Pneumatic clutch transmission device for truss crane pipe car

A technology of clutch transmission and crane tube, which is applied to transmission devices, gear transmission devices, and transportation buses, etc., can solve the problems of unstable speed of piston rod movement, difficult and unrealistic movement of the trolley, and increase the driving effect and facilitate sliding. , The effect of simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

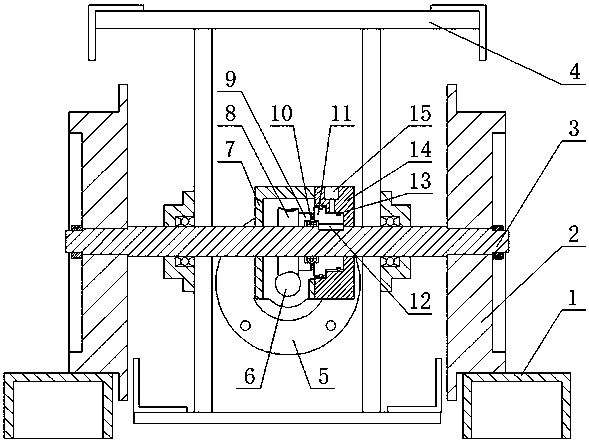

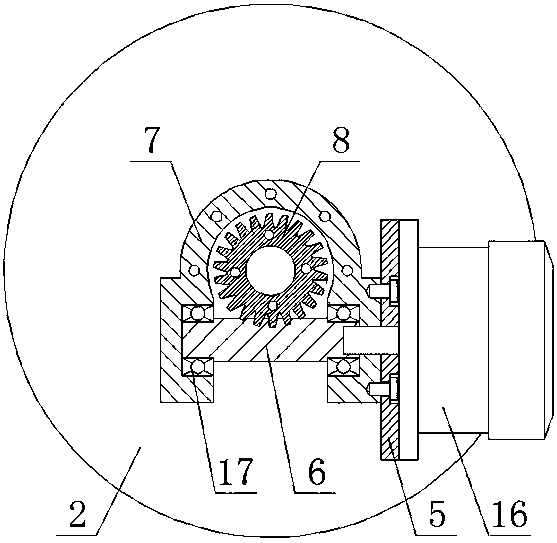

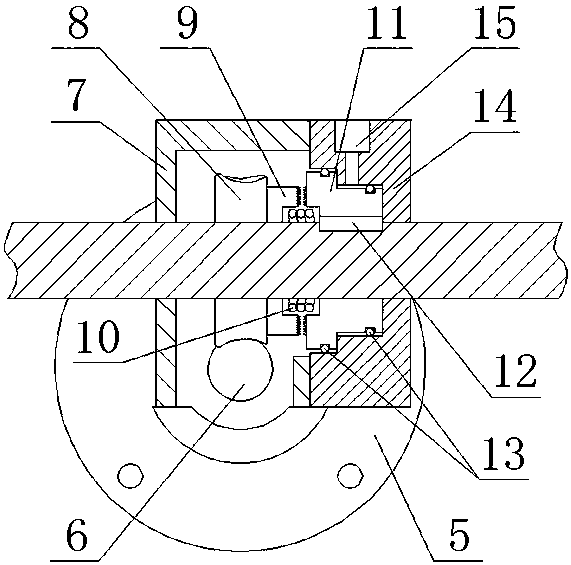

[0018] Referring to the accompanying drawings, the specific implementation is as follows:

[0019] A pneumatic clutch transmission device for a truss crane trolley, the truss crane trolley includes a vehicle frame 4, a wheel shaft 3 and a wheel 2 for traveling along a track 1, a motor 16 is installed on the vehicle frame 4, A flange 5 is installed on the motor 16, and the end of the flange 5 towards the motor 16 is provided with a plurality of stepped holes capable of accommodating bolt heads. The flange 5 is connected with one end of a housing 7 by bolts, and the motor 16 The output end of the worm shaft 6 is connected with a worm shaft 6. The worm shaft 6 is passed through the housing 7 and supported by a bearing 17. The wheel shaft 3 is provided with a worm wheel 8 meshed with the worm shaft 6. The wheel shaft 3 There is also an active face gear 9 and a passive end face gear 11 set thereon, the active end face gear 9 is connected to the worm wheel 8 so that the active end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com