Pavement joint cutting machine

A seam cutting machine and steel bar cutting machine technology, which is applied in the field of construction machinery, can solve the problems of wasting water resources and uneven cooling water for cutting blades, and achieve good effects, good water storage effects, and water saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings.

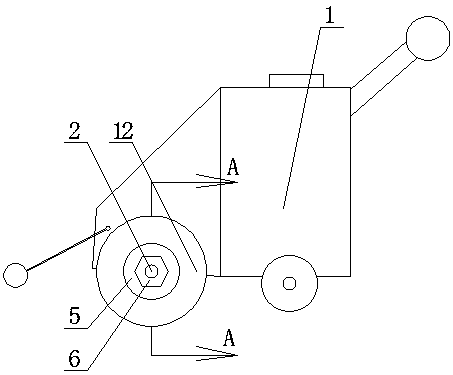

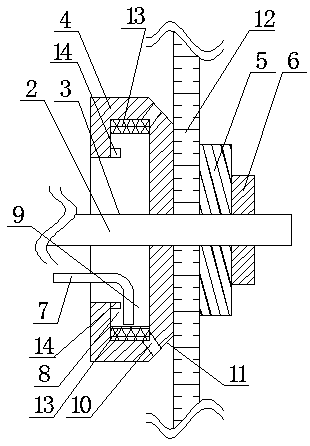

[0020] Such as figure 1 , 2 , 3, a road cutting machine includes a frame 1, a power shaft 2 is installed on the frame, the power shaft has a cutting blade seat 3 on which a cutting blade is installed, and the cutting blade seat has a circular ring The first backing plate 4, the ring-shaped second backing plate 5 and the tightening nut 6;

[0021] A water spraying device is also installed on the rack, and the water spraying device has a cooling water outlet pipe 7;

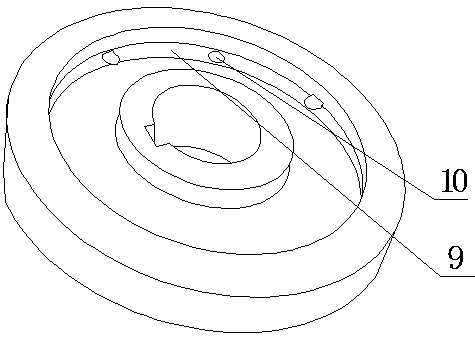

[0022] It is characterized in that: there is a groove 8 around the outer side of the first backing plate, and the groove is formed by the outer edge of the first backing plate being extended outwards and then folded inward, and the first backing plate is folded inward to form a torus. The opening 9 of the groove faces its central axis, and there are a plurality of evenly distributed small holes 10 on the bottom plate of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com