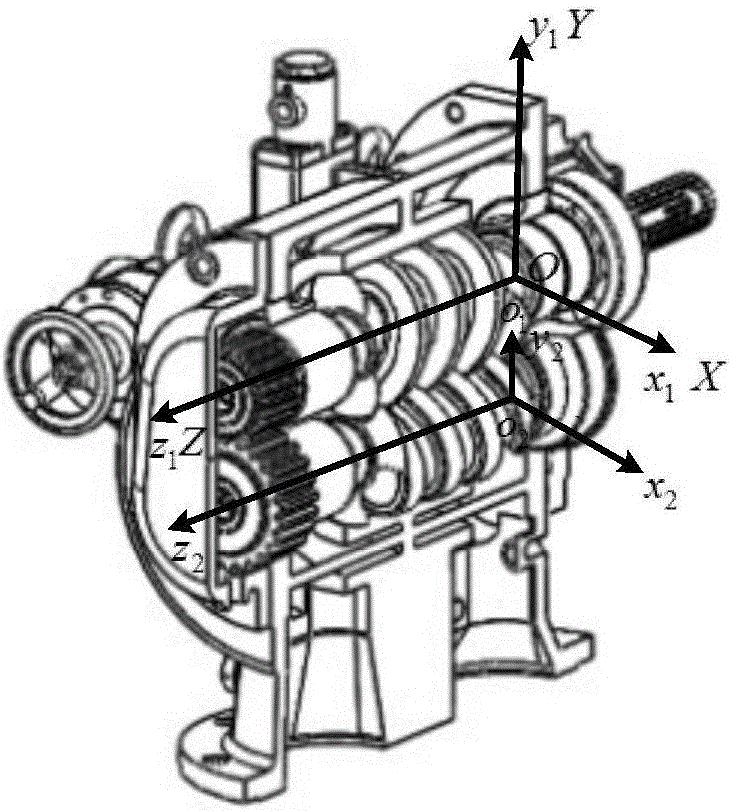

Two-screw pump rotor interference detection method based on assembly error

An assembly error, twin-screw pump technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of rotor abrasion, normal operation, seizure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

