Installation method of production riser of self-elevating drilling platform

A technology for drilling platforms and installation methods, which is applied in the direction of drilling pipes, drilling equipment, drilling pipes, etc., can solve the problems of unsuitable jack-up platforms and large platform displacements, and achieve the effect of solving irregular positioning and evacuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

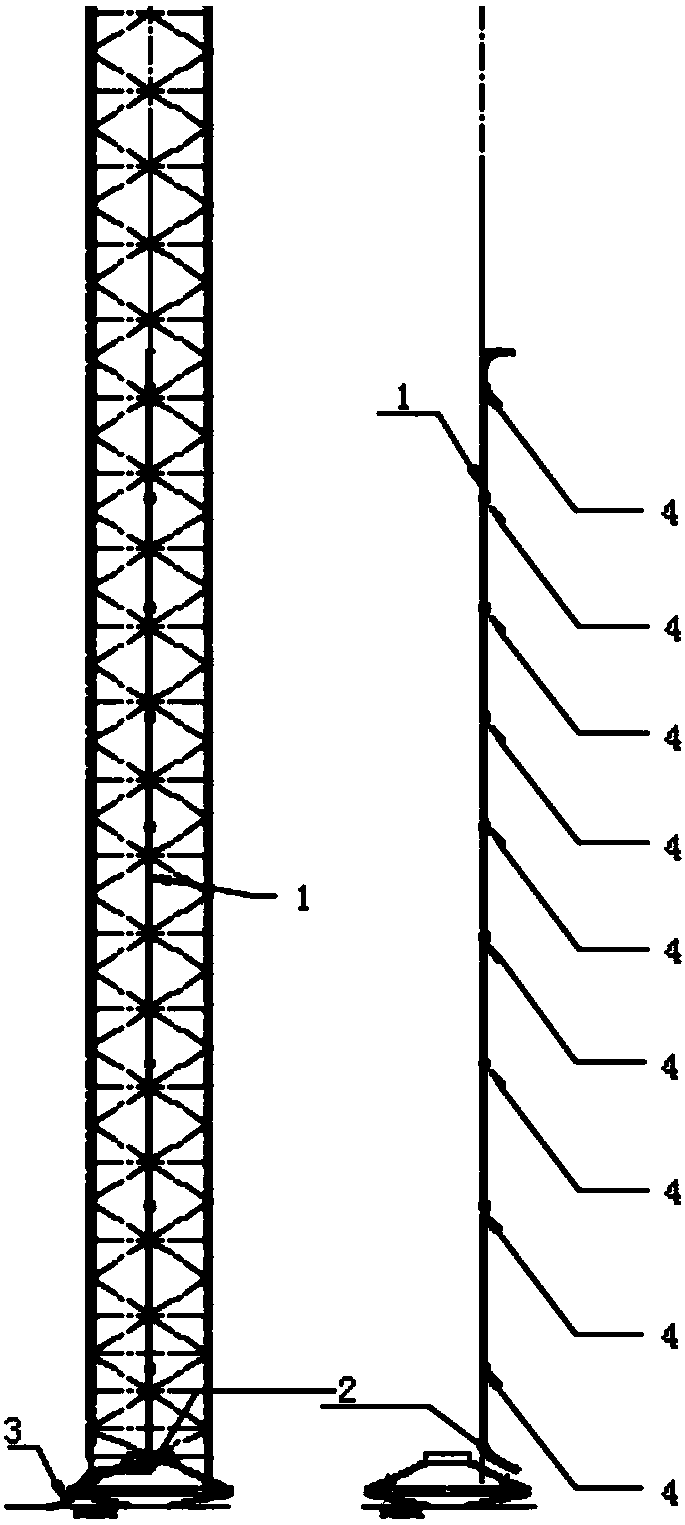

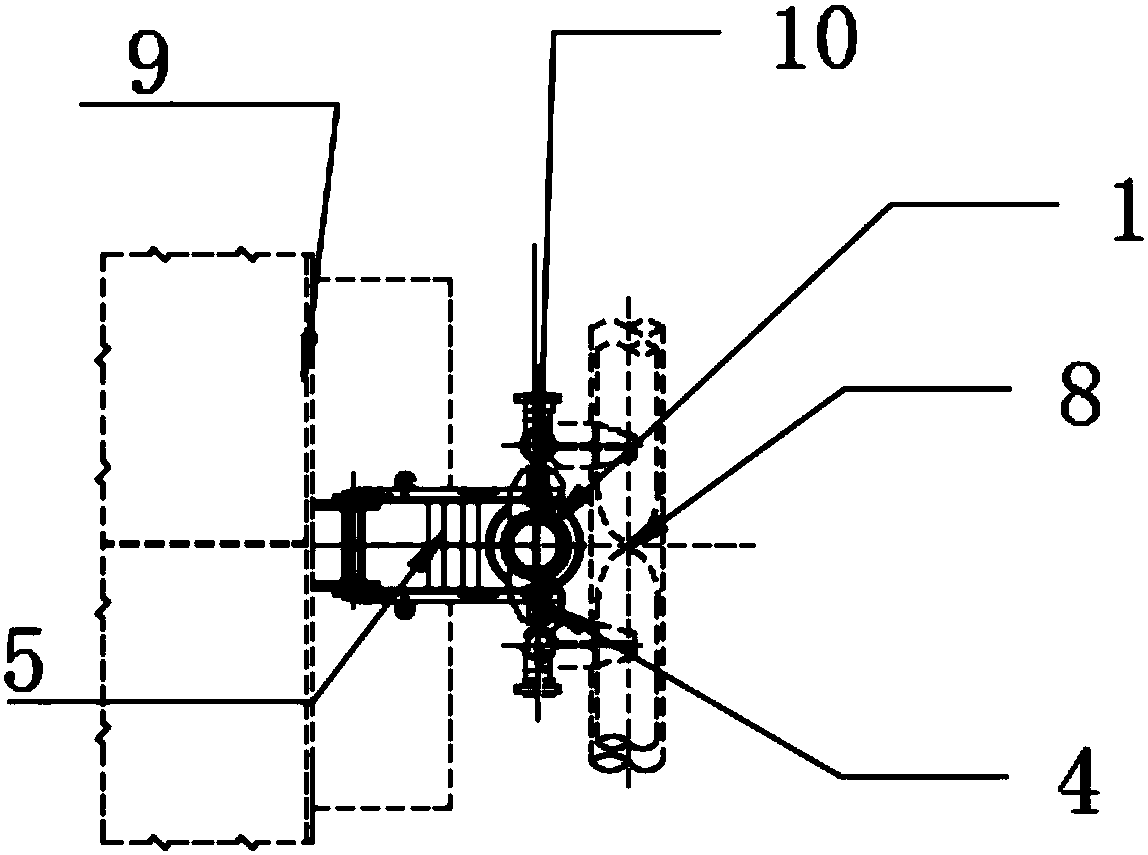

[0028] Such as figure 1 — Image 6 As shown, the present invention includes: a rigid standpipe and a hose expansion bend 3 connected with the rigid standpipe, wherein the rigid standpipe is limited by the standpipe pipe clamp 4, and is installed on the automatic riser by the standpipe suspension device 5 On the lifting drilling platform 9.

