Welding-free combined battery pack

A battery pack, welding-free technology, applied to battery pack components, circuits, electrical components, etc., can solve problems such as missing soldering, virtual soldering, product quality problems, etc., to reduce costs, save process steps, and facilitate rapid maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

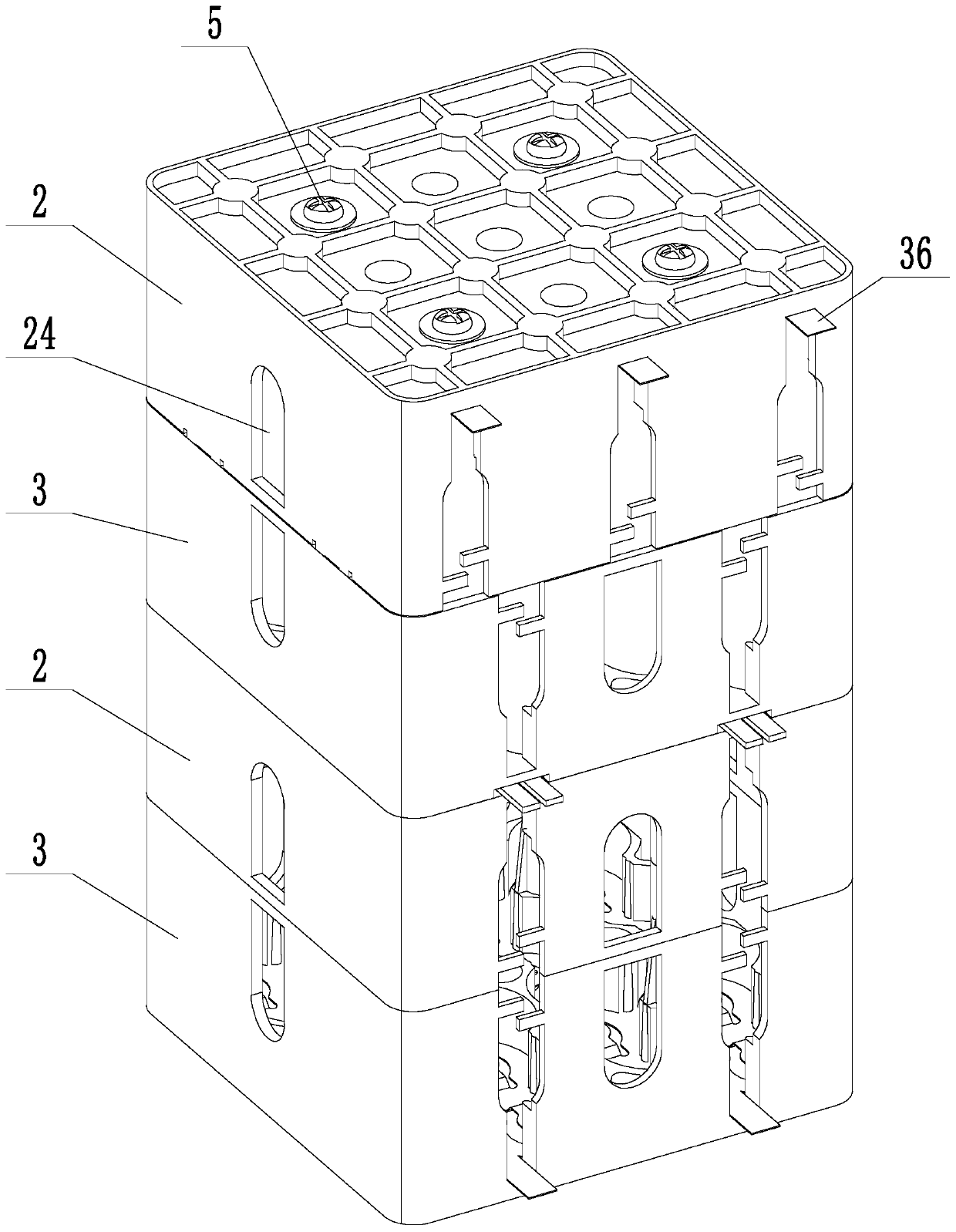

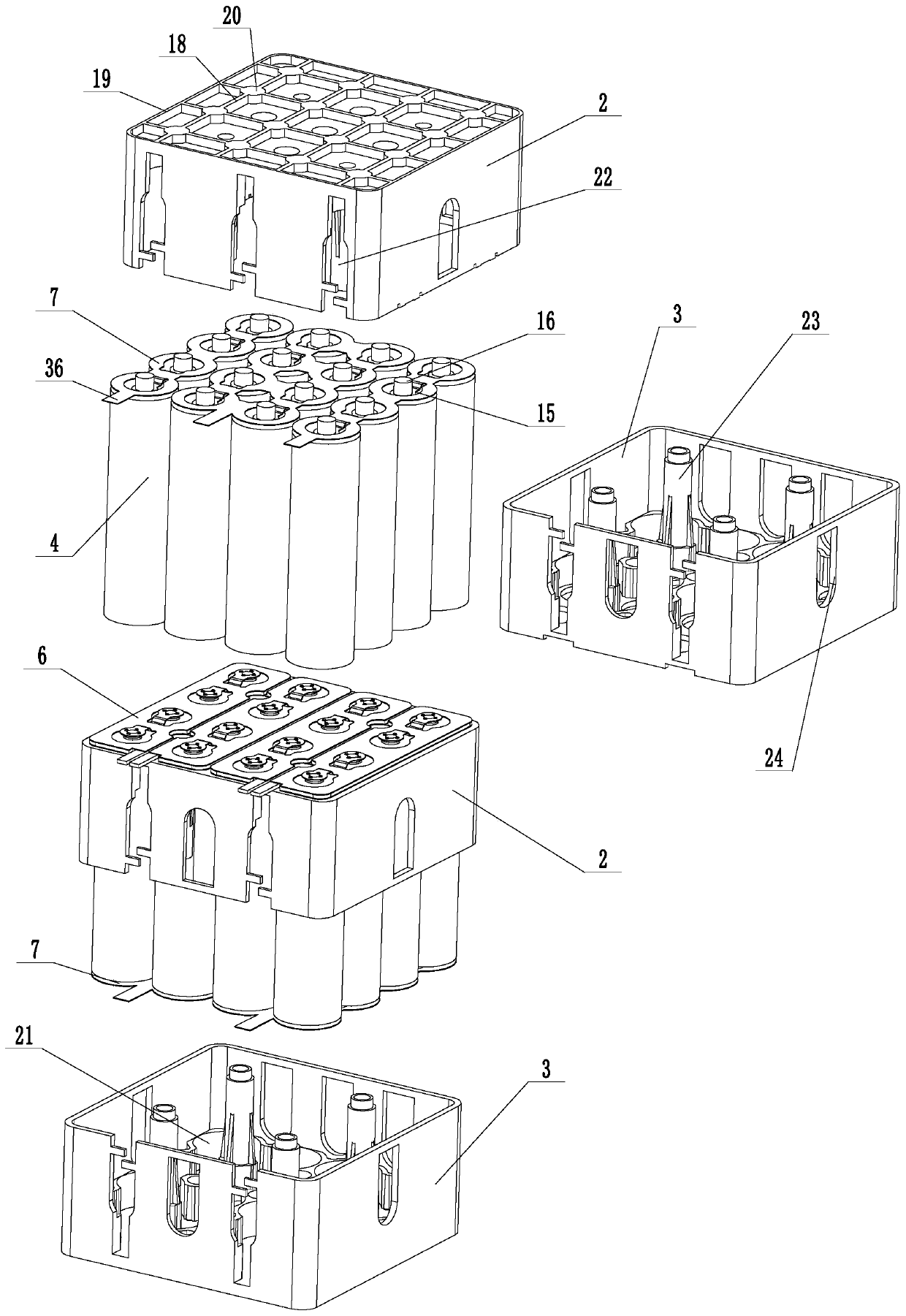

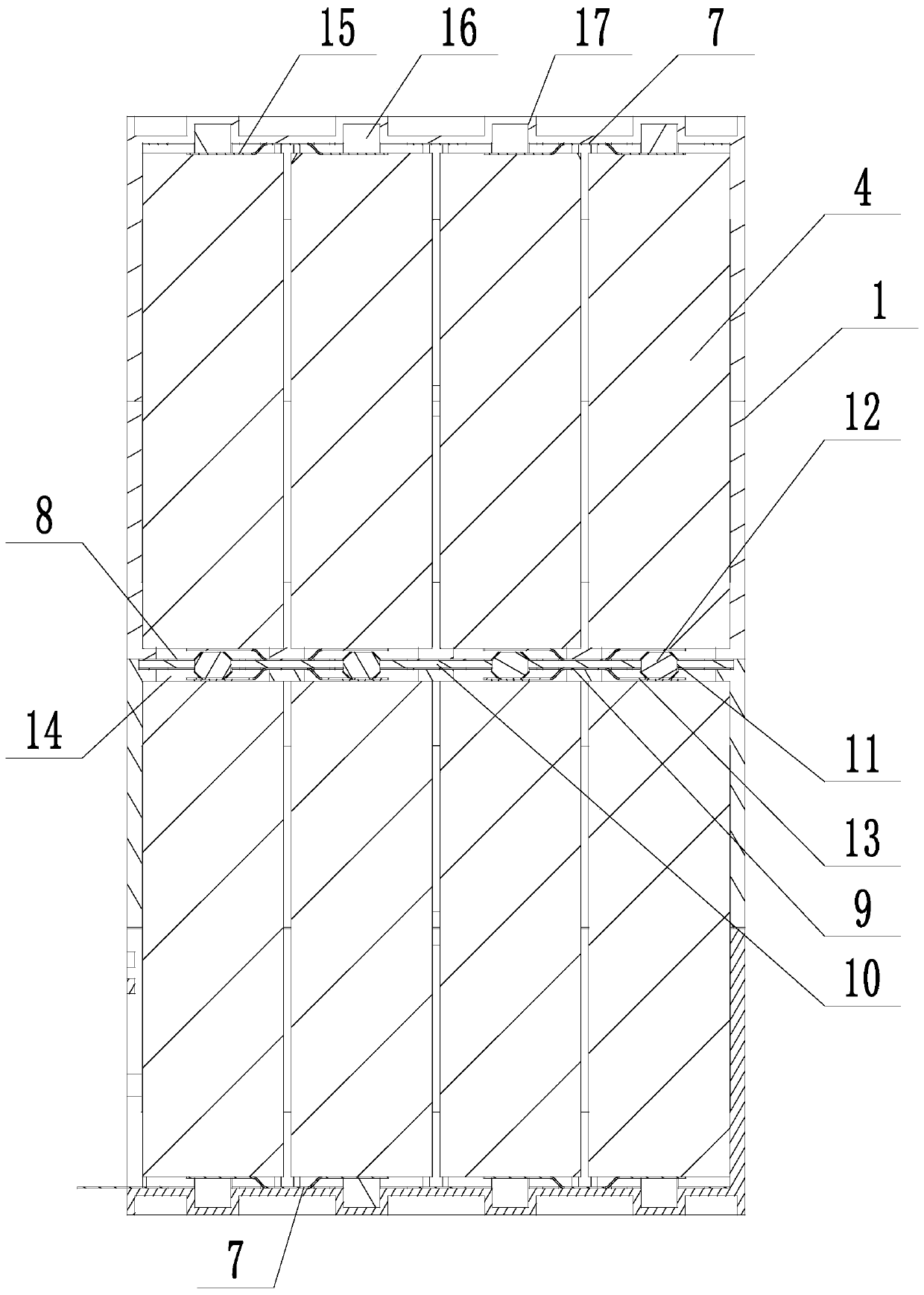

[0025] Embodiment 1: A kind of weld-free combined battery pack (see attached figure 1 To attach image 3 ), including a number of assemblies 1 connected together. In this embodiment, there are two groups of assemblies. The assembly includes an upper cover 2, a lower cover 3, and several groups of battery cells 4 installed between the upper cover and the lower cover. Each Four sets of battery cells are arranged in a combination, and the upper cover and the lower cover are closely connected together. Fastening screws 5 are connected to the battery pack, and the fastening screws fasten the upper cover and the lower cover of the assembly and the two adjacent assemblies together. A fastening screw is connected to the four corners of the battery pack. Between the upper cover and the lower cover of the two adjacent assemblies is connected the connecting piece assembly 6 for conducting the battery unit, between the upper cover of the assembly at the upper end of the battery pack and...

Embodiment 2

[0028] Embodiment 2: A kind of weld-free combined battery pack (see attached Figure 4 to attach Figure 6 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, between the upper cover and the lower cover of two adjacent assemblies and between the upper cover and the lower cover of the same assembly through the tongue 25 and the card Slot 26 is engaged. An extension plate 27 is arranged on the upper cover of the same assembly, a card slot is arranged on the extension plate, and a tab is arranged on the lower cover. In the two adjacent assemblies, the lower cover of the upper assembly is provided with an extension plate, and the upper cover of the lower assembly is provided with tabs.

[0029] The assembly columns above all the battery units are connected together by the upper pull plate 28 to form a whole, the assembly columns below all the battery units are connected together by the lower pull plate to form a whole, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com