Multi-rotor motor or generator

A motor and generator technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of narrow motor or generator range, low power density ratio, low transmission torque, etc., and achieve efficient working range and power density. The effect of high ratio and large torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

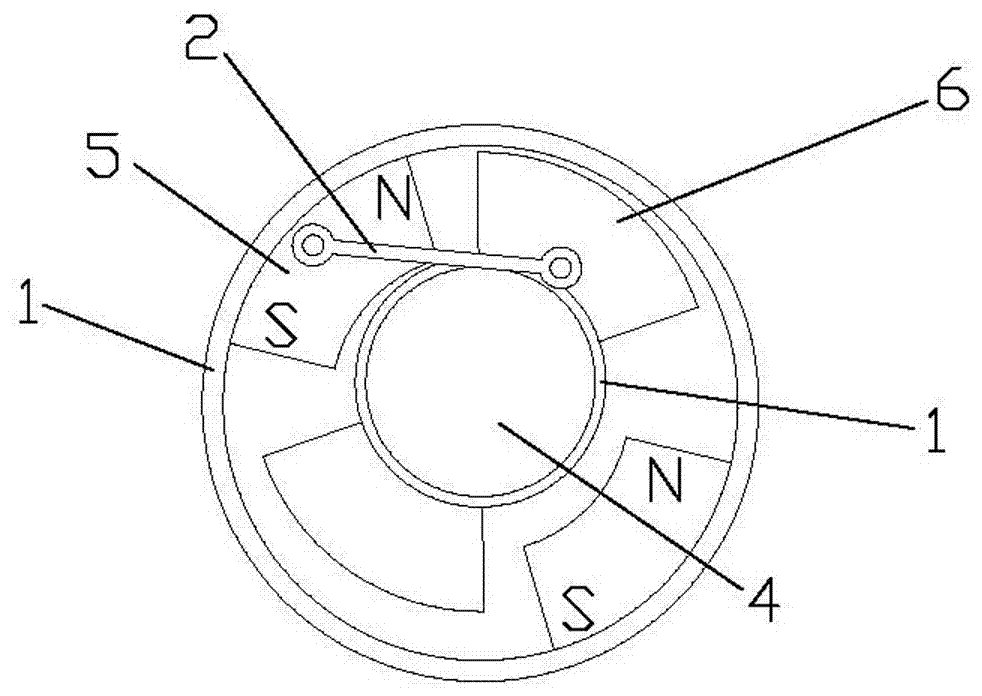

[0028] to combine figure 1 , The multi-rotor motor or generator includes a first rotor 1, a connecting rod 2, a second rotor 3, and an eccentric member 4; the eccentric member 4 is arranged on the frame, and the first rotor 1 is rotatably arranged on the machine frame On the frame, one end of the connecting rod 2 is rotatably arranged on the first rotor 1, the other end of the connecting rod 2 is rotatably arranged on the second rotor 3, and the second rotor 3 is rotatably arranged on the eccentric member 4. The eccentric 4 is not concentrically arranged with the first rotor 1 . In this embodiment, one first rotor 1 and one second rotor 3 are provided, a pair of first rotor magnetic poles 5 are arranged radially on the inner wall of the first rotor 1, and a pair of second rotor poles 5 are arranged radially on the outer wall of the second rotor. Two rotor poles 6. The first rotor poles 5 form a pair of N poles and S poles in the circumferential direction of the first rotor 1...

