Rotary sandblasting workbench for rotary vibration screen frame and bottom barrel workpieces

A technology of rotating table and rotating platform, which is applied in the direction of manufacturing tools, metal processing equipment, abrasive jet machine tools, etc., can solve the problems of high labor intensity, low labor productivity, and low efficiency of operators, and achieve the benefits of on-site workers and workshops. The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

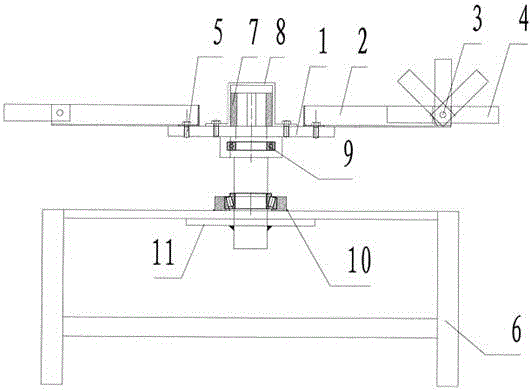

[0009] Embodiments are described in detail in conjunction with the above accompanying drawings, as figure 1 As shown, there is a chassis 11 for installing the rotating shaft at the center of the bracket 6, a rod brace connected to the bracket 6 is welded on the disk surface of the chassis, a shaft hole for assembling the rotating shaft is processed in the center of the disk surface, and one end of the rotating shaft 8 is connected to the rotating platform through the shaft sleeve 7. The central shaft hole assembly on the plate back side, the other end of rotating shaft passes upper bearing seat 9 and lower bearing seat 10 and is seated in the shaft hole installed in chassis 11, seals with cover plate on the central shaft hole of described rotating platform plate 1 front.

[0010] The rotating platform plate is a disc, and the supporting main arm 2 is fixed on the disc surface. The number of the supporting main arms is at least four, which are evenly distributed on the disc. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com