Bearing disassembling tool with hammering function

A technology for removing tools and bearings, which is applied in the manufacture of tools and hand-held tools, etc. It can solve the problems of difficult removal of bearings and short service life of bearings, and achieve the effect of labor-saving and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

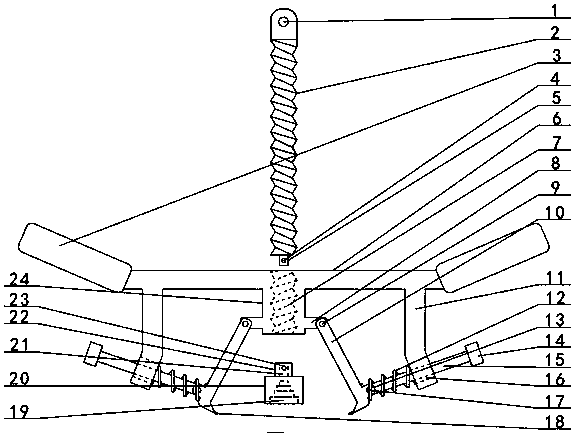

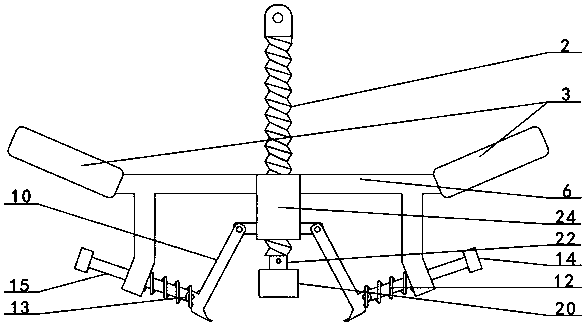

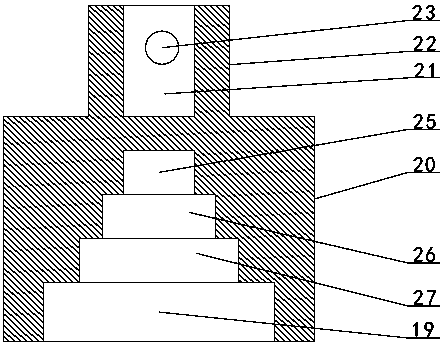

[0026] combined with Figure 1-7 The described bearing dismounting tool with hammering function comprises an internally threaded pipe 24, a beam 6, a vertical arm 10, a vertical rod 11, a push rod 15, a spring 12 and a screw rod 2, and the two ends of the beam 6 are respectively provided with upturned Rods 28; handles 3 are respectively provided on the two upturned rods 28 of the crossbeam 6, the middle part of the crossbeam 6 is connected to both sides of the upper end of the internally threaded pipe 24, and vertical rods 11 are respectively provided at the lower parts of the crossbeam 6 near both ends, and the internal thread Both sides of the bottom of pipe 24 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com