A Surface Roughness Analysis Method for Studying the Fatigue Resistance of Parts

A surface roughness and analysis method technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as the inability to accurately study and evaluate the anti-fatigue performance of parts, and the inability to compare the degree of influence of anti-fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

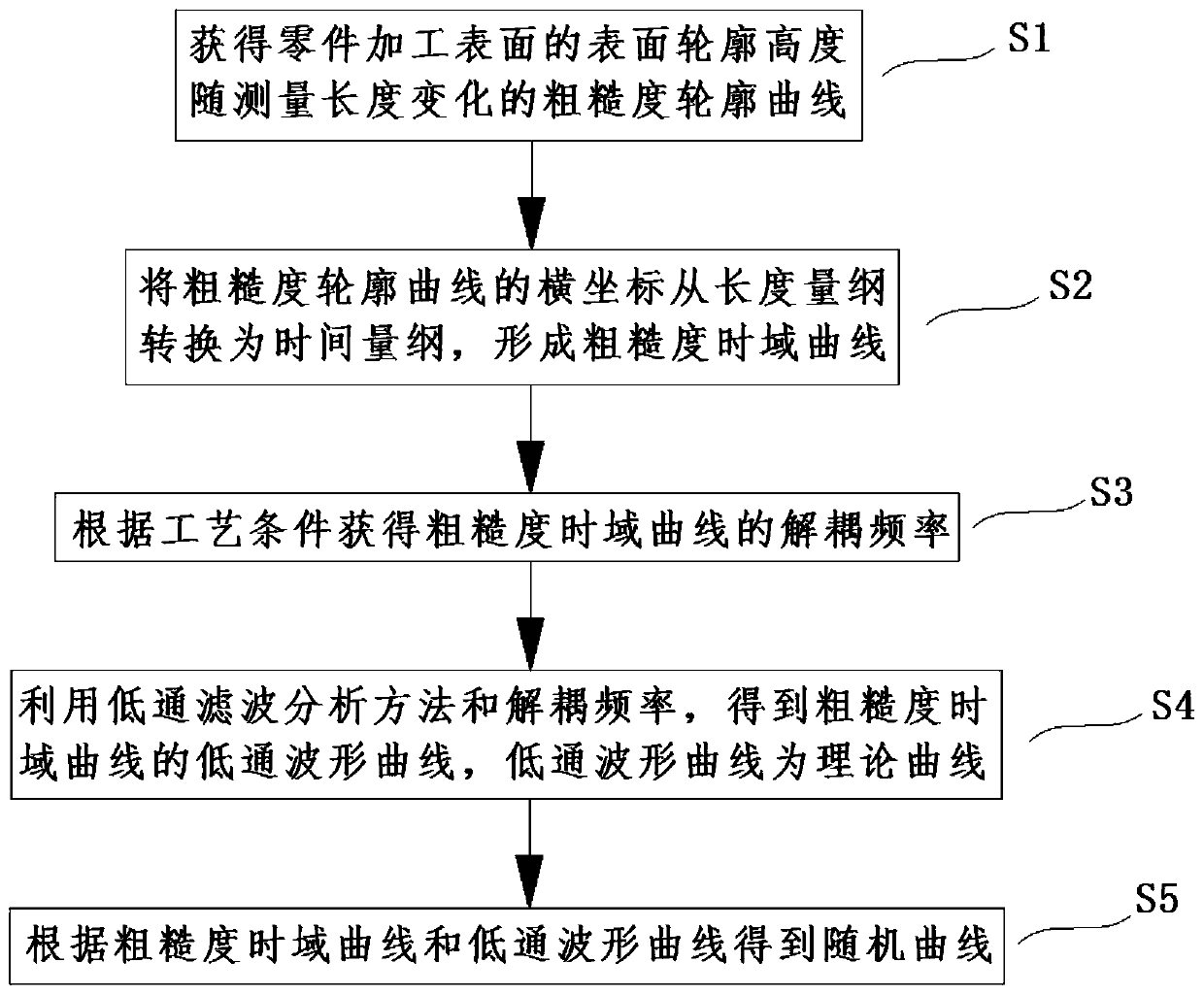

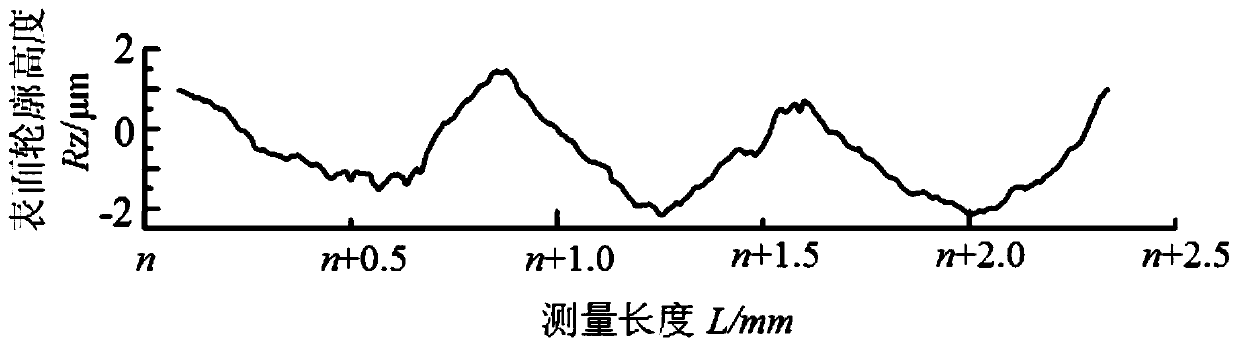

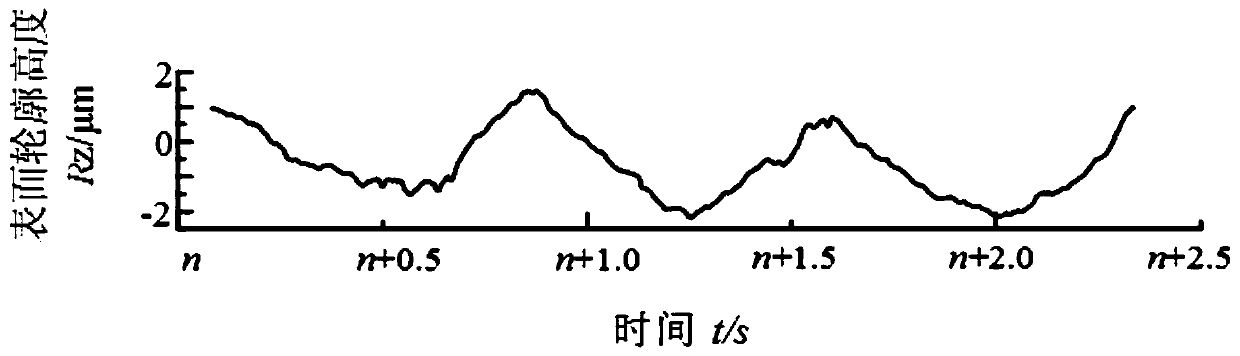

[0035] The present embodiment provides a surface roughness analysis method for researching the anti-fatigue performance of parts. The method uses the roughness profile curve of the surface profile height Rz of the machined surface of the part as the measured length changes (that is, the roughness profile curve is measured with a length of The abscissa, with the surface profile height Rz as the ordinate) is decoupled into a theoretical curve affected by process conditions and a random curve affected by random factors, wherein both the theoretical curve and the random curve take time as the abscissa, and the surface profile height as Y-axis.

[0036] As above, the decoupling analysis method for the machined surface roughness used to study the fatigue resistance p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com