Elastic buffer tool fixture

An elastic buffer, tooling and fixture technology, applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of economic loss and the broken objects of the milling cutter, and achieve easy production, avoid economic losses, and simple and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

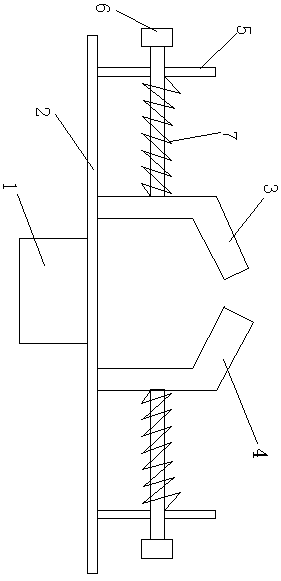

[0010] An elastic cushioning tooling fixture, comprising a base 1, a base plate 2 placed on the base, a left jaw 3 and a right jaw 4 placed on the base plate, the outer sides of the left and right jaws are respectively provided with fixed support plates 5, Adjusting bolts 6 are threaded on the fixed support plate, and the ends of the adjusting bolts are respectively connected to the outsides of the corresponding jaws. The adjusting bolts are provided with springs 7; the bottoms of the left and right jaws are provided with sliders. The base plate is provided with a chute at the contact position with the slide block, and the left and right jaws are slidably connected with the base plate through the slide block and the chute respectively. The inside of the left and right jaws is provided with an elastic buffer layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com