Lock body structure with function of double-cylinder synchronous control for unlocking

A synchronous control, lock body technology, applied in the direction of building locks, building structures, keys, etc., can solve the problems of not really exerting its application value, low anti-theft performance, etc., to increase security and technical opening difficulty, safety and anti-theft Performance improvement, the effect of improving anti-theft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

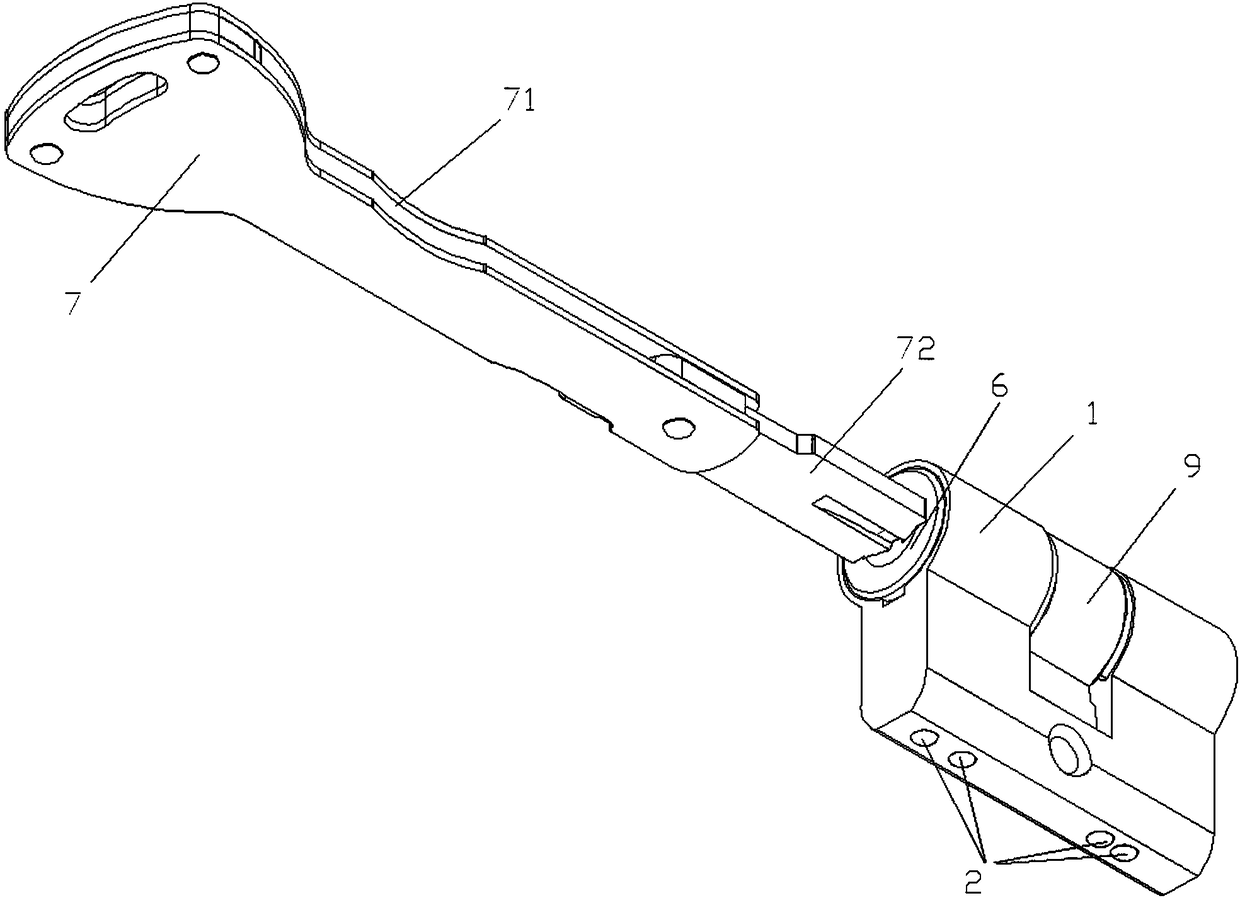

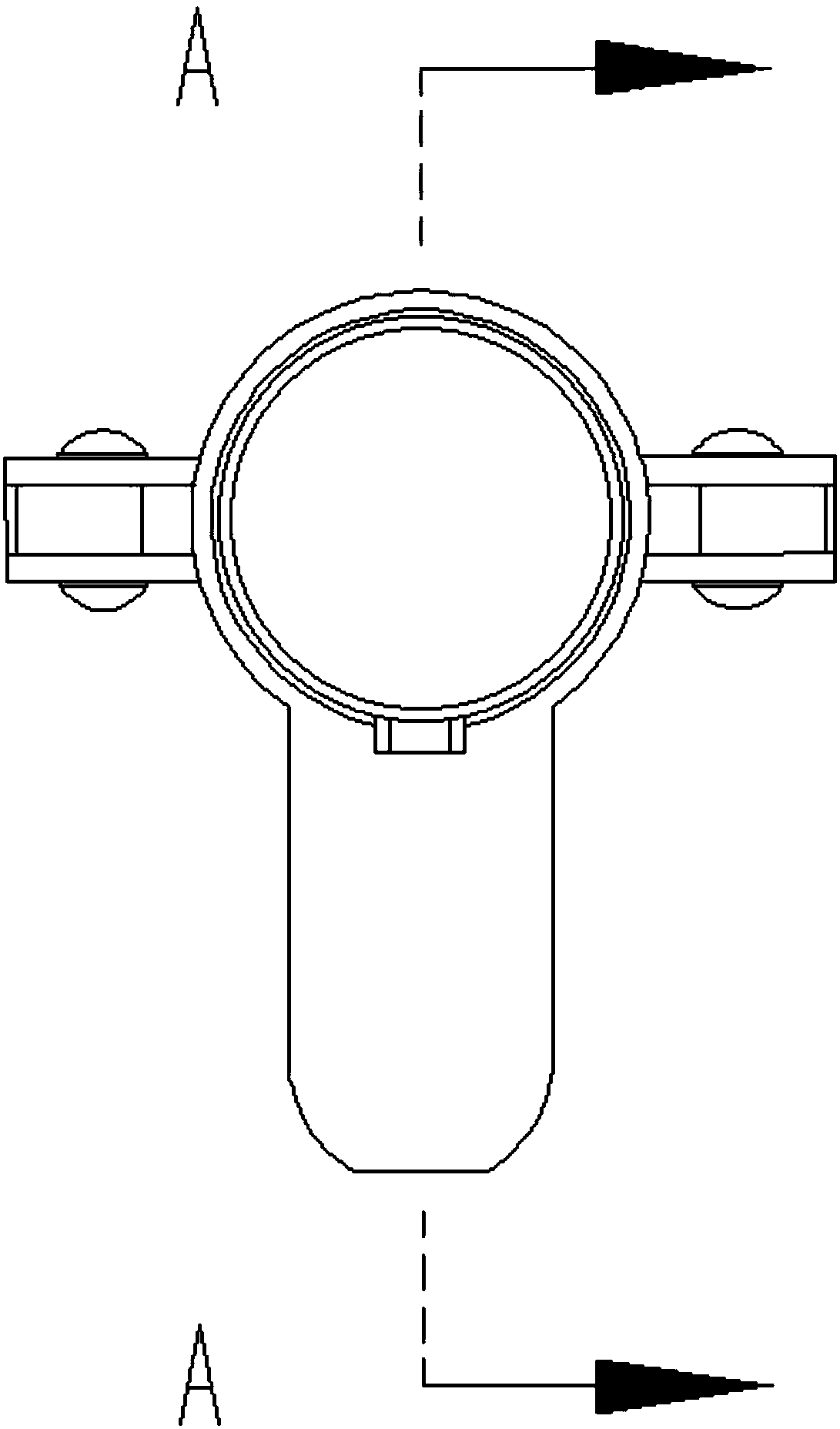

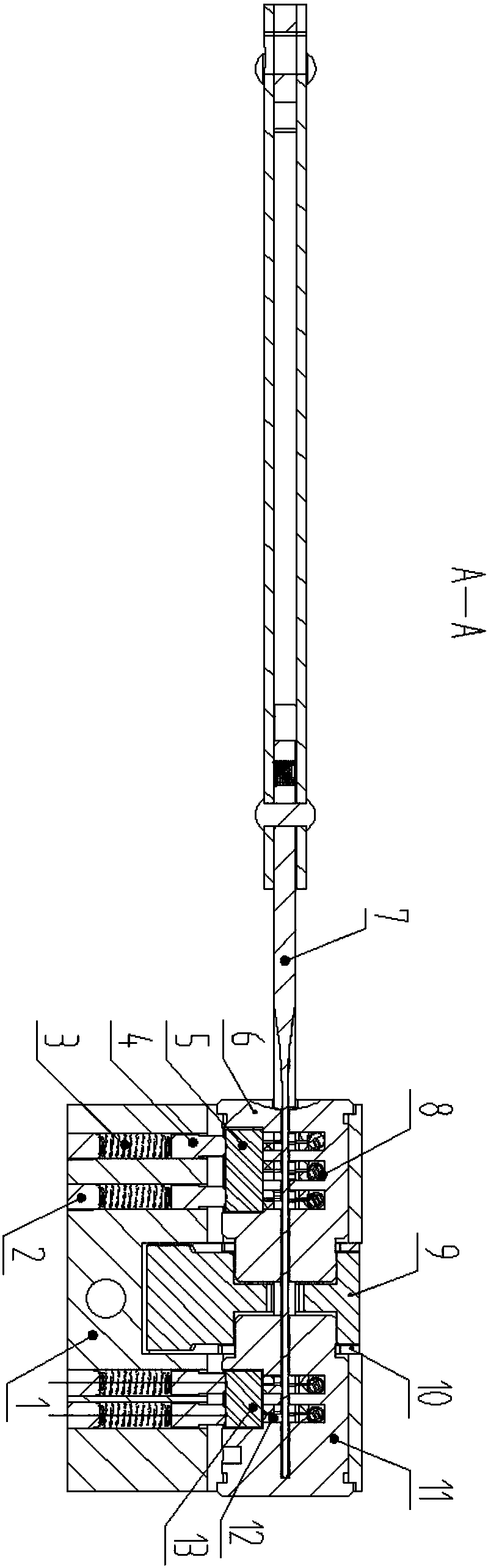

[0023] Such as Figure 1 to Figure 3 As shown, a dual-core synchronously controlled unlocking lock body structure includes a lock head 1 and a key 7, and both ends of the inner cavity of the lock head 1 are respectively provided with an inner lock core 11 installation hole and an outer lock core 6 installation hole, The inner lock core 11 and the outer lock core 6 are respectively installed in the inner lock core 11 installation hole and the outer lock core 6 installation hole, and the inner lock core 11 and the outer lock core 6 can rotate in the lock head 1.

[0024] The lock head 1 is also installed with a dial 9 for turning the lock. The center of the dial 9 is provided with a through hole. The two ends of the dial 9 are respectively sleeved with the inner lock core 11 and the outer lock core 6, which can pass through The inner lock core 11 and the outer lock core 6 rotate simultaneously to drive the dial 9 to rotate.

[0025] An inner locking mechanism and an outer locking me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com