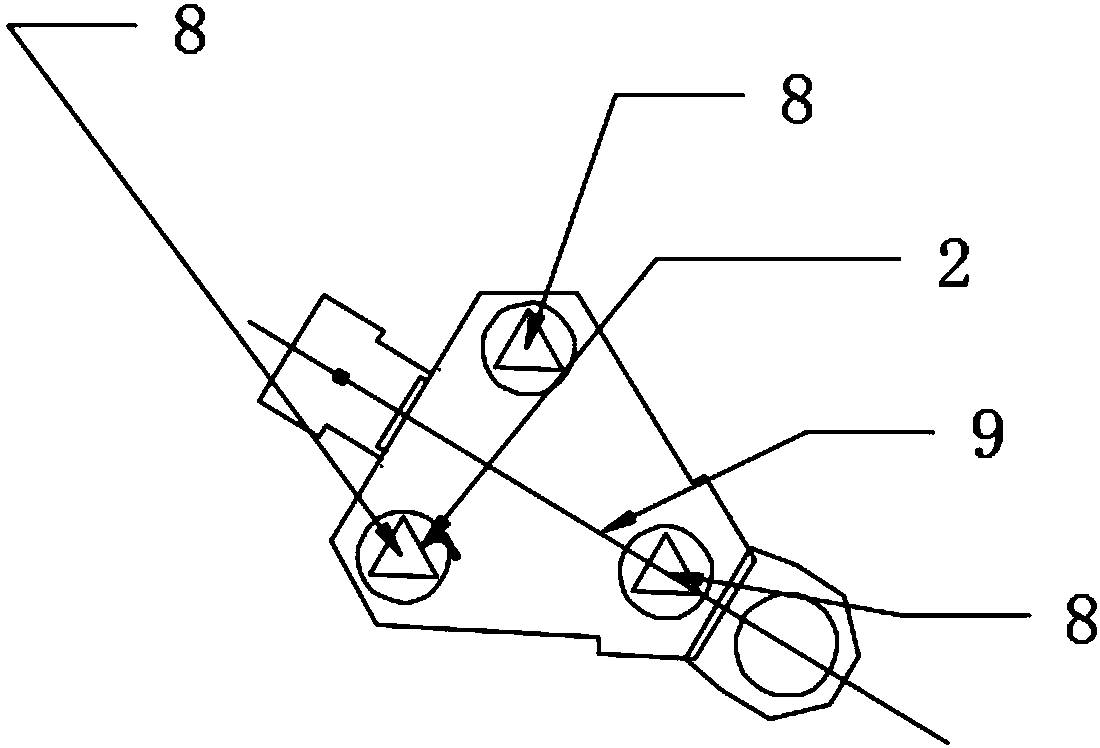

[0029] The above-mentioned rigid riser is composed of the production riser main body 1 and the production riser bottom 2, wherein the production riser main body 1 is composed of several segmented riser connections; the riser pipe clip 4 is composed of the clip main body 6 and the clip The limit structure 7 is connected to form.

[0030] The above-mentioned hose expansion bend 3 is connected to the bottom 2 of the production riser through a flange, the clip body 6 is installed on the set position of the production riser body 1 by welding, and the clip limit structure 7 adopts a bolt connection method and the clip body 6 connected togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com