Electronic assembly and method of producing the same

A technology of electrical components and electrical components, applied in the direction of applications, household components, household appliances, etc., can solve the problems of easy damage, loss of stability and elasticity, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] All features disclosed in the application documents are claimed as being of inventive value to the invention insofar as they are novel individually and / or in combination with respect to the prior art.

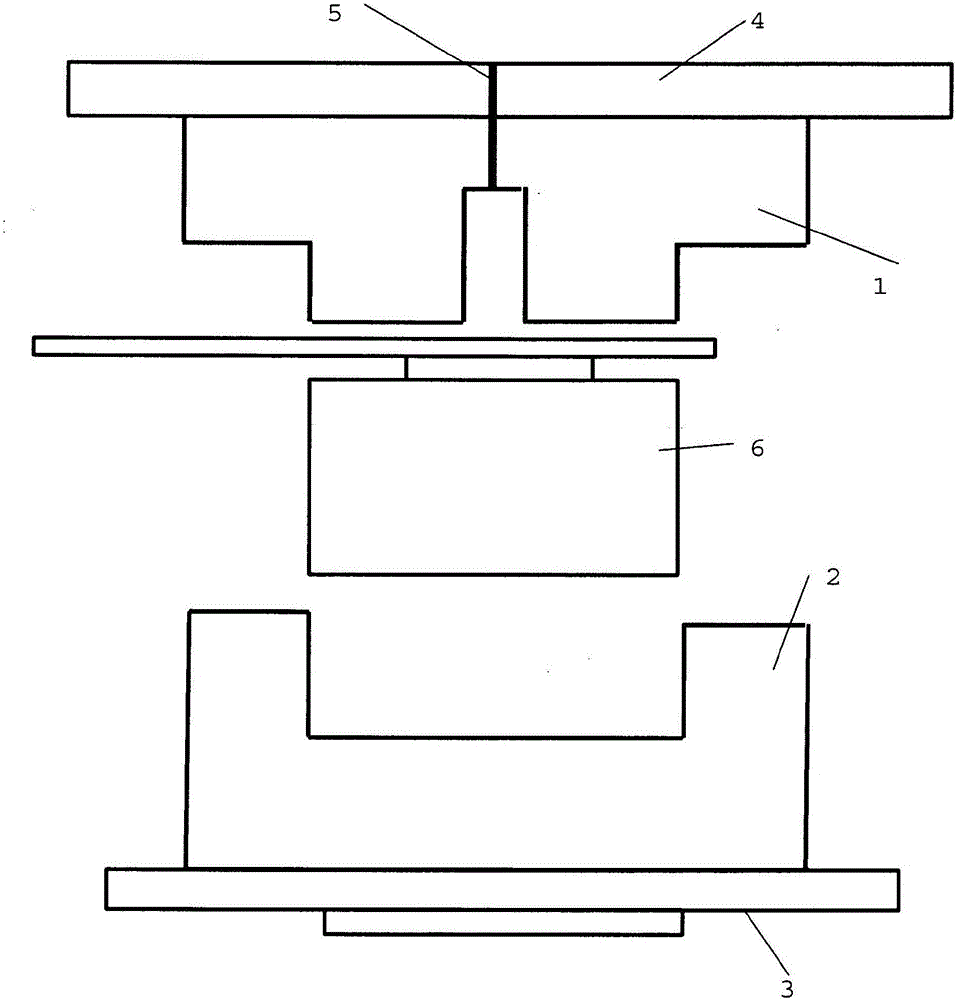

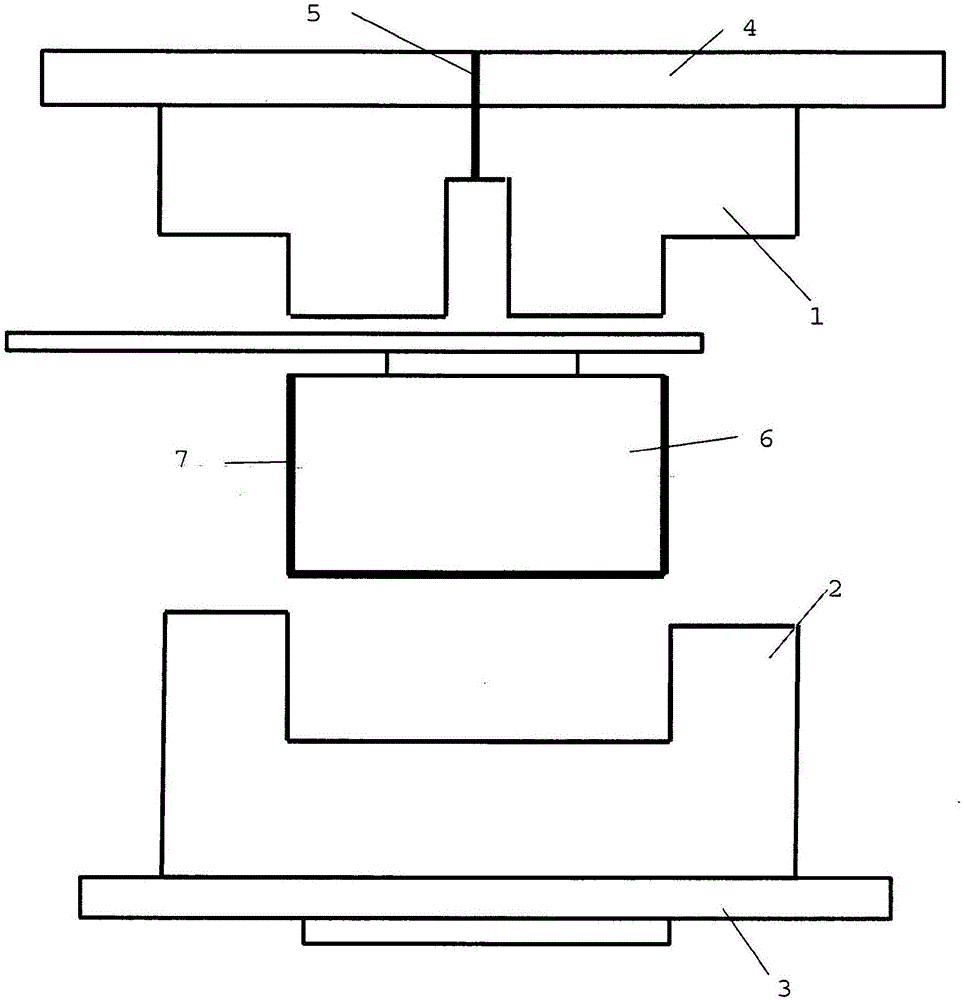

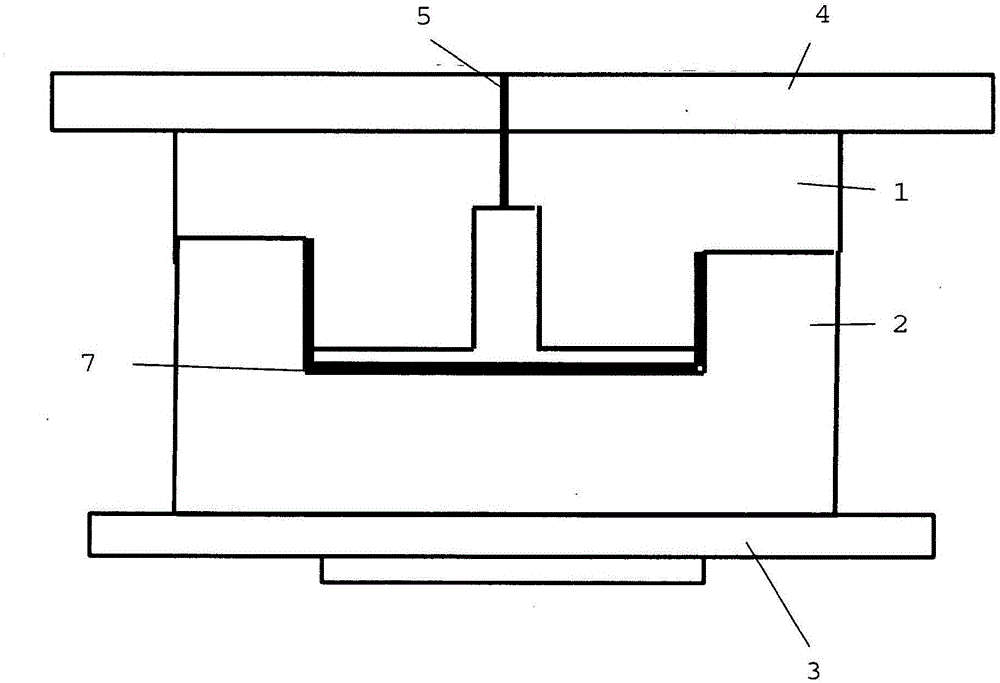

[0048] in about Figure 1 to Figure 6 In the description of the drawings, the same reference numerals are used for the same elements. This serves for a better understanding of the drawing description and its clarity. Reference signs are used in the corresponding figures only if they are meaningful for the description of the invention in connection with the corresponding figure.

[0049] exist figure 1 A schematic of the opened injection mold is shown in . The injection molding tool comprises two tool halves 1 , 2 which are each fixedly arranged on an anchor plate 3 , 4 . Integrated into one of the tool halves 1 is a sprue 5 into which the corresponding liquid plastic is pressed and fills the remaining cavity between the closed tool halves when the injection mold is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com