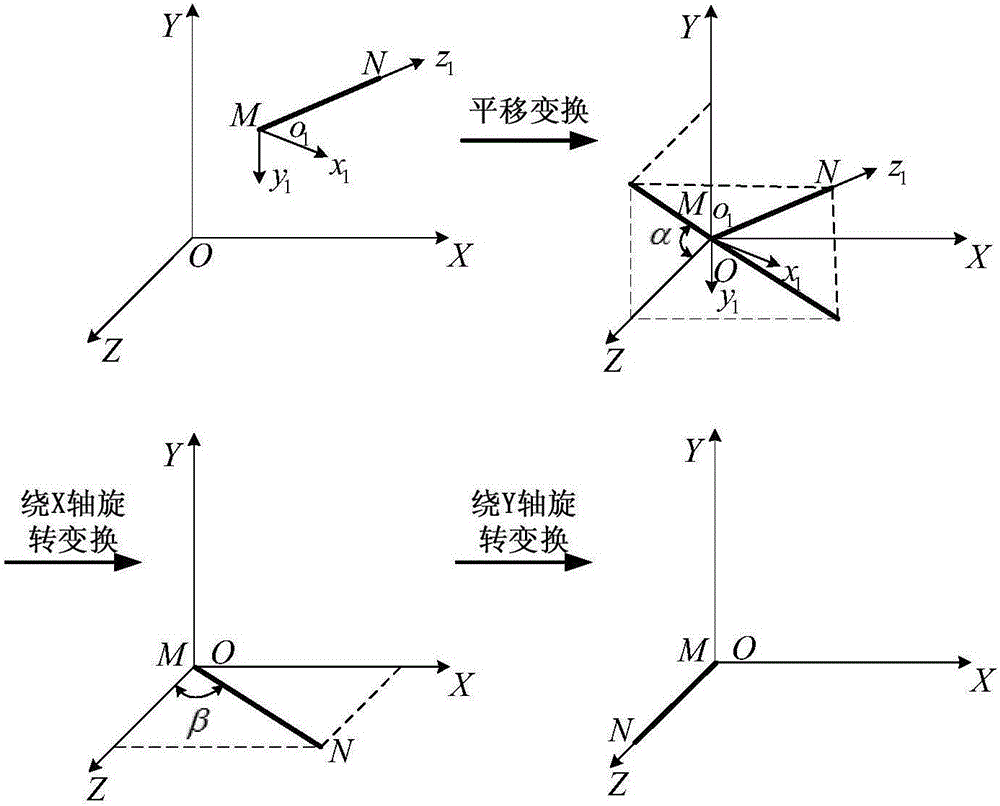

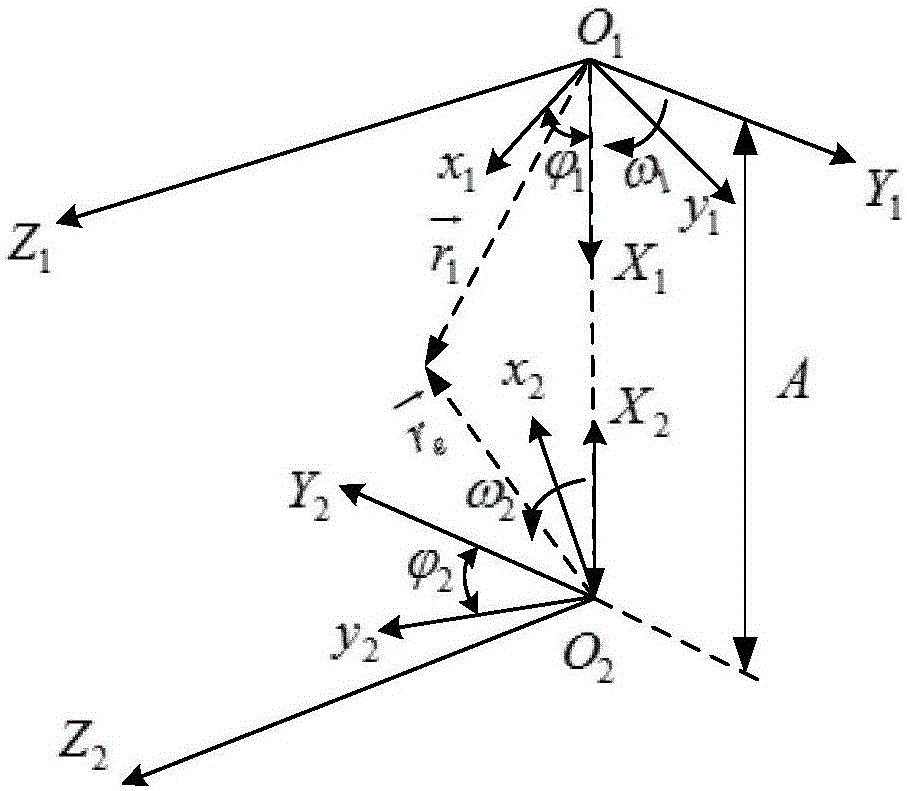

Method used

Image

Examples

Embodiment Construction

[0061] In this embodiment, the A-type tooth shape is used for analysis and calculation. The A-type screw end surface tooth shape curve equation is known. According to the above method, the helical surface equation and the meshing equation are combined to obtain the tooth surface contact line space curve, and consider the ideal situation. The inter-tooth gap is obtained by three assembly situations, the axis center distance of the master and slave screws is reduced, and the axis space of the master and slave screws is staggered (the axis center distance remains unchanged). Shift δ x ,δ y ,δ z The value is 0.02mm. According to theoretical calculation, the minimum inter-tooth gaps along the contact line are 0.120mm, 0.091mm, and 0.063mm respectively.

[0062] Geometric parameters of master and slave screws of twin-screw pump

[0063]

[0064] It is known that the tooth profile curve of the type A driven screw is composed of a long epicycloid, an involute, and a short epicy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com