A driving method and structure of a unidirectional closing and opening electrode

A technology of driving method and electrode structure, which is applied in the direction of contact driving mechanism, contact surface shape/structure, contact engagement, etc., can solve the problems of extremely high performance requirements and impossible realization of vacuum interrupter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

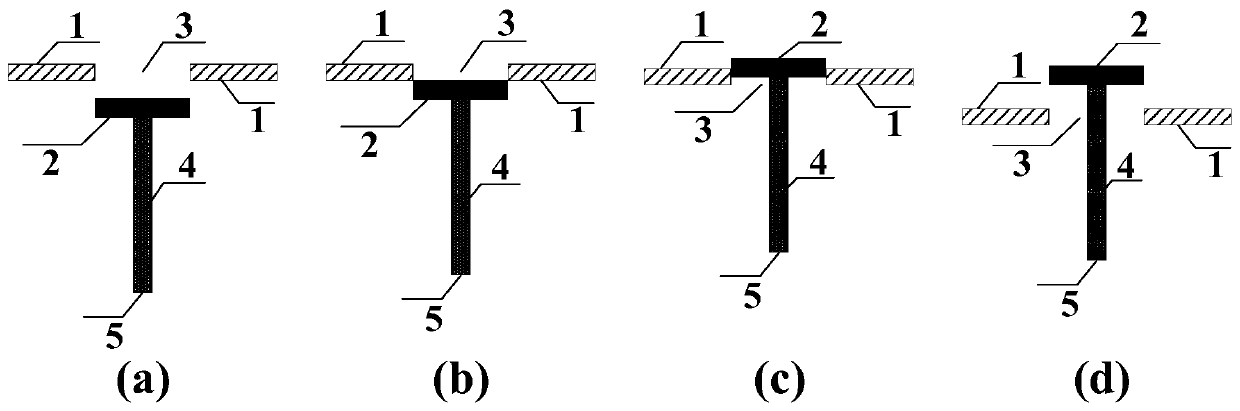

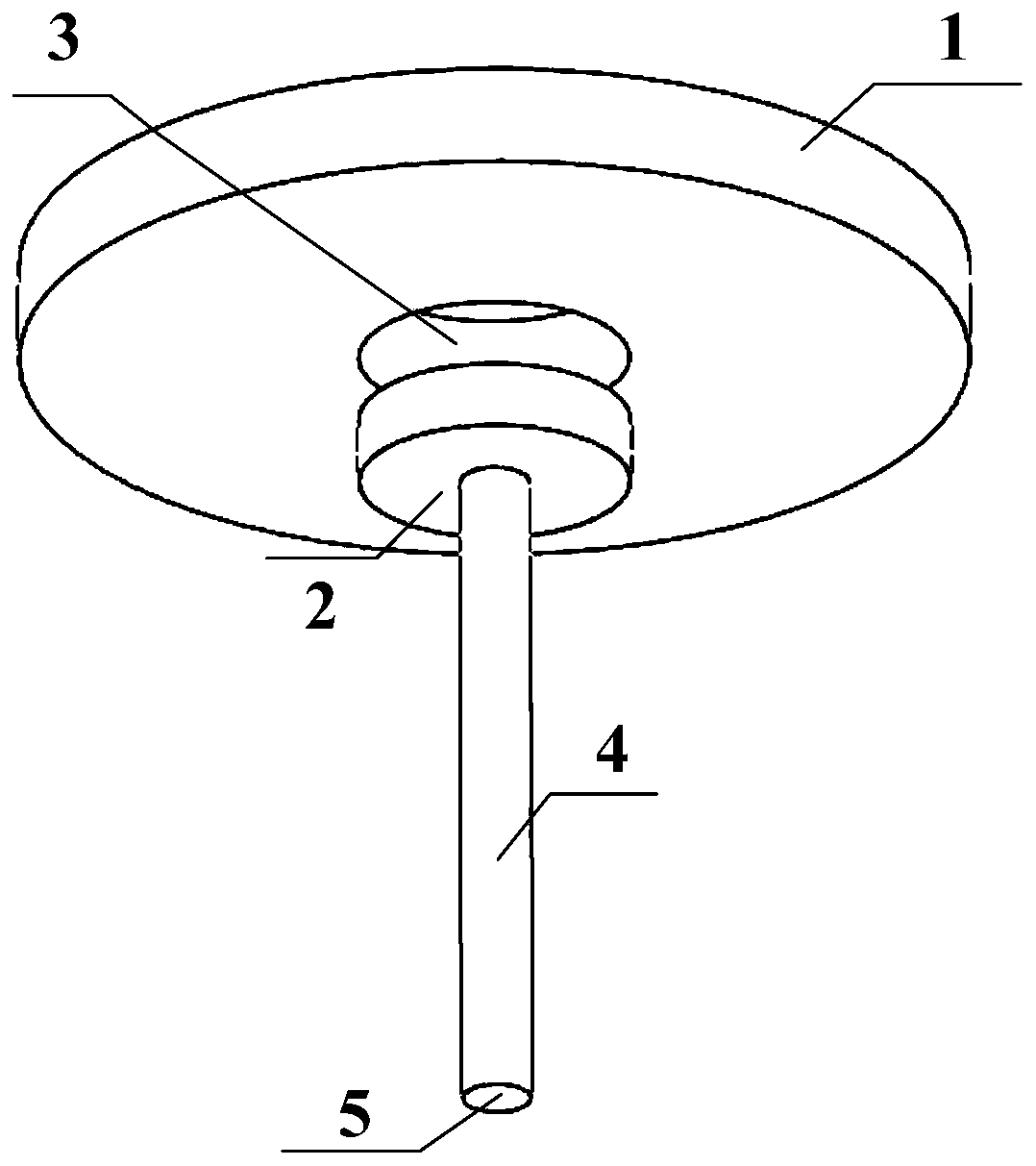

[0027] The invention provides a driving method for one-way closing and splitting electrodes, such as figure 1 As shown in (a), firstly, the moving electrode 2 is arranged on one side of the static electrode 1, and the moving electrode 2 and the static electrode 1 are in an open state, and the moving electrode 2 is opposite to the trigger hole 3, and the operating mechanism drives the guide rod 4 and The moving electrode 2 moves in a straight line towards the direction close to the static electrode 1; figure 1 As shown in (b), when the moving electrode 2 passes through the trigger hole 3 and just comes into contact with the static electrode 1, the moving electrode 2 and the static electrode 1 change to the closing state at this time, and the time to maintain the closing state begins to be calculated; figure 1 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com