Shear wall single-side formwork erecting method

A single-sided formwork and shear wall technology, which is applied to formwork/formwork/work frame, formwork/formwork/work frame connectors, and on-site preparation of building components, can solve the problem of exterior wall construction operation. Insufficient, inconvenient engineering, small distance and other problems, to achieve the effect of solving on-site construction problems, meeting construction requirements, and being suitable for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

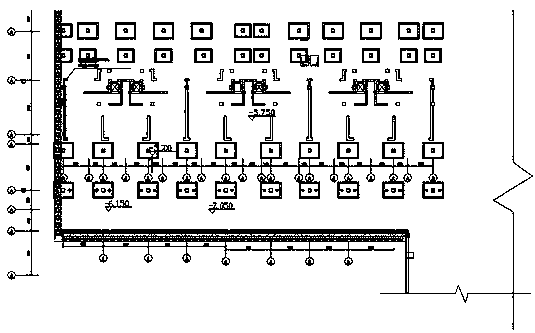

[0023] Such as Figure 1-2 Shown: a shear wall unilateral formwork method, it includes the following steps,

[0024] Step 1: Locate the reinforcement hole on the enclosure grouting pile 1;

[0025] Step 2: filling concrete 7 between the enclosure cast-in-place pile and the shear wall; the inner side of the enclosure cast-in-place pile is isolated by full paving of asphalt felt 6 .

[0026] Step 3: Install formwork on the outside of the shear wall; the formwork is made of plywood with a thickness of 16mm.

[0027] Step 4: Set several vertical inner corrugations 2 on the outside of the formwork, and set horizontal outer corrugations outside the vertical inner corrugations; the vertical inner corrugations use 48×3.0 steel pipes, and the distance between the vertical inner corrugations is 450mm; There are three horizontal outer corrugations, all of which are 48×3.0 steel pipes. The distance between the horizontal outer corrugations is 450mm. The overlapping position cannot be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com