cover 2, a filter screen 4, and a connecting plate 9; the electro-mechanical converter module adopts a torque motor, including a housing 11 and an armature 14 , permanent magnet 15, magnetizer 16, clip 19, motor cover 18, coil 22, motor pin 24, spring 25, spring rod 26, spring seat 12, limit rod 27, headless screw 32; the displacement sensor module includes LVDT Connecting rod 21, LVDT (composed of iron core 33 and coil frame 34) 20, meanwhile, the plug-in two-dimensional (2D) servo valve also includes O-ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com