Embodiment approach

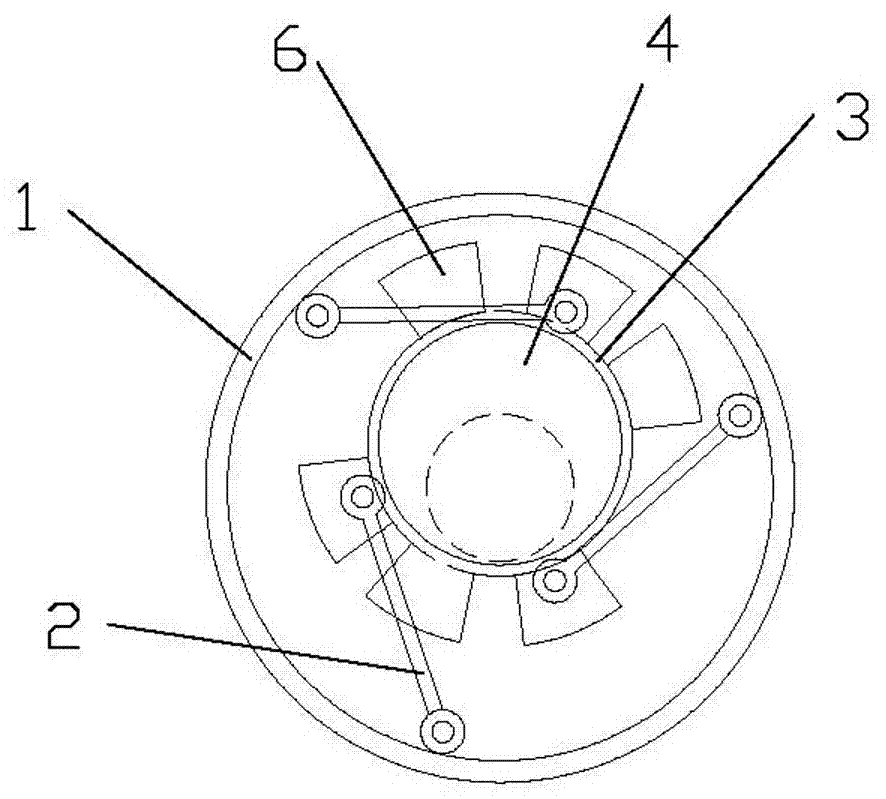

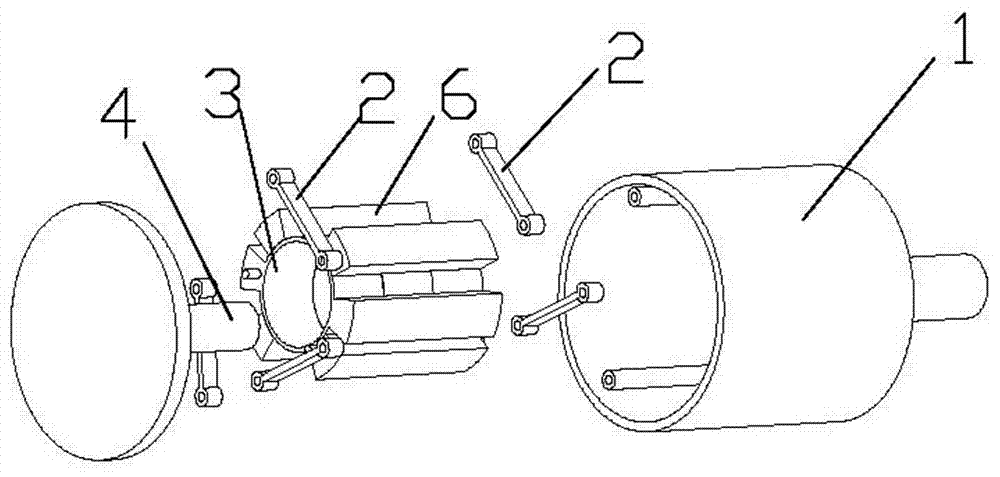

[0031] figure 2 It is a schematic plan view of the second rotor 3 of the present invention when there are three, image 3 yes figure 2 The schematic diagram of the decomposition structure of the shown embodiment, Figure 4 yes image 3 Schematic diagram of the assembled appearance structure, Figure 5 yes Figure 4 The A-A cross-sectional structure schematic diagram of Figure 6 yes figure 2 Schematic diagram of the internal rotor assembly structure.

[0032] figure 2 There are three connecting rods 2 in one-to-one correspondence with the three second rotors 3, and one end of the three connecting rods 2 is rotatably connected to the shaft / shaft hole evenly distributed on the inner wall of the first rotor 1, and the three connecting rods The other end of 2 is rotatably connected to the shafts / shaft holes distributed on the outer walls of the three second rotors 3 respectively, the three second rotors 3 are connected in series on the eccentric member 4, and the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com